Main characteristics (GOST 530–2012):

- Surface - corrugated;

- Frost resistance from 25 cycles;

- Water absorption 12–14%;

- Thermal conductivity - 0.44 W/m×C.

| Weight | 3,2–3,3 |

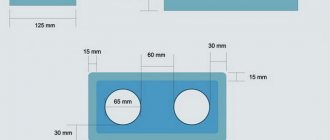

| Size | 250×120×65 |

| Number of pieces on a pallet (laying method): | |

| "Herringbone" | 336 |

| "Plastic bag" | 327 |

Products (bricks) are supplied on pallets measuring 1300x750 mm.

We pack the products in shrink film using the “package” laying method.

Carriage delivery rate: bricks and ceramic stones - 56–60 pallets.

We deliver by road and rail.

All products are made from environmentally friendly raw materials!

Ceramic brick

To make ceramic bricks, clay is used, which is fired in special ovens at high temperatures. There are two subspecies of it - solid and hollow brick. Solid contains a percentage of voids less than 13 and has a density of 2000 kg/cub.m., and hollow - from 1100 to 1400 kg./cub.m. Due to its high density, solid brick is used to construct load-bearing structures of buildings, which bear a huge load. Hollow brick is used for the construction of lightweight external walls, and also fills frames with it.

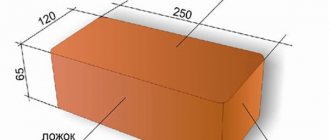

The photo shows ceramic bricks.

GOST standards

The characteristics of GOST 530-2012 include many parameters. It is worth highlighting several main points:

GOST 530-2012

- density - depends on the class indicator of the building material (for example, 0.8 - up to 800 kg/m3);

- thermal conductivity - according to GOST, is assessed exclusively in dry mode;

- strength - its determination is influenced by the possibility of bending and compression of the product;

- moisture absorption - this parameter of quality products does not exceed 6%;

- frost resistance - ceramic material must withstand the lowest possible temperatures.

GOST specifies methods for testing bricks to determine quality. During testing, the compliance of the declared dimensions of the voids and the product itself must be determined. After all requirements are met, the building material with the certificate is ready for sale and further use.

Related video: Ceramic brick - its pros and cons

Publications on the topic

Standard sizes of one and a half bricks

Overview of the capabilities and technical characteristics of the Akros 530 combine harvester

Pros and cons of ceramic bricks

Sand-lime brick

Water and a sand-lime mixture are used as the basis for the production of this type of brick. Sand-lime brick is classified into the same subtypes as ceramic brick. Solid sand-lime brick has a concentration of 1800 to 1950 kg/cub.m. The concentration of hollow sand-lime brick ranges from 1100 to 1600 kg/cub.m. Sand-lime brick differs from ceramic brick in a lower degree of water resistance. In this regard, it is not recommended to use it for the construction of partitions and load-bearing walls. A significant change in shape when heated makes sand-lime brick unsuitable for laying stoves. The main advantage of this type of brick is its low cost and the likelihood of obtaining different color schemes.

Sand-lime brick M-150 on a pallet.

Description of the red sample

There are several parameters that can characterize a brick.

- Strength is a parameter that indicates how much a brick can withstand loads without changing shape. The parameter is designated by the letter “M”, which indicates strength. The values next to the letter go from 25 to 300. This means how much load it can handle.

- Frost resistance is a characteristic that shows how resistant it is to temperature changes in winter. More precisely, this indicates how well the brick tolerates moisture saturation, as well as further thawing and freezing. The brick is marked according to this principle with a letter and a number, for example, F-15, F-35. The figure indicates how many freezing and thawing cycles a brick can endure, without changing the shape or quality of the material.

- Thermal conductivity is an indicator that indicates how much a brick is able to retain heat indoors. This characteristic is also indicated by a special coefficient. The lower the coefficient, the higher the heat-saving properties.

- Fire resistance is the most important and important characteristic. The material itself is fireproof and can withstand very high temperatures.

Fireclay brick SB 5 sizes and other data are indicated in the article.

The video shows information about the sizes of red solid bricks:

Standard width and thickness

Everyone who deals with brick should know its dimensions. In the construction world, there are sizes developed to standards, as well as custom sizes.

The standard dimensions of red corpulent are as follows: length is 2.5 cm, width is 1.2 cm, thickness or height is 65 mm. Additionally, it is worth knowing how much a solid red brick weighs.

Instead of facing bricks, you can use plastic facing panels for bricks, more details about which can be found in the article.

Of the many sizes offered, this is considered the most convenient to use. During the construction process, the bricks are placed perpendicularly, so longitudinal sides alternate with transverse ones. Please note that the sizes are almost double multiples of each other. Due to this, the arrangement is as convenient as possible; there is no need to saw the material.

The photo shows the dimensions of the red solid brick

One-and-a-half is also used . The width and length will be the same as those of standard bricks, but the thickness will be twice as different. The thickness of the stone is 88 mm. There is also a double pattern. Its thickness is 138 mm. These types of corpulent ones are considered the most common. Less commonly found in European sizes. Length 25 cm, width – 8.5 cm, thickness – 6.5 cm. Its weight is much less, it is easy to install. Usually non-standard sizes are used as decorations for roofs and facades. The decorative component is the main purpose of such a sample.

Specific gravity according to GOST

How much does it weigh? Solid red should contain a maximum of 13% voids, so its weight is quite high compared to hollow models. If the model has standard dimensions, then the weight of one brick will be from 3.5 kg to 3.8 kg. As a result, the volumetric weight is 1700 or 1900 kg/m3. But there are exceptions to every rule, so you can find models weighing 3, 2 kg and 4 kg. The weight of a non-standard one-and-a-half brick lies in the range from 4 to 4.2 kg. And the weight of a double is from 6.6 kg to 7.2 kg.

You can learn about the disadvantages of sand-lime brick from this article.

If you use a hollow facing brick, which is made according to GOST 530-2007, then its weight will be 1.32 - 1.6 kg, and the weight of one and a half is 2.7 - 3.2 kg.

But when carrying out construction work, few people are interested in the weight of an individual red brick or the weight of white sand-lime brick. Usually they focus on the weight of the entire wall. It is very important that the foundation of a red brick house can support the weight of the house itself. One, or rather its weight, is fundamental in order to accurately know the weight of the walls that will rest on the foundation. For one square meter you need 51 pieces when taking into account the seams. Usually the thickness of the walls is one and a half. To find out the total weight, you need to multiply it by the weight of one brick and the weight of the mortar. This is how the developer finds out the weight of a wall of 1 square meter.

You can find out the dimensions of the red brick stove from the article.

If the builder knows the weight of one object, then a specific model can be selected. At the same time, you must know for what purposes you want to use it.

Application

The area of use of solid bricks is wide:

- Application for the construction of a basement . Since this part of the building is subject to the constant influence of all precipitation and wind, solid red brick will be an excellent option for development.

- It will be indispensable for foundation construction . Constant dampness and moisture affect this part of the building. Solid brick tolerates such conditions well.

- Construction of stairs outside the building . It is used in this area due to the fact that its dimensions are suitable, and it can also be divided into parts. If the staircase is placed outside, then in any case it will be influenced by mechanical influences and environmental conditions. The corpulent ones are difficult to influence, so deformation is not a problem for them.

- During the construction of elevator shafts and chimneys, brick is able to withstand heavy loads.

- Masonry of stoves and fireplaces . The strength of stove bricks should be at least M-150 if you decide to build a stove or fireplace.

You can find out what composition of mortar is needed for laying brick stoves from this article.

In the video there is a solid red facing brick:

Clinker brick

Clinker bricks are widely used for work related to cladding the basement or façade of a building and paving the road surface. The basis for its production is red clay, which is fired at very high temperatures. This provides the brick with excellent wear resistance and high density. The concentration of clinker bricks ranges from 1900 to 2100 kg/cub.m. Among the disadvantages of this type of brick are its low thermal insulation characteristics at a fairly high price.

This is what clinker brick looks like

Now, having become familiar with the main types and properties of bricks, we can draw a definite conclusion that the choice of this product must be approached thoughtfully, clearly understanding its purpose. After all, it will depend on how correctly you can determine the main and one of the most important properties - the density of the brick. The right solution will ensure an increase in the service life of the structure and its level of strength.

Facing brick

Used for masonry on the outside of buildings. High demands are placed on its appearance. The brick must be even, smooth and glossy. It itself is hollow, due to which it performs 2 functions. The outer layer of brick is both decorative and insulating. For external masonry, material of various shades is used. A variety of colors is achieved through the use of different firing technologies, temperature conditions and composition of clay masses.

The density of facing bricks ranges from 1300 to 1450 kg/cm3, and porosity can reach 14%. This is enough to ensure a high level of strength, but at the same time do not forget about the thermal insulation properties. The requirements for frost resistance of the material are high, since it is constantly in contact with the external environment.

Table of properties of popular wall materials

| Material | Density kg./m.3 | Heat pipe. (W/m.0C) | Required wall thickness, m. |

| Solid brick | 1600 | 0,56 | 1,68 |

| Hollow brick | 1100 | 0,35 | 1,05 |

| Ceramic porous block | 800 | 0,2 | 0,6 |

| Aerated concrete (gas silicate) | 500 | 0,12 | 0,36 |

| Expanded clay concrete | 900 | 0,2 | 0,6 |