What quantity?

Having these data, you can clearly and effectively calculate the amount of non-ore matter and the proportions of the binder (cement) in the bags.

Almost all companies that produce and package cement use multi-meter paper containers as a basis, the capacity of which most often does not exceed half a ton.

But due to the fact that the solvency of the population has decreased significantly, different packages of cement can be found on store shelves.

Moreover, they are all equally popular among buyers. Taking into account the above, a person who plans to carry out certain repair work often has difficulties mixing concrete.

You just need to correctly calculate the bags of cement and not purchase something extra, because this will certainly lead to additional unnecessary waste. Despite this, the most popular, purchased and accessible volume is considered to be 50 kg.

50 kg bag

Initially, it is most optimal for carrying out manual, loading and unloading work. Such an acquisition is commercially profitable.

So how much material is there in question?

High-quality, freshly produced cement GOST 31108 is a matter with a fairly loose structure that consists of a number of small particles; they look like dust. Microscopic air particles can be found in between.

Cement

Cement in a loosened state is characterized by a bulk density in the range of 1100-1600 kg/m3. This indicator becomes the basis for the percentage of cement in the prepared mixture, which will ultimately affect the strength of the solid solution.

To simplify the calculations, the bulk density is taken as one thousand three hundred kg/m3, respectively, in a fifty-kilogram container the identical mass of cement is 42 liters.

If we take this indicator as a basis, it will not be difficult to calculate the number of buckets of bags of cement. If we take into account the different indicators of capacitive volumes that will be used for measurements, the indicators for a 50-kilogram bag will be as follows:

- 10 liter capacity – 4.2 buckets;

- 12 liter capacity – 3.5 buckets;

- capacity for 16 liters - 2.6 buckets.

For more information on how many buckets are in a bag of cement, watch the video:

How much cement is in a bucket?

When building a house or laying a concrete path, a question may arise regarding a simple measuring vessel - a standard bucket. How many kilograms of cement are in a 10 liter bucket? Let's try to figure this out.

Bulk density of cement

To find out the mass of a material, in our case cement, in a certain container, you need to know its bulk density. This indicator can be found in the quality certificate, or it is written on the bag of cement.

Calculating how much cement is in a 10 liter bucket is quite simple. You need to take the average bulk density and multiply it by the volume of the vessel. It is generally accepted that the average bulk density of cement is 1300 kg/cm3.

Now we can calmly make the calculation.

1300*10=13 kg.

That’s exactly how much, that is, 13 kilograms, a cement volume of 10 liters weighs.

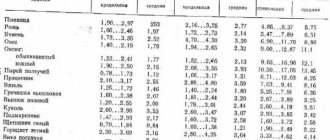

Average bulk density of different components and materials

Unfortunately, the bulk density cannot always be found on the packaging. And if you need to find out this property for several components, you will have to search for a long time on the Internet. For convenience, we provide a list of the most popular components and materials with their bulk density.

- Cement (in a loose state) - 1100-1200 kg/m3;

- Cement (in a compacted state) - 1500-1600 kg/m3;

- Cement (average value) - 1300 kg/m3;

- Sand (average value) - 1400 kg/m3;

- Crushed stone (slag) - 800 kg/m3;

- Gravel (fine) - 1700 kg/m3.

It is worth remembering that the bulk densities presented above are average. They are taken based on statistical averages. There may be special cases in which the bulk density will differ significantly.

Mass in different volumes

Usually a simple bucket is used for measurement, and only then they take on concrete mixers and other tools. Not everyone may have a bucket with a volume of exactly 10 liters on hand. Don’t be afraid, because as it turned out earlier, calculating the mass is quite simple.

So, you can calculate how many kilograms of cement are in a 12 liter bucket.

To do this, let’s go back to the average bulk density of cement and calculate everything.

1300*12=15.6 kg.

To avoid getting lost in all these calculations, a list can again come in handy.

- Cement (in a loose state) - 11-12 kg;

- Cement (compacted) - 15-16 kg;

- Cement (average value) - 13 kg;

- Sand (average) - 14 kg;

- Crushed stone (slag) - 8 kg;

- Gravel (fine) - 17 kg.

All data on the mass of components are calculated for a 10-liter bucket, since this is the most standard volume.

Thus, calculating the mass of the required material or component in a bucket is quite simple. To do this, you only need to know the bulk density and have a little understanding of mathematics.

salecement.ru

What is the importance of correct calculations

Cement mortar is often used for the construction of houses and repairs of massive objects, residential and non-residential building stock, as well as for minor work around the house.

As a rule, when repairs begin, an ordinary person does not know all the intricacies of calculations . He is not able to combine the amount of material used that is necessary to complete the construction work. This entails additional money spent and a waste of time.

You can roughly calculate the amount of material that will be needed. The basis here is the area of the object being processed. With cement the issue is much more difficult.

Decorative plaster "Bark beetle" began to be used quite often during the finishing of houses and various buildings. Here is the technology for applying it.

Frost-resistant tile adhesive can be used both outside and inside unheated rooms. Here is everything about the composition and popular manufacturers of this material.

Cement is the main building material in the manufacture of reinforced concrete and concrete products, as well as various mortars. By clicking on the link you will learn what cement is made from.

The container does not indicate the percentage of water in which the material in question should be diluted; the packaging displays only the weight of the mixture, which is in dry, powdery form.

But all recommendations and tips for carrying out repair work indicate the ratio of mortar in the equivalent of the container required for you.

Accordingly, in order to prevent unnecessary waste of money and time, it is necessary to carry out independent calculations of the amount of dry cement that is needed to prepare the solution. Powdered cement cannot be stored for long.

As a result of prolonged exposure to a room with high humidity, or when the bag is left open for a long time, the cement cakes and becomes an unusable lump.

In this case, it can no longer be used for construction and repair purposes. Therefore, at the stage of screeding the floor, concreting a garden path, creating a foundation for a future structure, or laying bricks, it is simply necessary to carry out all the calculations regarding the amount of cement mortar required.

In this case, it is not the weight that should be taken into account, but the volume.

How many liters of concrete will be produced from 50 kg of cement?

To find the correct answer to this question, you need to remember your school physics classes. As a rule, the material discussed in the article is sold in hermetically sealed paper containers. As stated above, the packaging and quantity of cement used may vary .

To prepare a liquid mortar used in construction, it is necessary to calculate the volume of cement in m3. Cement powder is selected by density, which in turn depends on the conditions under which it was stored and transported.

Characteristics

If we take into account the average indicators, they vary from a thousand to 1600 kg/m3. Such a colossal difference in density is explained by the fact that the material contains impurities and various chemical elements.

The composition of the powder itself includes 80-85 percent of a mixture of sedimentary rock, which contains lime, fine-grained sedimentary rock and other chemical components that are burned during exposure to elevated temperatures and become powder.

Most mixtures are several times smaller in volume than ready-made solutions because during grinding any composition will be filled with N2 and O2. When cement is not used for a long time, N2 and O2 begin to evaporate, and the material itself hardens. At the same time, its density begins to increase as much as possible.

weight of 1 m3 of solution m100

Weight of solution cube

In the Welcome section, the question is how many m3 is in 700 kg of ready-mixed cement masonry mortar? asked by the author Olga, the best answer is approximately 0.38 m3... The weight of 1 cube of solution directly depends not only on its components, but also on humidity. According to GOST, based on average density, solutions are divided into light and heavy. Light mortars include mortars with a volumetric weight of less than 1500 kg/m3. Heavy solutions, accordingly, include solutions with a volumetric weight of more than 1500 kg/m3. Heavy mortars are prepared using aggregates with a volumetric weight of more than 1200 kg/m3 and when hardened they have greater strength and density. Lightweight solutions, due to the presence of many air pores, have lower thermal conductivity. The weight of a cube of solution also depends on the size of the filler grains, as well as on the granulometric composition - the ratio of the filler grains by size. The greatest volumetric weight of the filler and, as a consequence, the solution will be if a certain ratio is observed between the number of grains of different sizes. For example, 1 m3 of sand with grains with a diameter of 1 mm weighs about 1400 kg, and a mixture of grains 0.15–5 mm already weighs 1600–1700 kg. And if you consider that sand is not the only type of filler, then we can conclude that that the weight of a cubic meter of a complex solution can only be determined experimentally, by weighing vehicles, or approximately using tables:

Original source https://sv777. ru/index.php/ves-stroiematerialov/skolko-vesit-kub-rastvora.html (remove the space before ru)Answer from 2 replies[guru]

Hello! Here is a selection of topics with answers to your question: how many m3 is in 700 kg of ready-made cement masonry mortar?

Answer from 2 replies[guru]

Hello! Here are more topics with the answers you need:

Answer the question:

22oa.ru

Stamps

The final volume indicators are also affected by the grades of the material in question. The marking is based on the ability of the finished dried and established mortar to withstand the load of other materials that were used during construction.

If you find an abbreviation or letter on the package, it symbolizes the percentage of additives. The indicator indicates the load that cement can bear during operation. For example, cement M 400 will withstand the corresponding load without any problems.

M-400

Thus, marking numbers inform the buyer about performance characteristics, which take into account the durability and flexibility of materials in ready-to-use form. At the testing stage, pressure is applied to the cube, which is formed from the material discussed in the article, with the required mass.

During this process, the material begins to deteriorate. Accordingly, the final indicator is considered the desired number. In other words, cement grade M-500 will withstand the corresponding mass pressure per cm3.

M-500

Volume calculation

Freshly made cement is always characterized by a lower density than that which has been on store shelves for a long time. Therefore, the indicators considered are also different. According to the construction standards that were signed and are still in force since the times of the USSR, the volume of cement containers weighing fifty kg was determined to be 0.0038 m3.

Volume can be calculated using the formula: weight indicators divided by average density. Working with the same formula, you can calculate liters of concrete. The basis is freshness, brand, storage conditions and delivery.

If it is necessary to calculate the number of buckets that will be required to lay the foundation or plaster of a large area, then, based on the formula described above, the volume in liters is taken as a basis, depending on the capacity of the container.

From fifty kg of dry cement mixture for work you will get:

- for a container with a capacity of ten liters it will be 2.4 kg, that is, about 2.5 buckets;

- for a container with a capacity of twelve liters it will be 3.8 kg, that is, approximately 4 buckets;

- for a container with a capacity of twelve liters it will be 3.2 kg, that is, approximately 3 buckets.

For the production of concrete, different proportions are calculated. The basis should be the scope of application of the composition, what will happen as a result. To carry out foundation work, the density of the material used must be at least 2000 kg/m3.

The percentage ratio of cement, Al2O3 and Fe2O3 and gravel is 1:2:3. If you substitute the indicators into the formula, you will end up with three hundred kilograms. Knowing the specific density of concrete, which is equal to 2400 kg/m3, you get: 300 divided by 2400 = 0.125 m3.

Types of raw materials

The assignment of concrete to a specific grade depends on its density, which in turn is determined by the manufacturing technology.

Easy

The composition, which, along with standard components, includes a porous filler:

- expanded clay

- perlite

- tuff

- pumice

- gypsum

The low density of these materials affects how much a cube of concrete made from them weighs. The range of densities of the finished product is from 500 to 2000 kg/m3.

The low density of the material is due to the fact that its structure contains many large pores.

When constructing walls, such material is not used due to its lightness. But it is used as a heat-insulating material.

Its advantages are as follows:

- Low thermal conductivity - the pores in the material are filled with air, which conducts heat very poorly. Accordingly, the material is used as insulation for walls.

- Light weight in the same volume - this quality gives several advantages: it is easy to transport, the foundation from it does not need to be reinforced with additional materials, and it is also quite easy to raise it to a height.

- High sound insulation is also associated with the microstructure of the material - the sound wave is significantly weakened when it enters the pores and is reflected from numerous walls.

- Since the material has a large porous structure, it is easy to work with – install, cut.

Such properties, along with high strength, make it possible to use it not only as insulation, but also in the construction of load-bearing walls.

Along with its advantages, the material has disadvantages, which are also explained by its structure - large pores easily absorb moisture, as a result of which it loses its strength over time.

NOTE. When purchasing lightweight concrete, it is best to choose brands that contain pumice - this material significantly reduces the absorption of water by concrete, so this material will last much longer.

Heavy

Heavy concrete as an additional component includes rocks such as:

- gravel

- granite

- marble chips

The latter is used much less frequently due to its expensive price. The presence of such dense fillers determines the large weight of a cubic meter of concrete. The range of its density values is from 1800 to 2500 kg/m3 .

Features of the composition affect the structure. The content of large fractions of granite or gravel significantly compacts the material and increases its wear resistance. The essence of this phenomenon can be clearly seen from the diagram below, which shows the structure of light, heavy and especially heavy concrete (from left to right).

Advantages of the material:

- Strength - these are the fractions that are most often used in the construction of foundations for multi-storey buildings and any complex structures, the stability of which requires a high resistance of the material to compression.

- Water resistance - since the pores are obscured by fractions of the heavy component, significantly less water penetrates into such material than into light analogues. Accordingly, the service life of the material increases significantly.

- This material also has low thermal conductivity and dampens sound well.

The degree of strength of different brands of heavy material depends on the content of different components per 1 cubic meter. Accordingly, several strength classes of the finished material are distinguished. You can understand the differences from the comparative table.

The strength class also affects the weight of a cube of concrete (the higher the class, the greater its density).

Extra heavy

This class of materials is used in the construction of special structures that require exceptional strength of load-bearing structures. For example, the walls of a nuclear power plant require not only the reliability of the materials from which they are made, but also their high density, which protects the surrounding area from harmful radioactive radiation.

The density of such material determines the extremely high weight of a cubic meter compared to all other brands (from 2500 to 3000 kg/m3) . Along with standard components, it includes:

- barite (its density is about 4500 kg/m3)

- magnetite (4900-5200 kg/m3)

- limonite (3300-3900 kg/m3)

- cast iron shot (6500-7000 kg/m3)

- steel fragments (7800 kg/m3)

It is the waste from the production of steel and cast iron that determines the property of such concrete to reflect radiation. The thickness of walls with these components is significantly lower than without them.

How much solution will be produced from 50 kg of cement?

Cement mortar is a material for construction, which in total consists of the following elements:

- cement of different brands, like a base that connects other elements;

- Al2O3 and Fe2O3 are fillers. Depending on the purpose of the solution, they can be river, quarry, or alluvial;

Gravel and crushed stone

- H2O is like a solvent.

In this case, depending on the purpose, a different ratio of ingredients should be taken as a basis . For example, to prepare a solution that will be used as a base for floor screed, the following proportions are used:

- M 400 or 500, weighing fifty kilograms;

- three bags of Al2O3 and Fe2O3 (one hundred and fifty kilograms);

- H2O – half of the amount of cement used.

Without a doubt, the prescribed indicators are relative, and if we take the practical side as a basis, they must be adjusted. This will depend on the required brand of mortar , which corresponds to GOST standards, class of cement, Al2O3 and Fe2O3 indicators and other components.

The “other components” include the use of additives - substances that are added to the composition of polymer materials. The latter have a great impact on the proportions and other ratios of the components that make up the solution.

If it happens that repair work will be carried out on a private property, the prescribed indicators will be enough to implement everything from a practical point of view.

At the finish, from a purchased container of cement weighing fifty kilograms, you can get a little more than 0.2 m3 of solution.

Another popular type of mortar is a material used to seal cracks and uneven areas on the wall. For this case, the solution should be mixed in proportions of fifty to fifty. Only water and cement without filler (Al2O3 and Fe2O3) are used. In this case, 0.1 m3 of ready-made solution is obtained from a bag of cement.

Cement bag volume

The result of the calculations is the volume of cement in a 50 kg bag. Having determined the volume of cement powder in a standard package, it is easy to calculate how much concrete mortar will be made from it.

To do this, you must proceed in the following order:. The volume of concrete mixture varies for different types of concrete. Let's consider concrete based on grade M cement. Its volume increases from 0. m3 for concrete grade M to 0. m3 for mortar grade M. In the field of housing construction, M cement or cement M is usually used. When constructing critical structures in the industrial and road sectors, cement M and higher.

The amount of cement required for the preparation of building compositions varies depending on the marking and purpose.

What is the volume of cement in a 50 kg bag, calculation rules, formula

If you need to calculate how much mortar is required per 1 m3 of brickwork, you should convert the weight ratios of the ingredients into volume ratios. A cube of concrete will require 6 bags of cement, 95 buckets of sand and 23 buckets of water. The amount of material is indicated subject to dosing of the specified ingredients in 10 liter buckets.

When calculating concrete or determining the need for material for masonry work, screeding or plastering, the procedure for performing calculation operations should be followed: The result of the calculations is the amount of concrete solution to perform specific work.

Recent Entries

During the construction process, it becomes necessary to determine how much a cube of concrete weighs. The mass varies widely depending on the brand of concrete mixture and is:. The accuracy of the calculations performed is influenced by a number of factors:. Qualitatively performed calculations allow you to correctly determine the amount of raw materials required for the preparation of concrete.

When using the volumetric proportion of components, it is necessary to know the actual volume of cement packed in bags. Having mastered the calculation methodology, it is easy to determine the amount of materials to prepare a strong concrete mixture.

How many buckets and how many liters of volume are there in a standard 50 kg polypropylene bag?