How does polyurethane adhesive differ from conventional building mixtures?

The glue has a number of significant advantages:

- Economical to use. If you count one bottle of glue per dry mixture, then the bottle is equal to 1.5 standard bags of cement or one bag of ready-made mixture weighing 25 kg. On average, one bottle of glue is used for 1 cubic meter of block masonry. Also, it cannot be spilled and thereby increase the intended consumption.

- High adhesive properties.

- Makes it possible to work in the cold season down to 10 degrees below zero.

- Increases the soundproofing properties of masonry.

- Significantly increases the speed of construction work.

Special construction adhesive of high mechanical strength for reliable fixation of masonry aerated concrete, polystyrene concrete, foam blocks, brick, tongue-and-groove blocks, gypsum, expanded clay concrete and reinforced concrete products, including FBS.

The advantage of this glue is its high tensile strength, excellent heat and sound insulation, installation speed and economical consumption without losses or spillage.

Adhesive for polystyrene concrete blocks: why should you choose it?

Polystyrene concrete block is a representative of lightweight concrete, which has a special set of properties that distinguish the material from the rest. That is why its application has its own characteristics. In particular, this applies to block laying.

In this article we will understand what material should be chosen when carrying out work, and we will pay special attention to the adhesive composition. Let's consider what is remarkable about adhesive for polystyrene concrete blocks, how to choose it correctly, and why experts advise using it as opposed to cement mortar.

What is polyurethane construction adhesive?

Currently, an alternative to conventional construction adhesives has emerged - polyurethane construction adhesive "Termolit" for aerated concrete. Similar adhesive compositions have already found active use in Europe, where they are in full swing in the construction of houses from the building materials listed above.

Our compatriots are still distrustful of the new technology, although many of them appreciate the innovation. Others argue about the reliability of such seams, because they think that polyurethane glue and polyurethane foam are the same thing. In fact, they differ from each other in their composition and scope of application.

The advantages of Termolit polyurethane construction adhesive include high construction speed and cost-effectiveness. Depending on the thickness of the seam being applied and the quality of the surface used, one cylinder can replace one and a half bags of cement or a 25-kilogram bag of dry mix. The cylinder is enough to complete a cube of masonry.

Complete readiness of the masonry is achieved within two hours, while glue from dry mixtures achieves the required adhesion only after 1-1.5 days. A wall made of blocks connected with polyurethane glue has a third lower thermal conductivity than when using cement masonry. This is achieved due to the minimum thickness of the seams and the exclusion of cold bridges.

Termolit polyurethane adhesive is very convenient, because with its use it is possible to carry out significant amounts of work even in winter, when the temperature drops no lower than minus 10 degrees.

Termolit adhesive, designed for the construction industry, is characterized by high mechanical strength, which ensures reliable fixation of masonry of a wide variety of materials for the construction of walls and guarantees reliable fixation of masonry products made from a wide variety of building materials, for example, aerated concrete or brick, gypsum or expanded clay concrete, reinforced concrete.

Overview of glue manufacturers

The main composition of adhesive solutions for polystyrene concrete products includes: water, Portland cement, mineral compounds, which include small granules of foamed polystyrene. The unique formula of the adhesive allows the surface layer to be endowed with hydrophobic, thermal insulation and properties. Useful components impart rot-resistant properties and reliable load-bearing qualities to the finished walls. Special adhesive compositions are presented on the market in the form of dry mixtures, suitable for both external and internal use. Before use, you will need to dilute the powder with water and mix thoroughly.

Adhesives of various brands for polystyrene concrete have a narrow focus, but have distinctive characteristics from each other. Each manufacturer's main goal is to stand out among competitors. Therefore, they focus on different properties. For example, one mixture has increased plasticity, while another has the main property of durability. It is recommended not to buy the most expensive option, but to consider manufacturers who have positive reviews from consumers.

Popular brands of dry adhesive and masonry building materials suitable for polystyrene concrete blocks:

- "Polystyrene" G-32 is a universal cement-sand mixture for external and internal use. The material differs from independently prepared compositions, since during the production process special impurities are added that regulate the influence of water permeability, atmospheric and biological stability. The composition has a frost resistance rating of 200 cycles and 10 minutes of adjustment time. The recommended thickness of seams is minimum 2 mm, maximum 8 mm.

- Betonkol is an adhesive mixture with increased viability, intended for building materials consisting of lightweight concrete. You can work with the prepared solution for up to four hours, but the time for adjustment is 5 minutes. maximum. Frost resistance properties - 200 cycles, has high peel strength. It is recommended to apply a layer of 2-5 mm.

- Construction adhesive "Keraflex" - designed for laying polystyrene concrete blocks and cellular concrete. The mixture is universal, has a high level of frost resistance and strength. Viability is 3 hours, and time for correction is 5-7 minutes. The manufacturer does not recommend using the adhesive solution at temperatures below + 5 degrees C. The thickness of the seams is from 2 to 10 mm.

- "Bolars" is an adhesive for blocks made of light compounds, an excellent option for carrying out repair work in winter. The minimum temperature is -10 degrees C. In comparison with the above compositions, this mixture has an increased compressive strength of 7.5 MPa. Typically, adhesives have no more than 5 MPa. Frost resistance is 50 cycles, 10 minutes are allotted for adjustment. The recommended thickness of seams is from 2-8 millimeters.

- “Blok” is a waterproof, frost-resistant, weather-resistant adhesive, suitable for installation on almost all lightweight concrete products. This universal mixture is characterized by high tensile strength and compression strength - 20 MPa. Viability up to 3 hours, correction of blocks up to 7 minutes.

Some developers and private builders claim that blocks can be laid using tile adhesive mortar. This opinion is erroneous, since the composition of such a mixture is intended for a different texture of building material, which has different qualities. When laying polystyrene concrete blocks, it is necessary to use adhesive solutions specially designed for this purpose. Otherwise, there will be a decrease in the physical and mechanical performance of the finished building.

The use of polyurethane glue in construction

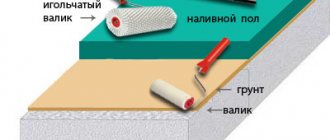

Polystyrene concrete, foam blocks, expanded clay concrete blocks: Glue is applied along the edges of the block with a diameter of 1.5 - 2 cm, as well as at the end, which provides excellent heat and sound insulation.

Tongue and tongue blocks: Glue should be applied along the ends of the block into the central part of the groove with a diameter of 1 - 1.5 cm.

It is necessary to take into account the variety of shapes and sizes of block and reinforced concrete products and approach the application of glue individually!

Storage: The cylinder should be stored and transported in an upright position. Store in a dry and cool place at temperatures between +5 °C and +30 °C.

Instructions for use: Place the cylinder with the valve up and screw it to the gun. Having secured the cylinder in the gun, shake it vigorously (at least 20 times) and place it upside down. The amount of glue released must be adjusted with the screw and hook of the gun (the approximate diameter of the glue released is 1-2 cm). Apply glue to the already fixed surface of the block or other fixed material along the edges (stepping back from the edge); depending on the size of the object, it is worth making additional lines of glue towards the center of the object. After applying the glue to the surface, it is necessary to press the object to be fixed to the fixing surface. You need to draw the zero mark as evenly as possible along the horizontal line of your structure. further simplicity and accuracy of work. Temperature range of use -10°C – +35°C. After drying, cut off excess glue with a knife.

We place the foam block on different solutions

There are only two options, it is either a simple cement mortar or glue. Let's consider today an option in which our main solution will still be glue .

Why glue

First of all, when laying foam blocks with your own hands, the dimensions of the material catch your eye. Unlike, for example, brick, foam block has large dimensions, and this imposes special features in the work.

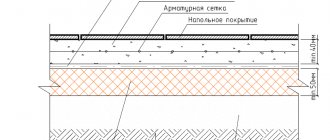

Let's start from the fact that when using cement mortar, we get a seam within 13 mm, and provided that the wall thickness is less than that of a brick, we get an excellent cold bridge.

Wide seam

In other words, the wider the jointing is, the more cold the wall lets through the seam, and this despite the fact that the foam block itself is an excellent heat-insulating material.

Now let's see what kind of seam we can get when using glue? And it comes out at 3 mm! That is, the jointing is almost 4.5 times thinner!

Glue layer

Important! Such jointing is also possible due to the fact that special additives are added to the foam block adhesive, which increase both the strength and ductility of the solution.

- What are foam blocks placed on?

Now about the pros:

- Much less glue consumption. With such jointing, consumption is reduced by at least 4 times compared to cement. Let us note right away that the glue consumption for foam blocks per 1 m3 in this case will be at the level of 16-20 kg. For simplicity, let's say that this is approximately a bag of glue.

- The glue binds the masonry quite firmly.

- The possibility of mold development in the joint area is completely eliminated.

- The reduction in total consumption suggests a significant reduction in price.

- Simplicity and ease of use, this allows us to speed up the construction of walls several times.

Important! During the operation of the house, we will be able to notice that the thickness of the seam had a direct impact on the thermal insulation performance and significantly reduced heating costs.

How to count

The easiest way, of course, is to proceed from what glue manufacturers display on their products. And there it is precisely indicated that we need from 16 to 20 kg of mixture per cubic meter.

The same applies to the area, here the glue consumption for foam blocks per 1 m2 will be on average 6 kilograms.

Important! When making calculations, it is necessary to make allowances for the professionalism of the work being carried out, as well as for how the masonry will be carried out: if it is a continuous layer, this is one expense, if it is a trowel with teeth, this is 30% less.

Correct application of the solution

Now let’s take the example of a house with an attic for calculation and use its example to calculate exactly how much glue we will spend. To make it easier to calculate, our example will be 10x10, this is what we start from.

Next step by step:

- We calculate the perimeter of the house. This is the addition of all sides of the wall, that is, 40 meters.

- We multiply the length by the height, it is 3 meters and we get 120 square meters.

- Based on an average consumption of 6 kilograms per square, we get 720 kg for the entire area.

Important! The calculation of consumption is very approximate; some adhesives, for example, cost 4.5 kg per meter. Therefore, now we are considering the calculation mechanism, and not the final numbers.

This is our figure for the first floor, excluding window openings and doors. Let's not count much, just subtract 20% of the area from the total, and we will have 576 kg. Just the approximate consumption of glue for a foam block in the masonry of the first floor 10x10.

Now the attic, there we have two gables, 4 meters high, we calculate their area, taking into account that these are triangles, and we get 20 square meters, there are two of them, so - 40. We also have an additional 240 kg of glue. We subtract the window openings, let it be 20%, and we get 192 kg.

Now let’s put it all in bags to make it easier to understand what we are talking about, 576 and 192 kg is 768 kg or 38, 4 bags of glue of 20 kg each.

Since we always purchase with a small margin of safety, it should take us 42 bags of glue for a masonry of 3 mm and a wall thickness of 20 cm!

Glue option for foam blocks

You can, of course, calculate from the point of view of cubic capacity, but the numbers will not differ much. We won’t count everything again, we’ll just say that you first need to know the volume, and then based on it it’s easy to find out how much glue will be used.

From our point of view, the instructions for calculating based on area are somewhat simpler, besides, here we have the opportunity to simply calculate the area of window and door openings, which play their own, and as we see, quite important role in the total amount of material.

Financial issue

If we can almost thoroughly calculate the glue consumption, then we can also come to a conclusion on the price.

On average, the cost of glue for foam blocks does not vary much by region, let's proceed from a certain average cost, and let it be 180 rubles for a bag weighing 20 kg.

Glue consumption and total estimate

This figure will be enough for us to quickly find out how much it will cost us to use glue.

Again, let’s return to our version with the attic, where we spent 42 bags of glue on laying the walls, and this comes out to 7,560 rubles.

And again, we remind you that such figures appear only based on our parameters, but in general, each of you can independently calculate all your costs, even up to tens of rubles.

To somehow summarize everything we've said, we can offer you a simple counting system:

- 1 cube = 18 kg of glue.

- 1 square meter = 6 kg of glue.

- 1 bag = 20 kg.

- 1 bag = 180 rubles on average.

Next is pure mathematics, more precisely, arithmetic.

Nuances in the composition

Moving a little away from the numbers, let’s return to the glue itself, it’s interesting why we can afford to use such a thin seam, and without loss of quality.

Thin layer application

It's all about the composition; here the components used for preparation are slightly different from those we find in simple solutions.

Let's label them:

- Finely crushed quartz sand, it is this that allows you to reduce the thickness of the seam.

- High quality Portland cement provides the required strength of the mortar binder.

- Additives, special components responsible for the quality of the solution in the areas of moisture resistance, frost resistance and moisture retention.

- Additives that allow you to increase the indicator of plasticity and frost resistance.

Important! The use of all of the above components means that the installation of foam blocks can be carried out even at an air temperature of minus 15!