HOW MUCH DOES A WHEAT GRAIN WEIGH: How much does 1 cube of wheat grain weigh?

There are many varieties of wheat and the weight of the grains in them will differ. Also, a lot depends on the soil where the wheat grows and on many other factors. When carrying out such work, it is necessary to take into account the climatic conditions of a particular region, the mechanical composition of the soil and the presence of nutrients in it.

If we talk about wheat, then one grain weighs approximately 35-40 mg. It all depends on the variety and quality of wheat. In this case, the bulk density of cereals and the specific gravity of wheat grains. The bulk density of cereals, wheat and the specific gravity of grain in physics are usually measured not in kg/m3 or in tons/m3, but in grams per cubic centimeter: g/cm3. Visitors to the site, when asking how much 1 cubic meter of wheat or rye weighs, often indicate specific units of mass in which they would like to know the answer to the question.

How much does 1 cubic meter of wheat grain, derti, cereal, grain weigh, the weight of 1 m3 of wheat grain, semgrain. The definition of nature arose at a time when grain was sold by volume (in measures - a quarter, a quadruple, etc.). The definition of nature served in those days to convert volumetric measures into weight ones. 1 cubic meter of wheat grain (1 cubic meter of cereal, 1 cubic meter of cereal, 1 m3 of spelled). Here you can carry out simple calculations, for example, thaw a liter glass jar, pour wheat into this container and weigh it again.

We are accustomed to measuring almost all substances, liquids, materials and even gases in cubic meters. After all, their costs, prices, rates, consumption rates, tariffs, supply contracts are almost always tied to cubic meters (cubes), and much less often to liters. 1 cubic meter of wheat grain (1 cubic meter of cereal, 1 cubic meter of cereal, 1 m3 of spelled).

How to calculate the weight of a cubic meter of crushed stone?

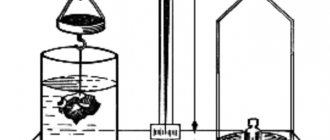

Calculation of the weight of a cubic meter of crushed stone occurs in laboratory conditions. To do this, standard containers of a strictly defined volume are used, into which non-metallic materials are poured, after which they are weighed. Knowing the mass of crushed stone and the volume of the container, experts determine their ratio. As a result of calculations, the bulk density of the material is determined, taking into account the voids between individual grains. The table above shows indicators for different types of crushed stone in accordance with GOST 8269.0-97 standards.

The bulk density of non-metallic materials is the mass of 1 cubic meter. m. It depends on several parameters:

- origin of crushed stone (type of rock from which it is obtained);

- moisture content of the material (when calculating standard indicators, dry bulk materials in an uncompacted state were used);

- fineness modulus (average size of individual grains in crushed stone).

The true density of crushed stone characterizes its strength. For gravel it is 2400 kg/cubic meter. m, for granite – 2600 kg/cubic. m, and for limestone - from 1800 to 2600 kg/cubic. m. But the bulk density (weight of 1 cubic meter including voids) is significantly lower: about 1300–1400 kg/cu. m for granite and gravel, up to 1300 kg/cu.m. m – for limestone.

How much volume does 1 ton of wheat take? Nature, or volumetric weight

Density can be considered as a complex characteristic that summarily reflects such indicators of the physical and chemical properties of grain as structure, chemical composition, weight of 1000 grains, glassiness, etc. The reciprocal of density is the specific volume. Grain density correlates with other indicators. For wheat, it was found that the relationship is satisfactory with glassiness (0.553≤r≤0.696), starch content (0.500≤r≤0.630) and protein (-0.700≤r≤ -0.800).

The milling properties of higher density grains are better. Grain density is significantly affected by humidity, temperature and other factors. Figure III-H shows typical graphs of changes in density ρ (kg/m3) of wheat grains of types I, III and IV under the influence of humidity. The data were obtained by the pycnometric method, using toluene, with evacuation of the pycnometer to evacuate air from the grain. For grain types I and III, there is a moisture region in which the density decreases especially sharply. The density of type IV grains decreases almost linearly. At a humidity of 16...17%, the rate of change in density decreases, this is especially noticeable in type I wheat grains. The study of this phenomenon showed that the decrease in density at 16...17% humidity is due to the structural transformation of the endosperm and, to a lesser extent, to the swelling of the shells and grain as a whole. At higher humidity, the latter factor becomes predominant. For other crops, a negative effect of humidity on density has also been established. Density changes noticeably increase with increasing temperature, both due to intensified changes in the structure of the endosperm and due to the developing swelling of the grain. Figure III-4 shows a series of graphs of the effect of temperature on grain density of wheat of different moisture content. Noteworthy is the presence of a minimum on each curve, the position of which shifts towards lower temperatures with increasing grain moisture. This reflects the complex processes occurring in the grain when moistened. As grain moisture increases, the moisture binding energy decreases and water becomes more mobile. As a result, conditions are created for the swelling of proteins, the development of biochemical reactions, etc.

6-09-2013, 15:07

In kind is the weight of a certain volume of grain or seeds. The current standard unit of volume for this definition is the liter. When determining the nature, the volume is composed of the volume occupied by grain or seeds, the volume of impurities present in a given batch, and intergrain spaces (porosity). Nature is a very variable indicator, the height of which depends on many conditions. The grain is determined on special grain scales called purkas. There are many purka systems, but the USSR adopted the metric purka. The nature of grain is expressed by the number of grams of grain in a volume of 1 liter. Without dwelling on the details of the device of the metric purka, since its description is available in many manuals, we will only indicate the principles of its operation. The grain under study is poured into a cylinder with a volume of 1 liter in a uniform stream. Excess grain over 1 liter is removed. The cylinder with grain is weighed on special scales. The weight of the empty cylinder is known. On the other arm of the scale, it is balanced by a special platform. The weights that must be placed on the scales to weigh the cylinder with grain will show the weight of the grain in grams, or in kind.

The size of the grain, at the same moisture content of the grain, depends on its specific gravity (density), shape, size, etc. The denser the grain is packed in the purka cylinder, the higher its density, the fewer lightweight impurities it contains, the better this batch of grain is . High-quality grain is valued higher. When collective and state farms deliver grain to procurement points, the grain is determined in kind, which is one of the important indicators. Based on materials from the State Commission for Variety Testing of Agricultural Crops, we present natural indicators for wheat grain of various qualities.

It was indicated above that the determination of nature often gives very inconsistent results among different analysts, when studying the same batch in different places, etc. This depends on many reasons: on the methods of filling a liter cylinder, on changes in humidity and contamination of grain, on the nature of its surface. The more densely the grain is packed, the lower its porosity and the higher its nature. Naked breads (wheat, rye) are stacked more tightly than filmy ones (oats, barley). In this regard, the porosity of the latter is higher. The amount of porosity of various crops ranges from 34-68 and is expressed as a percentage of the total volume occupied by grain. At one time, there was a negative attitude towards natural indicators due to the large variation of this definition depending on many conditions, often difficult to take into account. It was believed that this definition could be replaced by a more precise definition of the weight of 1000 grains.

It is not difficult to understand the incorrectness of this opinion.

The low weight of 1000 grains can be determined, on the one hand, by the hereditary small-grain nature of this variety (in Sibirka spring wheat, the weight of 1000 grains does not exceed 18-20 g), and on the other hand, by the underdevelopment of the grain of the large-grain variety due to drought or frost damage. In the first case, with good grain completion, a small-grain variety will show a completely normal or good nature, while a large-grain variety with the same weight of 1000 underdeveloped grains will have a sharply reduced nature. A.I. Nosatovsky has shown in numerous studies that the degree of underdevelopment (shallowness) of grain can be well expressed by the definition of nature. G.I. Donchenko in our laboratory observed a noticeable decrease in the grain quality of wheat when, during separate harvesting, it was exposed to rain in windrows. In many cases, the weight of 1000 grains remained unchanged, that is, there was no loss of substance from the grain. The decrease in nature was explained by the fact that under the influence of rain, the shell of the grain became dull, slightly rough, and this reduced the density of its placement in the purka cylinder. In conclusion, it should be recalled that by the volumetric weight (nature) of grain one can approximately determine the weight amount of grain stored in a bin of a certain volume. Let's assume that the volume of the bin is 3 cubic meters. m, and the grain size is 800 g. In 1 cubic meter. m 1000 l. Consequently, the weight of the grain in it is 800 kg, and in total there are 2.4 tons of grain. Qualitative How much does 1 cubic meter of wheat weigh, the weight of 1 m3 of wheat. The number of kilograms in 1 cubic meter, the number of tons in 1 cubic meter, kg in 1 m3. Wheat bulk density and specific gravity. What do we want to learn today? How much does 1 cube of wheat weigh, the weight of 1 m3 of wheat?

No problem, you can find out the number of kilograms or the number of tons at once, the mass (weight of one cubic meter, weight of one cube, weight of one cubic meter, weight of 1 m3) is indicated in Table 1. If anyone is interested, you can skim the small text below and read some clarifications. How is the amount of substance, material, liquid or gas we need measured? Except for those cases when it is possible to reduce the calculation of the required quantity to the counting of goods, products, elements in pieces (piece counting), it is easiest for us to determine the required quantity based on volume and weight (mass). In everyday life, the most common unit of volume measurement for us is 1 liter. However, the number of liters suitable for household calculations is not always an applicable way to determine the volume for business activities. In addition, liters in our country have not become a generally accepted “production” and trade unit for measuring volume. One cubic meter, or in its abbreviated version - one cube, turned out to be a fairly convenient and popular unit of volume for practical use. We are accustomed to measuring almost all substances, liquids, materials and even gases in cubic meters. It's really convenient. After all, their cost, prices, rates, consumption rates, tariff

pkkonakovo.ru

Mass of a cubic meter of crushed stone of different fractions

The most popular building material is crushed stone as a coarse aggregate for concrete mix or decorative purposes. Due to different technical characteristics, fraction and origin, the bulk mass of crushed stone in the same quantity may differ.

Varieties

Crushed stone is extracted from different rocks, and therefore is divided into several types:

- Limestone - used for low-grade concrete, as well as for the production of lime using a special firing technology. Loose calcium compounds are relatively light, even with the presence of other impurities.

- Gravel - obtained by crushing rocky rocks located in reservoirs or mountains. It is one of the most common due to its optimal strength and low cost.

- Granite is the most durable and durable, but at the same time expensive type. The grains have practically no voids, and the flakiness index does not exceed 5% according to GOST 8267-93. Allows you to achieve maximum bulk density of crushed stone.

- Slag - formed as a result of the processing of various metals. It has a fairly high weight and strength properties.

- Sandstone is mined by processing hard rocks and is widely used in the construction industry.

- Terricone is a black building material that is waste from the coal industry. Due to contamination, it is only suitable for road work.

Factors affecting weight

Each type has certain characteristics that can affect the weight of crushed stone. To determine it when purchasing and using, you should take into account the following parameters:

- Density directly depends on the characteristics of the rock. Gravel is denser than limestone, and granite is considered the most dense, but the value may vary. For example, material from heavy quartz types is much denser than ore mine residues.

- Volumetric weight determines porosity, so this indicator is statistically slightly lower than the previous one. Often it is influenced by factionalism.

- Bulk weight - determines a more realistic mass, since the calculation includes the pores between the stones. It is calculated before compaction in the container.

- Flakiness - pebbles can be not only cuboid, but also needle-shaped or flat. The presence of such inclusions significantly reduces strength and quality.

Basic indicators of volumetric weight

As a rule, the absolute density of crushed stone cannot be determined, which is due to the unevenness of the grains. When filling, voids are formed, their size depends on the fraction: the larger it is, the lighter the bag will be. If you pour small stone into it, the weight will increase due to increased density.

According to current regulatory documents, based on various characteristics, a table is compiled indicating the mass of a cubic meter, as well as recalculation for a standard bucket.

| Name | Specific gravity of 1 m3 of crushed stone, kg | Weight in a bucket 10 l, kg |

| Limestone | 1300-1350 | 12,9 |

| Gravel | 1400-1450 | 14,1 |

| Granite | 1470-1500 | 14,5 |

| Slag | 1500-1520 | 15 |

| Sandstone | 1330 | 12,9 |

| Terricone | 1200 | 11,6 |

| Tuff | 800-850 | 8 |

| Marble | 1550 | 15 |

Weight can also be affected by humidity. Often this figure does not exceed 3% of the total weight of the embankment. As the grain size increases, it can change downward, which can also be considered using crushed granite as an example.

| Fraction, mm | Weight of one cube, kg |

| 0-5 | 1400 |

| 5-10 | 1390 |

| 5-20 | 1360 |

| 20-40 | 1350 |

| 25-60 | 1380 |

| 40-70 | 1340-1350 |

Small crushed stone is superior in weight due to the dense filling of a given volume. When choosing a fraction of 0-70 mm, the density will be the highest and will be 1450 kg/m³. This is due to the fact that the voids between large grains will be completely filled with fine gravel, so the weight is much higher. However, it is difficult to find it in construction due to its generality. Many manufacturers prefer to package crushed stone in specific sizes.

Calculation of mass 1 m3

For example, you can take crushed gravel in a dump truck with a capacity of up to 20 m3. Since crushed stone of the 20-40 mm fraction has a mass of 1.35 t, then a cubic meter weighs: 20 m3 x 1.35 t = 27 t. If the mass of the material is known, you can calculate the volume obtained when using it: 20 t / 1.35 t = 14.8 m3.

When knowing the area prepared for backfilling, it is worth taking into account the compaction indicator. This coefficient is calculated and determined on the basis of certain parameters and varies between 1.05-1.3. Therefore, you should further multiply the result by the resulting compaction index.

Author: Valentin Tokarev

| Related articles: | |

| Crushed stone from gravel rocks with a fraction of 20-40 mm Crushed stone grade M800 Crushed stone fraction for preparing concrete solutions | |