Red brick weight from 2.5 kg to 4.1 kg

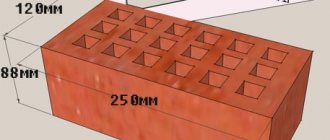

Brick dimensions according to GOST - height, length and width

Modern construction does not stand still. With increasing requirements for the construction of houses, the range of brick sizes has also expanded:

- Single

– 250x120x65 mm (fixed by GOST 530-2007). According to the European marking they are designated RF. - Double

– 250x120x138 mm. - One and a half

– 250x120x88 mm. - Modular

- 280x130x80 mm. - Euro bricks

- 250x85x65 mm.

The most popular bricks in Europe are NF (normal) - 240x115x71 and DF (thin) - 240x115x52, less common sizes are 250x85x65 mm and 200x100x50(65). Today you can buy material up to 500 mm long. The choice of standard sizes is growing every year.

According to their shape, bricks are divided into:

- full-bodied,

- hollow (slotted)

However, in addition to the main dimensions, such as height, length and width, permissions for deviations from the norm (defects) are also used. Their size depends on the type of building material - construction or facing. The latter is subject to more stringent requirements, since the aesthetics of the building depend on its characteristics.

For solid building bricks it is allowed:

- The presence of dullness and chips of ribs and corners of no more than 2 and no more than 1.5 cm in size along the length of the rib;

- Curvature of edges and edges up to 0.3 cm;

- On the side longitudinal (spoon) edges, a crack up to 3 cm long along the width of the brick is allowed.

For the construction hollow version it is allowed:

- No more than 2 dents on corners or edges 1-1.5 cm long, provided that they do not reach the voids;

- Full-thickness cracks in the bed. In width they can reach the first row of voids;

- One crack each on the butt and spoon (transverse side) edges.

For facing bricks it is not allowed:

- Chips of corners, the depth of which exceeds 1.5 cm;

- Presence of cracks;

- Broken ribs whose width exceeds 0.3 cm and length exceeds 1.5 cm.

In this case, a facing material that has:

- No more than 1 broken corners up to 1.5 cm deep;

- Separating handwritings that in total do not exceed 4 cm in length;

- No more than 1 broken ribs, no more than 3 cm in depth, and no more than 1.5 cm in length.

Architectural design often involves the use of different textures and colors. The modern choice of building materials is almost limitless. If desired, you can combine artificially aged, variegated and textured options in masonry without compromising the durability of the house.

One-and-a-half and double bricks are produced mainly as hollow ones. This allows the weight of the structure to be reduced.

The most popular in modern construction are porous large-sized blocks. Ceramic brick is lighter and warmer than the usual construction option. Its use makes it possible to simplify and speed up construction, while reducing the consumption of masonry composition.

To lay 1 m3, you will need 512 single-type bricks, and one-and-a-half bricks are 26% more - 378 pieces.

Solid red brick. Dimensions and calculations

First of all, it should be noted that three standard types of brick are used in construction: regular (single), one-and-a-half and double. The geometric size of a single red brick is 250x120x65 millimeters. The parameters of the one-and-a-half and double versions differ only in thickness. They are 250x120x88 and 250x120x140 millimeters, respectively. These are the basic geometric parameters that should be included in the appropriate formula when calculating the required number of elements of load-bearing walls and auxiliary structures. Here it should be borne in mind that it is not possible to ideally calculate their required number with an accuracy of one brick.

Red, silicate and facing bricks - dimensions and purpose

By type of material they are divided into:

- Red (ceramic).

This type of building material is obtained by firing briquettes from pressed clay. This is a universal material. It is widely used in the construction of foundations, wall structures, partitions, fences, and furnace laying. Solid red brick comes in the following grades - 300, 250, 200, 150, 120, 100, 75. The grade indicates how much pressure the brick can withstand (kg/cm2). The weight of 1 cubic meter of this material is 1700 kg (480 pieces).

- White (silicate).

It is produced on a silicate basis. Compared to red brick, it is a softer, lighter material and has lower strength than its red counterpart. In addition, the silicate version is inferior to red in versatility. It can only be used in the construction of walls and partitions. It is not recommended to use white brick as a material for the foundation and plinth, for laying fireplaces and stoves.

By purpose:

- Private.

A brick that ensures the performance characteristics of the masonry.

- Clinker.

It is characterized by low water absorption and high strength, which ensures proper performance characteristics of the masonry even in a highly aggressive environment. Clinker brick perfectly copes with the functions of a decorative material.

- Fireclay (fireproof).

For domestic purposes, the fireproof fireclay version, which is marked “Sh,” is most often used. For example, Ш-5 has dimensions 230х114х65 mm, Ш-6 – 230х115х40 mm, Ш-8 – 250х124х65 mm.

- Facing.

The facing brick can be chopped, smooth, imitating wild stone. Below are the main dimensions:

- 290x140x85 mm;

- 250x85x65 mm;

- 250x120x88 mm;

- 250x80x65 mm;

- 250x60x65 mm;

- 250x120x65 mm.

In addition to rectangular bricks, they can have a wedge shape. This type of building materials is used in the laying of vaults and semicircular arches of different radii of curvature. The end wedge Ш-22 has dimensions 230х114х65/55 mm, and for example the end wedge Ш-45 – 230х114хх65/45 mm.

The use of decorative (cladding) bricks allows for impeccable laying of external walls, as well as interior finishing of premises. When using facing bricks for internal walls, special attention should be paid to stitching the seams.

Since ancient times, stone of natural origin has served as the main construction material in the construction of capital buildings. However, the established foundations have not held up since the advent of the modern building material – brick. People were able to completely independently transform the required characteristics into the finished product. Day by day we everywhere see areas of application of this type of building materials in very diverse areas. Today there are no barriers, if you want to purchase a standard brick of a standard type: you can find out the dimensions, as well as the selection criteria, from the materials in this article.

- Application areas of typical bricks, brick size and classification

Standard brick can be considered, without false modesty, to be a very versatile material that is widely used in most construction fields. Today there are a couple of varieties and standards of bricks. Rational selection of standard bricks is the basis for a good result of the entire complex of construction work.

Standard brick - types

Depending on the main manufacturing components and the characteristics of the material, standard bricks are classified into 3 main groups:

- Standard red brick.

- Silicate (white) brick.

- Ceramic brick.

- Brick for cladding.

Areas of frequent use of bricks

:

- Removal of both load-bearing and ordinary walls;

- Construction of foundations and plinths;

- arrangement of basements;

- façade cladding;

- construction of stairs;

- removal of partitions;

- Installation of stoves, chimneys and fireplaces themselves.

The red standard brick that is familiar to all of us has gained the greatest demand, as well as distribution. Its technical characteristics are ideal for performing a variety of tasks in construction. It is used to construct elevator shafts in high-rise buildings, columns, and building foundations. Often standard type bricks are used as the basis for the foundation masonry of private houses.

If we are talking about the construction of stairs, then it is quite appropriate to use ceramic construction products. Ceramics are much more resistant to moisture, temperature changes and other atmospheric influences. Plus, ceramics are very susceptible to mechanical transformations, which makes it possible, if necessary, to cut bricks without difficulty.

Standard sizes of red brick

Home > Construction > Materials >

Artificial stone is made by firing clay mixed with water; under the influence of temperature, irreversible chemical processes occur in it. When purchasing, you need to consider the quality, characteristics, type and size of red brick. After all, all these indicators can give the product various properties that affect its use.

Types, their characteristics and application

1. Solid red brick of classic size is used for the construction of load-bearing and reinforced structures, laying foundations, fireplaces, and stoves. It has grades M-075, M-100, M-125, M-150, M-175, frost resistance F 50, moisture absorption 8-10%, thermal conductivity 0.51 W/(mK), voids up to 13%. The size of a single red brick for building a house is 250x120x65 mm. Unit cost is from 9.40 to 16 rubles.

2. Fireproof - created specifically for lining and laying a furnace; its production requires fired refractory clay (fireclay) and fillers. It does not melt or crumble and can withstand temperatures up to 1800 degrees, has several classes: quartz, fireclay, basic, carbon. Letters and numbers in the marking indicate the level of fire resistance. The brand and size of red facing bricks can be different and depend on the physical and chemical composition; there are hundreds of types, for example: Sh-5, Sh-8, ShA-5, Shb-47. Frost resistance F 50-75, thermal conductivity from 0.70–0.85 W/(mK), voids from 8%, moisture absorption 8%. The average price per piece is from 20 rubles.

3. Red “loaf” brick, also known as solid backfill, double, weighs up to 7 kg. Stronger than the classic one, it is used for the construction of load-bearing walls, frames and supports. Has grades: 75, 100, 125, 150, 200, 250, 300, frost resistance F 150, moisture absorption 10%, thermal conductivity 0.50 W/(mK), voids up to 13%. The price for a “loaf” is from 10 rubles.

4. Red ceramic is used to lay the foundation. It must be durable and withstand temperature changes and humidity. Dimensions of a standard red brick for a foundation according to GOST: 250x120x65 mm, grades: 150, 175, 200, 250, 300, frost resistance F 50-100, moisture absorption 6-16%, thermal conductivity from 0.70 W/(mK), void ratio no more than 13 %. The average cost per unit is 11 rubles.

5. The red brick for the plinth must also be durable, resistant to moisture and cold. Use grades no lower than M-125 or M-150. Fired and solid ceramic is well suited for these purposes, but “Turtle” remains the leader. Its grades are M-200, M-250, M-300, frost resistance F 100, moisture absorption 12%, thermal conductivity 0.51 W/(mK), voids less than 13%. The unit cost is within 16 rubles.

When calculating estimates, it is important to take into account the dimensions of the artificial stone, the main ones are shown in the table:

| View | Size, mm |

| single classic | 250x120x65 |

| one and a half | 250x120x88 |

| double | 250x120x138 |

| Euro | 250x88x65 |

| modular | 288x138x65 |

When choosing, pay special attention to the quality; if chips and cracks, uneven coloring are visible, then it is better to refuse the product.

Author: Evgeny Boyarov

| Related articles: | |

| Areas of use of crushed stone fraction 5-20 Crushed stone fraction 20-40 gravel Laying natural paving stones with your own hands | |

Brick size

Today there are single, one and a half and 2nd bricks; as for the exact dimensional characteristics, we will describe them below in the text.

Standard brick

During the period of the formation of construction crafts, a number of standards were developed according to which this type of material was produced. The size of the 1st type brick is: width 120 mm, length 250 mm, as for the height, it is 65 mm. It is these brick sizes that are ideal for laying with alternation along the longitudinal-transverse principle.

- How is a standard brick selected? Its technical aspects and characteristics

Before purchasing a standard brick, you need to understand your end goal as accurately as possible. It is this that will subsequently imply the choice of material for construction.

The color of a brick block directly depends on the type of clay on the basis of which it is made. The most common type is a red burning clay mass. It ultimately gives the product its final red hue. Less often we can find standard bricks of white, yellowish and apricot colors, for the production of which white-burning clay is used. It happens that for the desired result or shade, a specialized pigment is added to the base.

The usual one is suitable for removing wall partitions and building any structure.

- Standard typology of bricks: 250x120x56 mm.

In the future, this standard brick will definitely require finishing according to the type, plastering. Facing, in turn, has extremely flat and smooth surfaces, and does not require any finishing. But with all this, the cost of both the actual type and the size of the facing blocks varies dramatically.

Characteristics of appearance

Anyone involved in construction must know the dimensions of both the standard type of clinker and the universal materials produced. Standard sizes:

- length – 250 mm;

- width – 120 mm;

- thickness – 65 mm.

Of all the different sizes, the use of standard bricks is the most popular. Sometimes during the construction of buildings it becomes necessary to place clinker perpendicularly. During such masonry, a peculiar alternation of longitudinal and transverse sides occurs. Due to the fact that almost all dimensions are double multiples of each other, masonry can be done in any way. This property allows for minimal transfer of material without resorting to sawing.

The sizes of red clinker are not always standard; production includes the production of one-and-a-half bricks, the thickness of which is much greater. With standard indicators of other parameters, the thickness is 88 mm. On sale you can also find double stone, the thickness of which is 138 mm. The sizes may be different, but these three are on sale more often than others. Non-standard dimensions are mainly suitable for decorating external buildings and facades. The use of such bricks is possible for decoration.

Brick strength

A very important aspect when choosing a brick is strength, in other words, the ability of a block not to collapse under external loads. To build a house of one floor as a whole, a holding value of 100 kg per 1 cm is sufficient. If we are talking about multi-story construction, then the final value should be at least 150. The strength of a single batch is indicated on the manufacturer’s packaging.

There is also another indicator that affects the quality of blocks - frost resistance. This indicator is measured in cycles. Determined and set for each brand of blocks. The final product is placed in an aqueous environment and then added to the freezer. The test period is 8 hours.

Brick has long been a well-known building material, without which almost any construction is indispensable. Although brick blocks have been used since ancient times, standard brick sizes were first introduced only in 1927.

Standardization of standard sizes of brick blocks allows you to calculate the volume of brickwork in accordance with the project, the need for building materials, and also determine the weight of the structure.

The key factor in standardizing the size of brick products is the following aspect ratio of 1:1/2:4. Such proportions are considered optimal for laying building materials with alternating longitudinal and transverse positions.

In private construction, single products are in demand; the consumption of building materials per cubic meter of masonry is 513 units of products. In accordance with government regulations in force in Russia, the size of a standard single brick in millimeters is:

- 250 length;

- 120 width;

- 65 height.

In addition to single blocks, the construction market offers other types of standard sizes:

- one and a half;

- double.

One and a half building material was put into production during the industrialization of the country, in order to speed up the pace of construction. The standard consumption of building materials is 318 products per cubic meter. A characteristic feature of a one-and-a-half block is the increased height of the product; GOST establishes the following standard brick sizes (in millimeters):

- length - 250;

- width -120;

- height – 88.

A double brick with the same 250 millimeters in length and 120 millimeters in width has a height of 138 millimeters. Given their impressive dimensions, to reduce the weight of the product, double blocks are usually made in a hollow shape. Double products are widely used in various fields of construction. Building materials with increased height are used for the construction of both industrial and civil facilities.

Choosing the size of brick for masonry

Despite the fact that now manufacturers of brick, as well as artificial stone, have mastered a great variety of models for producing their products, all of them are tied to a standard range of standard sizes, the proportions of which allow solving a wide variety of architectural and technological problems.

For example, in a traditional single brick, the forming edges - bed, spoon and poke - have a ratio of 1:1/2:1/4, which allows you to freely orient it in the thickness of the masonry in mutually perpendicular planes, and also adds convenience to the mason in work, because such The shape fits well in the hand.

The coordination of product sizes was regulated by industry standards, starting from GOST 90035-39 , the first all-Union standard, and ending with modern requirements: GOST 530-2012 “Ceramic brick and stone. General technical conditions", GOST 379-2015 "Brick, stones, blocks and silicate partition slabs. General technical conditions", TU 5741-021-00284753-99 "Hyperpressed construction materials".

From the official regulatory and technical requirements it follows that the main difference between brick and artificial stone lies in their dimensions. The stone has a wide range of standard sizes with a thickness of 140 mm and is produced only in a hollow version, therefore it is preferable for the internal parts of load-bearing walls and partitions.

The brick can be either solid or multi-hollow (hollow), with a maximum thickness of 88 mm, suitable for universal use.

Dimensions and markings of bricks from Russian manufacturers

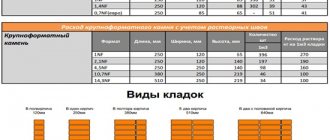

| Name | Size markings | Dimensions, mm | Name marking |

| Single brick | 1-NF | 250x120x65 | ABOUT |

| Euro brick | 0.7-NF | 250x85x65 | E |

| Modular single brick | 1,3-NF | 288x138x65 | M |

| One and a half brick | 1,4-NF | 250x120x88 | U |

| Thickened brick with horizontal voids | 1,4-NF | 250x120x88 | ISIS |

| Double brick (stone) | 2,1-NF 3,7-NF 2,9-NF 1,8-NF 4,5-NF 3,2-NF | 250x120x140 288x288x88 288x138x140 288x138x88 250x250x140 250x180x140 | TO |

| Large-format stone (ceramic porous block) | 14.3-NF 11.2-NF 10.7-NF 9.3-NF 6.8-NF 4.9-NF 6.0-NF | 510x250x219 398x250x219 380x250x219 380x255x188 380x250x140 380x180x140 250x250x188 | QC |

| Stone with horizontal voids | 1,8-NF | 250x200x70 | KG |

Today, the most popular normal format (NF) masonry materials in our country are: Single, with dimensions 1NF (according to the Euro marking - RF) - 250x120x65 mm; Double, with dimensions 2.1NF - 250x120x140 mm; One-and-a-half, with dimensions 1.4NF - 250x120x88 mm; Modular, with dimensions 1.3NF - 288x138x65 mm; “Euro”, with dimensions 0.7NF - 250x85x65 mm.

Dimensions of facing bricks

The width and length of all facing bricks are the same: 250*120. Differences in thickness. Types of sizes by thickness: Single – 65 mm. One and a half – 88 mm. Double - 138 mm.

European brick size markings

Europe is characterized by the use of the following types of products: Normal (NF) - 240x115x71 mm; Thin (DF) - 240x115x52 mm; Also - 250x85x65 mm, 200x100x50 mm and 200x100x65 mm. The dimensions of artificial stone can reach: length and width – 510 mm, thickness – 229 mm.

| Marking | Dimensions, mm |

| DF | 240x115x52 |

| 2DF | 240x115x113 |

| NF | 240x115x71 |

| RF | 240x115x61 |

| WDF | 210x100x65 |

| W.F. | 210x100x50 |

Permissible errors

Building materials are produced in strict accordance with production technology.

Brick block blanks, which are fired in kilns during the production process, are manufactured with an increase in geometric parameters by 8%. As a result of heat treatment, the product is reduced and brought to standard parameters. GOST allows a slight deviation in the geometric dimensions of finished products, namely, in length no more than 4 millimeters, width and height no more than 3 millimeters. The standard also allows for slight curvature along the spoon (no more than 4 mm) and along the bed (no more than 3 mm).

Weight characteristics

Weight must be taken into account by designers in order to ensure the most accurate load of the masonry being performed on the installed foundation. Sometimes the weight needs to be known to determine the carrying capacity of a vehicle for transporting bricks.

It is useful for masons to know that for a volume of 2 m3 of masonry, 1000 pieces are needed. ordinary single solid brick, by weight it is about 3380 - 3694 kg, 500 pcs are needed per 1 m3. raw materials.

A working full-bodied single has a mass of 3,300–3,600 kg; a volume of 2 m3 requires 3380–2650 kg.

A working hollow single has a weight of 2,300–2,500 kg; for a volume of 2 m3 2,360–2,566 kg are needed.

Facing and decorative hollow single has a mass of 1,320–1,600; a volume of 2 m3 requires 1350–1640 kg.

Types of brick products and their standard sizes

The dimensions of brick products depend not only on the standard size, but also on the type of building material. The main types in demand in the construction of residential buildings and the construction of industrial buildings are:

- Red brick;

- silicate;

- facing.

Red building blocks and their features

Red brick is a universal-purpose building material used for the construction of foundations, external enclosing structures and partitions in the house, and fences.

Red brick products are made from clay briquettes, which are pressed by firing. The dimensions and technical characteristics of the product are regulated by GOST 530-2007 and are (in millimeters):

- standard format – 250x120x65;

- thickened format – 250x120x88;

- double format – 250x120x138.

In addition to the popular standard sizes by GOST, less popular formats are also provided:

- 0.7 NF with parameters 250x85x65 mm;

- 1.3 NF with parameters 288x138x65 mm.

Building materials of the “European format” are used for decorative finishing of windows and other structural elements of the facade.

Sand-lime brick

Silicate brick blocks are a building material made on the basis of silicate, intended for the construction of load-bearing external walls and partitions in the house. The modular dimensions of white brick are 250x120x65 and 250x120x88 millimeters.

Silicate building blocks are produced in two types:

- full-bodied;

- hollow.

The void volumes of the silicate block, as well as the overall dimensions, are adjustable

state standards. Hollow silicate blocks are divided based on the volume fraction, diameter and number of blind voids having a cylindrical shape.

The following types of hollow sesquisilicates are distinguished:

- three hollow – the proportion of voids is 15% of the volume of the product, the diameter of blind holes is 52 mm;

- eleven are hollow – the proportion of voids in the total volume is 25%, diameter – from 27 to 32 mm;

- fourteen hollow - the proportion of voids varies from 28 to 31%, the diameter can be from 27 to 32 mm.

Facing brick

For facing facades, standard size facing bricks are used, which corresponds to the traditional counterpart.

The construction market offers several types of cladding products:

- clinker;

- ceramic;

- hyperpressed;

- silicate.

Clinker building blocks are used for finishing facades, for erecting decorative pillars, decorating window openings, and using this type of material to build arched windows. The material is characterized by a dense, smooth structure, excellent sound-insulating and frost-resistant qualities, is resistant to moisture, and retains heat well. Clinker can be colored and glazed, glossy and matte. Windows and facade walls faced with clinker blocks retain an attractive appearance for a long time.

Clinker facing

Ceramic facing products can withstand up to one hundred changes in natural seasons; the material is not afraid of sudden temperature changes. Brick retains its original qualities and appearance over a long period of use.

Ceramic veneer

Hyper-pressed material is made from a lime-cement mixture using the method of semi-dry hyper-pressing, followed by steam treatment. The material is used for decorative finishing of facades; it is used to highlight windows and doors. There are several types of facing material:

- smooth;

- spoon;

- figured;

- angular.

The standard dimensions of smooth and figured hyperpressed bricks are 250x120x65 mm. Standard spoon bricks have parameters of 250x85x65 mm, corner and narrow spoon bricks – 250x60x56 mm.

Hyperpressed facing

Sand-lime facing brick is an environmentally friendly frost-resistant material. Facing sand-lime brick amazes with its variety of colors; it differs from its ceramic counterpart in its uniform color tone over the entire area of the product. Silicate facade material is not used for cladding areas in contact with the ground.

Red, sand-lime and facing bricks - sizes and purpose.

1. Red (ceramic) brick is produced by firing pressed clay briquettes. Red brick is a multifunctional material; it is used in the construction of walls, various structures, partitions, foundations, fences, and when laying stoves. Brands of solid red brick: 300, 250, 200, 150, 120, 100, 75. The brand of brick shows how much pressure the brick can withstand (kg/cm2).

2. White (silicate) brick is produced on the basis of silicate. The characteristics of this material, in comparison with red brick: softness, lightness, low strength, versatility. The scope of application of sand-lime brick is narrower: the construction of walls and partitions.

types of bricks are distinguished by purpose :

• Ordinary brick (guarantees the performance characteristics of the masonry);

• Clinker brick (features a low degree of water absorption, high strength, which makes this type of material resistant to use in various aggressive environments). Scope of application: decorative material.

• Fireclay (fireproof) brick (marked “Ш”, used mainly in industry) • Facing brick (can be chopped, smooth, etc.). Basic brick dimensions :

- 290x140x85 mm;

- 250x85x65 mm;

- 250x120x88 mm;

- 250x80x65 mm;

- 250x60x65 mm;

- 250x120x65 mm.

In addition to the well-known rectangular shape, the brick can have a wedge shape. The scope of application of this type of brick: laying vaults and arches of radii of different curvature. When using facing bricks, it is possible to perfectly lay external walls and carry out interior decoration.

Non-standard dimensions

However, in the segment of facing building materials you can find products of non-standard dimensions. Custom-sized products are produced non-industrially, in organic batches. An atypical building material is used for restoration work, the introduction of original design ideas, and to emphasize the window opening. The dimensions of non-standard single material for finishing facades can be (in millimeters):

- 210x100x50;

- 210x100x60;

- 240x115x52.

European standards

In the European Union there are other standards that do not comply with GOST 530-2007. Thus, the most popular series in the countries of the European Union are the following series of building materials:

- DF – geometric parameters of the product 240x115x52;

- 2DF – 240x115x113;

- WDF – 210x100x65;

- RF – 240x115x61;

- NF – 240x115x71;

- WF – 210x100x50.

As a building material, brick has firmly occupied its niche since ancient times. This is explained by high strength properties, stability when exposed to temperature, moisture, and frost.

There are many variations of bricks on the market, some of which are universal in functionality, and some of which are used for special purposes. The operational differences of decorative, sand-lime or red brick can be successfully used to implement a variety of construction projects.

When choosing a material according to its intended purpose, they take into account such indicators as size. The most commonly used stone is a single stone, also called standard, normal or working.

Density of building material

- Full-bodied, without additional voids inside. The weight of a red brick measuring 250x120x65 is 3.501 kg - 1 piece.

- Hollow, has round, square, vertical or horizontal voids inside, the weight of the material varies depending on the number and size of the voids. Compared to the full-bodied type of material, this type is inferior in weight.

Size data:

- Single 250x120x65;

- One and a half 250x120x88;

- Double 250x120x138

Based on the indicators, it becomes clear that only the height of the material changes, all other indicators remain unchanged. The weight of such a product varies depending on the height of the product, and therefore it is important to take this data into account when laying.

Ceramic materials according to their purpose and use are divided into:

- Privates. They are used during the laying of load-bearing structures, walls, fences and partitions. The required amount may vary depending on certain application parameters.

- Facial. Consumed during cladding work.

- Special. They are used for laying stoves, chimneys, fireplaces; the raw materials should not be large or bulky, otherwise the structure will look ugly.

Appearance, characteristics and purpose of the material

According to technical requirements in modern construction, bricks are used whose dimensions correspond to the following parameters (in mm):

- single - length 250 (with a tolerance of +/-5 mm), width 120 (with a tolerance of +/-4 mm), height 65 (with a tolerance of +/-3 mm);

- one-and-a-half - length 250, width 120, height 88;

- double - length 250, width 120, height 138.

The dimensions of red brick or sand-lime brick are standard, in other words, the material from which they are made does not determine its parameters, therefore normal stones have a standard height of 65 mm.

The dimensions are determined not so much by the convenience for the worker (it is easy to hold a stone weighing approximately 3.4 kg in your hand), but by the features of the masonry.

For example, the use of working bricks is effective when alternating transverse and longitudinal stones: for every meter of masonry length there are 13 rows of bricks. The geometric dimensions allow for efficient laying, taking into account the need for bandaging.

Return to contents

Material Dimensions

This building material has been known for approximately 4,000 years. Over the years, it has changed its characteristics many times. Today, a standard has developed in Russia. The size of a red brick today is (in mm):

- length - 250;

- width - 120;

- height - 65 (Fig. 1).

Figure 1. Standard dimensions of red brick.

These are standard sizes that are followed by all factories producing solid products for construction. They can be supplemented with the letters NF. This means the normal format of the product. In practice, it turned out that it is precisely this aspect ratio that is most suitable for alternating the longitudinal and transverse arrangement of products in masonry. The same ratio allows the use of red solid bricks made at any factory. GOST is the same everywhere.

The remaining sizes of red clay building blocks are also related to the standard ones. The sizes differ only in their height. Red fired brick of 1.4 NF format is otherwise called one-and-a-half brick. It has dimensions of 250x120x88 mm. The builders nicknamed it thickened. It is slightly higher than the standard brick, but saves the working time of masons, since its consumption for masonry is much less. Factories also produce double bricks. The dimensions of the red solid double product are 250x120x138 mm. But these blocks are not 1.5 or 2 times larger than standard ones. This must be kept in mind when calculating materials for construction.

Red brick in Euro format is rare. It is used to repair ancient buildings or simply to create a beautiful pattern on the facade of a building. The dimensions of this kind of brick are (in mm):

- 0.7 NF - 250x85x65;

- 1.3 NF - 288x138x65.

Figure 2. Dimensions of hollow red brick.

Samples of products with a height of 65 mm are called building bricks by builders. All products from brick factories in the country are durable. It can be from M-75 to M-300. The letter F usually denotes the frost resistance of products. It comes from F15 to F50. Building stone of any format is laid on lime or (most often) sand-cement mortar.

The solid brick is quite convenient to hold in your hands. It fits well into the wall. For better adhesion to the solution, it is often made with a notch. The side with the notch is good for plaster during finishing work.

Along with solid products, hollow red ordinary brick has also gained great popularity. It is based on single and one-and-a-half samples (Fig. 2). This material is much lighter and has excellent thermal insulation properties. It is not recommended to be used for laying foundations. The foundation brick must have special strength. A hollow product is not suitable for constructing a furnace. But it is quite possible to make partitions and walls from it with reduced strength standards, but with increased thermal insulation properties.

Dimensions of facing bricks

The dimensions of standard single facing bricks are the same as those of ordinary bricks, but variations are possible. Thus, clinker stones with a length of 250 mm and a height of 65 mm can have a width of 120, 90, and 60. Hyper-pressed decorative blocks are characterized by the same dimensions as clinker ones. But the dimensions of the ceramic slabs are non-standard: length - 188, width - 88, and height - 63 mm.

The given parameters are a European standard that allows the designer to create the original appearance of buildings, which is more than relevant in the conditions of Soviet and post-Soviet typification.

According to the American standard, the width of the material is slightly smaller than that of the domestic one. Instead of the usual 120, it is customary to produce blocks with a width of 78 mm. These parameters allow significant savings in the process of transporting the material and when laying it. In construction, when using American material, it is possible to achieve a lower load on the foundation, and during restoration, a smaller thickness of the walls.

Return to contents

Established standards

In accordance with the standards, a number of requirements are imposed on single bricks.

Instances that do not comply with the standard are unsuitable for construction work.

It is necessary to pay attention to the fact that the maximum volume of voids of hollow ordinary stone does not exceed 13%. At the same time, the norm of volumetric weight fluctuates between 1700-1900 kg/m, the norm of the thermal conductivity coefficient does not exceed 0.7 kcal/m, and the norm of water absorption starts at 8%.

The weight of a red solid single brick is on average 3.5 kg, hollow - 2.4 kg, facing - 1.45 kg.

It is clear that the mass depends on the density of the material, while the weight of sand-lime brick is the highest by standards. Some manufacturers deviate from the standard and, guided by specifications, produce blocks whose weight is 5 kg.

Reliable adhesion and reduced thermal conductivity are ensured due to the porous structure, which excludes components such as stones and lime. According to standards, cracks are not allowed in the structure.

With standard sizes, the working stone has the shape of a rectangular parallelepiped with straight and even edges, edges, and corners. In hollow single blocks, according to standards, different types of holes are provided - oval, round. The most durable bricks are those that have square holes.

To establish deviations from the norm, material from one batch is measured, which makes it possible to identify discrepancies in size, the presence of curvatures, damage to corners or ribs.

The use of stone whose dimensions do not meet the standards leads to masonry defects, which later affects the performance characteristics of the structure as a whole.

When ordering materials, you need to know their parameters. Even such a well-known material as brick has a large number of types and varieties. The good news is that its parameters are standardized. The standard brick size and its quality characteristics have been determined.

What weight does sand-lime brick have?

This silicate product weighs about 4 kg, but the weight of one brick varies depending on the varieties and structure of this building material described above. Hollow brick, due to the existing cavities, has a lower volume, and therefore weight, compared to a heavier solid product. A hollow one-and-a-half silicate brick weighs exactly 4 kg, and a single one weighs 3.2 kg.

The weight of a single sand-lime brick in a solid version is 3.6 kg, and a one-and-a-half solid brick is 4.8 kg.

When designing and constructing buildings, an important indicator is the specific gravity of the brickwork, in other words, the weight of one cubic meter of masonry, taking into account the weight of the mortar. This parameter seriously affects the design of the foundation, as well as the weight of the building. The specific gravity of brickwork, which usually depends on the weight of the brick, ranges from 600 to 1800 kg/m3. (see Weight of 1 m3 of brickwork).

In the above picture you can see not only the weight of one silicate product, but also the weight of a brick cube, as well as how many pieces of brick are put on a pallet and how much they weigh, without taking into account the mass of the pallet, which weighs approximately 30-40 kg. In column o you can see how much the most common packages of bricks weigh on a pallet - in their minimum and maximum versions.

Types of building bricks

Based on the material, bricks can be ceramic (clay, red) or silicate (white). By purpose - ordinary (construction) and finishing (facade). Ordinary is used for laying walls and requires subsequent finishing, so a notch can be applied to the side edges (of the spoons) so that the plaster holds better.

Types of bricks - ordinary and special

Depending on the method of molding, bricks can be solid or hollow (hollow). A solid one is formed from a homogeneous composition. They are used where mechanical strength is important - foundations, load-bearing walls.

Hollow has a certain percentage of voids, due to which the weight of the structure is reduced and thermal conductivity characteristics are improved. But the presence of voids significantly reduces sound insulation performance - the voids act as resonators. So you need to use them wisely.

Types of white brick

The building material in question today offers only 2 types of execution:

- Hollow - has special voids inside, located perpendicular to the brick beds. The voids themselves can be created either through or not.

- Solid - as the name suggests, it has no voids.

Depending on the dimensional values, the following types are distinguished:

- Single , height, width and length of which are 65, 120 and 250 millimeters, respectively;

- One-and-a-half white brick, or, as it is also called, thickened, has the same width and length as a single brick, differing only in height, which is 88 millimeters;

- In addition to thickened and single bricks, manufacturers today can also produce ceramic and silicate stones with non-standard sizes , for example, 250*120*138 millimeters.

In addition to weight characteristics, sand-lime bricks can also vary in color. So today you can find colors of pink, white, yellow and gray.

Because of their ideal shape, silicate products lend themselves well to forming a relief surface and painting, so that a structure that is inconspicuous at first glance can be easily transformed with relief colored bricks. This decorative property is a great advantage of the building material in question.

With the help of relief bricks, craftsmen can create imitations of natural stone, significantly improving the architecture of the facade.

During the painting process, the brick is painted both outside and inside, which provides the material with high color reliability.

Ceramic brick size

Ceramic bricks are fired parallelepipeds formed from clay. Quality is largely determined by correctly maintained firing parameters, as well as the composition of the clay solution. High-quality ceramic bricks can be used for any construction operation: for laying a foundation (solid), constructing external walls and internal partitions.

Building bricks have certain dimensions determined by standards. The most commonly used single brick size is 250*120*65 mm

The main disadvantage of this building material is some variation in geometry. It is explained by the characteristics of the clay - it can have different “fat content”, which makes it difficult to accurately predict how much the dimensions will decrease during drying/firing.

What to look for when choosing

When choosing red brick, you should pay attention to its color. It displays the quality of the batch with a parameter such as brick size. It can be under-burnt or over-burnt. The second option is not bad in operation (it looks darker than usual), but it is better not to use unburned brick (lighter and looser) at all - it falls apart very quickly.

The second point that you need to pay attention to is the absence of foreign inclusions. The most common are light dots and expanded clay. Both lead to rapid destruction of the brick. So we select only batches with uniform coloring without any additives.

More quality criteria

That is, the requirements for ordinary building bricks are quite flexible. The presence of these defects does not affect the quality of the masonry, and the decorative component is unimportant, since the presence of finishing is assumed. Don’t forget to check the size of the brick - the spread in one batch should not be more than 3 mm.

The requirements for finishing (cladding) ceramic bricks are more stringent. Invalid:

- Chips of edges more than 1.5 cm deep.

- There should be no cracks.

- There should be no breaks on the ribs more than 3 mm wide and more than 1.5 cm long.

To comply with these requirements, the finishing bricks are placed on pallets, the corners are protected with boards knocked down at an angle, and the entire structure is wrapped in film. It is transported in this form.

Dimensions

The optimal size of clay bricks (red, ceramic) was determined historically. It has been produced for thousands of years, and as a result, the ideal combination of lengths has been developed, which is reflected in the standard. It was adopted only in the last century. There are three standard options:

One of the features is that a single brick can be solid or hollow. One-and-a-half and double - only hollow ones, otherwise they turn out to be too heavy for comfortable work.

In addition to the standard ones, there is a reduced brick. It is produced in Europe, but it also comes to us. Its parameters and international designation are summarized in a table.

| Marking | Brick size | Consumption |

| DF | 240*115*52 mm | 64 pcs/m2 |

| RF | 240*115*65 mm | 54 pcs/m2 |

| NF | 240*115*71 mm | 48 pcs/m2 |

| WDF | 210*100*65 mm | 59 pcs/m2 |

| 2DF | 240*115*113 mm | 32 pcs/m2 |

Which size is better

In the post-Soviet space, single brick is most often used. It is very familiar to our eyes; many masonry schemes have been developed for it. It’s worth mastering this kind of material.

One-and-a-half bricks are used less frequently. It provides some economic benefit. Firstly, a cubic meter costs a little lower. Secondly, since the masonry fragments are larger, less solution is consumed. Thirdly, the work goes faster. Time is saved due to the larger size. But it’s more difficult to work with a one-and-a-half brick, even if it’s hollow – it’s hard to hold in your hand. And the appearance of the wall is unusual.

Double brick is more often called ceramic building stone. When using it, the most noticeable effect is the speed of construction. In addition, the saving of the solution increases. But you won’t be able to grab such a brick with one hand. Therefore, it is better to work with an assistant. The appearance of the masonry leaves much to be desired, so exterior finishing is desirable.

If we talk about other countries, the most popular ones in Europe are NF and DF. Imported NF ceramic bricks have almost the same proportions as domestic ones. DF category is thinner, the masonry looks elegant.

Standard sizes of white (silicate) and red bricks

Size of ordinary single red and white brick (standard): 250x120x65

- Brick length - 250 mm;

- Brick width - 120 mm;

- Brick height - 65 mm.

Standard size of double silicate and ceramic bricks: 250x120x138

- Brick length - 250 mm;

- Brick width - 120 mm;

- Brick height - 138 mm.

The usual size of one-and-a-half (thickened) white and red bricks: 250x120x88

- Brick length - 250 mm;

- Brick width - 120 mm;

- Brick height - 88 mm.

Modular brick size: 280x130x80

- Brick length - 280 mm;

- Brick width - 130 mm;

- Brick height - 80 mm.

Standard size of euro facing brick: 250x85x65

- Brick length - 250 mm;

- Brick width - 85 mm;

- Brick height - 65 mm.

Table of standard sizes of red and white bricks

| Brick name | Brick length, mm | Brick width, mm | Brick height, mm |

| Single brick | 250 | 120 | 65 |

| Double brick | 250 | 120 | 138 |

| One and a half brick | 250 | 120 | 88 |

| Modular brick | 280 | 130 | 80 |

| Euro brick | 250 | 85 | 65 |

The dimensions of kiln bricks (refractory) are the same as the standard dimensions of red brick.

Video about brick size standards

Dimensions of sand-lime brick

Sand-lime brick is made from quartz sand (9 parts) and lime (1 part), and a certain amount of additives. This building material has better thermal conductivity characteristics (conducts heat worse) and is lighter in weight. The technology is such that it is easier to maintain geometric dimensions, so there are usually no problems.

But it is not as hard as red brick, and it is also afraid of moisture - with prolonged contact with moisture it begins to crumble. Because of this, the main area of use is for the construction of walls and partitions. It cannot be used either for the foundation, or for the basement, or for laying a chimney.

The second area of application is as a finishing material. The base composition has a white, slightly grayish color. You can add any dye to it and get colored bricks.

The dimensions of building silicate bricks are the same as those of ceramic bricks: single has a height of 65 mm, one and a half – 88 mm, double – 138 mm.

Single and one-and-a-half silicate bricks can be solid or hollow. A single solid one weighs 3.6 kg, a hollow one weighs 1.8-2.2 kg, depending on the size of the voids. A full-bodied one and a half has a mass of 4.9 kg, and a hollow one - 4.0-4.3 kg.

Double sand-lime bricks are usually made hollow. Its weight is 6.7 kg. Full-bodied ones are rare - due to their large mass (7.7 kg) they are difficult to work with.

Dimensions and weight

Everyone who deals with brick should know its dimensions. In the construction world, there are sizes developed to standards, as well as custom sizes.

The standard dimensions of red corpulent are as follows: length is 2.5 cm, width is 1.2 cm, thickness or height is 65 mm.

Instead of facing bricks, you can use plastic facing panels for bricks, more details about which can be found in the article.

Of the many sizes offered, this is considered the most convenient to use.

During the construction process, the bricks are placed perpendicularly, so longitudinal sides alternate with transverse ones. Please note that the sizes are almost double multiples of each other. Due to this, the arrangement is as convenient as possible; there is no need to saw the material.

The photo shows the dimensions of the red solid brick

One-and-a-half is also used. The width and length will be the same as those of standard bricks, but the thickness will be twice as different.

The thickness of the stone is 88 mm. There is also a double pattern. Its thickness is 138 mm.

These types of corpulent ones are considered the most common. Less commonly found in European sizes. Length 25 cm, width - 8.5 cm, thickness - 6.5 cm.

It weighs significantly less and is easy to install. Usually non-standard sizes are used as decorations for roofs and facades. The decorative component is the main purpose of such a sample.

How much does it weigh? Solid red should contain a maximum of 13% voids, so its weight is quite high compared to hollow models. If the model has standard dimensions, then the weight of one brick will be from 3.5 kg to 3.8 kg. As a result, the volumetric weight is 1700 or 1900 kg/m3.

But there are exceptions to every rule, so you can find models weighing 3, 2 kg and 4 kg. The weight of a non-standard one-and-a-half brick lies in the range from 4 to 4.2 kg. And the weight of a double is from 6.6 kg to 7.2 kg.

You can learn about the disadvantages of sand-lime brick from this article.

If you use a hollow facing brick, which is made according to GOST 530-2007, then its weight will be 1.32 - 1.6 kg, and the weight of one and a half is 2.7 - 3.2 kg.

But during construction work, few people are interested in the weight of an individual brick. Usually they focus on the weight of the entire wall.

It is very important that the foundation of a red brick house can support the weight of the house itself. One, or rather its weight, is fundamental in order to accurately know the weight of the walls that will rest on the foundation. For one square meter you need 51 pieces when taking into account the seams.

Usually the thickness of the walls is one and a half. To find out the total weight, you need to multiply it by the weight of one brick and the weight of the mortar. This is how the developer finds out the weight of a wall of 1 square meter.

You can find out the dimensions of the red brick stove from the article.

If the builder knows the weight of one object, then a specific model can be selected. At the same time, you must know for what purposes you want to use it.

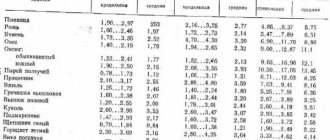

Weight of one piece: ceramic, silicate, ordinary, obverse

The weight of the brick is needed, firstly, to calculate the foundation; this parameter is especially important when; secondly, for cargo transportation; and thirdly, to determine quality and compliance with GOST requirements.

| Brick type | Purpose | View | Nominal sizes | Emptiness | Weight | Water absorption |

| Ceramic GOST 530-2007 | private (worker) | single, full-bodied | 250*120*65 | 0% | 3.3 - 3.6 kg | 10 -12% |

| single, hollow (hollow, slotted) | 250*120*65 | 30-32% | 2.5 - 3.0 kg (with 6% voids weight 3.8 kg) | 12 -17% | ||

| one and a half, full-bodied | 250*120*88 | 0% | 4 - 4.3 kg | 12 -17% | ||

| one and a half, hollow | 250*120*88 | 30-32% | 3.5 kg (with 6% voids - 4.7 kg) | 12 -17% | ||

| double, full-bodied | 250*120*140 | 0% | 6.6 - 7.24 kg | 12 — 17% | ||

| double, hollow | 250*120*140 | 30-32% | 5.0 - 6.0 kg | 12- 17% | ||

| facing (facial) | single, full-bodied | 250*120*65 | 0% | 2.6 kg | 9 — 14% | |

| single hollow | 250*120*65 | 30-36% | 1.32 - 1.6 kg | 9 -1 4% | ||

| one and a half hollow | 250*120*88 | 30-36% | 2.7 - 3.5 kg | 9 — 14% | ||

| Silicate GOST 379-95 | private (worker) | single full-bodied | 250*120*65 | 0% | 3.7 - 3.8 kg (according to GOST) | |

| single hollow | 250*120*65 | 15-31% | 3.1 - 3.3 kg | |||

| one and a half full-bodied | 250*120*88 | 0% | 4.2 - 5.0 kg | |||

| one and a half hollow | 250*120*88 | 15-31% | 4.2 - 5 kg | |||

| double hollow | 250*120*140 | 15-31% | 5.3 - 5.4 kg | |||

| facing (facial) | single full-bodied | 250*120*65 | 0% | 3.5 - 3.9 kg | ||

| one and a half full-bodied | 250*120*88 | 0% | 3.7 - 4.3 kg | |||

| one and a half hollow | 250*120*88 | 15-31% | 3.7 - 4.2 kg |

In addition to standard size bricks, there are a large number of lightweight finishing bricks. For example, there is a silicate one and a half, which weighs only a little more than a standard single - 4.1-5.0 kg.

There is the so-called “American” - with a standard single size and a weight of only 2.5 kg. Lightweight versions can be used in case of insufficient bearing capacity of the foundation. Although, it is better to use a lighter finish - facade slabs, for example.

Basic weight of red brick

It is impossible to say unambiguously what red brick weighs, since there are several modifications of this product, and each product has its own overall dimensions and weight.

The solid brick model contains a minimum of voids (up to 13%), it has high density, strength and weight greater than models of the same size, but with the presence of voids. The weight of one red solid brick, standard size, is in the range of 3.5 – 3.8 kg. Accordingly, the volumetric weight of such bricks is 1700 kg/m3 - 1900 kg/m3. But there may be samples weighing 3.2 kg and 4.1 kg

Decent strength, low thermal conductivity and high sound insulation are provided to the walls by another type of red brick - hollow. It has standard dimensions, is made from the same source material (clay), but has voids in its body, cylindrical or slot-shaped. As a matter of fact, the number and volume of voids determine the mass of the lightweight model. The weight of the red hollow brick NF format (size 250x120x65) ranges from 2.5 to 2.6 kg. Hollow brick is optimally suited for the construction of internal partitions on floor slabs.

The red color of the product means the presence of iron in the source material, clay. Depending on the percentage of iron in the clay mass, the color range of the bars varies - from light yellow apricot to dark red. In principle, the composition of clay does not significantly affect the weight of red solid brick. But he is responsible for the physical properties of the piece material and its technical characteristics.

Red brick weight table

Fireclay brick parameters

For the construction of stoves and fireplaces in the area of contact with fire, special fire-resistant bricks are used. In its production, a special type of clay is used - fireclay. That’s why such a brick is also called fireclay. The production process is the same as for building red bricks - molding, drying, firing in a kiln. But, due to the special properties of fireclay, the resulting building material can easily withstand prolonged contact with open fire. There are two brands of general-purpose refractory bricks used in everyday life: ShA and ShB. ShA can withstand temperatures up to 1690°C, ShB - up to 1650°C, all other parameters are identical. Therefore, their scope of application is the same - this is the molding of fireboxes for fireplaces and stoves.

Encode the size of the refractory brick in the number that appears after the abbreviation:

- ШБ-5, ША 5 - 230*114*65 mm;

- ShB-6, ShA 6, ShA 14 - 230*114*40 mm (flying blade);

- ШБ-8, ША 8 - 250*125*65 mm;

- ШБ-9, ША 9 - 300*150-65 mm;

Most often they use ShA 8 or ShB 8. They are the same in length and thickness as the ceramic red brick from which the rest of the stove is made. There is also a wedge-shaped refractory brick - for forming firebox arches and smooth curves in the horizontal plane.

There are two types of wedge refractory bricks:

These are not all the sizes and types of fireclay bricks. You will find more in GOST 8691-73.

Ceramic brick weight

Traditionally, ceramic material made from clay by firing is used for masonry. Briquettes have a lot of advantages - strength, reliability, light weight, the ability to withstand strong winds and precipitation even in climate zones with severe weather conditions.

The weight of the ceramic material reaches 4 kg; this figure can change in accordance with the brick format. If you say how much a brick platform weighs, filled inside, of course its weight exceeds that of a hollow brick, equal to 2.5 kg. A solid building material measuring 250×120×65 weighs 3.5-3.8 kg. If we are talking about double material, the mass is even greater.

Clinker brick

Clinker brick is another special type of ceramic brick. In its manufacture, a special type of clay is used - refractory shale. The molded blocks are fired at a very high temperature - 1200°C. As a result of this processing, the clay acquires the properties of ceramics, the color ranging from dark red to rich brown.

Clinker brick has very high strength and abrasion resistance. You can use it to pave roads or decorate porches. And they will serve for centuries. The surface of the clinker is flat, smooth, shiny. This allows it to be used also as a finishing brick - for finishing facades, etc.

The shape and size of clinker bricks can be very different - there are a lot of them, since there are not only standard ones - in the form of a parallelepiped, but also with beveled at different angles, rounded edges.

Sand-lime brick weight

Sand-lime brick is used to construct load-bearing and front walls and partitions. The main advantage of the material is the high level of noise insulation and the density of the material structure.

Due to the structure of silicate products, one unit of solid brick weighs 3.75 kilograms, and one unit of hollow brick weighs only 3.25 kilograms. This is one of the parameters that affects the weight of 1 m3 of brick. Solid working brick is characterized by weight indicators:

- 1905 kg/m3 – single.

- 1591-1896 kg/m3 – one and a half.

The working hollow material is lightweight:

- 1639 kg/m3 – single.

- 1401 kg/m3 – one and a half.

- 1306 kg/m3 – double.

Sand-lime brick

Sand-lime brick follows ceramic brick and has become increasingly popular lately. Such bricks are produced in autoclaves under the influence of excess pressure and the addition of steam, in contrast to the production of ceramic bricks in high-temperature kilns. Sand-lime brick contains about 92-94% sand, the rest is lime 3-5% and various additives 1-2% to improve qualities. Due to this production technology, sand-lime brick gains high strength, becomes a good sound-heat-insulator, and the service life of such bricks increases. The frost resistance of such bricks is guaranteed from 15 to 50 cycles of freezing and defrosting.

Sand-lime brick weight

The weight of sand-lime brick depends on its type:

- The weight of 1 hollow one-and-a-half silicate brick 250x120x88 is 3.8-4 kg

- The weight of 1 solid one-and-a-half silicate brick 250x120x88 is 5 kg

Sand-lime brick produced in accordance with GOST #379-53 will be 250X120X65 mm in size, and can have different degrees of strength: 75, 100, 150. The weight of one such brick is 1.8-3.2 kg.

Sand-lime brick lends itself well to coloring by adding various dyes to its composition, which allows you to obtain this type of brick in almost any color.

But you cannot build a foundation from sand-lime brick, because... it is not resistant to moisture, you cannot build stoves, because... this will lead to its decomposition, and it is quite difficult to plaster it, because... This type of brick is very even and smooth, making it easy to paint.

The weight of a brick, it turns out, depends on several parameters at once, first of all its composition, what it is made of and production technology. If you do not want to go into the details of this issue, but want to know the average weight of a brick, then it is 2.5 kg.

Related Articles: Removing Masonry

Ceramic brick weight

The weight of ceramic bricks is about 4 kg. This figure may vary depending on its type, for example, a hollow ceramic brick has many voids inside, which as a result leads to a decrease in its weight. The shape and size of these voids depend on the brick manufacturer.

The weight of ceramic bricks 250x120x65 (hollow) is 2.5 kg.

The weight of ceramic brick 250x120x65 (solid) is 3.4-3.8 kg.

There are other sizes of ceramic bricks, respectively having a different weight, for example, one-and-a-half ceramic bricks 250x120x88 mm, with a different structure of internal cavities. Despite the fact that such bricks weigh about 1.5 times more than ordinary bricks, you will build much faster, due to the fact that per m3 you will put 378 such bricks, for comparison you would have to put 512 ordinary bricks.

There is also a double brick, which weighs 2 times more than usual. Its dimensions are 250x120x103 mm.

One m3 of brickwork weighs about 1500-1800 kg.

Calculating the weight of a pallet is not a problem if you know the weight of one brick. As a rule, pallets contain from 300 to 500 bricks. The pallet weighs 20-25 kg.

The specific gravity of 1 m3 of brickwork depends on the weight of the brick, and varies from 700 to 1800 kg. This parameter must be known when calculating the foundation of a house.

Sand-lime brick weighs more than 1m3 1800-2000 kg.

Related Articles: Strength of Concrete

Ceramic brick

Ceramic brick -

the most standard and very popular type of brick. Ceramic bricks are produced from several types of clay or a mixture of them by firing in a kiln. Such a brick has many advantages, including such important ones as the ability to retain heat, the ability to withstand environmental influences, high strength, low price, low weight, which may not vary significantly depending on the technology of its production, and which is very important for many - this is its environmental cleanliness. Living in a house built from such bricks is very comfortable and absolutely safe for your health.

Volumetric weight of brick

The volumetric weight of bricks also needs to be known during construction.

After all, in reality, the large size of the bricks does not guarantee its large weight. A standard ceramic brick 250X120X65 mm weighs 3.5 kg. A standard ceramic brick with voids 250X120X65 mm weighs 2.3 kg. In this case, the specific gravity is 2600 kg/m3, while the volumetric weight will be 1800 and 1200 kg/m3, respectively.

To select the optimal strength, you need to know the volumetric weight. In order to determine the weight of bricks without taking into account the volume of voids, you need to calculate the specific gravity.

Using the characteristic of the specific gravity of bricks, its strength is characterized, because it does not take into account empty cavities, for example, if you take a brick with 3/4 of the specific gravity, this means that the strength will be reduced by almost 1/4

Table of specific gravity of brickwork

Below is a detailed table to simplify the necessary calculations, including such a parameter as the weight of the brickwork.

Specific gravity and weight of 1 m3 of brickwork depending on units of measurement

| Material | Specific gravity (g/cm3) | Weight 1 m3 (kg) |

| Average value of all types of bricks | 1,7 — 1,9 | 1700 — 1900 |

| Single Ceramic Solid Clay Red Brick | 1,7 — 1,8 | 1700 — 1800 |

| One and a half ceramic solid clay red brick | 1,6 — 1,7 | 1600 — 1700 |

| Double Ceramic Solid Clay Red Brick | 1,5 — 1,6 | 1500 — 1600 |

| Single Ceramic Hollow Clay Red Brick | 1,3 — 1,4 | 1300 — 1400 |

| One and a half ceramic hollow clay red brick | 1,27 — 1,3 | 1270 — 1300 |

| Double Ceramic Hollow Clay Red Brick | 1,1 — 1,27 | 1100 — 1270 |

| Single Ceramic Hollow Clay Red Brick Cladding | 1,2 — 1,7 | 1200 — 1700 |

| One and a half ceramic hollow clay red facing brick | 0,9 — 1,05 | 900 — 1050 |

| Single silicate solid white brick | 1,8 | 1800 |

| One and a half silicate solid white brick | 1,7 — 1,8 | 1700 — 1800 |

| Single silicate hollow white brick | 1,7 | 1700 |

| One and a half silicate hollow white brick | 1,5 | 1500 |

| Double silicate hollow white brick | 1,4 | 1400 |

| Single silicate hollow white brick facing | 1,5 — 1,7 | 1500 — 1700 |

| One and a half silicate hollow white brick facing | 1,3 — 1,5 | 1300 — 1500 |

| Single solid fireclay brick | 1,7 — 1,9 | 1700 — 1900 |

Characteristics of red sand-lime brick

This is how experts describe the composition of red sand-lime brick:

- 92-94% sand;

- the remaining part is impurities.

The advantages include excellent thermal and sound insulation, extraordinary strength and resistance to minus temperatures. A pallet of silicate material is determined depending on its category:

- if there is emptiness inside, a fragment with dimensions 250 × 120 × 88 is 3.9 kg;

- if it is filled inside, the weight increases to 5 kg;

- 250x120x65 equates to 3.7 kg, as for the hollow material, its weight is 3.2 kg.