Prices for installing curb stones

| n\n | List of works performed | Unit change | price, rub. |

| 1. | Site visit, consultation and budget preparation | linear meters | For free |

| 2. | Laying a 50 cm border. Excavating soil, installing beacons | linear meters | 250 |

| 3. | Laying a 1 meter curb Excavation, installation of beacons | linear meters | 350 |

| 4. | Installation of road curbs Excavation, installation of beacons | linear meters | 450 |

| 5. | Installation of drains 25 cm Excavation of soil, installation of beacons | linear meters | 100 |

| 6. | Installation of drains 50cm Excavation, installation of beacons | linear meters | 150 |

| 7. | Installation of deep drainage Excavation, installation of beacons | linear meters | 350 |

Typical technological map (TTK) installation of concrete side stones

TYPICAL TECHNOLOGICAL CARD (TTK)

INSTALLATION OF CONCRETE SIDE STONES

1 AREA OF USE

1.1. A standard flow chart (hereinafter referred to as TTK) was developed for a set of works for installing side stones.

1.2. The standard technological map is intended for use in the development of Work Projects and other organizational and technological documentation, as well as for the purpose of familiarizing workers and engineers with the rules for carrying out work on installing side stones.

1.3. The purpose of creating the presented TTK is to provide a recommended technological process diagram for installing side stones of grade BR 100.30.18 on a concrete base from a ready-mixed mixture on a section with a length of 40 linear meters.

1.4. On the basis of the TTK, as part of the PPR (as mandatory components of the Work Project), Working Technological Maps are being developed for the implementation of certain types of road construction work.

When linking the Standard Flow Chart to a specific facility and construction conditions, production schemes and volumes of work, labor costs, mechanization tools, materials, equipment, etc. are specified.

1.5. All working technological maps are developed according to the working drawings of the project, they regulate the means of technological support and the rules for performing technological processes in the production of these works.

1.6. The regulatory framework for the development of technological maps is: SNiP, VSN, TR, GESN-2001 and ENiR.

1.7. Working flow charts are reviewed and approved as part of the PPR by the head of the General Contracting Construction and Installation Organization, in agreement with the Customer's organization, the Customer's Technical Supervision and the organizations that will be in charge of the operation of these side fences.

1.8. The use of TTK helps to improve the organization of production, increase labor productivity and its scientific organization, reduce costs, improve the quality and reduce the duration of construction, safe performance of work, organize rhythmic work, rational use of labor resources and machines, as well as reduce the time required for the development of project planning and the unification of technological solutions .

1.9. The scope of work performed when installing side stones includes:

geodetic laying out and securing the line of the front side of the installation of side stones;

trench section;

crushed stone preparation device;

laying concrete;

installation of side stones.

1.10. The technological map provides for the installation of side stones as a complex link with a TO-49 excavator loader (based on the MTZ-82 tractor) equipped with special ED-3M equipment, as a driving mechanism.

Fig.1. Backhoe loader TO-49

1.11. Work is carried out all year round and is carried out in one shift. The working hours during a shift are:

hour,

where is the utilization rate of the backhoe loader by time during the shift (the time associated with preparing the machine for work and carrying out technical maintenance is 15 minutes, breaks related to the organization and technology of the production process and driver rest are 10 minutes every hour of work) .

1.12. Work should be performed in accordance with the requirements of the following regulatory documents:

SNiP 3.01.01-85*. Organization of construction production;

SNiP 3.06.03-85. Car roads. Rules for production and acceptance of work;

SNiP 3.01.03-84. Geodetic work in construction;

SNiP III-10-75. Landscaping.

SNiP. Occupational safety in construction. Part 1. General requirements;

SNiP. Occupational safety in construction. Part 2. Construction production.

2. ORGANIZATION AND TECHNOLOGY OF WORK EXECUTION

2.1. In accordance with SNiP 3.01.01-85* “Organization of construction production”, before the start of construction and installation (including preparatory) work at the site, the General Contractor is obliged to obtain from the Customer in the prescribed manner permitting documentation for:

— allocation of land;

— conducting construction work (work order).

2.2. The main work on installing side stones should be preceded by the following activities and work:

acceptance from the customer of a construction site prepared for work;

checking the availability of design and estimate documentation and familiarizing engineers and workers with working drawings and the Work Project;

preparing places for storing inventory, equipment and materials;

delivery and storage of side stones and crushed stones in stacks at the construction site;

checking factory passports for side stones;

equipped camp for workers;

drawing up an act of readiness of the object for work.

2.3. Before the start of construction and installation work, the customer is obliged to create a geodetic alignment basis for performing landscaping work and transfer to the contractor the technical documentation for it and the points of this basis fixed on the ground with signs. The geodetic alignment basis for construction should include:

a) high-altitude benchmarks (marks);

b) points securing the longitudinal axes of driveways and paths.

The geodetic alignment basis should also include points from which it is possible to lay out the axes of passages and monitor their position during the construction process.

During the construction process, the accepted signs of the geodetic alignment base must be constantly monitored for safety and stability and checked instrumentally at least twice a year (in the spring and autumn-winter periods).

Acceptance of the geodetic alignment base for construction should be documented in an act. The act of acceptance of the geodetic alignment base must be accompanied by a schematic plan for the improvement of the territory indicating the location of points, the types and depth of the signs securing them, the coordinates of points, their chainage values and elevations in the accepted system of coordinates and heights.

2.4. The work on installing side stones includes the following operations:

— marking works;

— cutting out a trench for installing side stones;

— arrangement of a leveling layer of crushed stone;

— installation of a concrete base;

— installation of side stones;

— backfilling of soil from the back side of the side.

2.5. The boundary line must be laid out from the axis of the roadway, red lines, existing buildings and other permanent structures. Vertical marks of the side lines in the profile are made using a level from a nearby benchmark.

The procedure for carrying out marking work

In the direction of the longitudinal line of the roadway, stakes are driven along the level, the top of which corresponds to the upper plane of the side stone according to the project. Intermediate stakes are driven into the sights. For more accurate installation of the side stone, cast-off boards and posts are used, driven into the ground to a depth of 0.6-0.7 m on both sides of the trench (see Fig. 2). At an angle of 90° to the front line of the side stone at a height of 1 m from the surface of the subgrade, horizontal boards (castoffs) 30-40 mm thick are sewn to the posts. On the upper edge of the board, driving 80 mm nails indicates the exact position of the side stone at the place of its installation in plan along the line of the front side. The cast-offs are installed at a level at the same level to ensure control of the height position of the side stones. The required thickness of the leveling layer, taking into account the material safety factor for compaction equal to 1.25, and the thickness of the concrete base are fixed on stakes. A cord (mooring) is pulled along the front side facing the roadway. The breakdown is made into shiftable volumes of work.

Get full text

Fig.2. Scheme for installing side stones using castings

1 — cast-offs from boards; 2 — sight; 3 - cord; 4 — side stone

2.6. Mineral material and side stones delivered to the site should be laid out in the brigade’s coverage area, creating at least a 2-shift supply, which must be constantly maintained. Side stones are delivered from the factory or from the enterprise's warehouse by dump trucks. Loading and unloading of stones is carried out using a truck crane. The stones are laid out along the trench in a line so that the distance between them does not exceed three meters.

No later than the shift before the installation of side stones, the work area is closed to traffic, fences and road signs are installed, and exits and detours are prepared.

Work on installing side stones is carried out on 2 grips 40 m long.

2.7. At the first grip, the following technological operations are performed:

— a fragment of a trench;

— arrangement of a crushed stone cushion under the base;

— installation of formwork.

2.7.1. Along the stretched cord, which marks the longitudinal line of installation of the side stone, an excavator is used to dig out a rectangular trench with a bottom width of 0.4-0.5 m to construct the base of the side stone. The depth of the trench depends on the design position of the top of the side stone, but must be at least 0.25 m.

During new construction, a trench for side stones is dug simultaneously with a trench under the roadway or sidewalks, pedestrian paths, medians, parking lots, etc.

Find out the cost of your work

Free order evaluation!

The base of the trench is compacted with a vibrating plate to at least 0.95 and presented to the Customer for inspection and signing of the Hidden Work Certificate.

2.7.2. A “cushion” of crushed stone of a fraction of 20-40 mm is placed along the bottom of the trench in a layer 0.10 m thick. The crushed stone is transported by a loader, leveled manually, compacted with a vibrating plate and presented to the Customer for inspection and signing of the Hidden Work Certificate.

2.7.3. On the finished “cushion”, a prefabricated formwork is installed with a height of 20 cm and a width 20 cm greater than the width of the side stone. The formwork is assembled from boards 40-50 mm thick and bars 40x40 (50x50) mm with transverse bracing of the walls. Nails are driven into the transverse spacers to secure the axis of the side stone. The formwork is secured with metal pins on the inside of the trench.

2.8. On the second grip, the following technological operations are performed:

— installation of a concrete base;

— installation of side stones;

- filling and jointing of joints with cement mortar.

2.8.1. The concrete mixture is placed into the formwork manually, using shovels from a loader bucket, in a layer of h = 10 cm, and then compacted with a vibratory rammer.

Heavy concrete of class B 15 (M 200) is delivered from the concrete plant in dump trucks and unloaded onto pre-prepared sites with the calculation of carrying (transporting) concrete no more than 20 m. The finished base is presented to the Customer for inspection and signing of the Hidden Work Certificate.

2.8.2. It is permitted to proceed with the installation of side stones only after preparing the base and instrumentally checking the compliance of the longitudinal line with the design.

Installation of meter-long side stones is done manually using a pliers or U-shaped device. A diagram of the installation of meter-long side stones using the specified devices is presented in Fig. 3.

Fig.3. Diagrams of devices and equipment for installing side stones:

1 - side stone; 2 - formwork; 3 - concreting section (clip); 4 - concrete preparation; 5—sandy underlying layer; 6, 7 - device for installing side stones

Before installation, the ends of the stones must be cleaned of dirt. Road workers clamp the curb with hand grips and install the stone face-to-face closely along the stretched cord; The stones are leveled and hung.

The side stone is installed on a concrete base 10 cm thick along a cord stretched between metal pins. The side stone is settled to the level of the tensioned cord using a wooden tamper. After installing the stone for its stability on both sides, a concrete cage with a height of 10 cm on the sidewalk or lawn side and 7 cm on the road side is placed manually in the formwork.

Subsequent side stones are laid over the original stone. A road worker uses a crowbar to fix its position after removing the grips. Each stone is placed tightly in the concrete mixture, paying attention to the tightness of the stones and the evenness of the outer and upper sides of the side line. If necessary, side stones are upset by blowing a hand tamper onto a board laid on top of the stone. In the case where the side stone cannot be leveled on top, concrete is selected from under the base of the stone.

Side stones on curves are installed in the same way as on straight sections, having previously laid out the outline of the curve using a template made from a thin board or along a cord. On curves, only patterned edge stone is used.

2.8.3. After checking the correct installation of the side stones and correcting the detected irregularities, the seams between the side stones are filled with a cement-sand mortar of a composition of 1:4, after the cement mortar loses its mobility, the seams on the side of the roadway are embroidered along the line with a cement-sand mortar of a composition of 1:2.

After opening the seams, the lower and rear parts of the side stone are sealed with concrete by tamping and then covered with a layer of sand. Only concrete is used for tamping under side stones. The lower and back parts of its cavity between the walls of the formwork and the stone, on both sides, are filled with concrete to a height of 10 cm.

The voids formed between the ends of the stones are filled with liquid cement mortar until they are completely filled. The width of the seams between curved side stones or at the junction of curved and straight products should not exceed 5 mm. On the reverse side, the side stone is covered with soil removed when the trench was excavated.

The side stone must be installed no later than 3 days before the construction of the road surface in order for the concrete frame and mortar in the seams between the side stones to gain sufficient strength.

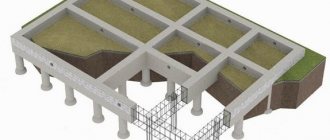

The technological sequence for installing edge stones is shown in Fig. 4.

Fig.4. Side stone installation diagram

1 - fragment of a trench; 2 — arrangement of a crushed stone cushion; 3 - laying a concrete base; 4 — installation of side stone; 5 - sealing joints with cement mortar; 6 — backfilling of soil from the back side of the side

3. REQUIREMENTS FOR QUALITY AND ACCEPTANCE OF WORK

3.1. Control and assessment of the quality of work on the installation of side stones should be carried out in accordance with the requirements of regulatory documents:

— SNiP 3.01.01-85*. Organization of construction production;

— SNiP III-10-75. Landscaping.

— SNiP 3.06.03-85. Car roads. Rules for acceptance and production of work;

— GOST 6665-91. Concrete and reinforced concrete side stones.

— GOST 8267-93. Crushed stone and gravel from dense rocks for construction work.

3.2. In order to ensure the required quality of installation of side stones, work must be subject to control at all stages of its implementation. Production control is divided into input, operational (technological), inspection and acceptance. Quality control of the work performed must be carried out by specialists or special services equipped with technical means that ensure the necessary reliability and completeness of control and is assigned to the head of the production unit (foreman, foreman) performing construction work.

3.3. All side stones arriving at the site must meet the requirements of relevant standards, technical specifications for their production and working drawings.

Before installation work begins, the edge stones arriving at the site must be subjected to incoming inspection. Incoming inspection is carried out to identify deviations from these requirements. Solid during acceptance in full, selective - 3 stones per object. Incoming inspection of incoming stones is carried out by external inspection and by checking their basic geometric dimensions. The front surfaces of the side stones must be flat, clean, smooth, without holes and cracks, the corners and edges of the correct shape.

Side stones received at the site must have an accompanying document (passport), which indicates the name of the structure, its brand, weight, and date of manufacture. The marking must be applied with indelible paint on the end face of at least 10% of the stones from the lot.

The results of the incoming inspection are documented and entered into the Logbook for the incoming inspection of materials and structures.

3.4. Stones on trucks should be transported in packaged containers or on pallets, tied with steel tape or wire, ensuring rigid fixation and safety of the stones.

It is prohibited to load stones in bulk and unload them by dropping them.

Stones should be stored in a finished product warehouse, sorted by grade in stacks or bags up to 2 m high.

Stones in stacks must be laid on wooden pads with a thickness of at least 30 mm or pads made of other materials that ensure the safety of the stones, located vertically one below the other at a distance of 0.2 lengths of the stone from the end. The bottom row of stones should be laid on transverse spacers with a width of at least 80 mm.

Get full text

3.5. During the installation process, it is necessary to carry out operational quality control of the work. This will allow you to timely identify defects and take measures to eliminate and prevent them. The control is carried out under the guidance of a foreman (foreman), in accordance with the Operational Quality Control Scheme for the installation of side stones.

During operational (technological) control, it is necessary to check the compliance of the main production operations with the requirements established by building codes and regulations, detailed design and regulatory documents. Instrumental control during the installation of side stones should be carried out systematically from the beginning to its complete completion. During the installation process, the following is checked: the horizontality of the top of the installed side stone using a level; straightness of the side plane according to the sights; installation of a pattern stone according to a template.

The results of operational control must be recorded in the General Work Log.

3.6. During inspection control, it is necessary to check the quality of work selectively at the discretion of the customer or general contractor in order to check the effectiveness of previously carried out production control. This type of control can be carried out at any stage of construction and installation work.

3.7. The results of quality control carried out by the customer’s technical supervision, designer’s supervision, inspection control and comments of persons monitoring production and quality of work must be entered in the General Work Log. All acceptance documentation must comply with the requirements of SNiP 3.01.01-85*.

3.8. Quality control of work is carried out from the moment the side stones arrive at the construction site and ends when the facility is put into operation.

The quality of work is ensured by compliance with the requirements for compliance with the necessary technological sequence when performing interrelated work and technical control over the progress of work set out in this map.

3.9. An example of filling out the Operational Quality Control Scheme is given in Table 1.

Table 1

| Name of operations subject to control | Subject, composition and scope of inspection, maximum deviation | Control methods | Control time | Who controls |

| Incoming inspection of side stones | Permissible deviations: — length and height ±5 mm; — width along the top edge ±3 mm; — width at the base ±5 mm; — the width of the chamfer of the stones is ±2 mm; — curvature along the length should not exceed 3 mm per 1 m | Measuring, tape measure | Upon arrival at the facility | Foreman |

| Construction of crushed stone base | The deviation of the layer from the design should not exceed minus 15 mm | level | When installing | Surveyor |

| Thickness of the concrete base layer | The difference between the designed and arranged base is ±1 cm; | meter | After 20 p.m. | Foreman |

| Installation of side stones | Ledges in rows of stones - 8 mm Displacement of the stone axis relative to the center axis ±12 mm Marking of the top of the curb ±0.5 cm; The width of the seam between the stones is ±0.5 cm; The height of the stone above the covering is ±1cm; The width of the road between the stones is ±0.5cm | level, theodolite, tape measure, template | After 20 p.m. | Foreman, surveyor |

3.10. Upon completion of the installation of side stones, the work performed is accepted according to the act, to which is attached:

general work log;

certificates of inspection of hidden work;

an executive diagram of the instrumental inspection of the installed side stones with the marking of deviations from the design made during the installation process;

passports for crushed stone, concrete and side stones.

3.11. A General Work Log, a Design Organization Supervision Log and a Geodetic Work Log must be maintained at the construction site.

4. CALCULATION OF LABOR COSTS AND MACHINE TIME

4.1. An example of calculating the cost of labor and machine time for installing side stones is given in Table 2.

table 2

| N p/p | Justification, code EniR, GESN | Name of works | Unit change | Scope of work | per unit of measurement | Labor costs for the entire volume | ||

| Person-hour | Machine hours | Person-hour | Machine hours | |||||

| 1. | Calculation No. 1 | Extracting a trench under the curb in soils of II gr. | m | 5,0 | — | 0,02 | — | 0,12 |

| 2. | E.25-14, vol.2, p.1 | Loading at the on-site warehouse and unloading curb stones at the installation site using a truck crane | PC. | 40 | 1,08 | 0,54 | 43,20 | 21,6 |

| 3. | Cleaning up irregularities when excavating a trench, soil grade II. | 100 m | 0,005 | 120,51 | — | 0,6 | — | |

| 4. | Compacting the bottom of the trench with pneumatic rammers, soil grade II. | 100 m | 0,04 | 12,18 | — | 0,5 | — | |

| 5. | Construction of a base made of crushed stone 0.1 m thick | 100 m | 0,2 | 26,24 | 3,17 | 5,3 | 0,63 | |

| 6. | Installation of side stones | 100 m | 0,4 | 76,08 | 0,72 | 30,4 | 0,29 | |

| 7. | Backfilling soil II gr. on the back side of the side stone | 100 m | 0,05 | 97,20 | — | 4,9 | — | |

| TOTAL: | m | 40,0 | 22,64 |

4.2. Labor and time costs are calculated according to GESN-2001, Collection 27* “Highways”, GESN-2001 Collection 1** “Earthworks”. The productivity of an excavator for excavating soil in a trench under a side stone is determined by the formula:

m/hour.

_______________

* GESN 01 is in effect. — Note from the database manufacturer.

** GESN 01 is in effect. — Note from the database manufacturer.

5. SCHEDULE OF WORK

5.1. An example of drawing up a work schedule is given in Table 3.

Table 3

| N p/p | Name of works | Unit change | Scope of work | T/capacity per person-hour | Name and number of brigades (units) | Month of start and end of work, duration of work, days |

| 1. | Installation of edge stone | m | 40,0 | 107,54 | Truck crane - 1 unit. Excavator - 1 unit. Workers - 6 people. |

5.2. When drawing up a work schedule, it is recommended that the following conditions be met:

5.2.1. In the column “Name of technological operations” all the main, auxiliary, accompanying work processes and operations included in the complex construction process for which the technological map has been drawn up are given in technological sequence;

5.2.2. The column “Accepted team composition” provides the quantitative, professional and qualification composition of construction professions for performing each work process and operation, depending on the labor intensity, volume and timing of the work.

5.2.3. The work schedule indicates the sequence of work processes and operations, their duration and mutual coordination along the scope of work in time.

5.2.4. The duration of the complex construction process for which the technological map has been drawn up must be a multiple of the duration of the work shift for single-shift work or a working day for two- and three-shift work.

6. MATERIAL AND TECHNICAL RESOURCES

6.1. Need for machinery and equipment.

6.1.1. Mechanization of construction and special construction work must be comprehensive and carried out by sets of construction machines, equipment, small-scale mechanization, necessary installation equipment, inventory and devices.

6.1.2. When choosing machines, it is necessary to provide options for replacing them if necessary.

6.1.3. An approximate list of the main necessary equipment, machines, mechanisms for the work is given in Table 4.

Table 4

| N p/p | Name of machines, mechanisms, machine tools, tools and materials | Brand | Unit change | Quantity |

| 1. | Truck crane, Q=14.0 t | KS-3577 | PC. | 1 |

| 2. | Backhoe loader, g=0.28 m | TO-49 | » | 1 |

| 3. | Theodolite | 2T-30P | » | 1 |

| 4. | Vibrating plate | LF 70D | » | 1 |

| 5. | Two-leg sling, Q=0.5 t | 2SK-0.5* | » | 1 |

| 6. | Vibratory rammer | LD 80D | » | 1 |

| 7. | Dump truck | KamAZ-65115 | » | 1 |

| 8. | Orange vests | » | 8 | |

| 9. | Safety helmets "Trud-1" | OST | » | 8 |

| 10. | Side stones | BR 100.30.18 | » | 40 |

| 11. | Concrete is heavy | class B15 (M 200) | m | 2,36 |

| 12. | Cement mortar | M 100 | » | 0,02 |

| 13. | Crushed granite, fractions 20-40 mm | M 800 | » | 2,5 |

| 14. | Softwood lumber, unedged | IV p. 40 mm | » | 0,07 |

| 15. | Construction nails | 100-120 mm | kg | 0,4 |

7. OCCUPATIONAL SAFETY

7.1. When carrying out work, you should be guided by the current regulatory documents:

- SNiP. Occupational safety in construction. Part 1. General requirements;

- SNiP. Occupational safety in construction. Part 2. Construction production;

— GOST 12.3.002-75* “Production processes. General safety requirements"

- RD. Occupational Safety and Health. Organizational and methodological documents.

7.2. Responsibility for the implementation of safety measures, labor protection, industrial sanitation, fire and environmental safety rests with the work managers assigned by order.

The responsible person exercises organizational management of the work directly or through the foreman. The orders and instructions of the responsible person are mandatory for all workers at the site.

7.3. Labor protection of workers must be ensured by the administration issuing the necessary personal protective equipment (special clothing, shoes, etc.), taking measures for the collective protection of workers, sanitary facilities and devices in accordance with current standards and the nature of the work performed. Workers must be provided with the necessary working conditions, food and rest. The work is carried out in special footwear and overalls. All persons on the construction site are required to wear safety helmets.

7.4. Sanitary facilities must be located outside hazardous areas. A first aid kit with medicines, a stretcher, fixing splints and other first aid equipment must be kept and constantly replenished in the workers' rest trailer. All workers on the construction site must be provided with drinking water.

7.5. The placement of construction machinery must be determined in such a way as to provide sufficient space for viewing the work area and maneuvering, subject to maintaining a safety distance.

The technical condition of machines must be checked before the start of each shift.

Each car must be equipped with an audible alarm. Before putting it into operation, you must sound a sound signal.

7.6. The person responsible for the safe performance of work is obliged to:

— familiarize workers with the Work Technological Map for signature;

— monitor the good condition of tools, mechanisms and devices;

— explain to employees their responsibilities and the sequence of operations.

7.7. When operating an excavator, the following rules must be observed:

— it is prohibited to carry out any work and to have unauthorized persons within a radius equal to the length of the boom plus 5 m;

— leveling the excavator parking area is permitted only when it is stopped;

— when the excavator is moving, the boom should be installed strictly along the axis of movement, and the bucket should be lowered to a height of no more than 0.5-0.7 m from the ground and pulled up to the boom;

— moving an excavator with a filled bucket is prohibited;

— it is prohibited to hold (leave) the bucket suspended;

— when stopping work, the excavator boom must be moved towards the face and the bucket lowered to the ground;

— during non-working hours, the excavator must be placed in a safe place, the cabin is closed, the engine is turned off, the chassis and turning parts are braked.

7.8. When performing loading and unloading operations, it is PROHIBITED:

— presence of people in the back of the vehicle, on the load and in the hazardous area of the crane;

— moving cargo over a vehicle, equipment, production premises;

— combination of operations when lifting (lowering) and moving cargo;

- level the load being moved by hand, and also adjust the slings while hanging;

— be between the lifted load and the equipment or stack with the load;

— lift the load if it has damage or faulty loops, is not lying freely (sprinkled, crushed, frozen, etc.), with the tension of the cargo ropes slanted.

7.9. When working on soil compaction mechanisms, the following requirements must be observed:

— before starting work, you should check the serviceability of the vibration switch of the vibrating plate and vibrating rammer at idle speed;

— check the completeness and reliability of fastening parts, the serviceability of the protective casing;

— to protect the eyes from dust, the driver must have safety glasses.

8. TECHNICAL AND ECONOMIC INDICATORS

8.1. Work on installing side stones is carried out by a team with a total number of 8 people.

| 6th grade excavator loader operator | — 1 person |

| Truck crane operator 5th category | — 1 person |

| Road workers | — 6 people |

8.2. Labor costs for installing 40 m of side stones are:

| Labor costs of workers | — 84,90 person-hour |

| Machine time | — 22,64 machine-hour |

8.3. Output per worker is 1.5 m/cm.

9. REFERENCES USED

9.1. When developing the Standard Technological Map the following were used:

9.1.1. TsNIIOMTP. M., 1987. Guidelines for the development of standard technological maps in construction;

9.1.2. SNiP III-10-75. Landscaping;

9.1.3. SNiP. Occupational safety in construction. Part 1. General requirements;

9.1.4. SNiP. Occupational safety in construction. Part 2. Construction production

The electronic text of the document was prepared by Kodeks JSC and verified against the author’s material. Author: - Head of VET, construction technologist (30 years of experience), St. Petersburg, 2008

Functionality of the road frame

Installing delimiters performs several tasks at once.

- Allocation of linear meters of the pedestrian zone, preventing cars from leaving the roadway onto pedestrian areas, which is counted as a gross violation of the rules.

- Massive curbs create a stop for the tiles and road surface and do not allow all types of paving slab coverings to creep away.

- With curb design, the road looks neat, finished and perfect.

Natural granite stone or concrete is used to make road design elements. Installing a concrete curb is cheaper than using natural stone blocks. Concrete is strong and durable in use.

Construction of the underlying layer and concrete base

To indicate the longitudinal line of installation of the curb, a cord is pulled. A rectangular cross-section trench with a bottom width of 0.4-0.5 m is torn along this cord. The depth of the trench depends on the design position of the top of the side stone (at the same level as the paving or higher), but must be at least 0.3 m.

A leveling layer of fractionated crushed stone or sand is placed along the bottom of the trench, which is leveled and compacted.

“Light” sidewalk or garden borders are installed on a sandy base.

(brand

BR.100.20.8, BR.50.20.8

), when they should be at the same level as the sidewalk surface.

In all other cases, side stones (road, highway) must be installed on a crushed stone base

.

For the construction of the underlying layer are used

:

- medium and fine sands of class II (according to GOST 8736)

- sands from crushing screenings of class I according to GOST 31324

- crushed stone fraction from 20 mm to 40 mm, crushability grade not lower than M600, thickness h = 0.10 m

It is not recommended to use a dry sand-cement mixture for the installation of the underlying layer.

.

Since the underlying layer is not load-bearing, the use of binder (cement) in its construction does not provide any advantages. In addition, the use of cement can be an additional source of efflorescence

- the appearance of white spots - on the surface of paving slabs.

The underlying layer material is distributed over the surface of the base manually or mechanically. When pouring the underlying layer, you should have a reserve thickness for vibration planting of stones

.

The amount of this reserve depends on the shape and size of the stones and the material of the underlying layer. It is installed locally. For a sandy base, the margin is ≈ 1.0-1.5 cm

.

A concrete base is installed on the prepared underlying layer (when pouring monolithic concrete, prefabricated formwork made from boards is used).

The construction of the concrete base is carried out manually, by laying and leveling fine-grained or heavy concrete

class B15 (M200) to the bottom of the side stone.

Benefits of using borders

All types of limiters have exceptional strength and durability. During operation, the material does not emit any toxins and is not afraid of frost and sudden temperature changes.

undertakes to lay the edges of roads of any type at affordable prices . The weight of massive road structures reaches 100 kg, so during installation the company uses special lightweight equipment that facilitates the work of workers and speeds up the process of installing each m2 of curb.

Caring for the road surface with the installed limiter is easy. The work of removing dirt and dust that collects at the base consists of treating the tiles with a stream of water from a hose or the nozzle of a sprinkler.

Modern concrete manufacturing technologies make it possible to produce products of different colors. Road barriers can be used taking into account the design of the street, giving visual integrity to the overall design of the space.

When repairing the road surface, the elements of the limiters do not need to be changed if they have retained the integrity and aesthetic appearance. If it is necessary to replace individual elements, the blocks can be easily removed and replaced with exactly the same ones, but new and intact.

What units are installed in Transkoye?

The installation process, which is simple but requires certain skills and abilities, is best left to professionals. will provide quick and competent installation of curbstones at an inexpensive price in Moscow and the region. The company’s specialists are equally well versed in the specifics of installing any types of delimiters, and the company’s prices are lower than those of other companies.

Curb frame for sidewalk

The sidewalk stone is narrower and shorter than the road stone, the length usually does not exceed half a meter, and the width of the upper part is 80 mm. When laying paving slabs, the curb, which is more correctly called a curb, is intended to hold various layers of soil. The soil of the lawn or flower bed does not mix with the paving substrate.

Road curb

Linear meters of stone blocks separate the road from the space for pedestrians, strengthen the road surface and give the entire structure a complete look. The installation of artificial or natural stone products accompanies the road construction process, but can sometimes be done separately. The side stone is wider and higher than the sidewalk stone, the price per linear meter is slightly higher. The prices in the company's price list look attractive. Buy finishing decoration for a road, yard or garden in rubles. can be done very inexpensively.

Garden borders

Fencing systems for gardens and parks are created from a variety of materials, from scrap materials to factory-made concrete garden borders, products made from natural stone, wood, metal or plastic. with equal success he will install massive curb stones on highways and take care of the beauty of the garden fencing of pedestrian paths or the worthy framing of an elegant flower bed.

Scope and effectiveness of the card

1.1. The map is intended for the rational organization of labor of workers involved in the installation of long concrete side stones on a concrete base from a ready-made concrete mixture when constructing a road surface.

1.2. Labor productivity indicators:

| No. | The name of indicators | Unit | Value of indicators | |

| according to EniR | on the map | |||

| 1. | Output per 1 person-day | m | 12,9 | 13,3 |

| 2. | Labor costs for installing 1 m of side stones | person-hour | 0,62 | 0,60 |

Note:

The labor costs on the card include time for preparatory and final work - 5% and rest - 10%.

A reduction in labor costs and an increase in output by 3% is achieved as a result of using the methods and techniques recommended in the map.

Features of the installation process

First of all, workers prepare the surface in the place where the curb will be installed. Pegs are driven into the ground to tighten the level. This ensures perfect laying evenness.

- A trench is dug to install the stones. The depth is made slightly greater than the height of the product. A sidewalk requires a trench 20 cm wide, and a road 30-40 cm wide.

- The trench is compacted using a tool specially made for this purpose. For the durability of the structure, it is necessary to achieve density of the bottom and walls.

- The bottom is compacted with crushed stone and a layer of sand.

- Carefully compact the resulting multi-layer “pie” for the concrete base.

- Using a rope level, they try on how the slabs will look. If the fitting was successful, proceed to styling.

- To secure the elements of the border, a cement mortar is used, which is applied to the bottom.

- The stones are driven into the prepared bed using a rubber hammer. The tool delicately adjusts the degree of immersion in the solution, planting density and height of the future fence.

- By applying the solution on both sides of the joint, the stones are fastened together.

- Having once again checked the evenness of the installation, completely seal the voids with cement mortar.

The technology for installing different types of slabs is almost identical. Order the installation of curbs in, use the services of a professional company that is well versed in the intricacies of road repair work. The prices for all the company's services are democratic. The services of professional road builders will cost you very little.

Preparation and conditions for performing processes

2.1. Before installing the side stones, the foreman and senior worker must carry out marking work. The unit's work does not include alignment work.

2.2. The crushed stone and gravel layer under the concrete base must be laid on a previously graded and compacted soil base.

2.3. Side stones should be laid on straight sections along a cord, and on rounded sections - according to a pattern, leaving gaps 3-5 mm wide between the stones. On curves, only patterned edge stone is used. Filling the spaces between the stones is allowed after checking the correct position of the bead.

2.4. Side stones made of concrete should not have a deviation from the design dimensions of more than 5 mm in the length and height of the stone; 2 mm in width.

2.5. To separate the roadway of intra-block driveways, main streets and highways, side stones made of grade 400 concrete are used.

2.6. Workers who have undergone safety training are allowed to work. All activities must be carried out in accordance with labor safety rules during the construction, repair and maintenance of highways.