VOLMA-Nivelir Express

SELF-LEVELING, FAST-HARDENING FLOOR

Quantity on pallet:

Description of VOLMA-Level Express

TU 5745-009-78667917-2008 “VOLMA-Nivelir Express” is a dry mixture based on a complex binder, fractionated quartz sand and modifying additives, which ensure high mobility of the solution, strength and optimal operating time.

For manual or mechanized work on leveling concrete and cement-sand floor subfloors indoors for subsequent decorative coatings (linoleum, laminate, tiles, parquet, etc.) with a thickness of 5 to 100 mm. Recommended for use in residential and public areas with dry and normal humidity levels.

The base must comply with the requirements of SP 71.13330.2017, be durable, without peeling, clean, free of dust, dirt and grease stains. The “age” of the cement-sand base must be at least 28 days, and the concrete base – at least 3 months.

Before pouring, you need to secure the damper tape around the perimeter of the walls and columns where they meet the floor. Protect all metal elements in contact with the mixture solution from corrosion.

The required thickness of the future layer is established using portable benchmarks and a leveling ruler. Mark areas to fill the floor. If the area to be leveled is more than 50 sq.m. and with a diagonal of more than 10 m, an expansion joint should be installed in the floors and always above the existing joints in the load-bearing foundation. The base of the floor and the areas of the walls that will be in contact with the self-leveling floor must be treated with Volma “Universal” primer 2-3 times. You can start pouring the self-leveling floor after the primer has completely dried.

For manual application: pour the dry mixture into clean water (water temperature from +5 to +20 ºС), based on the proportion of 0.29 - 0.34 liters of water per 1 kg, and mix using a professional mixer or drill with an attachment until homogeneous mass for 3-5 minutes. Let the solution sit for 3 minutes and then mix again. Do not overdose on water!

To check the consistency, pour 1.0 liters of solution onto a flat, non-absorbent base (for example, glass, film, foil). The diameter of the spot should be 50-55 cm.

For machine application: pour the dry mixture into the hopper of the machine (unit) and, by adjusting the water flow, select the required consistency of the mixture.

Checking consistency: pour 1.0 liters of solution onto a flat, non-absorbent base (for example, glass, film, foil). The diameter of the spot should be 50-55 cm.

1. Pour the prepared solution of the Volma-Nivelir Express mixture evenly to the required thickness, avoiding breaks of more than 10 minutes.

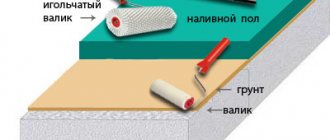

2. Then, starting from areas adjacent to the walls and columns, remove air bubbles from the solution using a 1 m or 2 m needle roller or construction mop. Movements of the construction mop are carried out along and across the poured surface, creating a “wave”.

3. The time for pouring the Nivelir Express self-leveling floor depends on the conditions (temperature, humidity, base absorption, layer thickness) and is no more than 40 minutes.

4. During hardening of floor mixtures with complex binders, drafts and direct sunlight should be avoided during the first two days. Then provide natural ventilation and ventilation of the premises without using heat guns. In winter, do not allow the room temperature to drop below +5° C.

5. The drying time of the self-leveling floor depends on the thickness of the layer, temperature and humidity in the room.

6. Laying of decorative coating on a leveled floor can be done no less than 7 days after pouring. The residual moisture content of the poured floor when laying the subsequent coating should not exceed 1%.

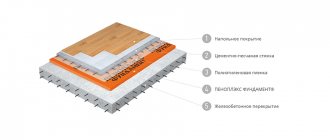

"VOLMA-Nivelir Express" is ideal for working in a "warm floor" system.

The minimum layer when pouring a self-leveling floor in a “warm floor” system is 45 mm. If the “warm floor” system is built into the base base, the thickness of the fill is from 5 to 100 mm. The first activation of the heated floor should be carried out no earlier than 7 days after pouring the floor, setting the temperature to 25°-27°C for 2-4 days. Full operation of “warm floors” is no earlier than after 28 days.

Bags of dry mixture “VOLMA-Nivelir Express” should be stored on wooden pallets in dry rooms. Pour the mixture from damaged bags into whole bags and use first.

Guaranteed shelf life in undamaged original packaging is 12 months.

Carry out work in accordance with construction requirements, standards and occupational safety and health regulations.

Leveler Volma coarse 25kg

“VOLMA-Rovnitel rough” is a dry multicomponent mixture, made on the basis of high-quality cement, lime with fractionated natural fillers, modified with polymer and chemical additives, reinforced with fiber. It has low shrinkage, high strength and adhesion to the base. Plastic, frost-resistant, easy to apply, level, and sand. The solution quickly sets and gains strength, which allows you to speed up the work process.

Application area:

“VOLMA-Rovnitel rough” is intended for the initial leveling of concrete and cement-sand floor bases, for creating a flat and durable base with a thickness of 10 to 80 mm (maximum 100 mm), for floor repairs (filling deep cracks and potholes), as well as to give the base the required slope. Can be used indoors and outdoors. Application method: manual.

If necessary, for subsequent thin-layer leveling of the floor, you can use self-leveling floors “VOLMA-Niveler-TOP” and “VOLMA-Niveler-Express”.

Preparing the base:

The base must be dry and durable. Compressive strength not less than 12 MPa, humidity not more than 4%. The “age” of the cement-sand base is at least 28 days, and the concrete base is at least 3 months. The surface must first be cleaned of various types of contaminants and substances that reduce the adhesion of the leveling layer to the base (fats, lubricating oils, bitumen mastics, glue, paints, etc.). Unstable areas of the base, including areas treated with “cement laitance,” must be removed mechanically. Then the base should be thoroughly cleaned of dust. Cracks in the base should be expanded, dusted and treated with VOLMA-Universal or VOLMA-Aqua primer and filled with VOLMA-Rovnitel rough mixture at least 3 days before leveling.

The prepared base should be treated with VOLMA-Universal or VOLMA-Aqua primer and completely dry. The primer prevents drying out and reduces the number of air bubbles reaching the surface of the leveling layer. Highly absorbent substrates (for example, old cement screed) should be primed twice with an interval of 2 hours after applying the first layer. A weakly absorbent base (concrete) is allowed before applying the screed; simply moisten the surface well, avoiding excess water and preventing the formation of puddles.

Preparation of the solution:

To prepare the solution, pour the dry mixture into a container with clean water, based on the proportion of 0.13-0.15 liters per 1 kg, and stir until a homogeneous mass is obtained for 3 minutes. Let the solution sit for 5 minutes and mix again. Mixing is done with a professional mixer, a drill with an attachment at a speed of 400-800 rpm or in a concrete mixer. The prepared solution remains mobile for 2 hours.

Attention!

Avoid overdosing on water, as excess water leads to peeling and loss of mechanical strength of the leveling layer, as well as the appearance of cracks on the surface. The dry mixture contains cement and when interacting with water it gives an alkaline reaction, so it is necessary to protect your eyes and skin when working.

Application:

The mortar mixture is laid with a steel spatula, a trowel and leveled between pre-installed beacons every 1.5-2 m, using a rule strip and a trowel. The correct installation of the beacons is checked with a level or level.

If necessary, after 7-8 hours the surface can be rubbed with a metal or plastic grater.

Drying time:

The leveled surface is suitable for walking after 7 hours at an ambient temperature of +20ºС. At lower temperatures, the time after which walking is possible increases to 12 hours.

The drying time of “VOLMA-Coarse Leveler” depends on the thickness of the layer and the temperature and humidity conditions in the room. Laying ceramic tiles is possible in 7-14 days. Complete drying time is 3-4 weeks. Laying of decorative coatings should be carried out in accordance with the manufacturers' recommendations with mandatory control of the base humidity.

Recommendations:

1. The screed should be protected from drying out too quickly: from exposure to drafts, heating devices and direct sunlight.

2. On an area of more than 36 m2, it is necessary to install anti-shrinkage (expansion) joints.

3. The expansion joints existing in the base should be repeated before laying “VOLMA-Rough Leveler”.

4. It is recommended to install screeds on very wet, contaminated (for example, bitumen mastics, machine oil, etc.) substrates, as well as those with low strength, on a separating layer. When using “VOLMA-Rough Leveler” on a separating layer or in a “floating floor” system, prepare the base according to the recommendations for the installation of a specific type of floor.

5. The temperature of the leveling mixture must not be lower than +10ºС.

The manufacturer is not responsible for non-compliance with technology when working with the material, as well as for its use for purposes and conditions not provided for in the technical description.

Storage conditions and packaging:

The dry mixture “VOLMA-Rovnitel rough” is supplied in 25 kg paper bags, which should be stored on wooden pallets in a dry room. The mixture from damaged bags must be poured into intact bags and used first.

Guaranteed shelf life in undamaged packaging is 12 months.

| Recommended layer thickness | 10-80 mm |

| Maximum layer thickness | 100 mm |

| Consumption at a layer thickness of 10 mm | 18-20 kg/m2 |

| Base temperature Base temperature | from +5 to +30ºС |

| Water temperature | from +10 to +30ºС |

| Amount of water per 1 kg of dry mixture | 0.13 - 0.15 l |

| for 25 kg of dry mixture | 3.25 - 3.75 l |

| Open solution time | at least 2 hours |

| Possibility of walking | 7 o'clock |

| At t = 5-10ºC layer 80 mm | till 12 o'clock |

| Compressive strength after 28 days | not less than 20 MPa, M200 |

| Adhesion strength to concrete base | not less than 0.3 MPa |

| Frost resistance | F50 |

| Pouring self-leveling floors, laying tiles | in 7-14 days |

| Laying linoleum, laminated parquet, parquet boards | in 3-4 weeks |

Dry mixture for final leveling of floors “Nivelir Express”

Self-leveling floor "Volma" is used to form a finishing coating before laying floor finishing materials. The mixture is based on gypsum with quartz sand as a filler. The composition also includes polymer, binder and modifying components that give the solution plasticity. The mixture is used only indoors. The layer thickness can vary from 7 to 100 mm.

Technical characteristics of Volma-Nivelir Express:

- Setting time is from 4 to 6 hours. Varies depending on ambient temperature and indoor humidity levels.

- The adhesion strength to the rough surface is 2 MPa.

- The floors mature completely in a week and a half maximum (depending on the thickness of the layer).

- The finished base can withstand loads of up to 16 MPa.

The price of one package is small - about 100-200 rubles for 20 kg of Volma-Nivelir Express dry mixture. The consumption is also low: with a layer thickness of 10 mm, such mass is enough for 4-4.5 m 2 of surface. Compared to similar formulations of other brands, Volgograd products are much more profitable. At the same time, its characteristics are similar, and in some cases even higher.

COME IN, POUR IT! 10 questions and answers about self-leveling floors

VOLMA self-leveling self-leveling floors are highly appreciated by craftsmen, whose interests are the most comfortable creation of ideal surfaces.

These products are considered quite new on the market compared to, for example, traditional screeds. This is probably why our consumers have many questions when using these materials.

We bring to your attention answers to a number of questions that our technical consultants receive via the hotline or on our website.

Question 1. I filled the subfloor using “Nivelir-Express” and made a mistake in the calculations.

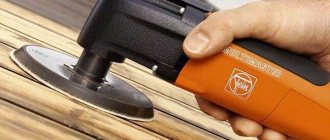

You need to add approx. 10 mm. How long after pouring 1 layer can a second one be poured? Answer: Before pouring, the first layer must be completely dry and primed. The drying process depends on temperature, humidity and ventilation in the room. The approximate drying speed is 5 days per 10 mm of layer thickness. Ventilation can begin a couple of days after pouring. Question 2. Is it possible to lay an electric heated floor on a 3 cm thick screed made with a mixture of VOLMA-Nivelir Express, on which the tiles will subsequently be laid? What is the minimum thickness of the screed in this case? Answer: Yes, it is possible to use VOLMA-Nivelir Express self-leveling floor on a heated base. It is worth considering that if the filling takes place along the separating layer, then the thickness of the self-leveling floor layer is desirable from 35-40 mm. Question 3. Please tell me what mixture of your products I can use to fill a two-wire floor heating cable in a bathroom. Under the cable lies: 3mm thermal insulation and galvanized metal mesh 20x20 mesh. The thickness of the screed is no more than 25mm. The area of the heated floor is no more than 1.4 m2. The warm floor will occupy the middle of the space in the bathroom and at the entrance to it. Answer: To fill the “warm floor” in a room with high humidity (bathroom), I recommend using the VOLMA-Nivelir Arena mixture. By the way, a 3mm layer of thermal insulation, with a high degree of probability, will not be able to work as a thermal insulating layer. You need to be prepared that you will have to warm up the entire floor slab. Question 4. Is it necessary to use a damper tape around the perimeter of the room when filling the floor screed with Volma Nivelir-Express mixture? Screed thickness 35 mm, room area 25 sq. meters. And a similar question for a kitchen of 14 square meters. meters, if you plan to install electric heated floors in it. Answer: Yes. The damper tape is necessary to compensate for the expansion of the solution during hardening. In the absence of a damper, separation of the self-leveling floor layer from the base may be provoked. Question 5. I bought Volma Level Express. They write on the forums that based on experience in using water, you need to add more water than indicated on the package. Is this true? How to eliminate premature setting of the solution? Answer: You need to rely on the recommendations on the packaging. Although exceptions are possible. Under certain (impaired) storage conditions, dry mixtures may slightly change their characteristics. When preparing a self-leveling floor solution, the main criterion for controlling the proportions of water is the spreadability of the finished solution. 1 liter of self-leveling floor Level Express should spread on a smooth, flat surface in a spot with a diameter of 50-55 cm. The adhesion of the self-leveling floor solution can be affected by the strong absorption of the base. To reduce the impact, priming is used. Question 6. How can I remove the excess height of the self-leveling floor after hardening? Layer 2-3mm, Now I remove it with sandpaper. Is it possible to wet the floor a little? Answer: A frozen floor can only be leveled with an abrasive tool. To speed up the work, you can use a coarse abrasive, for example 40, 60 grit. Wetting can worsen the characteristics of the floor itself, it depends on the base. Question 7. In the evening we filled the floor with the Volma Level-Comfort mixture. In the morning, irregularities (swells) were discovered. It is not possible to clean it with a spatula. Can we add (level) the mixture to these places in the morning, will the layer snap off? Answer: It is quite possible to level the first layer of self-leveling floor with a second layer, but taking into account several conditions: - the minimum layer of self-leveling floor required for self-leveling of the solution is 5 mm, — the second layer can be poured only after the first layer has completely dried and it must be primed. Question 8. Is it possible to use the Nivelir Express self-leveling floor directly on top of the floor slabs, without laying a rough screed on them? The differences in level are approximately 3-4 cm. Is laying reinforcing mesh necessary for such differences? What primer and waterproofing is best to use with this type of self-leveling floor? Answer: Using VOLMA-Nivelir Express self-leveling floor directly on the base base is quite acceptable. The condition for application is the absence of visible cracks or unfilled seams. All slab joints must be pre-sealed. Differences in the plane of the base itself of 30-40 mm are acceptable. The only thing that is desirable is that these differences are not linear, for example a groove or a similar depression, and do not significantly exceed the average layer of the overall fill. Reinforcing mesh is not required when pouring a self-leveling floor. For a concrete base, dust removal is quite sufficient. If the seams are sealed with cement mortar, then it is recommended to prime such surfaces with a VOLMA-Universal type compound after they have dried. Waterproofing is only required for wet areas. Question 9. Volma-level: the drying period is written on the bag: 7 days. Please tell me, for a 4mm layer, should it also wait 7 days before laying the laminate, or is the drying time for such a layer shorter? Answer: Under normal conditions, less. You can check the readiness of the layer (drying) with a simple film test. Covering 1 sq.m. for the night. check for condensation in the morning. If there is no darkening under the film, then the floor is dry and you can begin laying the laminate. Question 10. Is Volma Level Express based on cement or gypsum? Answer: The VOLMA-Nivelir Express mixture is created on the basis of a complex mineral binder consisting of gypsum and polymer. Please note that this material uses questions from real consumers of our products (the authors' spelling and punctuation have been preserved). Some of the questions may seem naive, but some will turn out to be quite useful and will be able to warn against mistakes. We hope you found the question-and-answer format interesting. We will be happy to continue sharing our experiences and answering questions. In the wide range of VOLMA you can find a suitable product to solve almost any problem.

Preparing the work surface

For the most part, leveling mixtures, including Volma self-leveling floor, are intended for leveling cement-sand or concrete screeds.

Preliminary preparation of such surfaces includes:

- Cleaning the base from construction debris, dust and dirt.

- Existing cracks are expanded, deformed areas and remnants of the old coating are removed.

- Secondary cleaning of the surface from dust is carried out.

- A layer of deep impregnation primer is applied. This is done only once. It is advisable to purchase a primer from the same manufacturer. The composition is applied using a paint roller.

- After the primer layer has dried, a damper tape is placed around the perimeter of the room.

Preparation of the solution

Volma-Nivelir Express dry mix is supplied in 20 kg packages. In order to prepare the solution, this volume of material requires about 6 liters of clean water. It is advisable to use cold liquid. The viability of the finished Volma-Nivelir Express solution lasts about 60 minutes. The characteristics of the mixture do not deteriorate after this time, but it becomes more difficult to work with. It is advisable to distribute the prepared solution over the surface within an hour. If you plan to process a large area, then initially it needs to be divided into several technological sections.

The volume of water indicated on the packaging of the mixture is poured into a pre-prepared container. Then, gradually and in small portions, dry material is poured from the bag. The resulting mixture must be stirred after 3-5 minutes. During this time, the powder should have time to be saturated with water. Mix the components using a construction mixer or a drill with a special attachment. After the first “shuffle,” the mixture is left to brew for 5-10 minutes, after which it is stirred again. After preparing the solution, you can begin leveling the floors.

Working with solution on the surface

Pour the finished mixture first into deeper potholes and cracks with a gradual transition to hills. It is advisable to do all the work by two people. One will prepare the solution, the second will pour it. To level the composition, a needle roller on a telescopic handle and a spatula are usually used. The length of the spikes should not be less than 30 mm.

The solution poured onto the surface is leveled using a spatula so that the resulting strips overlap each other. Upon reaching the edge of a limited area or one of the sides of the room, the composition is passed several times with a needle roller. This is done to eliminate air bubbles from the mixture, forming a flat surface due to the movement of the solution and vibrations.

Before you start pouring the Volma-Nivelir Express solution, you must close the doors, windows and vents so as not to create drafts. If left unaddressed, they can cause surface cracks and reduce the strength of finished floors.

After four hours have passed since the floor was poured, you can move on it; after two days you can begin laying ceramic tiles. Laminate or linoleum is laid only after the surface has completely dried.

Advantages of Volma self-leveling floors

Products manufactured by the Volgograd company have the following advantages compared to other brands:

- When the dry mixture is diluted correctly, the finished solution has a liquid consistency. The density of the composition can be controlled by adding clean water. Working with the solution is greatly facilitated due to the fact that it is independently distributed over the surface.

- Low price of dry mixture compared to imported brands. Despite this, the composition has proven itself at a fairly high level and has earned popularity among consumers.

- The composition includes polymer components that increase the service life of the coating and increase its strength. After 7-14 days - the full period of hardening of the mixture - the coating can withstand loads of 12 MPa.

- Processing of Volma mixtures is carried out both manually and automatically. Other self-leveling floors are only suitable for one treatment method.

Consumer reviews of products

Dry mixtures of the brand are one of the most popular and widespread among similar products. Many consumer reviews about the Volma-Nivelir Express self-leveling floor emphasize only the positive qualities of the solution - low price, ease of use, average consumption of the composition per square meter of surface, the ability to self-level on the base, high strength of the finished coating. However, many consumers also note that one of the advantages of the composition - fast hardening time - can be classified as a disadvantage. Especially for those who cannot carry out all the work in a short time. Despite this, the finished surface is perfectly flat and suitable for subsequent finishing and laying of floor coverings.

Reviews

The products of the Russian manufacturer of dry construction finishing mixtures are valued for their reliability and high quality, combination with many building materials, and the ability to use with almost any surface. Reviews of Volma-Nivelir Express self-leveling floors note their availability and reasonable price, guaranteed quality and durability of the installed coating.

Similar articles

- Do-it-yourself finishing floor leveling: technology, instructions (video)

To properly lay any floor covering (tiles, linoleum, parquet, etc.), you need to do its finishing leveling. This will help you achieve...

- Do-it-yourself floor screed in a private house: options for making a floor base

Before you make a floor screed with your own hands in a private house when decorating or renovating premises, you need to clearly understand what tasks are required...

- OSB floor slabs, OSB rough layer, required thickness, reviews

The process of processing waste that remains as a result of industrial wood processing is a very promising area that today...

Universal leveler (self-leveling floor) Volma Level Express self-leveling 20 kg

A fast-hardening self-leveling self-leveling floor based on a complex binder, fractionated quartz sand and modifying additives that provide high mobility of the solution, strength and optimal operating time. Designed for leveling concrete and cement-sand subfloors for subsequent decorative coverings - carpet, linoleum, parquet, ceramic tiles. Ideal for use in underfloor heating systems. It is used in all residential premises and public buildings. For manual and machine application. For interior work. For dry rooms.

Gross weight: 20 kg.

Leveler-Self-leveling floor Volma Comfort: pros and cons, characteristics

Self-leveling floor Volma Nivelir Express is a self-leveling and quick-hardening coating that is used only indoors with heating. Suitable for use on concrete and cement-sand substrates in places that are not prone to high humidity.

The mixture can be layered and used with differences from 0.5 to 10 cm. To dilute the solution from a 20 kg bag, you will need 5.8 liters of clean water. Mixing until smooth can be done using a drill with a mixing attachment. Make sure there are no lumps and let the mixture swell for a few minutes, then stir again and start pouring.

Specifications:

| Consumption | 12.5 kg/m²/10 mm |

| Layer thickness | from 5 mm to 100 mm |

| Maximum aggregate fraction | no more than 0.7 mm |

| Amount of water | for 20 kg – 5.8-6.8 l |

| Time to use the finished mixture | 60 minutes |

| Compressive strength after 28 days | not less than 15 MPa |

| Strength of adhesion to the base after 28 days | ≥1 MPa |

| Walking across the floor | 4-6 hours |

| Possibility of laying flooring | no earlier than 7 days |

| Quantity on pallet | 72 pcs |

| Manufacturer | Russia |

You may need

- Rollers

- Whisks for construction mixers

- High rise structures

- Demi-season

- Hand protection

- Protective nets and films

- Bags, packages, boxes, stretch

- Rules

- Painting tables, platforms

- Stepladders

- Construction containers

- Covering materials

- Spatulas, scrapers

According to club card 385

According to club card 306

According to club card 734

According to club card 683

Questions

Clean the supporting base from dust, dirt, lime, oils, fats, wax, and paint residues. Remove loose and loose areas of the base. Place damping pads (tape or thin strips of polystyrene foam) along the walls and columns where the floor meets. Seal cracks and large potholes with Volma Level Express mixed with less water at least 1 day before pouring. Protect steel elements in contact with the self-leveling mixture solution from corrosion. Prime the prepared base and areas of the walls that will be in contact with the self-leveling floor. Prime porous surfaces 2 – 3 times with an interval of 4 hours. Laying the self-leveling floor should be done only after the primer has completely dried.

Base cement floor mixture Volma-Rovnitel coarse 25kg

Base cement floor mixture Volma-Rovnitel coarse 25kg

“VOLMA-Rovnitel rough” is a dry multicomponent mixture, made on the basis of high-quality cement, lime with fractionated natural fillers, modified with polymer and chemical additives, reinforced with fiber. It has low shrinkage, high strength and adhesion to the base. Plastic, frost-resistant, easy to apply, level, and sand. The solution quickly sets and gains strength, which allows you to speed up the work process.

Application area :

“VOLMA-Rovnitel rough” is intended for the initial leveling of concrete and cement-sand floor bases, for creating a flat and durable base with a thickness of 10 to 80 mm (maximum 100 mm), for floor repairs (filling deep cracks and potholes), as well as to give the base the required slope. Can be used indoors and outdoors. Application method: manual.

If necessary, for subsequent thin-layer leveling of the floor, you can use self-leveling floors “VOLMA-Niveler-TOP” and “VOLMA-Niveler-Express”.

Preparing the base:

The base must be dry and durable. Compressive strength not less than 12 MPa, humidity not more than 4%. The “age” of the cement-sand base is at least 28 days, and the concrete base is at least 3 months. The surface must first be cleaned of various types of contaminants and substances that reduce the adhesion of the leveling layer to the base (fats, lubricating oils, bitumen mastics, glue, paints, etc.). Unstable areas of the base, including areas treated with “cement laitance,” must be removed mechanically. Then the base should be thoroughly cleaned of dust. Cracks in the base should be expanded, dust-free, treated with VOLMA-Universal primer and, after the primer has dried, filled with VOLMA-Rough Leveler mixture at least 3 days before leveling. The prepared base should be treated with VOLMA-Universal primer and completely dried. The primer prevents drying out and reduces the number of air bubbles reaching the surface of the leveling layer. Highly absorbent substrates (for example, old cement screed) should be primed twice with an interval of 2 hours after applying the first layer. A weakly absorbent base (concrete) is allowed before applying the screed; simply moisten the surface well, avoiding excess water and preventing the formation of puddles.

Preparation of the solution:

To prepare the solution, pour the dry mixture into a container with clean water, based on the proportion of 0.13-0.15 liters per 1 kg, and stir until a homogeneous mass is obtained for 3 minutes. Let the solution sit for 5 minutes and mix again. Mixing is done with a professional mixer, a drill with an attachment at a speed of 400-800 rpm or in a concrete mixer. The prepared solution remains mobile for 2 hours.

Attention!

Avoid overdosing on water, as excess water leads to peeling and loss of mechanical strength of the leveling layer, as well as the appearance of cracks on the surface. The dry mixture contains cement and when interacting with water it gives an alkaline reaction, so it is necessary to protect your eyes and skin when working.

Application:

The mortar mixture is laid with a steel spatula, a trowel and leveled between pre-installed beacons every 1.5-2 m, using a rule strip and a trowel. The correct installation of beacons is checked using a rule-level or a laser level.

If necessary, after 7-8 hours the surface can be rubbed with a metal or plastic grater.

Drying time:

The leveled surface is suitable for walking after 7 hours at an ambient temperature of +20ºС. At lower temperatures, the time after which walking is possible increases to 12 hours.

The drying time of “VOLMA-Coarse Leveler” depends on the thickness of the layer and the temperature and humidity conditions in the room. Laying ceramic tiles is possible in 7-14 days. Complete drying time is 3-4 weeks. Laying of decorative coatings should be carried out in accordance with the manufacturers' recommendations with mandatory control of the base humidity.

Recommendations :

1. The screed should be protected from drying out too quickly: from exposure to drafts, heating devices and direct sunlight.

2. On an area of more than 36 m2, it is necessary to install anti-shrinkage (expansion) joints.

3. The expansion joints existing in the base should be repeated before laying “VOLMA-Rough Leveler”.

4. It is recommended to install screeds on very wet, contaminated (for example, bitumen mastics, machine oil, etc.) substrates, as well as those with low strength, on a separating layer. When using “VOLMA-Rough Leveler” on a separating layer or in a “floating floor” system, prepare the base according to the recommendations for the installation of a specific type of floor.

5. The temperature of the leveling mixture must not be lower than +10ºС.

The manufacturer is not responsible for non-compliance with technology when working with the material, as well as for its use for purposes and conditions not provided for in the technical description.

Storage conditions :

Bags of dry mixture “VOLMA-Rovnitel rough” should be stored on wooden pallets in dry rooms. Pour the mixture from damaged bags into whole bags and use first.

Guaranteed shelf life in undamaged original packaging is 12 months.

"VOLMA-NIVELIR EXPRESS" FAST-HARDING SELF-LEVELING FLOOR.

| color | white |

| Recommended layer thickness | 5-100 mm |

| Material consumption for a thickness of 10 mm | 12.5 kg/sq.m |

| Water consumption per 1 kg of dry mixture | 0,29-0,34 |

| per bag 20 kg | 5.8-6.8 l |

| Viability of solution | 60 minutes |

| Application temperature (air, work surface, materials) | from + 5 to + 30ºС |

| Compressive strength after 28 days | not less than 15 MPa, (M150) |

| Strength of adhesion to the base | not less than 1.0 MPa |

| Possibility of moving on the floor | in 4-6 hours |

| Possibility to load the floor | in 72 hours |

| Coat with residual moisture | no more than 1% |

FOR VTR, VLG, CHLB – TU 5745-009-78667917-2008

For VSK – TU 5745-003-99145643-2012

“VOLMA-Nivelir Express” is a dry mixture based on a complex binder, fractionated quartz sand and modifying additives, which ensure high mobility of the solution, strength and optimal operating time.

Application area:

The mixture is intended for high-quality leveling of concrete and cement-sand subfloors with a thickness of 5 to 100 mm under subsequent decorative coverings - carpet, linoleum, parquet, ceramic tiles, etc.). It is used in all residential premises and public buildings. For interior work. The mixture is intended for manual and machine application.

Foundation requirements:

The base must be dry, durable, free from dust, dirt and grease stains. The “age” of the cement-sand base is at least 28 days, and the concrete base is at least 3 months. It is recommended to carry out floor installation work under the following conditions:

– base humidity not more than 6%;

– base temperature not less than 5ºС;

– air temperature not less than 5ºС;

– relative air humidity no more than 75%.

Preparing the base:

Clean the supporting base from dust, dirt, lime, oils, fats, wax, paint residues, etc.

Remove loose and loose areas of the base. Place damping pads (tape or thin strips of polystyrene foam) along the walls and columns where the floor meets. Fill cracks and large potholes with VOLMA-Nivelir Express mixture mixed with less water at least 1 day before pouring. Protect steel elements in contact with the self-leveling mixture solution from corrosion. On substrates that are very damp, contaminated (for example, with bitumen mastics, machine oil, etc.), as well as those with low strength, it is recommended to install floors on a separating layer.

The future thickness of the layer can be indicated by setting level templates using a leveling ruler and portable benchmarks. Designate technological areas for pouring the floor. If the area is more than 50 sq.m. and with a diagonal of more than 10 m, an expansion joint should be installed in the floors, but always above the existing joints in the load-bearing foundation.

Prime the prepared base and areas of the walls that will be in contact with the self-leveling floor with VOLMA-Universal primer. Prime porous surfaces 2 – 3 times with an interval of 4 hours. Laying the self-leveling floor should be done only after the primer has completely dried. It is not recommended to use other primers without prior consultation with a specialist from the manufacturer VOLMA-Nivelir Express.

Preparation of the solution:

For manual application: pour the dry mixture into clean water (water temperature from +5 to +20 ºС), based on the proportion of 0.29 - 0.34 liters of water per 1 kg, and mix using a professional mixer or drill with an attachment until homogeneous mass for 5 minutes. Let the solution sit for 3 minutes and then mix again. Do not overdose on water!

For machine application: pour the dry mixture into the hopper of the machine (unit) and, by adjusting the water flow, select the required consistency of the mixture.

To check the consistency, pour 1.0 liters of solution onto a flat, non-absorbent base (for example, glass, film, foil). The diameter of the spot should be 50-55 cm.

Work order:

1. Pour the prepared mixture evenly to the specified thickness, avoiding process breaks.

2. The designated technological area must be filled within 40-60 minutes. When pouring the floor manually, the area of the technological area should be 20-25 sq.m. or correspond to the area of one room.

3. Immediately after pouring the solution, it is necessary to remove the levels and remove air bubbles from the mass using a needle roller, squeegee or brush, making translational movements along and across the poured surface, starting from areas adjacent to the walls and columns.

Self-leveling self-leveling floor: which one is better to choose?

Self-leveling flooring is a great option to achieve a perfectly smooth surface. It can be used for rough or fine leveling of the screed. The filling method is characterized by its simplicity, thanks to which even an inexperienced person can perform all the work. Manufacturers today have developed a huge number of types of self-leveling floors, which differ in their composition, thickness of the leveling layer and quality.

Review

To ensure a perfectly smooth surface and long service life, it is necessary to choose time-tested products. Which to choose? Let's take a closer look at popular manufacturers.

Volma level express

Volma is a composition in the form of a dry mixture, which contains a complex binder, fractional quartz sand and modifying additives. Thanks to this composition, it is possible to achieve increased mobility of the solution, give it strength and complete all the work in a short period of time.

It will be interesting to know that it is also possible to use such finishing material as wood putty for the floor.

The main purpose of the composition is high-quality leveling with a layer thickness of 5-100 mm. After applying the mixture, you can use various decorative coverings - carpet, parquet, linoleum, tile. Volma can be used for all living rooms and public buildings. Use only inside the structure. The mixture can be applied manually or by machine.

It will be interesting to learn from the article about floor skirting boards, which will definitely come in handy after screeding.

The main condition for applying the mixture is a dry, strong and clean base. From the date of receipt of the base of the floor made of sand and cement, at least 4 weeks should pass, and concrete - 3 months. Work on filling the floor using Volma solution should be carried out according to the following rules:

- the humidity of the base should not exceed 6%;

- temperature indicators of the base are not less than 5C;

- air temperature indicators are not less than 5C.

The cost of such a mixture will be 285 rubles per bag.

It will be interesting to learn about laminated floor plinths.

Vetonit

This material is used when installing self-leveling floors as a base layer. Thanks to the excellent quality of the solution, it is possible to fill the floor under various finishing coating options.

Manufacturers today recommend the following brands to their consumers:

- Vetonit 3000 is a lightweight material based on concrete. Actively used for leveling final surfaces. As a result of using the product, it is possible to obtain thin layers, level out large surface distortions, and eliminate all flaws. The average layer thickness can reach 5 mm. Can be used as a base for coverings such as linoleum, carpet, laminate. Drying time is 3-4 hours and has no self-leveling properties.

After leveling the floor, you can use plywood for the floor for perfect execution, which you can highlight for yourself in the article.

- Vetonit 5000 is a material that does not contain casein. The composition dries very quickly and levels itself out. The mixture is based on cement. The mixture hardens in a short period of time and also has high adhesive properties. Vetonit 5000 is not afraid of serious loads, thanks to it you can create sloping floors in rooms where there is a high level of moisture. For this composition it is not a problem to level out differences of up to 800 mm. Can be used for pouring screeds in a warm field, the layer thickness reaches up to 80 mm. The solution becomes solid after 2-2.5 hours. You can purchase the product for 650 rubles.

Plywood floor thickness and other characteristics can be read in the article.

Prospectors

This mixture is made on the basis of sand and cement. The composition is also rich in polymer additives, due to which the self-leveling floor becomes fluid and can be protected from delamination. This product can be used for laying floors where there is high humidity, but on the condition that the floor will then be covered with finishing materials.

After using the base material and leveling the floor, it will be possible to use a material such as a decking board, the dimensions and other characteristics of which can be read from the article.

You can also use the Starateli mixture in unheated houses, since the product can withstand high and low temperatures. The cost of production is 500 rubles per bag.

Knauf

These products are among the leaders today. It has excellent qualities, and it can be used to fill the floor not only by a professional, but also by a person without any experience in this matter. In addition to excellent quality characteristics, the Knauf mixture is not that expensive. The approximate cost is 400 rubles per bag.

It will be interesting to learn about cement brands and their use.

Ceresit

This is also a popular mixture for creating a self-leveling self-leveling floor. The main advantages of the composition remain their quality and reliability. You can buy a bag of the mixture for 500-600 rubles.

From this article you can learn about the proportions of cement and sand for floor screed.

Bergauf

The composition also does not leave the leadership of quality products for self-leveling floors, although it does not have such high popularity. As a rule, Bergauf is taken in cases where you need to get a not very complex, but at the same time reliable and durable result. This product costs 250 rubles.

In this article you can find out which floor screed is considered the best.

Pouring technology

The process of pouring a self-leveling self-leveling floor involves two stages: preparatory operations and direct pouring. Preparation involves activities that include cleaning the base, sealing cracks and applying primer. Thanks to the priming solution, it is possible to penetrate into the pores of the screed and slightly level the surface. Next, the finishing coating will spread over the primed surface, forming an even, smooth outer layer.

In the article you can find out what are the pros and cons of dry floor screed.

The video shows a self-leveling self-leveling floor with your own hands: https://www.youtube.com/watch?v=w5LqDTsJzTc

To fill the floor, you need to dilute the mixture with water in the proportion indicated on the package. Liquid self-leveling floors are characterized by rapid hardening, so you need to prepare no more than 1-2 buckets of solution. To determine the solution consumption, it is necessary to know the thickness of the coating. If the layer is 10 mm, then the material consumption is 14-16 kg per m2. A bag weighing 25 mg will cover 2 m2 of floor.

Before stirring the solution, you need to install beacons for the self-leveling floor. Thanks to them, you will be able to know the level and height of the finished floor. Now you can pour the solution onto the floor and use a wide spatula to thoroughly level everything. To remove all air bubbles, you must use a needle spatula.

The video explains which self-leveling self-leveling floor is better: https://www.youtube.com/watch?v=Cxh774XfONE

Reviews

- Denis, 27 years old: “When I was pouring the floors at home, I used the Ceresit compound. What attracted me was the low price, but good quality indicators. Since I am new to this business, I thought that I would not be able to cope with the task, but everything turned out to be very easy. When the mixture was poured, it still took 4 hours to dry. The result is a reliable, durable and level floor. It’s worth noting that you don’t need to prepare the solution much, since after 30 minutes it begins to thicken.”

- Anatoly, 45 years old: “My work is related to construction and repair, so I often come across the task of pouring a self-leveling self-leveling floor. Most often I have to work with Volma Level Express mixture. Very high quality products, can be used to create the base of the floor for the kitchen and bathroom. After this, you can lay any type of coating.”

- Mikhail, 35 years old: “When my wife and I bought a house, it was in terrible condition, everything had to be done from scratch. To create the floor I used the composition Prospectors. I am very pleased with this manufacturer, it has saved me more than once. What I like about self-leveling flooring is the smooth surface it provides and the speed of work. I prepared the surface, installed the beacons and poured the prepared solution. After just 3 hours it hardened. Then I laid laminate on the floor.”

Self-leveling self-leveling floors are becoming very popular today. And this is not surprising, because this design is of high quality, strength, reliability and durability. And the most important thing is that all the work can be done by an ordinary person who does not have such experience behind him.