The basis for starting any capital construction is the creation of a cushion for the foundation. What is this foundation for? Its function is to prepare the site for the future foundation, make it as reliable and stable as possible and provide the future building with minimal shrinkage.

The specific type of pillow is indicated in the detailed design of the structure; in total, there are 3 main types of pillows:

- crushed stone;

- sandy;

- concrete.

The choice of one type or another depends on several factors that are relevant for a particular case:

- number of floors in the house;

- budget and building materials;

- soil type;

- groundwater level;

- geographical and climatic conditions of the region.

Reasons for soil compaction with crushed stone

A kind of pillow is created from crushed stone, its role is as follows:

- creating a flat base surface for subsequent work;

- strengthening weak soils;

- preventing moisture from entering the structure;

- ensuring stability under heavy loads.

The quality of the finished base “pillow” very much depends on the characteristics of the crushed stone itself. Naturally, it is very problematic to determine these indicators by appearance; they are usually indicated in the documents attached to the material.

What is a pillow under a strip foundation + correct installation technology

The design of a strip foundation is economical and simple.

In most cases, it forms a support for external and internal load-bearing walls, being their continuation in the lower part and resting on the ground.

To reduce the loads created by heaving processes and other factors, a layer of sand and gravel bedding is created between the tape and the bottom of the trench, which plays the role of a damping and drainage pad.

The functions of the sand cushion are important, but most untrained people do not have a complete understanding of its role in the structure of the strip foundation.

During self-construction, there should be no unclear questions, so we should talk specifically about the structure and functions of the sand backfill layer.

Types of crushed stone

This material is obtained by crushing huge boulders using special equipment; it can be roughly divided into the following types:

- granite is a very strong material that can withstand multidirectional loads, so its range of applications is very wide;

- limestone is also a very hard material, not much different from granite, excellent for housing construction, but its price is much lower;

- slag - this material is a waste product from metallurgical production, its price is much lower than the above materials, but the presence of harmful components limits its range of use;

- secondary - this material definitely cannot be used in all works, because it is made from fragments of concrete, brick, etc.

Before purchasing crushed stone, pay attention to the content of plate-shaped elements in the total mass; a large number of them greatly reduces the strength of the finished structure. This parameter is called flakiness - the lower it is, the better.

Laying technology

Let's consider the procedure for creating a pillow for a strip foundation. For more information, you should refer to the strip foundation for a massive two-story cottage made of piece materials (brick).

It is heavy enough to use a gravel bed.

The following work steps must be completed:

Sand backfill

This is the lowest layer, providing a horizontal and even surface. It has a thickness of 15-20 cm, is filled in and leveled horizontally . Thorough compaction is carried out with watering until maximum density appears.

A common method of monitoring the quality of sand compaction is to walk on the surface of the backfill - if no traces remain, the job has been done efficiently. Some sources suggest laying a layer of rubble stone under the sand backfill.

The recommendation is questionable, since sand fills the gaps between large fragments and is more difficult to compact, which will subsequently manifest itself in the form of increased settlement of the foundation.

Backfilling of crushed stone

The material is laid in layers, the minimum thickness of the backfill is 25 cm. When laying, the material is carefully leveled horizontally and compacted with moisture and the use of a construction vibrating plate.

The presence of sand in the crushed stone mass makes it possible to obtain a more dense layer that allows for high-quality compaction. The main task is to constantly control the horizontal surface of the backfill layer. If you do not check the condition and level, you can end up with a wavy layer with a noticeable slope, which is unacceptable.

Leveling layer

After laying and compacting the ASG layer is completed, a relatively thin (about 5 cm) layer of sand is refilled. It performs leveling functions and seals the surface of the crushed stone layer, forming a dense and smooth surface for laying geotextiles.

This material is necessary to prevent water leaks when pouring the concrete base (if it is planned), or when pouring the main tape. The material is laid on a compacted leveling layer with an approach to the walls of the trench so that the poured concrete ends up in the hollow and the water from it does not go into the ground.

When pouring the main tape, a layer of geotextile serves as additional protection against leaks in case the reinforcement cage breaks the waterproofing film .

Fractions and purpose of crushed stone

The scope of application in construction and landscape design depends on the fraction of crushed stone and the compaction coefficient. To do this, we advise you to use approved standards; in GOST 8267-93 you can find specific markings and numbers, they will help you decide on the purchase of crushed stone.

Selection of crushed stone for various types of work:

- small - suitable for creating decorative elements in landscape design, arranging courtyards and garden paths;

- medium (from 20 to 40 mm) - can be used for filling cushions under the foundation, added to concrete mixtures and when creating reinforced concrete products;

- large (from 40 to 70 mm) - will be an excellent base for sites on “fluid” soil and for the construction of road surfaces, bridges and other structures that require a strong and dense foundation that can withstand heavy loads and strong mechanical stress.

What is a cushion under a strip foundation?

A pad is a compacted layer of sand or sand and gravel bedding that forms a flat and horizontal platform for placing a concrete strip.

It performs several important functions:

- Align the reference line.

- Compensation for heaving loads created by soil layers.

- Replacement of problematic soils in direct contact with the belt with more stable and stable layers.

- Cutting off the concrete tape from moisture, preventing capillary absorption of water.

The backfill layer, looser than the surrounding soil, allows the trench to be drained by collecting moisture at the bottom and discharging it through a system of drainage pipes into a special well.

In addition, even a relatively thin layer of sand can effectively compensate for heaving loads, which is especially noticeable on shallow types of belt.

Why is compaction done with crushed stone?

Many newcomers to construction believe that it is enough to scatter and level this material, which is strong in its characteristics, and the next stage of construction can begin. This is not true, and here's why:

- crushed stone obtained by crushing has a wide variety of shapes, so material that is not compacted will have voids between the elements, which will significantly reduce the reliability of the base under load;

- the disappearance of voids under the influence of compaction makes it possible to create an additional margin of safety; filling the space between the elements forms a monolithic base;

- the thickness of the compacted layer should be from 0.05 to 0.25 m, depending on the load calculated on it - moving cars, the mass of buildings or the weight of pedestrians.

What crushed stone is suitable for creating a pillow?

The most common type of crushed stone for pouring under the foundation, having a fraction of twenty to forty millimeters. It is included in the first category of radioactivity and is absolutely safe for human health. Strength - M1200. It has frost-resistant characteristics, which is very convenient for compacting pillows from it.

If we consider a cheap option, then it can include secondary crushed stone, which is obtained by crushing old concrete.

In order for the building to stand for many years, and the foundation not to be modified, crushed granite stone is used. This is the most expensive option. But thanks to its characteristics, it will withstand any construction. Typically, granite crushed stone is combined with other building materials, most often with sand.

Compaction methods

Existing soil compaction technologies are based on removing air from the poured material using mechanical devices.

The following compaction methods can be distinguished: compaction, vibratory compaction, rolling, vibrating, combined - the use of several methods.

Before proceeding with soil compaction, it is necessary to analyze it, determine the groundwater level, and conduct soil studies. The final result will depend on this, because subsidence can occur in the most unpredictable places.

Important: when it comes to building a foundation, do not neglect laboratory tests and specialist recommendations. This information is important not only for building a reliable, durable building, but will also ensure the safety of everyone who will live in the house.

Manual compaction methods

If you do not have a vibration installation, then craftsmen are always ready to help and share information on how to make a tamper yourself. We are also ready to share advice, however, with such compaction it will be necessary to apply a lot of physical force; we still recommend using muscular force for small amounts of work.

There are a huge number of types of this device; the simplest option can be a wooden beam with a large cross-section. The length of the beam depends on the individual parameters of the worker; it is usually calculated from the ground to the chest.

Mechanical means of compaction

For large areas that require compaction, it is impossible to do without mechanizing the process. Therefore, for this case there are specialized devices - vibrating plates or vibrating rammers. They greatly facilitate the work, and also allow compaction in hard-to-reach places, for example, areas located next to buildings.

Compaction occurs due to vibration of the slab. This effect is transmitted by eccentric mechanisms. The installation is very reliable, mobile and easy to use. For domestic needs, a vibrating plate weighing 60–120 kg is sufficient.

Both an internal combustion engine and an electric one can be installed on the device. Equipment with an electric motor is slightly lighter in weight and is widely available in specialized stores; you can also purchase it secondhand. If you don’t need it in the future, you can always rent it for a while.

Important: of course, it is prohibited to start working with this equipment without studying the instructions.

Calculation of material quantity

Many craftsmen have faced the problem of an overabundance or shortage of building materials. Agree, both situations are unpleasant, so knowing how much crushed stone you will need is a very important aspect.

So, for the calculation we need the following parameters:

- the thickness of the base base after compaction is often 0.2–0.25 m;

- compaction coefficient - 1.3. This parameter is suitable for most materials that have been compacted using mechanical devices;

- specific gravity of the building material, this parameter is usually indicated in the accompanying documentation; for crushed stone it is 1.5 t/m3.

Now you can calculate the required amount of crushed stone for filling 1 m 2 of a 0.25 m thick surface: 0.25 × 1.3 × 1.5 = 0.49 t. It is better to round up.

Source: sunway-online.ru

The technology of soil compaction is associated with a large number of subtleties, as you have already noticed, so do not neglect the advice and recommendations of specialists. Only then will you be able to achieve decent quality work. See you again on the pages of our website!

In accordance with applicable law, the Administration disclaims any representations and warranties that may otherwise be implied and disclaims liability in relation to the Site, the Content and its use. More details: https://seberemont.ru/info/otkaz.html

Was the article helpful?

Tell your friends

Soil compaction: crushed stone

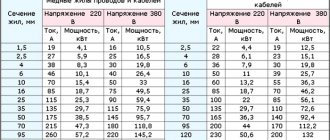

LOCAL RESOURCE STATEMENT GESN 11-01-001-02

| Name | Unit |

| Soil compaction: crushed stone | 100 m2 compaction area |

| Scope of work | |

| 01. Layout of the base. 02. Watering the soil with water. 03. Spreading, leveling and pressing gravel or crushed stone into the ground. |

The price contains only direct costs of work for the period 2000

(prices in Moscow and the Moscow region), which are calculated according to

2009

. To draw up an estimate, you need to apply the conversion index to the prices of the current year to the cost of the work.

You can go to the pricing page, which is calculated based on the standards of the 2014 edition with additions 1 The basis for using the composition and consumption of materials, machines and labor costs are GESN-2001

| № | Name | Unit Change | Labor costs |

| 1 | Labor costs of construction workers Grade 2.8 | person-hour | 7,7 |

| 2 | Labor costs for drivers (for reference, included in the price of the EV) | person-hour | 0,88 |

| Total labor costs for workers | person-hour | 7,7 | |

| Workers' compensation = 7.7 x 8.38 | Rub. | 64,53 | |

| Payroll for drivers = 9.24 (for calculating invoices and profits) | Rub. | 9,24 |

OPERATION OF MACHINES AND MECHANISMS

| № | Cipher | Name | Unit Change | Consumption | Article number Rub. | Total RUB. |

| 1 | 030101 | Forklifts 5 t | mach.-h | 0,33 | 89,99 | 29,70 |

| 2 | 050102 | Mobile compressors with internal combustion engine pressure up to 686 kPa (7 atm), capacity 5 m3/min | mach.-h | 0,46 | 100,01 | 46,00 |

| 3 | 153101 | Self-propelled smooth road rollers 5 t | mach.-h | 0,09 | 112,14 | 10,09 |

| 4 | 331100 | Pneumatic rammers when operating from mobile compressor stations | mach.-h | 0,93 | 0,55 | 0,51 |

| Total | Rub. | 86,31 |

| № | Cipher | Name | Unit Change | Consumption | Article number Rub. | Total RUB. |

| 1 | 408-9136 | Crushed stone from natural stone for construction work, fraction 40-70 mm | m3 | 5,1 | 0,00 | |

| 2 | 411-0001 | Water | m3 | 0,22 | 2,44 | 0,54 |

| Total | Rub. | 0,54 |

TOTAL BY RESOURCES: 86.84 RUB.

TOTAL PRICE: 151.37 RUR.

Look at the cost of this standard at current prices open page

Compare the price value with the value of FER 11-01-001-02

To draw up an estimate, the price requires indexation of the transition to current prices. The price is based on the GESN-2001 standards, as amended in 2009.

in

2000

.

To determine the intermediate and final price values, the DefSmeta

. Crushed stone today is the most practical, cheap, effective, and, accordingly, the most common materials . It is mined by crushing rock, most often the raw material is obtained by blasting in quarries. In this case, the rock is destroyed into pieces of different sizes, and the compaction coefficient of crushed stone strongly depends on the fraction.

What to choose, sand or crushed stone?

The choice of backfill material is determined by the weight of the building. The heavier it is, the larger the backfill fraction should be used . The sand layer has a more noticeable settlement, so it is most often used for frame, wooden houses, buildings made of cellular concrete, etc.

Pure coarse-grained river sand is used, which does not have foreign (especially organic) impurities or clay inclusions.

The crushed stone layer has greater elasticity and load-bearing capacity . It is simpler and easier to compact, the pillow is more rigid and reliable. Backfill made of gravel or crushed stone is used in the construction of higher-rise buildings made of heavy and dense materials.

Crushed stone is not used in its pure form; in practice, a sand-gravel mixture is used in a ratio of 60% crushed stone to 40% sand, although in some situations the volume of sand can be reduced or increased.

Fraction

Crushed granite is the most common option because it has a high level of temperature resistance and practically does not absorb water. The strength of granite meets all technical requirements. The most popular fractions of granite:

- small – 5-20 mm;

- average small – 5-40 mm;

- average – 20-40 mm;

- large – 40-70 mm.

Each type has different areas of application; the fine fraction of slag is mainly used for:

- preparation of ballast layers that are necessary for railway tracks and roads;

- added to building mixtures.

Based on what to choose relative compaction

The compaction coefficient strongly depends on various indicators and characteristics of the material; the following must be taken into account:

- average density, usually set by the manufacturer, but generally ranges from 1.4 to 3 g/cm³. This is one of the key parameters used in the calculations;

- flakiness to predict the plane of crushed stone;

- fractional sorting, smaller grain size – higher density;

- resistance of the material to frost depends on the breed;

- radioactivity of rubble. The first class can be used everywhere, and the second only for country roads.

Varieties and characteristics

Various types of crushed stone can be used for construction; the range today is quite large, but the properties also differ significantly.

Depending on the type of rock, the following main raw material groups :

Granite rock is the strongest because it is the material that remains after the magma cools. Due to the high strength of the rock, it is difficult to process. Produced on the basis of GOST 8267-93.

Crushed stone 5-20 mm has become widespread, as it can be used for almost all types of construction.

The gravel variety is more free-flowing , and accordingly the compaction coefficient of crushed stone is higher. It is mined by grinding rocks, which makes it a cheaper material, but also less durable.

Is she needed?

Despite the important and responsible role of the sand cushion, there are often arguments against its use.

The arguments given by opponents of the bedding are as follows::

- No matter how carefully the sand layer is compacted, some settlement will be present in any case. The thicker the cushion, the stronger the settlement, which creates a significant danger for the belt due to its unevenness. Because of this, the thickness of the bedding is limited - it should not be more than three times the width of the tape.

- A layer of sand poured into a trench dug in clay soil will become an accumulator for moisture. The clay will not let it out of the recess, so a high-quality drainage system is necessary.

- The cushion layer has to be taken into account when calculating the depth of a trench or pit, which increases the volume of excavation work and the amount of excavated soil.

Experts with many years of practice are unanimous in the opinion that the main function of the cushion is to level the bottom of the trench (or pit). It is never possible to create a flat and horizontal area by digging alone.

All attempts in this direction result in a significant waste of time without satisfactory results, so bedding allows you to reduce preparation time. With regard to drainage, the situation is usually known in advance, since the hydrogeological situation at the site is analyzed first.

Therefore, the priority task of the pillow is to form an even and horizontal reference line at the desired height level.

The remaining functions of sand backfill can be considered additional , although they are of considerable importance and are performed quite effectively.

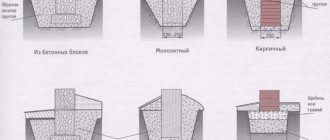

There are several design options for a pillow under the ribbon:

- Sandy . It is a layer of sand of a certain thickness, maximally compacted and horizontal. Distributes the load from the weight of the belt and the building, provides a cutoff from groundwater, and allows you to replace unsuitable soil with more stable and cheaper river sand. It is used primarily for relatively light buildings; such a pillow is not used for heavy and massive buildings.

- Gravel bed . A layer of gravel or crushed stone is used, which can significantly increase the weight of the building. In private construction, this type of pillow is used quite widely, since it allows the backfill layer to be more densely compacted and has a high load-bearing capacity for any home. Sand is also present in the gravel backfill, filling the cavities between larger elements, which makes the layer more dense. Usually there are 60% crushed stone and 40% sand.

- Concrete screed (concrete footing) . It is a poured layer of concrete of lower density. The most durable and reliable pillow option, providing horizontal position and high load-bearing capacity. It is used for the heaviest buildings and costs significant amounts.

The choice of the most suitable option is determined by the weight of the future building, soil characteristics and other factors. It is made during the creation of the project, when calculating the foundation.

Why know the compaction coefficient according to GOST

The compaction coefficient is regulated by SNIP, as well as GOST, where the corresponding recommended density parameters are indicated.

Thanks to the values, you can determine how much crushed stone can be compacted, that is, reduce the physical volume of the material.

In this case, compaction occurs intentionally (for example, with a vibrating plate) and unintentionally (during transportation). Mostly the value fluctuates between 1.05-1.52.

Regulatory documents indicate the compaction coefficient of sand and crushed stone according to GOST:

- mixture of sand and gravel – 1.2;

- sand – 1.15;

- expanded clay – 1.15;

- crushed gravel – 1.1;

- soil – 1.1 (1.4).

In practice, there are several reasons for determining the coefficient:

- used to calculate the required quantity of purchased materials. Thanks to this approach, additional costs for the purchase of excess crushed stone or batch purchases are eliminated;

- The figure is also used to find out how much the level will drop when the crushed stone is compacted with a vibrating plate.

The formula for determining the required amount of material is as follows:

Volume of the mold to be filled (m3) * specific gravity (kg/m3) * compaction coefficient

By substituting the numbers, you can reliably determine the amount of material involved, but you need to take into account some undesirable effects: slag residues at the spill site, perhaps a slightly lower weight of the delivered material. Therefore, you should calculate with a small gap.

There are special tables with average information on the weight of gravel depending on the fraction. For example, 0-5 mm of crushed stone in 1 m3 is approximately 1.5 tons, and the crushed stone compaction coefficient of 40 70 can be calculated, taking into account the approximate mass of 1.47 t/m3.

Cushion material

The backfill layer is made with sand or crushed stone. Mixed sand-crushed stone and sand-gravel pillows are also used. On heaving soils, and in other cases where high strength is required, concrete pads are installed. For their production, lean concrete, grade 100, is used. It is prepared using crushed stone with a fraction of up to 10 mm, and very little water is added. They are not placed by pouring into formwork, but by pouring them into the bottom of the pit. Then it is compacted by rolling.

Such a structure is stronger than a cushion made only of sand and crushed stone, however, it does not have the property of drainage. Therefore, it is preferable for constructing foundations on clay or dense loam. Where soils do not form an aquifer.

When constructing cushions, it is not allowed to use materials contaminated with natural soil (loam, black soil) or organic residues. With a dust particle content of more than 10%.

The characteristics of pillow materials are regulated in more detail by GOST 25100-95.

Compaction coefficient (margin of safety) according to the SNIP table

The normal value of crushed stone compaction is presented in the form of a SNIP table. There is a certain formula thanks to which you can calculate the compaction coefficient; the most important condition is the fraction. So, let's consider the bulk density of the material:

| Fraction, mm | Bulk density | |

| Granite crushed stone | crushed gravel | |

| 0-5 | 1500 | |

| 5-10 | 1430 | 1410 |

| 5-20 | 1400 | 1390 |

| 20-40 | 1380 | 1370 |

| 40-70 | 1350 | 1340 |

To obtain more reliable data, you can weigh a certain volume of crushed stone, then carry out a calculation based on the formula:

Weight = mass/volume.

Then it is necessary to roll the mixture into a condition that will be used on the site, then the area is measured. The calculation is performed again using the same formula. This gives us 2 numbers: density before compaction and after.

Technology for compacting soil with a roller or vibrating plate using crushed stone

Crushed stone is mainly used to compact the top layer of soil. A preliminary study of the soil is carried out, a hole is drilled 50-70 cm deep, then the presence of groundwater, composition, and type of soil are determined.

After passing the tests, if the surface condition is normal, you can backfill with crushed stone.

The technology for compacting soil with crushed stone in industrial conditions includes the use of large-sized equipment: bulldozers, tractors, excavators; in small, home conditions, an ordinary shovel can also be used. It is also necessary to determine the water content of the soil; it may need to be moistened or, on the contrary, dried.

compact using a vibrating plate or . It should be taken into account that the layer will become smaller after compaction. It is recommended to make a 50 cm deepening by filling the surface with crushed stone, but a different depth may be required.

Tamping continues until the soil stops settling, otherwise the foundation is doomed to crumble. Testing crushed stone compaction can be done using the same equipment by determining if there is movement in the top layer.

Soil compaction with crushed stone is standardized by SNIP documents, which indicate the quantity and density of the embankment. In this case, soil compaction plays an important role, and then together with crushed stone.

Mostly, the compaction procedure is first carried out in a dug pit before the material is poured in order to prevent the soil from being pushed through. For more details on soil compaction with crushed stone, watch the video.

Cement can truly be called the main component of most buildings and structures. By following the link you will learn how to properly dilute cement.

Today, tile adhesive is widely used during renovations; it can be used to glue a wide variety of materials. It's all about its composition.

Decorative bark beetle plaster is often used to decorate the facades and walls of houses and a wide variety of structures. Here everything is about the technology of its application.

The price for the compaction procedure can vary greatly depending on the contractor’s company, the quality and type of crushed stone, but it especially depends on the remoteness of the construction site, as well as the complexity of the conditions.

In some cases increased embankment density is required when environmental conditions are prone to destruction of the foundation, for example, swampy areas, high humidity, risk of landslides, etc.

sand cushion

Sand cushion for prefabricated strip foundation.

Using sand to cushion the foundation is the most economical option. The formation of a sand cushion can provide optimal load on the lower part of the building. In addition, this sand will protect it from being washed away. It can also be used if there is an unfavorable layer at the ground level chosen to begin construction. In this case, the unsuitable soil must be removed and replaced with a layer of sand. To do this, its factions must be large.

The optimal thickness of the sand cushion for the foundation is 20-25 cm. To form it, it is recommended to carefully level and compact the surface so that the sand layer acquires the necessary strength. It is advisable to compact the sand for the foundation cushion using a specialized tool - a vibrating plate. Using improvised means for this will worsen the quality of work. During compaction, it is necessary to constantly moisten the surface. This will give it density.

When forming a sand cushion, it is necessary to take into account the depth of groundwater. If they are located too close to the soil surface, then drainage must be made under the layer that serves as the base. If this is neglected, it may be blurred.

Forming a sand cushion is advisable in the following cases:

- groundwater is located quite deep;

- lightweight materials will be used for the construction of the building (foam blocks, polystyrene foam, frame structure);

- the house will be one-story.

The advantages of using sand are that it is the cheapest and most practical material. However, it is worth considering that the construction of powerful, impressive houses on it is unacceptable.

Bulk density for decluttering and other types of construction

Quite often you need to find out the density of crushed stone of an embankment after transportation in a car. This procedure can be useful in determining the required compaction device, the amount of concrete and its composition for decluttering.

The density of the embankment can be calculated using a simple procedure:

- it is necessary to prepare an empty vessel for filling with crushed stone and weighing, it is necessary to determine its weight;

- fill the container with crushed stone and weigh it;

- it is necessary to determine the net mass of the material, that is, subtract its own mass from the weight of the filled vessel;

- divide the weight by the volume of the vessel.

When laying the foundation, it is necessary to clearly achieve the compaction coefficient specified in the regulatory documents. Otherwise, this is fraught with accidents and rapid destruction of the building, and this remark applies to all types of construction.

After the event, the compaction must be measured and checked for density. This can be done using a simple calculation, determining the mass and volume of crushed stone poured and the thickness of the layer. This way you can find out how much the volume of material has decreased after compaction.

There is also special equipment for determining the efficiency of compaction - a density meter.

A good tool is the BPD-KM, which indicates the actual density. The purpose of the equipment is to monitor the quality and level of compaction of soil, gravel, and crushed stone.

At the same time, the device is very accurate , the flow rate in the readings does not exceed 0.01 g/cm³. The basis for determining the density with the device is the method described in the document GOST 28514–19.

Purpose of the structure

The cushion or preparation performs the following functions:

- Evenly distributes the pressure of the foundation base onto the ground. The heel of the foundation, if laid directly on the ground, will not rest on its entire plane. The bottom of the trench (pit) has uneven surfaces, so when laying, the foundation will first rest on the protruding parts. As the load increases, it will begin to crush the soil. This process will continue until the protrusions are level. The draft may be scanty, but it will still be there. Moreover, a misalignment of the base by a millimeter can result in tens of centimeters in the upper part of the house. The cushion material, sand or crushed stone, has a relatively fine fraction. It fills all the irregularities, providing the foundation with a continuous support area. Even if settlement occurs due to natural compaction of the soil, it will be uniform. In addition, due to a phenomenon called a pressure prism, the load through the pillow is not transmitted strictly vertically, but at an expanding angle. Which gives the greater the supporting surface, the greater the thickness of the layer of bedding under the foundations.

- Serves as a leveling layer. Even digging with a shovel, not to mention excavators, produces deviations from the horizontal, producing the same unevenness that we talked about in the previous paragraph. With the help of a cushion, the base for the foundations can be brought, as builders say: to zero.

- Provides precise adjustment of the foundation elevation. The bottom of the foundation slab must be located relative to other objects at a height strictly (up to a millimeter) determined by the project. When digging a pit with an excavator (or even manually), it is extremely difficult to reach exactly this mark. Therefore, builders choose soil slightly lower than the foundation planting level required. This reserve is compensated by the pillow.

- Strengthens the top layer of the soil base. By developing the soil, we inevitably violate its integral structure. In addition, the process itself does not occur instantly. Therefore, the soil at the bottom of the pit is exposed to moisture, wind, etc. for at least hours.

- Since concrete does not allow water to pass through, moisture can accumulate in the layers adjacent to the foundation body. In such cases, the pillow acts as drainage, allowing water to pass freely. This property is especially important at the foundation for fences, which often impede the movement of melt and rain soil water.