Polystyrene concrete - what is it?

Polystyrene concrete is a composite concrete material that contains granulated polystyrene filler (PVG - granular foam polystyrene). Polystyrene (or expanded polystyrene) is nothing more than polystyrene foam. Polystyrene granules come in diameters of 2-8 mm. The size of the granules determines the properties of the finished polystyrene concrete .

Basically, only positive reviews can be heard about the material. PSB, as a material, is especially praised by self-taught craftsmen who use it in private construction. Polystyrene concrete is easy to work with, so construction can be done by just one person . This is another advantage of this material, because you can save on attracting labor and construction equipment.

The more polystyrene in the block, the “warmer”, lighter and more fragile it is.

Polystyrene concrete is produced in several grades, each of which is intended for its own area of construction:

| Brand of polystyrene concrete | Application area |

| D 200-300 | As insulation |

| D 350-450 | When building walls |

| D 450-600 | For load-bearing structures |

Technical characteristics of PSB

Polystyrene concrete has the following technical characteristics:

- density of polystyrene concrete - 150-600 kg per cubic meter (according to GOST R51253-99);

- PSB belongs to the G1 flammability group. This group includes low-flammable materials;

- has frost resistance of 25 cycles or more;

- material density up to 500-600 kg per cubic meter. meter (B 0.35-B 2.5).

Composition of polystyrene concrete

it yourself at home . In this case, you will only have to buy the filler - polystyrene, and getting the rest of the components will not be difficult. Polystyrene is sold in a bag of a certain volume. Usually it comes with a package of dry mixture, the volume required for the correct proportion.

Polystyrene concrete consists of the following components:

- granulated polystyrene (PVG);

- cement;

- sand. Special quartz sand is used in production. When making it yourself, you can use washed river sand;

- water. Just enough water is added so that the polystyrene concrete mixture is viscous and does not spread;

- plasticizers (if you make your own, you can use a regular detergent as a plasticizer).

In the industrial production of polystyrene concrete, Portland cement or Portland slag cement is used. But when making the material yourself, you can use any cement. Typically, cement grade D-400 is used as a basis.

To make blocks from any materials, use cement of the highest grades M400 and M500

When producing PSB with your own hands, you need to monitor the amount of water : there should be neither more nor less. In the first case, the mixture will spread; moreover, with a large addition of water, the strength properties of the material are lost. In the second case, the mixture will turn out to be too dry, which can subsequently lead to the formation of cracks in the finished material.

PSB blocks

You can hear a lot of good reviews from builders about polystyrene concrete blocks. They are made in industrial production from the resulting polystyrene concrete. Plastic blocks can also be made independently . In this case, it is necessary to build a form whose dimensions will be equal to one block. Then you need to mix the solution in a concrete mixer and pour it into molds to harden.

Proportions of polystyrene concrete:

- 1 part cement;

- 3 parts sifted sand;

- 6 parts expanded polystyrene (PVG);

- water optional;

- plasticizers and accelerators.

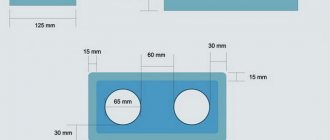

The blocks are large in size (588x138x300 mm - the dimensions of the wall block). Therefore, the speed of building construction increases many times over, compared, for example, with construction from ordinary brick . So, one polystyrene concrete block replaces 17 bricks. One plastic block weighs about 15 kg, so one person can work with the material.

PSB blocks can be laid on regular polyurethane foam . In addition, the blocks can be laid with special glue. The layer will be small, so you can further save on installation.

PSB for monolithic construction

Amateur builders leave many good reviews about polystyrene concrete due to its use in monolithic construction. Walls made of monolithic polystyrene concrete do not have masonry joints, which reduces thermal conductivity and increases sound insulation properties .

Polystyrene concrete floor screed also has many good reviews. This screed is well suited for the second floor. Because the material is light, there will be no additional load on the monolithic floor and it will not sag, unlike if the screed was filled, for example, with ordinary concrete.

Polystyrene concrete floor screed must be reinforced

With monolithic construction, there is no point load on the foundation. The weight of the structure is distributed evenly throughout the entire foundation . Due to this, the shrinkage of the building is minimal, which can prevent shrinkage cracks in the walls.

How to choose a house project made of polystyrene concrete

The procedures for choosing a layout option and the appearance of a mansion made of polystyrene concrete are not much different from such a process in the case of purchasing projects made of brick or timber. The provided documents should be assessed according to the characteristics of the site and available materials.

It is easier to make the right choice if a competent specialist helps you. It is often suggested to focus on the following criteria:

- Total area of the building. To what extent does it correspond to the size of the land plot and the wishes of the future owner?

- Number of floors. Sometimes the choice of a two- or three-story house turns out to be a forced measure (due to the modest areas of the land provided).

- Number of bedrooms, rooms for other purposes. The house should be comfortable for all family members.

If none of the ready-made options are completely satisfactory, it is more profitable to order a new turnkey project. Then all the nuances will be taken into account, the cottage is guaranteed to suit both the local landscape and the personal tastes of the customer with his real needs.

Projects of houses and cottages made of polystyrene concrete - prices from 100 rubles.

| Projects of houses and cottages made of polystyrene concrete | Prices |

| RUB 28,500 | |

| RUB 22,900 | |

| RUB 28,600 |

“Construction experience. We share our impressions of construction: from the project to the finished house. We tell you about our mistakes and stages of construction. Even if the house is not ready, everyone will be interested in seeing real construction, not in theory, but in practice.”

I deliberately did not create a topic about building my house until I finished construction. If I had done this earlier, then the questions and advice of forum members would have awakened in me all sorts of doubts about what is not good in the process of work. And now the job has already been done and it’s too late to change anything. I'll just share my experience. I will copy here some of the texts and photographs from the diary. If you have any questions, I will try to answer in more detail.

The most important question is what to build from? I didn’t struggle with this question for long. The option made of timber, after the fire, was no longer needed. A frame house using “Canadian” technology was also excluded for the same reasons. There is not a large choice of non-combustible materials. Brick, foam or aerated concrete blocks, or a monolith using the Lego-house technology. I started looking for information and came across polystyrene concrete. I liked the material according to its description. Last October I went to Moscow to the City Building exhibition. I hoped that I would find something interesting for myself in the low-rise construction section. The exhibition disappointed me. But it was at this exhibition that I met an interesting person named Igor Solomonovich Khaimov, who headed the laboratory of lightweight concrete at the Research Institute of Reinforced Concrete Concrete. His words: “Young man! All lightweight concrete is shit. But PSB is the best of all this shit!”, I was convinced. I started looking for manufacturers of PSB blocks here in Khabarovsk and couldn’t find them. But I found a construction company that has been producing PSB for several years and uses it to insulate attics and ceilings. The director of this company suggested to me the idea of a monolithic house with permanent formwork. I really liked this idea because it solved several problems at once. Namely: the problem of a vertical seam when laying blocks. The problem of preparing interior walls for finishing. The problem of preparing external walls for façade finishing. You can also hide all communications and electrical wiring inside the formwork.

So, February 2010. I am slowly starting to design a new house. I have a friend who works as an architect. In true Carefan style, he undertook to help me with the project. Here's to the beer! I explained to him what I wanted. He took measurements of the foundation that was left after the fire and gave me two options for the layout of the house. The first option is that he sees my house like this. The second option is mine. True, in my version, the bathroom on the 1st floor should have been under the stairs. But Igor said that this would not be a toilet, but a closet for debtors, and carried it out into the passage. To be honest, I like my version better. But my wife liked Igor’s version. I didn't argue. Now Igor is painting facades. I called today and asked what I would use to decorate the façade and in what colors. Apparently his muse visited him today! Today I was at the “Cottage Construction” exhibition, which opened in our athletics arena. I didn't see anything interesting there. Except for the German one, which decided to introduce heat pumps in our market. Their stand is very decent. But VERY expensive! Turnkey installation for our house from 700,000 rubles. However, I will do it myself cheaper. Moreover, China is nearby. It seems they have already finished celebrating the New Year. This means we need to terrorize them about TN. 1st floor plan proposed by Igor. The 1st floor plan that I proposed.

A new cement-based building material, which is gradually beginning to win more and more positive reviews, is polystyrene concrete. This new product has its advantages and disadvantages, which affect the performance of the building. If you decide to build a house from polystyrene concrete with your own hands, then in our article you will find a step-by-step guide to its construction. In addition, we will list the pros and cons of this relatively new building material so that you can make the right choice.

Pros and cons of polystyrene concrete

Reviews of the material are mostly positive. And all thanks to the fact that polystyrene concrete has more advantages than disadvantages compared to other building materials. Its price is also reasonable.

Advantages of polystyrene concrete:

- simple manufacturing technology. The material can be made at home with your own hands;

- light weight, due to which there is no additional load on the foundation or ceiling. You can save on attracting labor and construction equipment;

- thermal insulation. The house will always be warm. Moreover, you can save on heating;

- high speed of construction. If a building is built from plastic blocks, then the walls are erected quite quickly, because the blocks are large. Even one person can build a small one-story structure in a few days;

- the material does not burn. But when exposed to fire, polystyrene concrete can lose its strength;

- does not rot and is not susceptible to attack by insects and rodents;

- durability. If the necessary construction technology is followed, the building can last up to 100 years;

- the material lends itself well to processing. For example, a plastic block can be cut with a regular hacksaw;

- expanded polystyrene concrete is not at all afraid of moisture. On the contrary, he pushes her away;

- attractive appearance of the building, which will save on exterior decoration. Special decorative blocks are sold, with a decorative design applied to the front side. This block is available in different color categories and with different patterns.

All these advantages were noted by private builders.

But, like any other building material, polystyrene concrete also has its disadvantages:

- additional plastering of the walls from the inside is required;

- poor adhesion to plaster. In this case, you will have to build additional structures before plastering, which may affect the budget;

- the necessary openings for ventilation and sewerage need to be thought out before construction begins, because this will be problematic later.

You can see that the pros outweigh all the cons, of which there are not that many. That is why the material is in demand.

Features of the material

Initially, polystyrene concrete was conceived as a building material for the construction of house walls, which completely eliminates the need for additional thermal insulation of enclosing structures, as well as replaces flammable foam plastic with a more fire-resistant material. Polystyrene concrete contains the following components:

- Portland cement;

- foamed polystyrene granules;

- water;

- resins with plasticizing additives.

Among the main advantages of this material are the following:

- There are no temperature restrictions for its use. The material can easily withstand the lowest temperatures, as well as temperature fluctuations and extremely high temperatures.

- High moisture resistance. Expanded polystyrene concrete can be used in any ambient humidity.

- Increased frost resistance contributes to the durability of the material. The product can withstand up to 300 freezing and thawing cycles. At the same time, its strength and thermal insulation characteristics will not change.

- Due to the low specific gravity of the material, a lightweight foundation can be laid under a house made of polystyrene concrete, which reduces costs and increases the speed of construction.

- The material can be given any shape by pouring the solution into the formwork of the desired configuration.

- Polystyrene concrete blocks are easily and simply laid, which guarantees ease of construction of the house.

- If you wish, you can build a monolithic structure.

- The material can easily withstand high temperatures. It is flame resistant.

- The product is strong enough and dense, which allows you to hang furniture and various devices on the walls.

- High sound and heat insulation qualities.

- If you decide to build your house yourself, then this is one of the best materials, since you will not need special equipment during the construction process. You can also save on shipping.

- Economical. This material is much cheaper than other block products for building houses.

- When installing the product, it is very easy to adjust. For this you will need a regular hacksaw.

A house made of polystyrene concrete, reviews of which are mostly positive, also has some disadvantages associated with the disadvantages of this material:

- The product has low vapor permeability. Because of this, moisture can accumulate in the wall structure, which will cause a decrease in the thermal insulation characteristics of the enclosing structures.

- It has not been fully studied how polystyrene behaves after long-term use.

- Also, the toxicity of the material has not been fully studied, because styrene can easily be released into the environment.

- During a fire, the material, although not subject to fire, emits toxic gases. Moreover, after a severe fire, the walls of a polystyrene concrete house will have to be completely dismantled, since the strength of the material is significantly reduced.

Important: during the test, polystyrene concrete was exposed to a temperature of 1000°C for an hour, but this did not lead to destruction of the material.

Price category

Polystyrene concrete has an attractive price compared to other building materials made from cellular concrete.

PSB price per cubic meter:

| Brand PSB block | Price per 1 m3 |

| D-400 | 3790 rub. |

| D-500 | 4090 rub. |

| D-600 | 4390 rub. |

The price of polystyrene concrete blocks depends mainly on the size and quality of the granules and the brand of cement

Price per block of polystyrene concrete:

| Block size ( L x W x H ) | Price for 1 piece |

| 588x138x300 mm | 106 rub. |

| 588x92x300 mm | 51 rub. |

| 588x300x380 mm | 282 rub. |

| 588x188x300 mm | 139 rub. |

Polystyrene filler has the following price per cubic meter:

| Size (diameter) of granules | Price |

| 5-7 mm | 1300 rub. |

| 4-6 mm | 1800 rub. |

| 2-3 mm | 2800 rub. |

Types of polystyrene concrete blocks

Polystyrene concrete comes in different forms. Cheap, low-density material is excellent for thermal insulation, however, it cannot be used to build a house.

Comparison of porosity of polystyrene concrete blocks with others

This polystyrene concrete can serve as a construction aggregate, which is placed as a layer between load-bearing structural elements. Another type of polystyrene concrete has a high density. This is an excellent construction material.

All its disadvantages boil down to the fact that it has a higher price and insufficient strength to be used for the construction of load-bearing structures.

Scope of application for polystyrene concrete

The construction of a residential building with your own hands is progressing at a rapid pace, provided that polystyrene concrete blocks are used. They are used for the following purposes:

Answers to skeptics

There are still different opinions regarding the construction of polystyrene houses. Often people who are categorically against the construction of houses made of polystyrene have little understanding of this issue. They use disposable tableware and appliances, and insulate the walls and foundation of their home with extruded polystyrene. But all this contains styrene. It turns out that everyone criticizes, but uses it.

Contrary to the opinion of skeptics, manufacturers claim that polystyrene concrete is considered an environmentally friendly material. In its production, only food grade polystyrene is used, which is used in the manufacture of food packaging. Its toxicity indicator does not exceed the established norm. It is odorless and has no negative impact on human health.

Saying that styrene releases toxic substances during a fire, skeptics forget that a fire in a wooden house is no less dangerous. Most of the materials we use emit acrid smoke when burned, but we do not refuse them because of this. In addition, the building material polystyrene concrete is not flammable. All modern building materials are self-extinguishing, flammable materials are currently prohibited for use