How to choose the right wastewater container?

Sewage containers can differ in volume - from 2 to 100 cubic meters, and in the material used in production - plastic, fiberglass, metal, reinforced concrete. Depending on the number of people living in the house, one can judge the volume of wastewater, and, consequently, the required size of the storage tank. If there is a bathhouse, swimming pool or other infrastructure elements on the site, this should be taken into account when choosing a container. It is also necessary to decide how often the storage tanks are scheduled to be emptied.

Types of containers

A set of structures made of reinforced concrete that allows the storage of process fluids is concrete tanks. Due to their relatively low cost and long service life, they are also used in housing and communal services. The low thermal conductivity of the container prevents the rapid evaporation of liquid products.

Concrete containers - common types of objects

| The principle of separation | View | Characteristic |

| Preparation method | Monolithic | The design of the facility is carried out at the site of future operation by pouring concrete |

| Prefabricated | Built from individual blocks | |

| Mixed type | Assembled from large elements connected from prefabricated blocks using heavy-duty concrete | |

| Form | Rectangular | Made in the shape of a rectangle |

| Cylindrical | Produced in the form of a cylinder | |

| Location | Overhead | The main structure is above the ground |

| Underground | Designed for underground use |

Where are storage tanks for drinking water used?

Water containers are useful where there are constant interruptions in the water supply system - this is more the norm than force majeure. High-quality still tanks and 200 liter containers are designed to make a person's life fresher and more comfortable throughout the year. Water tanks are also useful for summer residents to care for their gardens and gardens. As you know, water that has been warmed up for several days in the sun has a more beneficial effect on plants than its counterpart from a well. Having decided to buy a drinking water tank, you will never experience discomfort associated with interruptions in water supply.

Model range of water tanks

| Nominal volume, m³ | Dimensions | |

| Length (m) | Width (m) | |

| 50 | 5 | 5 |

| 100 | 10 | 5 |

| 150 | 7,5 | 10 |

| 200 | 10 | 10 (5) |

| 250 | 10 | 10 |

| 300 | 10 | 10 |

| 400 | 10 | 10 |

| 500 | 12,5 | 10 |

| 1000 | 25 | 10 |

| 2000 | 20 | 20 |

| 3000…(30 000) | on request | |

How are tanks for petroleum products made?

Oil tanks are often manufactured using a roll-to-roll or sheet-to-sheet assembly method. There are tanks with a floating roof, as well as with a stationary roof with a pontoon and without a pontoon. In some cases, it is rational to use tanks with an additional protective wall.

Basically, horizontal tanks for petroleum products are used for storing aviation kerosene, diesel fuel, gasoline and other petroleum derivatives that have a saturated vapor pressure of up to 0.08 MPa.

As a rule, an oil tank includes a set of mandatory equipment: measuring pipes, as well as deaeration, filling, dispensing and desludge lines, however, at the request of the customer, some models can be equipped with additional technical equipment.

Specifications of water tank panels:

| Parameter name | Unit | Parameter value |

| Water pressure inside the tank | hydrostatic | |

| Wind load | kgf/m² | 385 (up to 60 m/sec) |

| Snow load | kgf/m² | 60 (with snow depth up to 1 m) |

| Water temperature inside the tank | °C | no more than 40 |

| Foundation strength requirements | kgf/cm² | 180 |

| Tensile strength | kgf/mm² | 90~100 |

| Flexural strength | kgf/mm² | 190~200 |

| Tensile force | kgf/mm² | 15,9 |

| Compression force | kgf/mm² | 100 |

| Impact strength according to IZOD | kgf-cm/cm² | 1,055 |

| Coefficient of thermal conductivity | Kcal/m²*hour | 0,204 |

| Superheat transfer coefficient | Kcal/m²*hour | 0,000016 |

| Glass fiber content | % | 31,4 |

| Toxicity | hydrostatic | |

| Water pressure inside the tank | No | |

| Possibility of bacteria | No |

Waterproofing materials

The requirement is that the product is environmentally friendly and reliable. The insulating layer must adhere securely and not dissolve in liquid. The product used complies with sanitary environmental standards.

For waterproofing the following are used:

- roll and sheet;

- polyurethane mixtures;

- mineral components for viscosity;

- natural dry mixtures;

- environmentally friendly polymers.

Waterproofing of clean water tanks is carried out with compounds that do not dissolve in liquid and do not emit harmful substances.

The insulation layer is applied as a homogeneous film without transitions, through which moisture does not enter the joints and does not affect the walls of the container.

The applied product dries quickly, has no odors, does not freeze on ground structures, and is resistant to high humidity and vapor formation. External protection is not affected by the soil and air environment, acids and alkalis.

Mastics

Metal above-ground tanks are insulated using mastics and sealants that prevent the influence of an aggressive environment. Elastic compositions based on glue, binders, multicomponent fillers.

Used to seal seams and joints. Available in the form of ready-made mastic for cold application or for composition for hot application. Warranty period – 10 years.

Since the metal is susceptible to rust, a membrane layer is applied. Geosynthetic material is a homogeneous film covering metal. Protects from chemical, mechanical influences, ultraviolet radiation.

Rolled polymer membranes

Heat-resistant waterproofing of clean water tanks is carried out using a rolled polymer membrane. The film density is reinforced with a fiberglass layer. It is environmentally friendly, elastic, durable.

Does not emit odors or toxins, and is not affected by biochemical substances. Used in storage facilities with water whose temperature does not exceed +35°. Installation is carried out using special welding press rollers.

Swiss produces film insulation. Seam width 2 m, length 20 m.

The cost per linear meter is 147 rubles.

Geomembrane

The geomembrane in the form of a roll film is placed inside the container and connected with a special welding machine.

Advantages:

- elasticity;

- easy and quick installation;

- no filler;

- unaffected by liquid media.

Manufactured in the Russian city of Kirishi, Leningrad Region, the geomembrane is produced using modern European equipment.

The laboratory checks production cycles according to the parameters of the Certificate and GOST standards, as well as European EN standards.

Cost 200 rub. linear metre.

Bitumen-rubber mastics

Waterproofing of above-ground drinking water tanks is carried out using bitumen-rubber mastics. Two layers are applied for additional roll protection stickers.

The outer side of the container is coated with two layers of construction mastic. The insulating mastic is elastic, moisture-resistant, and securely attached. Silicone and sealant additions extend the service life.

Mastic has a drawback - temperature differences: elevated temperatures soften the layer, frost makes the mastic brittle. Therefore, the double layer is covered with reinforcing propylene fiber and concrete screed.

Rizolin

An elastic self-adhesive material, Rizolin, is produced on the basis of fiberglass. Additional filling is bitumen-polymer substances with additives that protect against corrosion.

Rizolin is available in three types:

- adhesive on both sides;

- one side is adhesive, the other is coated with a polymer composition;

- sticky on one side, the other covered with aluminum foil.

The same fabric with a copper reinforcing mesh inside, covered with an ultra-thin layer of foil on one side, has twice the service life.

Country of origin: Russia, strip width 1 m, length per roll 10 m. Cost per m² – 200 rubles.

Classic bitumen

Based on petroleum products with the addition of polymer additives, time-tested bitumen is produced that protects the metal from corrosion.

Important! Petroleum products that make up bitumen are highly flammable, so waterproofing is used on underground metal surfaces of reservoirs.

Bitumen is bought in construction stores for 100 rubles. per liter

Liquid rubber

Might be interesting

Waterproofing

Foundation waterproofing: optimal choice of technology

Waterproofing

Instructions for waterproofing a swimming pool

Waterproofing

Selection of materials, methods of waterproofing work...

Waterproofing

Types of adhesive waterproofing

Liquid rubber is a material with a polymer base, after application of which a homogeneous membrane is created. A viscous liquid is produced by Technoprok, Marisil.

The average price for 1 kg is 200 rubles.

Integrated system "Penetron"

The use of the complex composition "Penetron" provides a guarantee of waterproofing. Each ingredient complements and enhances the protective effect. A set of protective measures is carried out both at the construction stage and during repair and reconstruction. Waterproofing with the Penetron complex is used on tanks of all types of structure.

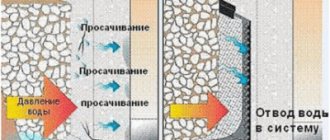

Joints and seams are insulated, voids are filled under pressure during reconstruction, and structural blocks are sealed. The substance in the voids crystallizes, connects with the base, and forms a barrier to water penetration.

The composition includes high-quality cement, quartz sand, and chemical additives that crystallize in the pores upon contact with concrete.

The PPR for waterproofing underground and above-ground tanks with the Penetron mixture meets the requirements of insulating materials for drinking water tanks. The materials comply with certification acts and are environmentally friendly. Comprehensive insulation with Penetron mixture is guaranteed for 30 years.

Hydrol

Waterproofing of underground tanks is carried out using hydrol. The main component is rubber, which allows the mastic to be used on wet structures in the cold season at a temperature of -10°.

The material is released. Price 1 kg – 65 rub.

Fiberglass tanks

Rice.

2. Fiberglass tanks Fiberglass tanks come in a wide variety of shapes and sizes. They are used for storing technical and waste liquids, and in special versions - for storing drinking water and in the food industry.

Fiberglass tanks are not subject to corrosion and do not require expensive maintenance. According to manufacturers, the service life of the tanks varies from 25 to 50 years. Under the influence of external loads (for example, seasonal soil fluctuations), microcracks may appear and further water saturation of the wall material structure, which significantly reduces the load-bearing capacity of the hull. It is worth noting the low maintainability - in case of damage or depressurization, you cannot do without the help of the manufacturer.

Monolithic or prefabricated reinforced concrete tanks

Reinforced concrete tanks have a rectangular shape and compact dimensions. This allows you to place a larger volume of water in a small area compared to horizontal cylindrical tanks. The standard service life of a reinforced concrete tank does not exceed 30 years, and for aggressive liquids - about 20 years. A scheduled inspection is carried out twice a year, and the first full technical inspection is carried out 10 years from the date of commissioning.

During operation, the tank may depressurize due to the formation of microcracks in the walls. This leads to deterioration of water quality (groundwater infiltration) or exfiltration into the ground, causing leaching and sinkholes. Therefore, when choosing reinforced concrete tanks, it is necessary to take into account the costs of their operation, current and major repairs. The undeniable advantages of large-volume reinforced concrete tanks (from 1000 cubic meters) are the low cost of construction and a wide selection of standard designs of various designs, including for seismic areas. Many of these projects were developed in the early 1980s. Among the disadvantages are the high cost of operation and the long duration of construction and installation work.

Types of tanks by volume and location

Based on the method of placing containers, the following types of tanks for storing petroleum products are distinguished:

- aboveground - vertical or horizontal, as well as oil tanks located entirely on the surface of the earth;

- with semi-underground placement - with a depth from one third to the entire volume of the container, while its neck is located above the zero mark;

- underground - single- or double-walled horizontal tanks for oil products with reinforced stiffening ribs that can be buried in the ground at a distance of over a meter (from the top point of the tank to the zero mark);

- underwater - used for storing oil in offshore production areas, localized under water, most use water-cushion storage technology.

Separately, “natural” frames are considered - excavations and natural voids in the rock, ice-soil storage facilities, mines, and so on. They can be placed in an independent category and not included in the basic classification.

The second type of dividing containers is by useful volume:

Small tanks include tanks up to 50 cubic meters. They can be manufactured directly at oil refining complexes, supplemented with the necessary components during subsequent installation.

Large containers include containers up to 100,000 cubic meters, which are produced at specialized enterprises and transported to assembly sites in sets.

The volume and placement of tanks are also taken into account when classifying them into classes:

- The first includes tanks whose size reaches 10,000 cubic meters. The category also includes containers up to 5000 cubic meters. m, provided that they are located within the city or on the banks of a large river or reservoir.

- The second class includes tanks for petroleum products measuring 5,000-10,000 cubic meters. m.

- By the third - up to 5000 cubic meters.

Metal

Metal containers are used to store petroleum products at oil refineries and water at pharmaceutical and food industry enterprises, so waterproofing from the inside and outside of the tank is necessary to protect against moisture. For this purpose, materials are used that do not emit harmful substances and are inert to water. The best choices for waterproofing above-ground tanks are:

- environmentally friendly water-repellent paints;

- geosynthetic polymer membranes that prevent contact of liquid with metal and prevent corrosion, and are also resistant to chemicals and ultraviolet rays;

- penetrating waterproofing suspensions made from natural mineral components and creating a unified structure in the internal space of the container.

From below, the bottom of above-ground metal containers located on the supporting foundation is treated with bitumen-rubber mastic with sand. To waterproof tanks buried in the ground, polyurethane (polymer) or bitumen compounds are used. Tanks used at wastewater treatment plants and water treatment plants for storing wastewater, septic tanks, liquid fertilizers and other aggressive liquids are constantly exposed to chemically active environments. Polymer sheet materials that can withstand the destructive effects of moisture for a long time are suitable for their waterproofing. The peculiarities of the work are as follows:

- first, focal oxides are removed from the surface, oil stains and traces of rust are cleaned;

- a geomembrane, liquid rubber or a penetrating suspension is applied to the treated surface, the work begins with the joints between the bottom and the walls of the container;

- Welding seams are processed in two passes, after which a waterproofing coating is applied to the remaining surface.