Construction work involves financial expenses, effort and calculations that are not always possible to do on your own. It is not enough to build a wall of a certain thickness from foam concrete; you need to understand in detail the design, the rules for carrying out calculations, and the specifics of the work. For this reason, it is very important to understand how the thickness of future walls made of foam blocks is calculated so that it meets the requirements of generally accepted standards.

Why is it important to know the thickness of the walls?

Reflecting on the question of what the thickness of walls made of foam blocks should be, you can hear a lot of reasoning, many of which are misleading.

In order for the decision you make to be correct and safe, it is recommended to know a number of features that you need to build on:

- Find out what the coldest winter temperatures are in the area where you live. It may be necessary to thicken the walls with the installation of an additional thermal insulation layer.

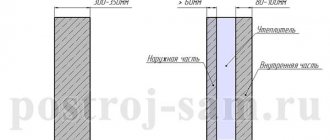

- The type of insulation material must be determined - you will have to install it, or everything will come down to a simple layer of plaster. If the walls of a house under construction are built from foam blocks, the thickness of which is 30 cm, it is recommended to apply thermal insulation of 5 - 10 cm.

- The insulating layer not only affects the material that retains thermal energy, but also protects the foam blocks from ultraviolet radiation.

It is necessary to select foam concrete products taking into account their density. The higher its indicator, the more expensive the material is.

Features of the definition

In order for the thickness of a foam block wall for a home to be optimal, it is necessary to understand the thermal insulation advantages of foam concrete. For example, you can take a wall whose thickness is 600 mm, and see what dimensions walls made of other materials with similar thermal conductivity should have:

| name of material | wall thickness, mm |

| timber | 520 |

| expanded clay concrete | 1010 |

| brick | 2300 |

| concrete | 4500 |

It turns out that foam concrete can only be compared with wood in its ability to retain heat; other types of building materials require an additional insulating layer. Otherwise, the walls will turn out incredibly thick, or heating costs will exceed all expectations.

The thickness of the foam block for external walls is determined by a number of parameters:

- Density. In a one-story building with wooden floors and a light roof, grade D 600 - D is used for load-bearing walls. In a multi-story building with floors made of reinforced concrete slabs, it is recommended to use a higher grade of D 900 - D 1200. Partitions are made from blocks whose grade is D 200 - D 400.

- Size and thickness. In areas with a temperate climate, the thickness of the foam block for walls is 300 mm. To build them, it is recommended to take blocks whose size is 300x300x600 and lay them lengthwise. In the northern regions, the thickness of the walls is doubled, laying the same blocks in double rows. Internal partitions are constructed mainly from blocks twenty centimeters thick. Semi-blocks are suitable for bathrooms.

- Soundproofing. What thickness of foam block for external walls is best if there is a need to protect the room from extraneous noise? A material whose thickness is 300 mm is considered reliable. Otherwise, you will have to install a soundproofing layer.

- Insulation. If an external insulating layer is planned, then you can use foam blocks, the thickness of which is no more than 30 cm. In this case, the cladding is made of any material, placing a heat-insulating material between the main wall and the finishing.

When building a house without an insulating layer from blocks with a finished facade, the thickness of the walls must be increased to 600 mm.

Today it is possible to purchase insulated blocks that already have insulation and cladding in their design.

The thickness of one block in this case will be:

| layer | thickness, mm |

| foam concrete | 200 |

| Styrofoam | 80 – 100 |

| facade tiles | 10 – 15 |

Such walls will perfectly protect from any frost.

How to choose foam blocks?

First of all, when choosing a material, you should pay attention to the size of the blocks. It should be the same. This is easy to check: you need to place the products on a flat surface and look at the quality of the connection. If there are no gaps or protrusions, then foam blocks are suitable for construction.

The blocks should also be inspected for cracks. If they exist, then most likely the material drying technology was violated. This may also indicate internal stresses, which often causes the collapse of foam concrete during use.

Uneven distribution of air bubbles is also an alarming sign. They should be located in approximately the same quantity over the entire area of the block. The shape is also important: round bubbles up to 1 millimeter are the norm, while oval ones reduce strength.

You should also pay attention to the color of the blocks: normally there are no stains on the surface, and the color of the walls matches the inside.

Density dependence

Remember that sound insulation and thermal conductivity depend on the density readings of the material. For example, a wall made from a D 600 block, the thickness of which is 450 mm, can be compared in its ability to retain thermal energy with an analogue built from D 800 with a thickness of 680 mm.

This feature also applies to internal partitions. The D 200 foam block, whose thickness is 100 - 150 mm, will better protect the room from extraneous sounds than the D 300 or D 400 material, which has the same thickness.

In order to understand exactly how thick a wall made of foam blocks should be, how much material is needed and what brand, you can use the calculator on one of the construction sites.

And from the corresponding SNIP II 3 79 you can take the necessary indicators, with the help of which the thermal conductivity of the wall of any composition and foam blocks of different densities can be determined.

Calculation of wall thickness

In order for your wall made of foam blocks to be sufficiently reliable and warm, you should perform thermophysical calculations and determine the strength. The calculation actions will be based on foam concrete material, the density of which is D 600.

Remember that the thermal conductivity resistance of external walls (including all finishing layers) must exceed 3.5 degrees per m2/W.

To determine the thickness, it is proposed, taking different densities of foam concrete as a basis, to analyze this process in more detail:

- as follows from the technical indicators, blocks of the D 600 and D 800 brands have corresponding coefficients of 0.14 and 0.21 degrees * sq.m./W;

- The finishing material will be brick for facing work and a decorative plaster layer, the coefficients of which are 0.56 and 0.58 deg* sq.m/W, respectively.

Let's start performing calculations:

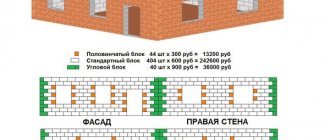

- First you need to decide how thick the brickwork and plaster layer will be. As a rule, an uninsulated facade is covered with a double row of brick material, which is 12 cm;

- convert the resulting size into meters and divide it by the heat conductivity index of the material for facing work. The result is a resistance index of 0.21;

- We perform the same calculations with the plaster material. The desired value should be 0.33.

The next step is to substitute the resulting numbers into a simple formula:

- (foam concrete block with a certain density - brick - plaster layer) multiplied by 0.14 (coefficient corresponding to our block). We convert the resulting result into millimeters, and the desired value will be approximately 450 mm. This is an indicator of wall thickness if you use a D 600 block;

- Having performed similar calculations for the D 800 foam block, you will obtain a thickness of the future wall of 68 cm.

Please note that the second option requires a thicker wall. It follows that the financial costs will be much more serious. And if you add a layer of expanded polystyrene, the thickness of the facade walls will decrease.

It is appropriate to add that a two-story structure with dimensions of 10 by 10 meters for every 10 cm of wall thickness creates a load reaching tens of tons. This is despite the fact that the ceiling, roofing structure and walls of the upper floor weigh 15 - 18 tons. Added to this is the mass of things on the floor, the probable load created by the snow cover, masonry defects and wear and tear of materials from use are taken into account. Based on the above factors, the design solution determines the thickness of the walls made of foam blocks to be 30 cm.

No. 2. Advantages and disadvantages of foam blocks

If the foam block is made with high quality and in compliance with all requirements, then it receives a lot of excellent performance qualities, which is why it has gained such significant popularity.

The main advantages of foam blocks:

- high compressive strength . This figure reaches 3-5 MPa and grows over time. A comparison of a new, recently manufactured foam block and a foam block that has been in use for 50 years showed that the density of the latter is 3 times higher;

- low density . For blocks of different brands, this figure is 400-1200 kg/m3;

- light weight , which simplifies the transportation of material, construction work and reduces the load on the foundation;

- ease of use . Large and lightweight blocks allow you to build a house quickly and easily. The material is easy to process, so it can be given any shape;

- thermal insulation properties. Due to the porous structure and large amount of air inside the material (up to 40-80%), the thermal insulation qualities of the material increase. Compared to brick, the thermal conductivity coefficient of D700 foam block is 3.5 times lower. In practice, this means that you can make the masonry thinner, reducing the load on the foundation, and in areas with a warm climate, provided the masonry is of high quality, you can do without additional thermal insulation at all;

- soundproofing qualities . The porous structure of the foam block allows you to significantly dampen external noise, especially low frequencies. A 30 cm thick wall absorbs noise of 60 dB;

- environmental friendliness . Foam blocks are absolutely harmless to human health, are made from environmentally friendly materials, and the foaming agent used in production does not produce harmful gases. Foam blocks do not rot and do not decompose;

- high fire resistance, moisture resistance and frost resistance . The material almost does not absorb moisture, and thanks to this and the closed pore structure, foam blocks can easily withstand dozens of freezing and thawing cycles without losing strength and integrity;

- acceptable cost . 1 m3 of foam block costs several times less than solid wood or timber and is much cheaper than brick, so building a house from foam block will be more economical.

The main disadvantages of foam blocks:

According to this indicator, the material is significantly inferior to concrete and reinforced concrete, however, with increasing density, the strength of the products also increases, but at the same time the thermal insulation properties decrease. Remember that foam concrete increases strength over time and reaches the indicators necessary for the construction of buildings already on the 28th day. It is not recommended to use a newly made foam block, and this type of material is often present on the market in the midst of construction work, so it does not hurt to let it settle for 3-4 weeks after purchase before construction;

low bending strength.- Often the geometry of the blocks is far from ideal, which complicates installation. It is better to buy foam blocks from trusted manufacturers who offer high-quality products with the most accurate dimensions;

. Within two months after completion of construction, the foam block shrinks, which is associated with strength gain. Shrinkage reaches 2-4 mm per linear meter. Since it is uniform, the structure is not in danger, but finishing work will be delayed for several months;

natural shrinkage- not the best appearance , so houses built from foam blocks are additionally finished, for example, with decorative or ordinary bricks, equipped with ventilated facades, etc.

Foam blocks have more advantages than disadvantages, and if you choose the right material, the construction will be durable and reliable. From foam blocks you can build houses up to three floors high. To increase strength, it is recommended to reinforce the walls.