Types of paving slabs

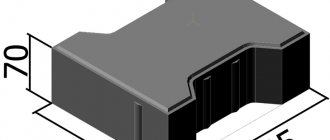

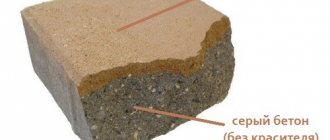

Tile masonry is at the peak of popularity today, so it is not surprising that the material is presented in a wide variety of products. It mainly differs in design and production method. Most often it is given the following form:

- rectangle;

- rhombus;

- square.

Molds for square paving slabs

Universal paving stones and modular tiles are in great demand.

As for production technology, tiles can be:

- Cast.

- Press.

The latter is produced exclusively in factory conditions, but the former can be easily made at home. All that is required for the work is a special form and concrete solution.

Making tiles yourself using a mold is not difficult.

Advantages

The ability to make tiles with your own hands, directly on the site, saving yourself from solving problems with their transportation and loading/unloading. If you calculate all the costs (and the cost of the cheapest, small-sized products starts from 760 rubles + other expenses), then the savings in general are quite significant.- Variety of options. Paving slabs can be made of any shape and thickness, rather than wasting time searching for appropriate products.

- If it is necessary to “spot” repair a path or site, it will not be difficult to make one or several copies right on the spot.

What do you need for this? Assembling the molds, making a vibrating table, and everything else - solution, dyes, plasticizers - is no longer a problem.

Ready-made forms for pouring paving slabs: types and characteristics

Today there is no shortage of assortment of such products. They can be purchased by both amateurs and professionals working in the field of large-scale production of paving slabs. They go on sale in sufficient quantities.

The problem lies in the quality of the forms themselves. Since they are made from a variety of materials, their performance characteristics vary markedly. The production of molds today includes:

- Polypropylene.

- All kinds of plastic.

- Polyethylene.

- Rubber.

- Polyurethane.

- Silicone.

You need to be especially careful when purchasing plastic derivatives, since here you can often find forms made from recycled materials. It is difficult for a non-professional in construction to distinguish them, but if you know what to look for, it is possible.

When purchasing a mold for paving slabs, pay attention to the material

A product that is not of very high quality has a rough surface and an unattractive appearance due to the lack of gloss and chips and other flaws clearly visible to the naked eye. Before pouring the working solution into such a mold, it will definitely have to be additionally lubricated. There will also be problems with removing the finished tiles. You can’t get it unless you steam the workpiece in hot water. The manufacturer does not provide guarantees for such copies, therefore, one cannot count on long-term service. The only thing that can somehow compensate for the existing shortcomings is a reasonable price. Let's see what the rest of the proposals are like.

Rubber molds for paving slabs

These types of forms are not in great demand, as they are quite heavy, quite expensive and difficult to operate. To work with them, you will need special equipment in the form of a vibrating table, a drying rack and portable shields, with the help of which the workpieces will be sent to the drying place. Purchasing rubber options is not very justified even for business, as it requires a substantial investment. In addition, the production of rubber itself is constantly becoming more expensive and, in order to maintain a competitive price for the material, manufacturers are beginning to add carbon black to it, that is, to add carbon to the original composition. Naturally, this reduces the quality characteristics of products made from rubber; in addition to this, paving slabs from this form may come out dark in color, as they will be colored by the soot present in the material. It will be impossible to produce something original and non-standard configuration in rubber molds for paving slabs .

Rubber molds for making paving slabs

After use, the molds will have to be washed with hydrochloric acid, which, to put it mildly, is not pleasant, and it’s bad for your health. In general, if you plan to do the casting of tiles yourself, then it is better to take a closer look at the blanks in a more modern design.

Sheet plastic products

The concept of sheet plastic includes:

- PVC;

- polystyrene;

- acrylic;

- ABS.

They are stamped on special thermal vacuum machines using the vacuum molding method.

PVC plastic

“This type of mold for paving slabs makes making blanks with your own hands a little easier”

It is presented in different variations. The least practical forms are obtained from the film variety. Their walls are thin, so you will have to move the workpieces filled with solution to the drying zone exclusively on the shield. You need to make sure that the shape does not become deformed, so you will almost always need to use a stand.

After use, containers are washed in soapy water to avoid concrete sticking. This takes a lot of time. But even the most careful care and careful operation do not make film forms durable. After 15-25 fills they become completely unusable, so it is not profitable to use them for large volumes of work.

Two-millimeter PVC plastic is a more durable option, however, the wall thickness of 2 mm declared by the manufacturer is often just an advertising ploy. In reality, this figure barely reaches 1.5 mm.

Molds for paving slabs made of PVC plastic

This type of mold for paving slabs doesn’t make it much easier to make blanks with your own hands. This will also require the use of stands and specially equipped places for drying. There should be no pressure on the filled containers. To prevent the concrete from sticking in the mold, you only need to use it clean and keep the concrete solution in it for at least two days, that is, until it dries completely.

In terms of strength, thickened PVC plastic is superior to film plastic, although it has a tendency to burst. The mold will withstand up to 70 pours.

ABS plastic

Forms made from such material meet the standards, but it is customary to use them to make larger concrete structures such as fences, columns, and other things. As for paving slabs, it will be difficult to give them even outlines in such containers. The presence of rounded contours will greatly complicate the subsequent installation of elements, since quite noticeable gaps will form between them. Tiles that are not organically joined will never allow a path or area to look aesthetically pleasing.

We must give credit to the products. The tiles cast in them have an inherent gloss, however, they will need to be kept in molds for up to two days. After use, the latter are thoroughly washed to remove adhering concrete.

ABS plastic tile molds

If the offer seems interesting, then it’s a good idea to look into the selection criteria. A good ABS mold will never come in a dark color. Such shades are the prerogative of low-quality plastic made from recycled materials. Low-quality ASB is thin at bends and a product made from it, even with slight deformation, makes a suspicious crackling noise, while good plastic will not burst at the bend.

Silicone molds for paving slabs

This is the most popular form model. People like to work with them because of their ease of use. The products are elastic. They make it possible to display the smallest details of the design on the cast tile. Using silicone you can create an imitation of artificial stone. However, mass production of tiles in silicone molds is not justified, since the containers do not have a large margin of safety, despite the fact that they belong to the middle price segment. But for home use they are simply irreplaceable. You can easily create tiles of an unusual design, which in turn will become the highlight of the garden.

A silicone mold will allow you to cast tiles of an original shape

Polyurethane

The molds are made of good quality polyurethane and are durable. They are durable, so they can be used in large-scale production. Such blanks perfectly convey texture, so the end result is an excellent imitation of boulders and natural stones. Polyurethane molds are indispensable in making paving slabs with your own hands. The only thing that makes you think about the choice is the price of the products.

Polyurethane molds are durable

Formoplast

Today this version of forms is not in demand. Disposable products. It is rarely possible to use them for more than one fill. Given that even the smallest country alley requires far more than 10 tiles, it becomes obvious that such an acquisition is extremely unprofitable. Even the low price of blanks does not help the situation.

Polystyrene

It is used to produce molds for pouring high quality paving slabs. The containers are able to perfectly convey the texture of marble, not only in the design, but also in the splendor of its shine, which makes paving slabs a real exclusive.

Polystyrene molds are easy to use. They do not need to be soaked or washed after pouring. The tile comes out of the container easily.

Polystyrene molds do not need to be soaked or washed

Be careful when purchasing. High-quality polystyrene molds are protected with a film on the inside. If there is none, it is most likely a fake.

Fiberglass

Such forms are used in the production of volumetric slabs and small garden forms. With their help, you can not only cast dimensional tiles for paving paths, but also figurines for garden decoration and landscape decoration. Fiberglass products are not very convenient to use. They require pre-lubrication before use, which sometimes causes the formation of pores and even cavities in the cast elements. They will not have a glossy shine either. Sometimes, after removal from the mold, the tiles have to be modified. Having analyzed the above, it is easy to conclude that fiberglass forms are not the best solution.

Fiberglass molds require pre-lubrication

How to make your own mold for paving slabs from polyurethane

Polyurethane molds are more difficult to manufacture, as they require compliance with certain rules and safety precautions. This is primarily due to their ability to release unsafe substances. Therefore, before you start work, make sure that the room is well ventilated and that you have gloves, goggles and a respirator. The clothing in which you will work must completely protect you from direct contact with polyurethane.

However, all these difficulties are not in vain, because by making a mold from polyurethane, you will receive an incredibly durable and reliable template that will serve you for a very long time. It will take 3 days for the polyurethane to completely harden, but the effort is worth the result.

As you can see, making a mold for paving slabs with your own hands is not so difficult. Just select the material that is most suitable for you and follow the simple instructions to make the blanks. At least, this option does not require too many financial costs and, as a last resort, you can always buy molds for paving slabs, where all the requirements have already been met and all you have to do is lubricate them and pour the solution inside.

Based on materials from: https://remoo.ru

How to choose a practical mold for casting paving slabs?

The quality of products of this kind is directly proportional to the quality of the material used for their production, as well as the status of the manufacturer. Priority should be given to products from large, reputable enterprises that have been presenting their products on the market for several days.

As for materials, it is worth taking a closer look at forms made from virgin polyethylene. They are distinguished by their correct contour, good rigidity, and the absence of deformations and cracks. According to experts, such forms for the production of paving slabs are ready to withstand about a thousand concrete pours .

High-quality forms will withstand about a thousand concrete pours

Derivatives of secondary polymers are no less good in operation. The tiles cast using such forms will receive ideal geometric proportions and will delight you with the clarity of the pattern. The strength reserve of the molds is designed for 500 pours. However, you need to be vigilant when purchasing copolymer “blanks”. Under their guise, unscrupulous manufacturers can display products made from cheaper recycled materials. Naturally, their characteristics will be far from those described. Knowing the following factors will help you avoid mistakes. Good recycled resin molds do not crack when squeezed, and their surface is always shiny.

Molds made from recycled polymers are designed for 500 pours

What else is worthy of attention are granulated polystyrene blanks. The molds have proven themselves remarkably well in home production. Each of them is capable of producing up to 100 paving slabs, while they will receive ideal geometry and gloss on the surface. True, it will take about 2 days to keep the concrete in the molds for this, but no one is in a hurry, right?

And the last recommendation. Before buying a uniform, be sure to study the quality certificate for it. In it you will find accurate information about the raw materials used for its production and other important characteristics.

Plastic

Perhaps the most budget-friendly option is to make molds for paving slabs from plastic bottles. Basically, five-liter containers are used for this purpose. To obtain the product, you need to cut the bottom to a height equal to the desired height of the finishing material.

In addition, you can use other types of homemade plastic molds for paving slabs. They are made from containers, unnecessary packaging and other items that fit the configuration and size.

For the manufacture of paving slabs, ordinary plastic containers and other containers used in everyday life are suitable.

There is also another way that allows you to make more interesting forms for the production of paving slabs with your own hands. To do this you need to use plastic, blanks and formwork. First, melt the plastic raw material. Please note that this may release harmful substances and just an unpleasant odor, so it is better to work outdoors. Then pour the mixture into the formwork with the template and wait until it hardens completely. After this, remove the product and the container for pouring the solution will be ready.

Making a mold for paving slabs with your own hands

Instead of spending money on dubious quality blanks for the production of paving stones, you can work on their creation with your own hands. This is a great way to save money and a chance to make the area adjacent to your home original and unique. To make a blank, sometimes you don’t even need to spend money, since the materials at hand are quite suitable for this.

There are many ideas for designing molds for casting paving slabs. The selection of consumables is also varied. At home, you can make a molding container:

- made of wood;

- gypsum;

- metal;

- silicone;

- polyurethane.

You can make a tile mold yourself

What's good about each option?

Tree

Wooden formwork is the most affordable way to cast tiles at home. Assembling it with your own hands is as easy as shelling pears. You can use not only boards, but also moisture-resistant plywood. The formwork can be adapted for loading into a machine used for producing vibration-pressed products at home.

An example of making a mold from wood and a rubber mat

To assemble the mold, you need to prepare not too thick strips. Structural elements will be cut from them, which will later be assembled into a workpiece using nails. Do not try to nail the fasteners tightly. It would be better to leave it freely so that when removing the tiles, the formwork can be removed without any problems. Wooden molds are ideal for producing simple tiles in standard configurations and clear shapes. You can’t count on anything exotic with this approach. To cast the original tiles, you need to look for other options.

Miracle plastic

The most budget-friendly option that allows you to build a blank for casting tiles from plastic bottles, which are indispensable in the household. The most popular in our case is the five-liter container.

Plastic containers are suitable for casting tiles

To make a mold, just cut off the bottom of the bottle. This must be done at the height at which the paving slabs are needed. In principle, containers for pouring concrete mortar can be: edged canisters, food packaging and other items that are suitable in shape and size for your project.

Gypsum

“Even people who are very far from construction can make plaster molds for paving slabs”

A popular idea, often implemented in private practice. Even people who are very far from construction can make plaster molds for paving slabs. Moreover, a plaster model of the blank will make it possible to cast not only simple geometric specimens, but also figured tiles of any design.

To work, you will need a sample of the tiles planned for production, formwork and gypsum mortar. The formwork can be a wooden structure, an old aluminum or plastic bowl, or a piece of a car tire.

An example of a plaster mold for making tiles

Before proceeding to the production process, a sample tile is covered with a layer of fat. This is a necessary measure to allow the part to be easily removed from the mold in the future. The next step is to place the prepared part in the formwork and fill it with gypsum mortar. It must be prepared only before pouring, since gypsum tends to set quickly. To increase the strength characteristics of the future form, it is recommended to introduce additives such as plasticizers or cement into the working solution.

The prepared gypsum solution must be poured so that the tiles lying in the formwork are covered with it by at least 2 cm.

Although plaster tends to harden quickly, you should not rush to remove the mold. Let it sit for a day. In this case, you will receive a clear imprint of the workpiece, reflecting the smallest details of its decor.

Criticism of gypsum molds for paving slabs for their fragility is undoubtedly justified. During active use, shocks and falls, the form may be damaged. But this is not a reason to discount the idea, because the cost of manufacturing a new blank is minimal.

Metal

It makes sense to make forms from metal if large-scale work on the production of paving slabs is ahead. Assembly will require the use of a welding machine, although today they are increasingly trying to make workpieces collapsible, since metal is not inherently flexible and when knocking the finished tile out of shape, there is a high risk of damage to the concrete product.

There are several ways to assemble a metal mold. It all depends on the imagination of the master. It can be given the shape of a square, hexagon, etc. But the result will be much more interesting if the mold for the production of paving slabs has a relief bottom that imitates a wood structure, the texture of stones, or simply carries a geometric pattern . The finished products will look very colorful.

Diagram of a metal mold for paving slabs

If you don’t want to bother yourself with welding and other intricacies, look at the pipe scraps left over after building the house. It would be great if they had different diameters. To obtain a blank for casting tiles, simply cut the pipes into pieces of the same width. Now all that remains is to fill them with concrete and after a couple of days remove the nice round elements from the molds.

Molds for paving slabs from pipe scraps

You can lay different-sized tiles in any order or creating a specific pattern. A path paved with multi-colored tiles will look interesting. To get it, just add dyes of the desired shade to the concrete.

Polymers

“It’s better to make silicone molds for exclusive paving slabs yourself”

Polyurethane and silicone are considered the best materials for creating blanks for casting paving slabs. Using them, you can cast the most unusual elements in their design, which have no restrictions either on the configuration of shapes or on decorative details. It is better to make silicone molds for exclusive paving slabs yourself. Is it possible? Quite! In stores there is a special mass that comes complete with a hardener. An example of the future form can be either purchased tiles or laid out personally. If you want to get a patterned surface, place a pattern of sticks, wire, shells, and beads on top.

Special mass for making molds

Next you need to follow the algorithm for working with plaster. Mix the liquid mass with the hardener and immediately pour the resulting mixture onto the tiles laid in the formwork. The base layer of the mold should be at least a centimeter thick. After setting, excess material will need to be cut off from the upper surface, after which the workpiece can be completely removed.

The polyurethane mold is made in the same way.

Natural gifts

Nature itself will help you make tiles of interesting design. Try shaping it in the form of, for example, burdock leaves. This idea will appeal to those who want to have paths in their dacha landscape that will attract attention with their uniqueness.

Original tiles in the shape of leaves

To obtain unusually shaped elements, a thick layer of thick, moldable concrete mortar is applied to the burdock leaf, which is pressed tightly against the green base. After the composition has dried, the tile is cut along the contour of the sheet. Such concrete “leaves” need to be laid at some distance from each other on the path. The ideal walking distance is 20 cm.

Process of making sheet tiles

Common composites for mold making

Paving slabs in landscape design

To make molds for road tiles, materials such as:

- common and strong polyurethane

- unpretentious and durable silicone

- no less durable plastic

- cheap plaster

- inexpensive and laconic tree

Homemade silicone molds for paving slabs, greased or oiled before pouring, are filled with concrete mortar. The main thing here is that the lubricant is colorless.

Wooden configurations

Templates from this material are made like formwork. To do this, take plywood that is not afraid of water or slats, cut them to the required size and connect them with nails. The resulting fasteners should be easily removable when the solution dries.

A wooden mold for paving slabs can be created instantly. It won't take a lot of money or effort. But along with the advantages, this method of pavement blind area also has disadvantages:

- wood is not resistant to high humidity

- strips made of this material are not suitable for the manufacture of complex configurations

Wooden forms are made following a specific algorithm:

- Cut the bars to the required size.

- Next, they are fastened with metal corners, screws or nails.

- The prepared forms are placed on cellophane or a metal plane.

- Then they are filled halfway with concrete mortar.

- Afterwards the reinforcing mesh is installed.

- The molded sides are tapped to compact the mixture.

- The remaining solution is poured on top.

- Wait two days for it to dry.

- The mold is disassembled and the resulting sample is removed.

The wooden mold is suitable for quickly and inexpensively casting 10 or 20 tiles in polygonal or square configurations.

Plaster templates

Simple and cheap gypsum is also good for making molds for pouring paving slabs yourself. You can make any templates from it, even designer ones. Such forms are cast using a sample of tiles and a gypsum mixture. The example is lubricated and placed in wooden formwork. It is better to dilute the gypsum immediately before work so that it does not harden ahead of time.

Hypoforms for paving slabs

Cement or a plasticizer is often mixed into this material for strength. With this mold, which will never crack, you can cast a lot of tiles. The mixed liquid composition is poured in a small amount into the formwork and allowed to harden for 24 hours.

Plaster molds should be handled very carefully as they are very fragile. But if the template does get damaged or broken, making a new one will be cheap and easy. Added plasticizers and cement will give additional strength to gypsum.

Details of creating a plastic template

A plastic form will be the most durable and reliable. This configuration can serve to create about 1000 patches. The plastic, which does not lose its shape and does not crack, very accurately copies the originals. It is comfortable to work with to create tiles with non-standard shapes.

To prepare such a template, molten plastic is poured into a wooden frame. In this case, they use such materials and tools as:

- sandpaper

- plastic

- level

- screws or nails

- saw

- hammer or screwdriver

- wooden blocks larger in size than the tile being created

Using a plastic template, you can create incredibly clear designs and shapes. The steps for making such molds for paving slabs are as follows:

- They make a wooden frame by fastening the bars with nails or screws. Its internal capacity will correspond to the size of the desired source. At the same time, the level controls the straightness of angles and lines.

- The base is placed horizontally and molten plastic is poured into it. After an hour, the frozen material will turn into a finished form.

- The sample is removed from the base by disassembling it into boards. If necessary, the template is processed with sandpaper.

Making silicone molds for paving slabs

You can also make silicone molds for paving slabs yourself. After all, such templates very accurately convey the smallest details of the original plane. The material for them is usually three-component silicone, consisting of a hardener, catalyst and base.

Silicone molds for paving slabs

This form is made using:

- scissors

- mixer used in construction

- plasticine for sculptures

- lubricant

- solid matrix

- the silicone itself and the container for filling it

The matrix can be a finished tile with the necessary relief and structure. It must be cleaned and degreased. When creating a silicone template for tiles, prepare a container for pouring the material.

Plasticine is placed there completely and evenly. Then the prepared matrix is placed on it, having previously lubricated it. Afterwards, the well-mixed silicone mixture is poured in a thin stream into the container to harden. The finished template is pulled out and trimmed if necessary.

Polyurethane template

This tile shape is more complex than the others. Due to its harmfulness, it is made on the street, wearing glasses, a respirator and gloves. When producing these templates, it is recommended to avoid wet surfaces and dampness. But polyurethane molds are suitable for creating both road tiles and paving stones.

Mandatory nuance

Whatever type of molds you work with for pouring paving slabs, they will certainly have to be lubricated before use. The lubricant must contain fats or oils. What is suitable as a lubricant?

- Workout.

- Animal fat.

- Vegetable oils (palm, sunflower).

- Specific lubricants.

Before use, the molds must be greased

When choosing the type of lubricant, you need to take into account its side effects in order to prevent the tiles from becoming undesirable tones or stained.