The definition of a plinth from experts is a room buried 200-220 cm into the ground under the main building. As a rule, the height is sufficient for arranging a warehouse, workshop or other premises. If it is necessary to create a living space, the height increases to half a meter. But in order to make a foundation for the basement floor, which according to standards should be buried in the ground no more than half its height, you will have to carry out a lot of preliminary calculations and test the soil for durability.

Choosing a foundation design

When pre-selecting the foundation of a house, it is important to determine the location and height of the underground ground aquifer. If the level is low, then you can go several meters deep and use strip or monolithic foundation technologies.

Important! Arrangement of the basement floor requires thinking through the ventilation system.

When the groundwater level is high, monolithic foundation technology is considered more suitable. Such a base will resist moisture and prevent flooding of the basement of the house, but will require careful waterproofing. The advantage of a monolithic foundation is its ability to accept heavy weight loads. However, when choosing a slab foundation for a house with a recessed level, made of reinforced concrete slabs, you should understand the need to fill the pit with cement mortar or lay factory-made slabs.

By giving preference to a strip foundation, you can arrange a drainage system that will help minimize the threat of flooding when the groundwater level rises seasonally. The system will effectively remove moisture from the base and basement floor, reducing the factor of erosion and destruction.

Monolithic foundation

The foundation cannot be called inexpensive, but this particular technology is optimal in terms of its ability to withstand the maximum weight of the building; even a multi-story mansion can be built on such a monolith. The process begins with digging a pit of the required depth plus 50 cm for laying a gravel cushion under the base. The pillow is compacted, filled with concrete mixture up to 10 cm thick, and then the entire structure is waterproofed. Then again a layer of concrete and reinforcing mesh to maintain the strength of the foundation of the house. Now the final pouring of concrete (layer up to 30 cm) and final finishing.

This type of foundation is called floating and helps maintain the integrity of the structure during soil movements.

Strip foundation

The technology is widespread and in demand. Any owner can make a strip foundation with his own hands if the building is located in an area where the groundwater level is quite low. This type of foundation is economical, reliable and durable. It is important to understand that the basement will be located directly under the main rooms, there will be only one walls, and this will divide the entire area of the basement into compartments, each of which can be used at its discretion.

There are two types of tape type base:

- Block foundation for a house, built from individual reinforced concrete elements. Advantages: ease and efficiency of installation. Minus - it is built only on dense soils with low water levels.

- Monolithic - has a similar device, but involves digging a ditch as for a slab base and pouring the mixture, for which you need to make formwork, strengthen it with reinforcing mesh and when pouring concrete, make sure that air escapes from all layers.

Advice! If you are planning to make a foundation for a building with a basement floor, it is best to use monolithic strip foundation technology.

Pile foundation for a house with a plinth

Not a very common, but quite convenient base option. The foundation is reliable, while being independent of soil movements and the level of the aquifer. Installation of pile structures is carried out in any season, while correctly selected piles, for example, screw piles, minimize the risk of moisture entering the main room.

An additional plus is that the arrangement of the basement floor of any format is allowed. The downside is the cost of materials. To make the basement of a house, you will have to individually select pile elements depending on the type of soil, freezing point and other factors. In addition, it is mandatory to treat piles against corrosion and other aggressive environmental influences.

The basement floor is a room buried 2-2.2 m into the ground under the structure. Typically, this height is quite sufficient for constructing a warehouse, vegetable storehouse, workshop or other technical premises. If it is planned to install it in the basement of a living room, then the height is increased by 40-50 cm.

If the construction of a structure is carried out on unfavorable soils, then the thickness of the walls of the basement in a residential building cannot be less than 20 cm.

The underground room serves as an insulating layer for the above floors. It does not allow dampness from the soil and cold air to penetrate. To do this, when constructing an underground room, it is important to arrange an effective ventilation system.

Types of foundations for the basement

- Recessed plinth. This is the most common type of foundation, as it best helps protect the base and walls of the building from moisture penetration, significantly increasing the service life of the entire structure.

- Protruding base. This type of foundation is most suitable for buildings with thin walls. When constructing a basement floor as a living space, a protruding plinth will be quite justified. If you plan to use the basement as a technical room, then its walls can be made thinner;

- The basement level with the foundation is not the best option. First of all, this is the lack of effective protection from moisture and precipitation. In addition, such a base requires additional waterproofing, and therefore costs, and from the outside it does not look very aesthetically pleasing.

Many developers strive to increase the ceiling height of the basement floor, making it a full-fledged room. To do this, you need to dig a pit of the required depth. The thickness of the basement walls can be equal to the thickness of the building walls. When construction is carried out on “weak” soils, the thickness of the walls should be 20 cm greater than that of the walls of the house.

Solid concrete blocks may be quite suitable for wooden cottages.

During seasonal floods, close groundwater, including high levels of ground freezing, it is important to know how to protect the foundation.

Negative environmental impacts

The base is constantly exposed to moisture from moisture, which is not only a consequence of precipitation and melt water, but also rises from the soil through microcracks and capillaries of the material. Liquid accumulates in the structure of the brick, which in winter leads to freezing and expansion of water particles.

A certain number of cycles of such freezing will inevitably lead to destruction of the structure of the building material, which can cause a violation of the strength and reliability of the entire house. It is for this reason that it is necessary to choose the right brick, which will not only match the aesthetic qualities of the structure, but also protect it from inevitable destruction.

The choice of the required product must meet all standards, among which aesthetics play an important role. For example, the smooth surface of the walls of a house will be combined with a base made of rubble stone or torn brick, while brick walls are suitable for a base made of a simple type of brick.

The use of silicate-type stones is only relevant if there is high-quality waterproofing, because this type of product is quickly saturated with water. As a rule, this type of brick is not used for these works.

There are several common problems that have a negative impact on the building material of the plinth:

- in comparison with the walls of a residential structure, the base is located in an unfavorable environment;

- rainwater regularly accumulates on the surface of this building element, which leads to wetting and moisture absorption;

- in the winter season, snow accumulates around the perimeter of the base, which in the spring leads to severe wetting of the building element;

- the ground floor is subjected to great pressure from the entire house, which requires enormous structural strength;

- heaving of the soil layer puts pressure on the foundation from below, which negatively affects the condition of the base;

- freezing of moisture in the brick leads to the gradual destruction of the entire base.

Construction of a slab foundation

The most advantageous type of foundation that can support a building of any weight. This type of foundation is called floating - in the process of seasonal soil movements, the concrete foundation lowers or rises along with the structure.

When constructing such a foundation, the pit is made half a meter below the planned depth, and the selected soil is replaced with sand, which must be thoroughly watered and compacted. After this, crushed stone is poured. The thickness of the layer of sand and crushed stone should be at least 15-20 cm.

The “cushion” arranged in this way is filled with concrete 4-5 cm thick. Then waterproofing is laid. As a rule, roofing felt or waterproofing film is used, after which everything is again filled with concrete to the same thickness.

Then the reinforcement is laid, a thermal insulation layer is laid, and concrete is poured again. This time the layer thickness should be at least 20 cm.

What is plinth brick and how is it used?

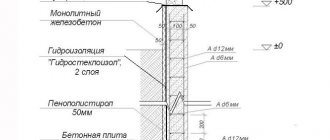

The plinth is the part at the bottom of the structure, its foundation. It is made from basement bricks. The basement part of the building rests on a base consisting of foundation blocks (image No. 1).

Image No. 1. Scheme of the basement of the building.

Its height should not be lower than the height of the snow in this area. This part of the building, along with the base, experiences loads from the walls and from a variety of atmospheric phenomena. It is influenced by melt and groundwater and frozen soil. Thanks to this, the base material should hold it all perfectly and look decent.

Construction of a monolithic strip foundation

After the pit is ready, markings are made at the bottom of the dug hole according to the diagram of the load-bearing walls of the building. Next, according to the markings, trenches with a depth of at least 30 cm are dug. Then a drainage system is installed - the trenches are strengthened with formwork and covered with crushed stone on top.

Then reinforcement is made and the concrete mixture is poured. The width of the pillow should be greater than that of the basement walls and, as a rule, it is 30-40 cm high and 50-60 cm wide.

This type of foundation is made from piece products - factory-produced reinforced concrete blocks. Its advantages are speed and ease of assembly.

However, it is recommended to use this type of foundation for the foundation only on dense soils, where groundwater lies quite deep.

Laying block walls

Before starting work on the laying of external walls, it is necessary to level the surface of the foundation, lay cut-off waterproofing, and install beacons at the site of future door and window openings. For waterproofing, you can use roll and coating materials. When using roll waterproofing, the width of the layer should slightly exceed the width of the foundation. Laying blocks is only allowed over a waterproofing layer.

Beacons made from the smoothest blocks are placed at the corners of the building (without mortar), after which a series of measurements are taken to confirm the evenness of the corners of the building. The first row of block masonry is made in the direction of the walls from the exposed beacon stone.

It is very important to ensure that the block is not laid flush with the walls; it is better that the wall hangs outward relative to the base or foundation.

Watch the video on how to install the blocks correctly.

When laying blocks, it is allowed to reinforce the walls, for which a layer of reinforcing mesh is laid, which must be completely recessed into the mortar.

For laying blocks when constructing external walls, it is allowed to use only cement-sand mortar.

A separate stone must be laid on the mortar no later than 10 minutes in advance; for better adhesion, the blocks must be pre-moistened with water.

Waterproofing

Even if the soil is not oversaturated with water, it is impossible to do without waterproofing. Its absence can ruin the entire building, even if the basement floor is planned to be used exclusively as a technical room.

There are two ways:

- coating waterproofing is produced using bitumen mixtures, which are applied to the surface in a heated state;

- adhesive waterproofing is made from materials intended for roof waterproofing using the appropriate application technology.

Waterproofing must be done in two layers. It is mandatory to cover with waterproofing all vertical and horizontal sections of the foundation and walls that come into contact with the earth's surface.

Before erecting the walls of the basement, you will need to insulate them from the cushion to prevent moisture from entering, and subsequently connect the vertical insulation of the walls as tightly as possible with the insulation of the floor and cushion.

After erecting the walls of the ground floor, a sufficiently wide blind area should be built from the outer part of the building, using a concrete mixture for this.

Modern craftsmen are quite capable of laying a foundation for the basement floor with their own hands. Of course, in such a rather labor-intensive task, assistants and construction equipment will be required. But for a person with minimal experience in construction, this is possible.

A monolithic foundation is the supporting part of a structure, which is responsible for the length of the building’s operational life. It is the supporting structure of the entire structure. It is labor-intensive to build a basement on such a foundation.

Therefore, to select a foundation and the method of its construction, it is necessary to pay attention to the characteristics of the soil of your site and its bearing capacity, take into account the operational and design features of the future house, as well as what material the structure will be built from.

Base made of brick or concrete: which is better?

We often hear the question of which plinth is better - concrete or brick. There is no definite answer, and it all depends on the design features of both the house and the floors in it, as well as the basement itself. But we are more inclined to the second option, despite its higher cost. There is a rational explanation for this.

Photo 1. An example of a laid-out aerated block wall on a brick plinth

Building a house is a complex task for which there can be no universal solutions, so the final decision is up to you.

Criteria for choosing a monolithic foundation with a basement

The most popular structures for the foundation of a structure are monolithic foundations. The popularity of monolithic building supports is explained by the high degree of reliability, as well as the ability to withstand heavy loads. The use of modern monolithic casting technology in the construction of the foundation makes it possible to implement all kinds of architectural solutions and obtain various building configurations known today for arranging the basement, however, this is labor-intensive to do with your own hands.

The main advantage of founding a house with a basement is, of course, the additional space in the house. A basement can increase the usable area of a home by up to 30%, making it more functional. In private houses, it is often used for technical needs or a garage; in multi-apartment high-rise buildings, parking lots are installed. A new trend of the times has been the use of a large basement floor for shops or public places where the noise level is high.

Requirements for basement floors during construction

The basement floor is a room with a floor level below the zero level, but not more than 50% of the height of the room. In project buildings, the ground floor is placed for the purpose of the most economical use of building and earthen volumes. The ground floor can be built under part of the building, such premises are explained by the terrain. Underground premises can occupy the entire area of the structure. The design of the underground floor is similar to that of the building.

According to SNiP 3.03.01-87 “Load-bearing and enclosing structures” and 2.02.01-8 “Foundations of buildings and structures”, the following requirements are imposed on the ground floor:

- The basement floor is the premises of the building, which must be below the zero level and above the ground level of no more than 50% of the height of the basement floor. The height of the room must be at least 1.80 m.

- The width of the flights of stairs in the basement must be at least 0.9 m.

- The basement room must be provided with a separate exit to the outside.

- To ensure ventilation flows, it is necessary to equip vents, which should be located at a height of 20-25 cm from the zero mark.

- Construction of pits (window openings in basements or ground floors), regulated by sanitary standards and rules SNiP 2.2.1/2.1.1.1278-03 “Hygienic requirements for natural, artificial and combined lighting of residential and public buildings.”

Types of monolithic foundations according to construction method

In regions with frozen or floating soils, it is often problematic to build a house with a basement with your own hands. Such soil factors determine the method of laying the foundation of a future structure.

Foundations using monolithic casting technology can be presented in several ways:

- slab;

- tape;

- prefabricated

Plinth for slab monolithic foundation

A slab monolithic foundation is also called a floating foundation. The uniqueness and genius of the engineering solution lies in the fact that the monolithic slab is indifferent to soil movement. The need to construct a monolithic slab with a basement arises when there is a large volume of groundwater.

A monolithic slab foundation with a plinth is constructed for small buildings. For larger projects, the slab is additionally reinforced. The method of arranging a monolithic base on a slab boils down to installing formwork for the walls on a base filled with lightweight concrete for leveling, and a waterproofing layer. Concrete is poured onto the leveled pad, after installing the reinforcement cage. Then the walls are erected.

Advantages of a monolithic slab:

- Aligns horizontal and vertical movements.

- Penetration of water into the basement floor is excluded.

The method of constructing a monolithic slab with a plinth is expensive.

Plinth for strip foundation

Strip monoliths are divided into recessed and shallow types. Recessed foundations are constructed below the freezing point of the soil. If the foundation strip is laid above this point, then the monolith structure is considered shallow.

Considered durable. Its effectiveness is determined by the fact that it is located deeper than the outer wall, thereby being more protected from precipitation. An undeniable advantage is its cost-effectiveness during construction, since less materials are required.

Flush with the wall

The plinth, which is in the same plane as the outer wall, has a disadvantage and is more susceptible to moisture.

Significantly affects the humidity and temperature conditions of the premises inside it. The higher the ground floor, the drier and warmer the air in the room.

From an aesthetic point of view, a low base gives the building an unrespectable appearance.

Which brick to use for the plinth – Working with Brick

The foundation base of a country house is the basis and support for load-bearing walls. Its main purpose is to protect the inside of the building from water leakage and cold air penetration. Carefully selected bricks for the foundation plinth eliminate problems in subsequent operation.

Basement brick should not only be beautiful: strength and moisture resistance are equally important characteristics

Choosing the right brick for the plinth

First of all, when figuring out which brick is best for a plinth, it is worth remembering that it must combine high levels of strength, durability and decorativeness.

These three main parameters are not the only ones. In addition, it is necessary to pay attention to the frost resistance of the brick, its minimum water absorption capacity and resistance to deformation. And, of course, it is advisable to fit all this into a small budget.

Don’t forget that the chosen brick must match the design of the house and look beautiful.

Arrangement of the basement

When arranging the basement, it is very important to choose high-quality material, this reduces the risk of shortening the life of the building. If the physical properties and technical characteristics of the brick are appropriate, more than one generation will live in the built house.

The layout of the plinth is shown in the following figure:

Classic plinth on a strip foundation

For its reliable subsequent operation, the following recommendations must be observed during installation:

- The thickness of the plinth is determined based on the wall materials. For brickwork, you need a base with a base of at least 51 cm. If the walls of the house are made of timber, then a width of 25 cm is quite sufficient.

- When laying a brick plinth, properly selected cement mortar is very important. A mixture with the following composition optimally meets all requirements: cement M200, sand and lime. The proportions should be 1:6.7:6.7. The mixture is brought to a dough-like consistency.

- The existing system for calculating materials allows you to prepare the required quantity for arranging a brick plinth. For 1 m? the ground floor needs 400 bricks (size 250? 120? 65 mm) and 30 cm? cement-sand mixture

Properties that a brick for a plinth should have

Considering all of the above, it is clear that the brick for building a basement must have the following properties:

- increased compressive strength (from 200 MPa);

- standard dimensions - 250x120x65 mm;

- high environmental friendliness;

- moisture resistance;

- relief surface.

The strength of the brick ensures the reliability and durability of the base and the entire structure as a whole. Standard sizes will ensure a smooth and attractive appearance of the base and the entire building in particular.

The beauty of the base speaks about the thoroughness and thoroughness of the work done

In addition, the construction of the basement will be less labor-intensive. The absence of harmful impurities in the brick will prevent harm to the residents of the house. The embossed surface of the brick adheres remarkably well to the mortar and prevents the formation of cracks and cracks and, accordingly, cold bridges.

Types of brick plinth

A brick base can be equipped in three different ways:

- sinking;

- protruding;

- same level as the walls.

When arranging a sinking base, its walls are slightly thinner than the main walls of the building. A base of this type is made if there is a need to protect the structure from sedimentary water coming from above. Most often used in regions with high rainfall.

This is what a sinking base looks like - rainwater flowing down the walls goes straight to the blind area

The protruding base is built with greater wall thickness compared to the walls of the building. In most cases, such a base is equipped with additional protection from precipitation, for example, metal canopies covering the protrusion.

The protruding plinth is additionally protected by a low tide, which can simultaneously perform decorative functions

Which brick is suitable for the plinth

If you follow the standards prescribed in clause 6.65 of SNiP, then ordinary solid red brick is universal for many regions; it is also called well-fired plastic-pressed ceramic brick. It is manufactured in accordance with GOST 7484-78 and TU and GOST 530-2007.

Solid brick with high density has a mass of 3-4 kg. Its volumetric weight is 1500 – 1900 kg/m3. It is used when it is necessary to organize high levels of structural strength, sound insulation, thermal conductivity and heat capacity.

Standard solid red brick

Despite the obvious positive characteristics of such bricks, there are better options, although they cost much more. We are talking about clinker, fireclay and subtypes of clay bricks.

Clinker immediately stands out with its obvious advantages:

- water absorption (no more than 5%);

- strength (from M250);

- frost resistance (from F100);

- increased wear resistance.

Types of clinker bricks

In some cases, a combined option is practiced, in which the masonry of the base is made of red brick, and its facing is carried out with clinker.

Clinker brick is ideal in terms of wear resistance. Its front surface retains its original appearance for many years. Its characteristics are much superior to red brick, which, accordingly, directly affects the cost of clinker bricks. The high price is its disadvantage.

Fireclay brick is also commonly called fireproof brick. Accordingly, it has the following characteristics:

- water absorption does not exceed 3%;

- starting strength – M25;

- increased acid resistance protects against aggressive environmental influences.

Well, fire resistance, which allows the product to withstand high temperature changes. Summing up, we can safely say that red solid brick of the M150-200 brand with frost resistance F35-50 is the best option for a base that can reliably serve for hundreds of years.

Fireclay brick

Clinker and fireclay bricks also meet all the requirements of a brick for a plinth, but are much more expensive.

Ordinary clay brick grade 150-250 is durable, frost-resistant and low in price. Its significant drawback is its completely unpresentable appearance. The base made from it definitely needs finishing.

The appearance of ordinary clay brick can hardly be called presentable, but the brick base can be additionally decorated with tiles

Which brick should not be used for the plinth?

Due to its high hygroscopicity, sand-lime brick is absolutely not suitable for arranging a basement. The base built from it will gradually collapse, since silicate perfectly absorbs moisture from the soil and is destroyed by temperature changes.

In just a couple of years, the basement will need a major overhaul. A collapsing base will, in turn, lead to the destruction of the foundation and, accordingly, the building as a whole.

Sand-lime brick: beautiful, but not suitable for a plinth

Laying the plinth in stages

The process of arranging a basement is quite complex and responsible, requiring the participation of professionals. The brick base plan is as follows:

- from the 1st to the 4th row - masonry;

- 5th row – transverse wall;

- 6th row – brick layout;

- Row 7 – filling the space with insulation.

Before starting laying, it is necessary to correctly set the corners for the subsequent laying of the base. At the preliminary stage, the solution is not used. This row is set purely according to level, since subsequent rows can no longer be moved. After the first row is set, measure all sides, two diagonals and make sure the structure is even. The evenness of the masonry must be perfect.

The largest permissible discrepancy should not exceed 2 cm. In this case, the discrepancy can still be corrected during further laying.

After completing the measurements, they begin to equip the ground floor. It is laid out with bricks with cement-sand mortar having the following proportions 3:1:1 (purified sand, cement, water).

Laying out the plinth

Minimum plinth width 380 mm. If the plinth wall involves only brick laying without insulation, the thickness is at least 500 mm. If the insulation is supposed to be polystyrene foam, the thickness of the base is 380 mm.

When arranging the base, the foundation should be 30-40 cm. This width provides a beautiful base, of sufficient height, allowing you to equip a large room that can be equipped as a boiler room or utility room.

You can see the choice of brick for building a basement in the following video:

Conclusion

To summarize, we can say that before arranging the base, careful measurements must be taken, since the choice of materials largely depends on the expected maximum loads.

The best option is brick. It is warmer than concrete, which greatly improves the comfort of your stay and reduces the cost of subsequently maintaining an optimal microclimate. Making a base out of concrete is unprofitable from an economic point of view.

Source:

What brick to use for the plinth. Evaluation criterion, types of clinker material, requirements. Diagram, types of masonry relative to the wall, insulation

It would seem, well, what else can you come up with with this ancient building material, when suspended ceilings and self-leveling floors are in use. However, improvements affected him too. In the age of rapid individual construction, brick has proven to be indispensable as a very convenient material that is always in demand.

Regardless of how you answer the question of which plinth brick is better, the principles of its installation will remain the same; the photo shows the most common masonry

Perhaps concrete looks like a more preferable material for such an important part of the building as the basement, but in many cases the use of a special type of brick and only a trowel, with your own hands, can successfully replace concrete, welding, a metal frame and a concrete mixer.

Types of clinker (see description in text)

Yes, using brick seems much more convenient in terms of the cost of completing the work. But first you need to understand the evaluation criteria.

Evaluation criterion

The main criteria for assessing the quality of bricks are two, taking into account the conditions of its operation:

- strength, primarily compressive strength, and,

- frost resistance.

Here is a classification according to these indicators:

- strength - from M75 to M300 (usually designated this way, but often the letter is omitted);

- frost resistance - from F15 to F50 (also through a letter, which is sometimes also not used);

- average density (kg per cubic meter) – 1600 – 1900;

- porosity (%) – 8;

- thermal conductivity coefficient (W per meter) – 0.6 – 0.7.

- hollow (characteristics accordingly):

- M75 – M300 / F15 – F50 / 1000 – 1450 / 6 – 8 / 0.3 – 0.5.

- M75 – M250 / F25 – F75 / 1300 – 1450 / 6 – 14 / 0.3 – 0.5.

- M400 – M1000 / F50 – F100 / 1900 – 2100 / 5 / 1.16.

- M75 – M250 / F15 – F50 / 1970 – 1900 / 8 / 0.6.

In addition, we advise you to take a closer look at glazed facing with an average density of 1300 - 1450.

Based on the data presented, we conclude that the most suitable brick when answering the question of which brick is suitable for a plinth will be clinker with a strength of at least M400 and a frost resistance characteristic of at least F50.

Types of clinker bricks

Thus, the further choice is to find a solution to the problem - what kind of brick to make the plinth from, taking into account such a variety of clinker options.

There are 5 main types:

- A – facing;

- B – construction;

- C – single;

- D – one and a half;

- E – double.

The choice largely depends on the expected degree of load and the thickness of the walls, but all things being equal, we answer the question of what kind of brick is needed for the plinth, we answer – clinker one-and-a-half grade M500 and frost resistance – F75.

Requirements

But no matter how you answer in practice the question of which brick goes on the plinth, the requirements for it will be quite serious:

- it must have increased strength;

- there should be no signs of deformation or chips on it;

- it must be made in accordance with all GOST sizes;

- it must be very frost-resistant,

- must have high environmental performance;

- it should not allow moisture to pass through, and,

- be resistant to its effects;

- Given the use of cement mortar as a binding material, it must have good adhesion to the mortar.

Source: https://center-esm.ru/kladka/kakoj-kirpich-ispolzovat-dlya-tsokolya.html

Main stages of construction

For the construction of foundations, concrete is used, which includes crushed stone, sand, water and cement. To give strength to concrete pours, reinforcement is used. The video explains in detail the process of building the foundation.

In order for the foundation of a house to last a long time and be able to withstand all loads, it is necessary to use high-quality materials. The choice of building components for the future foundation of a house must be approached professionally and the following factors must be taken into account when choosing building mixtures:

- Density of the concrete mixture.

- Waterproof.

- For regions with cold climates - frost resistance.

- Mobility of concrete.

The concrete monolith experiences the loads of the structure and soil. Atmospheric precipitation has an aggressive effect on it. The higher the grade of the concrete mixture, the higher its density, therefore, the body of the foundation and basement floor will be stronger and drier, and it will be more difficult for moisture to penetrate into the mass of concrete.

For large brick houses, concrete M350 and higher is used. For light buildings (country houses or panel houses), lighter concrete can be used. When pouring piles with your own hands, use heavy concrete.

To add strength to concrete foundations and the basement floor, metal reinforcement is used with a spread in cross-section from 6 to 40 mm. The choice of rod diameter depends on the project. For private houses, frame reinforcement uses metal frame rods with a cross section of 10-20 mm. The frame for the monolith is a mesh with a pitch of 100-200 mm. The frame mesh is secured with your own hands using knitting wire or plastic clamps.

Modern construction technologies offer know-how - polymer mesh or fiber for structures made of poured concrete. Their purpose is to prevent the slab from deforming or cracking. They significantly affect the quality and strength. In this case, the volume of concrete for pouring the structure will be economical.

Basic physical characteristics of some types of bricks

In order to understand the fundamental difference between one material and another and choose the one needed for arranging the base for walls, you need to know the basic physical properties of some types of bricks. So, as an example, we can consider silicate, red clay and ceramic bricks. Each type of this material is widely used in modern construction.

Sand-lime bricks

The technology for manufacturing sand-lime bricks is developed in such a way that the finished material is not intended for use in conditions of high humidity. Under prolonged exposure to moisture, bricks absorb it, swell, lose strength and gradually collapse. Making a plinth from a material such as sand-lime bricks is only possible in a dry climate and under the reliable protection of high-quality waterproofing. If you decide to choose building materials of this brand, pay special attention to their strength.

Clay red bricks

Unlike silicate bricks, clay bricks are not pressed, but baked. This means that technologically red brick is more suitable for making the foundation and plinth of a building. But even this material perfectly absorbs moisture, so the choice here must be made based on the brand. Thus, M 150 materials can withstand about 50-60 freezing cycles, but some factories have developed types that are more frost-resistant. In humid climates and heavy rainfall, it is advisable to use material grade M 250.

Why are properties such as frost and moisture resistance important? First of all, this determines the durability and strength of the material. Penetrating into the microcracks of each brick, water freezes there and destroys the structure of the material from the inside, as a result of which it turns into dust and loses its performance characteristics. The higher the level of freezing cycles, the longer the material will last. Even in dry climates, when building a house from sand-lime brick, it is preferable to equip the base with red clay bricks.

Ceramic bricks

Ceramic brick is recognized as the material with the highest durability. Today it is produced in a wide range, and the number of types of this material is growing every year. Ceramic materials also include clinker bricks, which are recognized as the best for arranging the basement of a country house. Such a brick is made from special clay, baked at high temperatures until it produces a fine ringing sound, that is, when tapped, the bricks emit a thin ringing sound. They are not afraid of moisture, have high frost resistance, and the load-bearing capacity of this material is comparable to ordinary red brick.

Efficiency of monolithic foundations with basement floors

- Increasing additional usable area in the structure.

- Reducing the cost of heating a building (in winter, heat leakage can reach up to 50% due to errors in the designer’s calculations or developer errors in the construction and insulation of the underground part of the structure).

- Isolation of moisture and radon indoors (in some regions of Russia this problem is quite relevant).

- The tightness of the monolithic foundation eliminates deformation of the structures of the higher floors.

- Types of socles

- Basic elements of the plinth

- DIY basement construction

- Features of the structure

The upper section of the foundation, located above the ground level, is called the base. The most common base height varies between 60-80 centimeters. We are building a basement so that the structure is protected from the penetration of groundwater and wastewater into it. The ability of the house to retain thermal energy also depends on how correctly it is constructed. A properly designed plinth can give a building a more aesthetic appearance.

Basement floor foundation power circuit diagram.

Main strength characteristics

All this speaks to the need to choose the highest quality and reliable building product from which an extremely reliable basement can be made. The general durability of any building material depends on several characteristics. Strength can be determined by testing the ultimate strength characteristics, which will determine the loads that a certain stone can withstand before the period of destruction begins. The second indicator is the ability to absorb a certain amount of moisture.

This characteristic shows the level of liquid and the time during which the product is completely saturated with water. In this case, a high-quality brick is one that has minimal indicators of moisture absorption, which has a positive effect on the resistance to freezing of the stone.

The final characteristic can be considered the frost resistance of the material, which will show how many cycles of thawing and freezing are required in order to lead to the destruction of the structure of the building product.

Let's consider the most optimal types of bricks that can be used to build this element of the house.

Such information will allow the developer to make the right choice of the brick that will be used for construction work. When considering the further description, it is worth paying attention to the important strength characteristics that will provide the main resistance to the environment.

Types of socles

Depending on the method of making the foundation, a variety of structures can act as a plinth. So, if you build a house on a columnar foundation, then the plinth will act as a plinth; if on a strip foundation, then this will be the upper section of the foundation. In the case when the house was built together with a basement floor or when the building was deepened into the ground, a wall acts as a basement.

The quality and length of service life depend on the correct selection of building materials. It is advisable to use frost-resistant and water-resistant mixtures during construction. The strict selection of building materials is due to the fact that throughout the entire operational life of the house, the base will be exposed to many external factors: frost turning into thaw, groundwater, rain, dew, wind, etc. It is best if the filling is done with concrete. It is advisable to reinforce concrete intended for the construction of a plinth. This is necessary to prevent cracks from occurring in the structure. The longest service life is for the plinth, which is made without seams along the entire perimeter of the structure. An element made of natural or artificial stone will also last a long time.

In appearance, the base can be recessed (recessed), protruding, or located at the same level as the foundation. One of the most reliable and common types of base is.

Due to its design, it does not require an additional waterproofing layer and saves building materials.

The most basic type of plinth is a fence installed between piles or foundation pillars. Designed to protect the house and foundation from snow drifts, dust and moisture. Priming is mainly used in wooden houses built on a columnar foundation. Most often, the fence is constructed from the same material as the pillars for the foundation.

Return to contents

Basement brick

- Text updated: 10/17/2016

The plinth is the outer foundation part and base of the facade. It takes on the same loads as the foundation and experiences the same aggressive atmospheric influences as the façade. It also interacts with groundwater and melted water, and is located next to frozen ground.

Regardless of all this, the plinth, being a façade part, must not only perform its main functions, but also look appropriate.

Plinth brick is at the same time strong, reliable, wear-resistant and an excellent material. How to choose a brick for a plinth?

Basic elements of the plinth

A mandatory element of the basement section of each house must be a layer of waterproofing, made in the form of a blind area. The approximate thickness of this layer should vary between 20-40 centimeters. In the event that it becomes necessary to build a house in an area with dry soil, a sand-cement screed, the thickness of which is 5 centimeters, can serve as an insulating layer. When building a house on wet soil, it is advisable to lay several layers of roofing material on the surface before screeding. In order to secure building materials together, you can use mastic.

When the design of the house assumes the presence of a basement, small holes must be created in the cavities or plinth to provide ventilation (about 25 centimeters). To protect against rodents, it is advisable to install grilles in these openings. If you intend to store food or grain in the basement or basement, it is advisable to use additional pest repellent systems.

One of the functions of the plinth is to redirect the weight of the building towards the foundation. This suggests that its construction requires high-quality and strong materials.

Materials and tools required for the construction of the base:

- waterproofing layer (cement-sand mixture or roofing felt);

- mastic;

- protective grilles for ventilation;

- reinforced concrete slabs;

- sand;

- fittings;

- boards for formwork;

- cement mortar;

- welding machine.

Return to contents

Conclusion

We tried to talk in detail about what kind of brick to lay the plinth and how to properly make masonry of different thicknesses. Finally, we would like to advise - if you do not have experience in masonry work, first practice laying out, for example, a flowerbed or any other less important element yourself. It turned out great, otherwise it would be more advisable to involve a specialist, since a poor-quality basement part of the building will significantly reduce the service life of the entire structure.

And finally, a video on how to lay a brick plinth with your own hands:

www.st-par.ru

DIY basement construction

If the construction of a basement is intended, it is advisable to use a prefabricated or strip monolithic foundation when building a house. You must first calculate the foundation, in particular its depth. In any case, the foundation and base can under no circumstances be level with the ground. It will be correct if the foundation is located lower than ground level.

Construction can begin on the 10-12th day, after the base has been poured. Depending on the design, the plinth is found in two types: monolithic and prefabricated.

In order to build a prefabricated plinth, you must use any piece of material: brick or reinforced concrete slabs. Often, during construction, ready-made blocks up to 60 centimeters in thickness are used. The material for creating such blocks is concrete. If construction takes place on soil with low bearing capacity, it is advisable to place a reinforced concrete pad and a layer of sand under the blocks. There is no special way to properly build a reinforced concrete plinth; all work is carried out as usual. So, the blocks are simply laid on the surface and fixed to each other and to the foundation.

In some cases, pieces of reinforcement are used to secure the blocks.

A more complex design is. Pouring a base is a complex technological process that requires a lot of attention and skill. So, work begins with the creation of formwork for the base. It is necessary to begin work when the foundation has received the maximum degree of strength.

The formwork can be ordered ready-made or created independently from planed boards. When doing the work yourself, you can trim the formwork boards only on one side that comes into contact with the concrete. Subsequently, these boards are fixed along the entire perimeter of the foundation. As an alternative, special boards are made from boards, which are also fixed. The fill for the base is a cement solution. To increase the strength of the structure, it is advisable to reinforce it. For this purpose, you can use steel reinforcement from which the mesh is mounted. If the height of the base is large, it is necessary to use several of these grids located at different levels. The grids are fastened together by vertical bridges.

After the formwork has been stripped, it is necessary to clear the surface of the concrete and carefully seal all kinds of cracks and irregularities.

In some cases, a monolithic base is poured together with the foundation.

If the base is concrete blocks, you need to use cement mortar to fix them.

The most complex design is a plinth made of natural stone. Due to the wide variety of shapes and sizes of stone, laying out an even, stable structure can be quite difficult.

To create a brick plinth, red, well-burnt brick is most often used. After completion of construction work, it can be plastered and finishing and decoration work can be carried out. A good material to properly build a plinth is decorative solid brick. It has good properties and attractive appearance. The height in such a structure should be at least four bricks.

If desired, you can decorate it with various decorative materials: siding, tiles, natural stone.

If you want to give your house an original and even luxurious look, build a basement. Many land owners would like to build it, but not everyone knows the technology.

Below we will talk in detail about the basement, basement, how they differ and how to build them yourself.

Calculator for calculating the amount of bricks for laying a plinth

When building a foundation for a future house, this approach is often practiced - the lower part of the base is a reinforced concrete monolithic strip, placed just above ground level, and then the base is laid out of brick to the required height. This significantly lightens the entire foundation structure and makes it warmer, which is extremely important for maintaining a comfortable microclimate in the premises of the first floor.

Calculator for calculating the amount of bricks for laying a plinth

Many owners prefer to carry out most construction work, if possible, on their own, and laying a brick plinth is no exception in this regard. But once such a decision is made, it is necessary to correctly determine the amount of materials required. A calculator for calculating the amount of bricks for laying a plinth will be an assistant in this matter.

Some brief explanations on working with the calculator will be given below.

Calculator for calculating the amount of bricks for laying a plinth

Explanations for the calculation

The principle of calculation is simple: the total volume of the brickwork is determined and then compared with the volume of one brick. But there are several important nuances:

- The calculation is carried out only for building bricks - single (65×120×250), one-and-a-half (88×120×250) and double (130×120×250). Numerous formats of finishing bricks are not included in the program - simply laying out the base from facing material seems like an unreasonably expensive undertaking.

- In the corresponding input field, you must indicate the thickness of the masonry, expressed in bricks, that is, a brick, one and a half bricks, and so on. Half-brick masonry is not practiced when creating a plinth, but, nevertheless, it is also indicated in the general range of options.

- The height of the masonry is in accordance with the expected height of the base.

- The program adjusts the size of each brick for the presence of joints filled with masonry mortar. The most commonly used seam thickness is 10 mm.

- The length of the base is indicated as the total length, measured along the outer perimeter. If the building plan contains internal foundation lintels, on which a brick base is also erected, then their length should also be included in the overall value.

- Finally, the number of internal and external corners of the plinth is requested. This data is necessary to make adjustments to the total volume of brickwork. If there are areas of abutment or intersection of the walls of the plinth, then they are also indicated in the external corners field.

- Usually, when calculating any building material, it is customary to include a certain reserve. Its value may depend on the level of qualification of the master, on the quality of the purchased material and on other reasons. In this case, the user has the opportunity to independently choose what supply of bricks to include in the calculation - from 0 to 15%.

The calculation result will be indicated in pieces.

How to learn to do proper bricklaying?

You should not assume that building a brick wall is a simple task, and the matter will immediately go smoothly. Practice shows that before obtaining impeccable masonry, a novice master will still have to go through a considerable training path. To help those who are taking their first steps in this field - an article from our portal How to lay bricks .

General information

The base is the continuation of the foundation above the zero point of the construction site. Usually it rises 500-700 mm above the base, making a kind of transition to the wall. Its main purpose is to protect the house from moisture penetration from the foundation.

Basement floor - a room from above the zero point of the construction site to the level of the first floor. If it is located lower, then it is called a basement. The ground floor of the foundation is used in a very varied way, for example, a gym, a bathhouse, a home theater or a children's playroom are placed here.

Types of base

Experts identify three options:

- flush with the foundation;

- protruding;

- recessed

The last option is considered the most common, and not because it looks more attractive in terms of construction. It is in this case that the least amount of moisture gets on it, since it quickly drains from it, thereby protecting it, the walls and the foundation of the building from destruction. The undoubted advantage of this type of base is its economic feasibility, since its price is much lower than other designs.

What you should know

- For thin walls of a house, it is better to use a protruding version of the base

. It is also most justified when planning the arrangement of the premises on the ground floor, because they will be warm, since they will be located almost underground. - If the room is intended to be used as a storage room for unnecessary things, it is more advisable to make it thin.

- It is not recommended to build the base flush with the base, since it will practically be the beginning of the walls, and therefore will not provide the necessary protection from moisture. Constructions, which are not economical from a financial point of view, and also will not add beauty to the structure.

Construction

Remember, if the house has an underground floor, from the inside. The instructions say that the minimum height of the plinth is 500 mm, the minimum height of the basement is 1500-2000 mm.

Don't forget to leave ventilation holes for the basement space. Usually they are done at the same level at a height of 150 mm from the ground.

Tip: to protect the ventilation holes from debris, cover them with a mesh or, in cold weather, with a thick cloth.

Foundation with basement

Most often, the foundation for the basement floor is made monolithic, strip-type or prefabricated. When calculating its parameters, it is necessary to determine the depth of the foundation. For example, if it turns out that the freezing point of the soil is located below the zero level at a depth of 1.6 m, then the foundation should begin to be built from 1.8 m.

Advice: start building the basement only 10-14 days after pouring the foundation, when it reaches approximately 80% strength.

Process

Before making the foundation of the basement floor with your own hands, it is necessary to analyze the soil on the site and determine at what depths the groundwater lies. If closer than one and a half meters to the surface of the site, the recess under the room should not exceed one meter. The area should be leveled, and if necessary, add an additional layer of soil.

If the location is very close to the groundwater surface, the area should be drained before foundation work. To do this, drainage lines are laid, which make it possible to divert water from the object and allow the construction of a deeper foundation.

The structure of the base can be:

- Prefabricated, when it is laid out from any piece of material, for example, from red brick or even from reinforced concrete slabs. Very often, the basement is made from foundation blocks 400-600 mm wide with a pitch of 100 mm. Their length is 900-1200 mm in increments of 100 mm. When the soil is weak, a layer of sand (150 mm) must first be laid under them, and then a reinforced concrete pad.

- Monolithic, which is much more difficult to make, therefore there will be more technical errors in this case. After the foundation has gained sufficient strength, formwork is installed for the basement floor. You can purchase it ready-made or make it yourself from boards with a smooth surface on the concrete side. Shields should be made from them and secured to each other in different ways. After this, a frame of reinforcement is installed in the formwork to give strength to the product. Rods Ø 12 mm are used, which are connected by welding or knitting wire to a cell of 150-250 mm. In this case, the reinforcement should not reach 50-100 mm to the edge of the base. Then a fresh concrete solution is poured into the formwork.

When planned, several such frames may be needed. Therefore, they should be placed at different levels with a distance of 300-500 mm from each other. Attach the structures to each other with vertical jumpers, also made from reinforcing bars.

Another option for laying the reinforcing mesh: pour a layer of mortar (150 mm), when it hardens slightly, lay the reinforcement, again pour a 300-400 mm layer of concrete on top and lay the mesh again. The process can be continued to the desired level. After 10-12 days the solution will become strong, then remove the formwork.

You can make a plinth using natural stones, but this will require certain knowledge. In most cases, because the material does not have the same size and shape.

The most common base is made of red brick. Moreover, they use both a special decorative material and prepare it for further plastering or cladding. You can look at other interesting projects of foundations with a basement on our website.

Silicate and ceramic types of bricks

This type of brick is rarely used for the construction of a basement, because it does not have the required characteristics that can provide adequate resistance to environmental influences. As a rule, the use of such material for the construction of a base requires finishing with special insulating materials, which will act as a protective mechanism. The remaining characteristics of such a brick are quite high quality.

It has an accurate and regular shape, has good strength and resistance to mechanical wear and, most importantly, has an extremely low cost. Most often, this material is used for the construction of walls of a residential building, which do not require high levels of protection from environmental influences. To make this building material, lime and quartz sand are used. The moisture absorption of such a brick is about 15 percent of its total mass, which can be considered extremely low protection against moisture.

For the construction of a basement floor, this type of brick is relevant only in conditions of extremely dry climate, which is very rare for our countries. In other cases, the use of this material does not have proper recommendations, which indicates minimal quality and reliability of the future structure. The necessary use of additional materials to ensure the required reliability will lead to increased financial costs, which can rarely benefit the developer.

Ceramic bricks can be safely called a universal building material, which is used for such construction elements as walls, foundations, cladding, plinths and fireplace stoves. The moisture resistance of this material is extremely high, which plays a rather important role in the construction of the basement.

The strength and reliability indicators of such a building material are quite significant, which allows us to count on the utmost quality and resistance to loads from the weight of the entire house. Among the disadvantages of such bricks, one can note its relatively high cost, which can become a real problem when building a house.

So, we have provided the most optimal options for building bricks, which are used to construct such an element as the basement floor of a residential building. Further choice depends only on the owner.

moipodval.ru