Description and production technology

How does the manufacturing process go:

- the clay is passed through a grinding process and pressed through toothed rollers;

- using magnets, all metal parts are removed from the material;

- add liquid to the clay and knead it until a homogeneous composition is created;

- materials are formed using special equipment, which are then dried at a temperature of 150°C throughout the day;

- The dried products are fired in a tunnel kiln for two days.

The color of the final workpiece depends on the type of clay taken, the time and temperature of firing, as well as the addition of auxiliary components.

Advantages and disadvantages of the material

Like any other product, clinker paving stones have their advantages and disadvantages. Its advantages include:

- good strength and durability;

- excellent moisture resistance;

- frost resistance exceeding fifty cycles;

- withstands weak acids;

- excellent environmental performance;

- can retain colors throughout the entire period of use;

- can be machined.

The disadvantages include the high price, as well as a meager range of shapes and colors.

Clinker paving stones - beauty and durability

When you visit European countries, you are struck by the lack of concrete pavement on sidewalks, pedestrian zones and other places of permanent use.

Compared to the concrete paving stones that we are used to, paving clinker is distinguished by its practicality, beauty and durability.

It’s strange, but Europe has been using clinker paving stones for more than two centuries, but in Russia it appeared only recently.

As a rule, paving with clinker paving slabs in our country is considered a key element of landscape design of household territories.

Why choose clinker over concrete?

Many people believe that clinker tiles are expensive, so laying them is unprofitable.

On the one hand, such tiles are more expensive than concrete tiles, but, on the other hand, the high price is compensated by performance qualities that do not deteriorate with prolonged use.

When making clinker paving stones, natural clay is used, which has a small amount of impurities and high refractoriness.

After high-temperature firing, the clay produces a dense, pore-free material. For example, concrete tiles have a porous surface that quickly collapses after exposure to temperature to the water in the pores.

Deposits of clay for clinker paving stones are found in few European countries. These include: Germany, Poland, the Netherlands, Spain.

The high cost of clinker products is associated, firstly, with high energy costs during production, and secondly, with a limited number of deposits.

Advantages of clinker paving stones

As already noted, the main advantage of clinker paving stones is considered to be the optimal ratio of cost to durability.

Compared to concrete analogues, there are other advantages.

- 1. High compressive strength. It is four times higher than that of concrete.

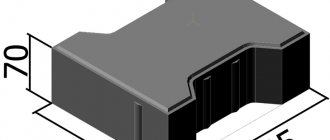

- 2. The thickness is half that of concrete tiles. In this regard, the laying technology is simplified, and delivery costs are also reduced, since the required volume of tiles is reduced.

- 3. Double-sided smooth surface allows installation on either side. This means that it is possible to change the side of laying damaged tiles.

- 4. High resistance to mechanical stress. The paving stones do not wear off and retain their color until the end of use.

- 5. Not destroyed by exposure to chemical materials.

- 6. The surface is smooth but not slippery. A very valuable quality for the winter period.

Installation of clinker paving stones

The condition of installation depends on compliance with the technology of work performed in several stages.

- 1. Site preparation.

• The entire site is cleared of soil, a slope is made for wastewater, and the surface is thoroughly compacted. - • To compensate for the load, a load-bearing layer up to 100 mm thick is laid from a mixture of crushed stone and gravel. In addition, moisture that gets under the paving stones will be removed through this layer.

- • A side curb is installed along the contour of the site, which will prevent the paving stones from moving during installation and use.

- • Sand is laid on the supporting layer in a layer of up to 30 mm. The sand is evenly distributed in compliance with the slope chosen earlier.

- • Such a base is necessary in places where passenger vehicles park and move.

- • This type of base is used in areas with problematic soil and in areas with heavy loads.

So, due to its high performance qualities, the popularity of clinker paving stones is increasing.

Laying it does not require much work, the main thing is to work carefully and control the level and position of the seams.

Types of clinker paving stones

Clinker paving stones are divided according to their areas of use and shape.

You can also divide these products by strength and size, but the first two indicators have a more significant influence on the choice itself. When classifying material by shape, the following types are noted:

- square;

- rectangular;

- half;

- crossbar;

- mosaic;

- shaped.

Shaped products also include paving stones of oval, polygonal, rhombic and other geometric shapes. According to purpose, the material is divided into:

- sidewalk;

- road;

- road for freight transport;

- aquatransit, for special trays;

- lawn

This also includes products with a clearly textured surface.

Scope of application of clinker paving stones

This is not only a construction material, but also a design material. Since different types of clay can be added to the raw mixture, the fired tiles may vary in shades. These are red, yellow, brown, peach, straw, and beige shades!

Clinker paving stones are used for paving:

- City squares;

- Roadway;

- sidewalks;

- Children's playgrounds;

- Entrances to houses;

- Park alleys;

- Parking;

- Garden paths on a personal plot;

- Areas in front of shops and restaurants;

- Territories in front of garages in the country.

From this material lay out:

- Curbs;

- Cornices;

- Stair steps.

In some cases, clinker paving stones are used for laying on walls in restaurants, wine cellars, pubs and bars. Finally, it has found application in landscape design.

Schemes for laying clinker paving stones

Paving clinker paving stones are laid in various ways, it all depends on the imagination of the specialist, but mainly three scheme options are popular:

- Christmas tree. Here the material laying technique involves 2 diagonals.

- In a chess arrangement. The parts are laid offset by half a stone in the form of a half dressing;

- Quarter dressing. Similar to the first option, but the offset is made only by ¼ of the length of the element;

You can choose any scheme that suits you best.

Laying clinker

The first step is to install curbs to prevent the edge stones from tilting. They add great aesthetics, and are installed only on mortar. Their surface should be no more than 5 mm below the level of the paving stones. The clinker stone is placed on a concrete base using glue.

Laying schemes

Most often used:

- Half – dressing is carried out on half the stone.

- Christmas tree.

- Quarter – dressing is performed on a quarter of the stone.

Main rules when laying clinker paving stones

The guide in the paving process is the curb. If it is missing, you need to tighten the cord to control evenness. The thickness of the seam is from 3 to 5 mm. During the work, it is necessary to regulate the evenness of the masonry and the slope, which should have formed automatically with the correct installation of the base. At the end, using a certain technology, the gaps between the stones are filled.

Technology for laying clinker paving stones

Clinker is laid on a base made of ordinary or reinforced concrete, which is initially poured onto a special sand bed. In addition to the concrete substrate, a substrate based on special route compounds of the TDM + TNH-flex and TPM-D4 + TNH-flex brands is used as a base.

The process of laying sidewalks and paths covered with paving stones is in many ways similar to laying natural materials, but there are some differences. The entire arrangement process takes place in several stages:

- marking;

- preparing the base;

- laying the material;

- finishing operations.

The marking is carried out according to a pre-formed plan using a tape measure or measuring tape, by driving in pegs and pulling a cord along them. In addition, it allows you to visually evaluate and change the contours of the path before starting work.

Clinker paving stones and its price

An important issue when choosing materials is their cost. Clinker paving stones are not inexpensive materials, but if you look at their service life and strength characteristics, then in terms of calculation it turns out that the price is not so high.

Another advantage is the wide range of these products available on the building materials market.

The cost of clinker bricks will also depend on the chosen manufacturer. For example, the price of paving stones from Germany will be higher than the price of local producers. The cost of German paving stones is certainly higher, taking into account the costs of transportation costs.

An excellent alternative to German and Dutch paving stones is Polish products. Its quality and performance properties are at the same level as those of its more Western manufacturers, but due to the geographical location of Poland, significant savings on transport costs are obtained. As a result of this, Polish paving stones currently have an excellent price-quality ratio and are deservedly very popular among buyers.

For information on how to properly lay clinker bricks, read the article Rules for laying paving bricks. We also recommend watching a video about how paving stones are laid in China using German technology: