When choosing a building material for a future home, there is no clear answer to the question: “which house is better made of timber or foam blocks”? Each material has its own advantages and disadvantages. Even at the design stage, climatic conditions, terrain features and soil composition must be taken into account. Depending on these and other indicators, an approximate list of building materials that can be used in the construction of a particular facility is formed. But there are building materials that have a universal property that makes them suitable for any low-rise buildings - these are wood and foam blocks. Comparative characteristics will help you understand which house is better, wooden or made of foam blocks.

What is cheaper than a house made of logs or foam blocks?

For a comparative analysis, let’s take the cost of one cubic meter of building material. 1 cubic meter of wood costs slightly more than the same volume of foam blocks. But if you take a finished structure, then the tree does not need external, and sometimes internal, finishing, which cannot be said about a block made of cellular concrete. The facade made of foam blocks looks gloomy and untidy, so additional finishing is simply necessary for such a structure. In this case, wood material wins. But the performance characteristics indicate that houses made of foam blocks are not susceptible to rotting, while houses made of wood require constant maintenance, which entails extra costs. This time the winning place goes to a structure made of foam blocks. To sum up, which house is cheaper, wooden or made of foam blocks, we can say that the score is equal - both building materials have an affordable price and excellent performance characteristics.

Combination of materials

The essence of technology

The photo shows an example of a combined house.

Combining building materials in the process of constructing residential buildings is by no means a new practice. Many builders make decisions such as covering a wooden house with foam blocks, covering stone walls with wooden clapboards, making an extension from foam blocks to a wooden house, etc.

One way or another, almost every modern house combines stone and steel, wood and plastic, glass and concrete. Therefore, the idea itself is not revolutionary, does not violate the canons of construction science and does not pose any risks for the developer. But it has a lot of benefits, the essence of which we will try to reveal and convey to the reader.

An extension made of foam blocks to a wooden house is an example of combining building materials.

The fact is that today there are a lot of new and well-forgotten old building materials that have excellent characteristics in some areas, but have not performed well in others. We are considering wood and foam blocks.

Wood is an excellent material for the construction of low-rise housing, but its reliability and load-bearing capacity raises some doubts. This is especially true for the ground floor and the walls of the first floor in a multi-story building. Also alarming is the fear of moisture and fire, combined with the proximity of the ground and the accessibility of walls in the event of a fire.

A wooden house is a classic of private construction.

Wood is not best suited for various household and technical premises, such as a kitchen, workshop, garage, sauna and the like. At the same time, wood is ideal for bedrooms, offices, living rooms and playrooms, creating a unique coziness and a special comfortable atmosphere.

At the same time, foam blocks are a fairly young and relatively cheap material that has excellent thermal insulation and performance properties, the ability for active gas exchange, and low weight. The structural characteristics of foam blocks, although inferior to classic brick or concrete, still fully satisfy the requirements of frequent low-rise construction.

A self-built combined house.

Important! In all respects, foam block can be called a stone analogue of wood, only more durable and solid, fireproof and reliable.

Thus, we get the opportunity to build the first floor, subject to much greater loads and more active wear, from foam blocks, and the second floor from wood. This principle was also used by Alpine shepherds (only instead of blocks they laid stones); later it became quite popular and was called “chalet”.

Alpine combined chalet style house.

Here are the arguments in favor of this decision:

- The use of foam blocks allows the use of lightweight types of foundations, as is the case with wood. This reduces the cost of the project and simplifies construction work;

- Foam blocks will perfectly cope with the loads from a wooden superstructure, while the overall shrinkage of the building will be much less than when using pure wood;

- Wooden structures will not come into contact with the ground, snowdrifts, or be moistened by moisture vapor rising from the ground, and will become less accessible to ground-based wood pests and insects. This will significantly extend their service life and reduce wear;

- By placing all technical rooms on the ground floor, such as a boiler room, workshop, garage, kitchen and sauna, you can use the area of the wooden second floor for children's rooms, bedrooms, living rooms and other apartments where comfort and a pleasant atmosphere are important;

- The price of the project will be lower than that of a completely wooden house, while you will be able to enjoy all its advantages while maintaining the reliability and solidity of the building.

The facade of the first floor can be finished with a blockhouse, and then it will be indistinguishable from the second.

Important! Don’t rack your brains over which house is better – wooden or foam blocks, build a combined structure.

Typical projects

Glued laminated timber and foam block in a private cottage project.

It must be taken into account that the combination of various materials during construction must be done correctly, taking into account their characteristics, compatibility and possible mutual influence. This imposes certain design requirements.

It is almost impossible to cope with a serious architectural project on your own, without special knowledge and experience, so you will be faced with a choice: invite a professional, whose services will not be cheap, or use a ready-made project.

Typical project for an extension to a wooden house made of foam blocks.

In fact, most private houses have very similar architecture, dimensions and, accordingly, technical features. Therefore, many home designers and developers create a base of standard designs, which can then be used with various minor changes or without them in many cases.

Many projects are accompanied not only by detailed instructions, but also photographs of finished structures.

Important! Today it is not difficult to find a ready-made standard project on our website or online, and it can be freely available or cost little money. This is a great way to save money.

Which house is warmer made of timber or foam block?

In terms of thermal conductivity characteristics, cellular concrete and wood have approximately equal values. But depending on the brand of blocks, the thermal conductivity characteristics may increase, thereby surpassing the wood material. The preservation and accumulation of heat by timber directly depends on its size. Houses made of medium-sized timber require additional thermal insulation. It is worth noting that the heat loss rate also depends on the region. For the Moscow region, the approximate thickness of a wall made of wood should be at least 60 cm, and of foam blocks - 56 cm. To ensure an ideal heat transfer coefficient in the central and northern regions of our country, it is enough to build a two-layer wall of foam blocks with mandatory facade finishing. A wooden beam, with a thickness of 20-28 mm, will need additional insulation.

Advantages and disadvantages

The specific weight of one block is small, therefore the total weight of the structure is less than that of a brick house.

When deciding whether to build a house made of timber or foam blocks, you should pay attention to the advantages of the latter:

- The specific weight of one block is small, therefore the total weight of the structure is less than that of a brick house.

- The foam block can be easily cut with a hacksaw. This makes it easier to work with it during the installation process and after the construction of the house, when you need to tap walls for communications.

- The porous structure of the material helps reduce its thermal conductivity, so a house made of foam blocks is very warm and reliably protected from noise from the street.

- Foam concrete is a non-flammable material that is not susceptible to damage by insects, mold and rodents.

- Due to the large size of one element, the speed of wall construction is much higher than when using bricks.

- Since the total weight of the foam concrete structure is small, a lightweight, shallow foundation can be erected under the structure. You will also save on the production of such a foundation compared to the traditional capital structure of a recessed foundation.

- Thanks to the cellular structure of the material, an optimal microclimate is maintained in the house. In winter, the house will retain heat well, and in summer it will not be hot.

Among the disadvantages of foam blocks, it is worth mentioning the following:

A house made of logs or timber - which is better to build?

- The tensile strength of foam concrete is low.

- Hygroscopicity of the material. That is why walls made of foam blocks need a protective cladding, which will simultaneously perform decorative functions.

- Since the material is quite fragile, it can be damaged both during transportation, storage, and during installation.

Why is it worth taking part in a construction tender?

Finding a construction company that meets the customer’s requirements in terms of price, speed of construction and quality of work can take a lot of time. After all, among the numerous advertisements, finding a suitable organization is not easy. The Association "APVSiPS" invites everyone to take part in the tender, where 338 reputable construction companies will compete for the right to build the proposed facility. Having chosen the right company, the developer receives a gift certificate in the amount of 100 thousand rubles. And that is not all. The association strictly monitors compliance with building standards, and in case of violation, guarantees compensation payment commensurate with the damage caused.

Fill out the application below

Comparison of building materials.

We should start with a short description of these materials:

- foam blocks. They are made from cellular concrete, which has a porous structure, thanks to which this material has fairly good thermal insulation characteristics, in addition, it shrinks slightly, and also does not burn, but at the same time absorbs moisture, so frost resistance directly depends on the quality of its finishing. Due to the fact that the technology for manufacturing foam concrete blocks is quite simple, products not only from leading companies are on sale, but also homemade building materials are often of poor quality;

- timber Made from wood, so it can burn. Types of timber are divided into: profiled, solid, glued material. Its price and characteristics are mostly determined by the moisture content of the timber. Timber is made in different sizes: the greater the thickness and width, the more expensive it is; naturally, how much timber in a cube depends on the size of this building material.

Timber in house construction and its comparison with foam block

Houses made of timber and foam blocks do not lose their attractiveness. When choosing timber, the developer must take into account that several types of material are used for construction:

- ordinary and cheapest non-profiled;

- profiled, which is more expensive;

- glued, the most expensive.

When comparing the cost of different materials, we are talking about non-profiled timber, since its price is closer to the foam block. By the way, during the construction of private houses, non-profiled products are the most in demand and popular.

A log house uses absolutely pure ecological wood material, usually coniferous. The presence of resin in wood prevents it from rotting and gives strength. However, the main obstacle to choice is the high cost of lumber.

It will be correct to compare timber and foam block if you use performance characteristics and cost. For example, timber parameters such as bending and compression strength make it possible to build a house of 2–3 floors using modern technologies.

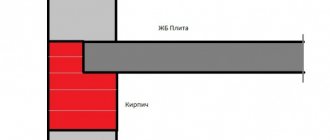

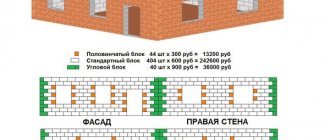

A house above one floor is built from foam blocks with an average density of D500, strength classes B2 or B2.5, and only factory-produced. In this case, reinforcement is used between the rows and a monolithically reinforced crown with insulation between floors.

Construction practice has answered the question of what is cheaper: foam block or timber. When building a house designed for permanent residence, it is preferable to use foam concrete.

Since houses made of timber are more expensive due to the high cost of high-quality material, they are built mainly on summer cottages from available lumber.