During construction and during finishing work, it is often necessary to create a coating with improved properties - even, moderately durable. Chipboard (chipboard) has the necessary characteristics. The sheets are made from wood, but the base is not solid wood, but shavings. The slabs are susceptible to moisture, but this disadvantage is outweighed by their advantages. When choosing, you should consider different options for materials; they differ in appearance, properties, and therefore are used under different conditions.

Features of the material, history of appearance

Previously, the issue of recycling wood chips obtained during production for various purposes often arose. It was solved thanks to the appearance of slabs made from this raw material. Wood-based products first began to be used in the thirties of the last century. They were used for commercial purposes later - in the 40-50s. XX century Since then, the material has been used more and more often, and annual production has increased several times.

Raw materials: chipboard

Chipboard is a type of board made from shredded wood. They got their name due to the type of raw material that underlies them (wood shavings). Particles of different sizes are used, they are held together with a binder of non-mineral origin (synthetic glue, often based on phenol-formaldehyde resins). This feature limits the scope of application. The material contains a certain amount of toxic components, their dose is minimal, it is regulated by standards, and therefore the sheets are not prohibited. They are often used, including in the production of various pieces of furniture, and when performing finishing work.

What are chipboard and laminated chipboard

Chipboard is a composite material widely used in construction and furniture production. The boards are made from sawdust, which is put through a hot press and then impregnated with various additives and formaldehyde resins.

The surface of the slab becomes rough and porous. To protect the surface from moisture and give it an aesthetic appearance, the slabs are lined with veneer, paper, plastic and other materials.

Chipboards are classified according to the level of processing:

- polished (untreated);

- unpolished (processed);

- laminated;

- veneered;

- laminated.

Laminated chipboard is a board made of wood chips, which is treated with a laminated melamine film (laminated).

Advantages of laminated chipboard

Laminated chipboards have many advantages over chipboards. The main advantage of laminated chipboard is the protective melamine film.

Other advantages of laminated boards:

- strength (thanks to an additional layer - lamination);

- resistance to fungus and other types of bacteria;

- resistance to mechanical damage;

- emit less formaldehyde, a poisonous gas;

- aesthetically attractive appearance;

- variety of colors;

- heat resistance and ease of processing;

- do not require further processing or painting;

- in case of damage they are easily restored;

- high coefficient of heat and sound insulation;

- high wear resistance;

- low cost.

The beautiful appearance of laminated chipboards allows them to be used in the manufacture of furniture products, and the high parameters of heat and sound insulation make laminated chipboard an indispensable material in construction.

Flaws

Laminated chipboards are actively used today in the production of furniture products, but not in all types due to a number of negative characteristics.

Disadvantages of laminated chipboards:

- fragility during processing, inability to make curly cuts;

- insufficient moisture resistance and resistance to high temperatures;

- deep milling is contraindicated;

- formaldehyde fumes can harm human health;

- Long-term loads (more than 12 kg for 30 minutes) are contraindicated.

Stages and features of production

To make chipboard, raw materials of different sizes and types are used:

- chips: they are produced on rotary-type machines;

- chips are the result of the operation of special equipment (for example, a chipper or a knife shaft).

To produce particle boards, you need raw materials whose particles correspond to standard parameters with deviations (to a lesser extent from the specified values):

- thickness – 0.5 mm;

- width – 5 mm;

- length – 40 mm.

The quality of the finishing material depends more on the thickness of the chips. It is better if it is as thin as possible. When specially harvested wood is used, rather than production waste, round timber or large boards will be needed. After preparation (removing the bark, dividing into smaller pieces, soaking), the material is crushed. This is how the raw materials are obtained, which are used to produce the top layer of the slab. Inside there are large chips, they are compressed, but in the section you can see the difference between the structure of the layers. To improve the quality of the raw material, it is additionally dried and sifted, then re-grinded.

Stages of plate production:

- All types of raw materials (for internal and external layers) require drying. This is done after calibrating it in size.

- The chips fall into the mixers, which are constantly rotating. Here it is mixed with binding components. It is important that every particle is coated with resin. This result is achieved by blowing a stream of air along with drops of the binder component. The resin envelops the chips.

- The mass falls on the conveyor belt, where future sheets are formed - layers of material of different thicknesses are created.

- The layer is cut into slabs and compacted using the vibrocompression method at a temperature of +180°...+220°C.

- Heating can increase the strength of the boards, which is achieved due to the effect of temperatures on the resin.

- Products are cooled. Moreover, to obtain materials with the desired properties, a gradual decrease in the temperature of the plates is required - in a natural way.

Chipboard: sheet size. Basic indicators of length, width and thickness

Standard dimensions of laminated chipboard sheets are regulated by GOST. In accordance with this standard, the width, length and thickness of the slabs are determined.

Laminated chipboard with a processed edge is used for the manufacture of interior items

Main dimensions of laminated chipboard

There are 18 standard lengths: 1830, 2040, 2440, 2500, 2600, 2700, 2750, 2840, 3220, 3500, 3600, 3660, 3690, 3750, 4100, 5200, 5500 and 5680 mm. In this case, the permissible length inaccuracy is ±5 mm.

The width of laminated chipboard slabs is determined by 9 indicators: 1220, 1250, 1500, 1750, 1800, 1830, 2135, 2440 and 2500 mm. As with length, the permissible error does not exceed ±5 mm.

The thickness of laminated chipboard ranges from 3 to 38 mm with an acceptable inaccuracy of ±0.3 mm.

It should be clarified that, depending on the capabilities of the equipment, each manufacturer produces several basic sizes of chipboard, but the following are considered the most popular on the market:

- 2800x2620 mm;

- 2800x2070 mm;

- 2620x1830 mm;

- 2500x1830 mm.

Chipboard thickness ranges from 3 to 38 mm

Thickness of laminated chipboard sheets

Their strength and ability to resist loads, and therefore their scope of application, directly depends on the thickness of the laminated chipboard. It is important to remember that heavy thick slabs are very durable, but thin laminated chipboards bend without being deformed.

Most often, the thickness of laminated chipboard ranges from 8 to 38 mm. 8-10 mm sheets are used for the production of containers, drawer bottoms, door and wall cladding, as well as for furniture fronts.

Overview of types of chipboard

In its original form, chipboard is used without additives, auxiliary layers, or structural elements. However, it is often necessary to use improved material. This led to the emergence of different types of slabs:

- laminated (laminated chipboard): coatings of several varieties are tried on (paper-resin film, plastic and paper-laminated material), which can affect the properties of the product;

laminated chipboard

- fire-resistant boards: contain fire retardants, making the material more resistant to high temperatures;

- moisture-resistant: they contain urea-melamine resins, hydrophobic polymer additives; boards of this type can be distinguished by their greenish tint;

Moisture-resistant chipboard

- veneered: similar to solid wood, but only externally, because the outside is covered with veneer, due to which the material imitates natural wood;

- tongue-and-groove (chipboard Quick Deck): they differ in the configuration of the cuts; grooves and tenons are formed here, making it possible to assemble a seamless durable coating.

Tongue-and-groove chipboards.

Separately, perforated boards should be noted. They are produced by extrusion. This type of material is used primarily in the production of door panels (laid inside), so it is not found on the open market. Features of such plates:

- presence of through holes;

- high sound insulation qualities;

- increased thermal insulation;

- resistance to deformation due to exposure to temperature changes.

The narrow scope of application of such chipboard is also due to its insufficiently high strength. Veneered material differs from this variety. For the coating, veneers of different species are used, but more often - oak, ash, which improves the quality of the slab, it becomes stronger, and better resists mechanical loads. Veneer, like lamination, gives the material decorative qualities. At the same time, wear resistance increases. At the same time, moisture resistance increases.

Important! Even if the material is covered with veneer or polymer film, this does not make it waterproof. Such slabs withstand exposure to a humid environment better. However, prolonged contact with water is not recommended. The material remains hygroscopic, depending on the type, it swells by 5-30%, which means it is deformed in such an environment.

Material calculation

To determine the required quantity of products, the scope of application should be taken into account:

- Wall covering. The width and height of the surface are measured, and a suitable wood-based material is selected. The simplest option is to calculate the area. If the base dimensions are 5 m and 2.5 m, then the area will be 12.5 m2. The sheet dimensions are 183 and 275 cm, so the area of one fragment is 5 m2. 12.5/5 = 2.5 (3 whole panels).

- Floor covering. The most effective, but very painstaking method is drawing up a diagram. To do this, the width and length of the horizontal structure are measured, and the data is transferred to the drawn plan. Next, based on the possible dimensions of the chipboard sheet, the material is adjusted. This will allow you to take into account all the nuances and avoid unnecessary trimming.

- Furniture manufacturing. This is a responsible job that requires skills. If the interior item is made according to individual parameters, then a detailed drawing is drawn up. Then the dimensions of each part are sequentially determined, taking into account its location in relation to other elements. All obtained dimensions are transferred to the cutting program, which allows you to accurately determine the required number of slabs.

To work with chipboards, high-quality high-speed tools are used.

Chipboard is perfect for creating furniture and lining the interior surfaces of a house, which is explained by the availability and good quality of the material.

Classification

One of the first parameters that people pay attention to is the type of surface treatment. There are 2 options: sanded and unpolished slabs. They differ in the quality of the coating, which determines the area of application of the material. In addition, the slabs are distinguished by structure:

- ordinary (designated by the first letter – O);

- fine-textured (M).

The second option is used in the production of laminated boards. This is due to the fact that the film adheres better to the surface of such a product.

Surface quality

Slabs of different types are produced, differing in the number of defects:

- 1st grade – without changes in the structure of the material, defects;

- Grade 2 – a certain amount of damage is acceptable (regulated by regulatory documentation).

Due to average strength and moisture resistance, chipboard with more significant defects is not used, since it will not perform its main functions. The service life of the material will be significantly reduced.

Emission class

There are types of stoves that differ in the degree of danger to human health. They contain varying amounts of toxic components (in particular formaldehyde):

- E0.5;

- E1;

- E2.

Is chipboard harmful?

If you need to use the material indoors, only the first two options are considered. The concentration of formaldehyde in the structure of the binder component and when released into the surrounding space is minimal and is considered acceptable. However, the rule here is: the less, the better, so option E0.5 is preferable.

Strength level

There are types:

- P1 – general purpose;

- P2 – products intended for the manufacture of furniture and finishing work indoors.

The second option is more durable, so the scope of application of the slabs of this group is wider. P1 products are more often used for rough finishing, temporary structures or as auxiliary material. The strength of chipboard varies: 550-750 cubic meters. m. At the same time, the range of density values is also different: 0.5-1.0 g/cubic. see. Tensile strength is also taken into account:

- when bending – 10-25 MPa;

- when stretching - 0.2-03.5 MPa.

Advantages and disadvantages

First, it is necessary to note the positive qualities of the material:

- the products are resistant to deformation due to long-term use (the slabs do not crack or dry out);

- the material is not susceptible to fungal development;

- does not attract insects;

- Chipboard is not subject to flare-up, does not ignite well, and the combustion process is not intense;

- you can make a coating no worse than a monolithic one - the slabs fit together and form an ideal coating without cracks;

- The products cost much less than other wood materials.

Chipboard also has disadvantages:

- low thermal insulation properties, such products are used as auxiliary;

- the material is still flammable, although its combustion rate is low;

- the plates are hygroscopic, it is not recommended to use them in damp rooms;

- Do not screw in self-tapping screws from the end side, this reduces the strength of the product;

- the composition contains toxic components, the material does not belong to environmentally friendly coatings;

- low bending strength.

Application area

The main direction of use of particle boards is furniture production. Certain types of chipboard are used in construction and interior finishing. Problems that can be solved using this material:

- fencing at construction sites;

- formwork for the foundation (dismantled);

- building structures (minor elements);

- interior doors;

- a substrate for the subfloor that prevents abrasion of the main structural elements;

- ramps;

- panels (for finishing walls, ceilings);

- floor finishing material;

- insert stands;

- roof structural element (cladding);

- storage container.

When it is planned to install temporary structures or permanent structural elements, waterproofing (film materials) is used. Chipboard is not used for finishing facades. The exception is when good protection from water is simultaneously created and an effective ventilation system for the structure is installed.

Application area depending on chipboard thickness

Chipboards are most often used for making furniture, but are also actively used in other areas:

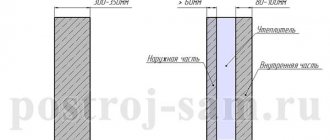

- Laminated chipboard panels with a thickness of 6 and 8 mm are suitable for interior wall cladding and the construction of partitions. The products are also used in constructing a system of aluminum sliding doors for sliding wardrobes: they are inserted into the frame, providing structural rigidity and adding decorativeness. The material performs the same function in framed facades.

- Sanded or unsanded elements with a thickness of 16 to 18 mm are suitable for arranging the floor with subsequent cladding with laminate or carpet. The same result can be achieved by using two thin 8 mm slabs. They are placed in different directions, providing greater rigidity.

Thicker panels are used for the floor than for the walls. - 16 mm laminated chipboard sheet is the main furniture material. It is cut to the required size and parts are obtained for all parts of cabinet furniture, including facades. Fragments of interior items manufactured in European countries most often have a thickness of 18 mm.

- Products with a thickness of 22 mm are used for dresser lids and tabletops of computer desks with 4 support points. Untreated products are suitable for hemming horizontal non-hanging structures.

- Products with a thickness of 25 mm are used for the production of office table tops and as internal window sills.

The panels used under the tabletop are considered the densest and highest quality material. - 28 mm thick slabs are suitable for kitchen countertops and bar counters. The minimum size of such a product is 26 mm, but these parts are usually classified as “economy”. For greater reliability and decorative appeal of kitchen items, material with a thickness of 32–38 mm is used.

- If the desired option is not available, two elements with a thickness of 16 or 22 mm can be spliced.

On a note! Often found large parts of European furniture are called “tambourate”. They are covered on top with thin laminated chipboard panels or other material, and the inside has a cellular structure.

Tamburat is a new word in the furniture industry

Subtleties of using chipboard in furniture production

Chipboards (the laminated variety) are often found in the form of furniture walls, shelves, countertops, facades (inexpensive items), and frames. The advantage of chipboard compared to natural wood in such production is that there is no need to additionally process the material, sand it, or paint it. It is enough to determine the dimensions of the structural elements, cut them, and assemble the product using standard fasteners.

However, there is a difficulty when working with laminated chipboards - edge processing. To protect it, an impenetrable material is glued at the production stage, which serves as a decorative and protective element. It is difficult to use such film on your own.

Gradually, laminated chipboard, like chipboard, is replacing MDF - this is another type of particle board, but it is more expensive. However, such plates have improved characteristics.

Standard sizes

The dimensions of manufactured products are based on regulatory documents. So, for simple chipboards without treatment there is GOST 10632-2014.

Dimensions of chipboard sheet (sanded and unsanded):

- Length – at least 180 cm, with further gradation of 10 mm.

- Width – no less than 120 cm.

- Thickness – from 1 mm increasing by 1 mm.

There is a size range for each sheet thickness

On a note! Exact parameters are determined to order or based on demand.

Chipboard size according to the existing standard:

- Length – from 183 cm, maximum – 568 cm.

- Width – 122–183 cm.

- Thickness – from 3 mm to 40 mm, with gradation of 1 mm.

Any standard has its own tolerances and permissible deviations.

The parameters and characteristics of laminated chipboard (LDSP) are determined by GOST 32289-2013 and technical specifications 5534-002-54482892-02.

The most popular sizes of laminated material are: length – 244 and 275 cm, width – 183 cm and thickness – 6, 8, 10 and 16 mm. Accordingly, the sheet area is about 5 m2.