- home

- Useful articles

- How to fix a dowel in a loose wall

»

»

Anyone who has ever hung a shelf or other interior items or furniture has encountered the problem of securing a dowel in a loose wall. At the same time, dowels, with the help of which almost all such issues are solved today, cannot always help if the selection is not guided by the relevant rules. Let's talk about them in more detail.

Concept

The design features of the anchor make it possible to effectively use fasteners in the process of installing objects of impressive size and weight to the surface of a material of varying density and strength.

The products are actively used in the construction industry, including for repair work.

Hardware is presented in a wide range. They differ in design, material of manufacture and purpose. Along with universal options, anchors are produced that solve highly specialized problems.

The main thing is to choose the right anchor bolt for a specific situation. The base material to which the fastening will be made, the dimensions and weight of the object that needs to be securely fixed to the wall are taken into account.

The principle of operation of fasteners is simple. The anchor element is inserted into a previously created hole corresponding to the cross section of the spacer sleeve. The nut is tightened. The cone tip opens. The sleeve increases in diameter, fixing the anchor bolt in the seat.

Important! A variety of hardware are produced that are allowed to be used in special conditions - aggressive chemical environments, in rooms with high humidity.

ad

The sands of time flow and with this flow everything around us turns into sand.

Today we’ll talk about “sand walls” in old houses, in fact, of course, this is not a squeak, more often it is either “shingles” or experimental materials based on gypsum, asbestos or other silicate-containing materials mixed in various proportions with various fillers to reduce the cost construction. This approach was popular not only during the construction of “Khrushchev” buildings, alas, and now in our time we often see unjustified ways to save money, I’m talking about modern partitions made of gas and foam blocks, because primarily these materials are intended for insulating external walls, but some for some reason they consider foam and gas blocks to be suitable materials for the construction of partitions. But now we are not talking about modern methods of constructing partitions, but about modern life in the conditions of old Khrushchev walls and partitions. The best way out of the situation is to demolish such a partition and rebuild it from solid brick, but when there are no funds for repairs, and life goes on, then you have to proceed from the current realities. But the reality is that old walls don’t hold up, dowels fall out of them, shelves and cornices tilt and fall. How do you attach a curtain rod or TV bracket to a sandy wall where you can't be sure it won't drop your plasma or the curtain rod won't fall on a child clinging to the curtain?

Methods of fastening to old Khrushchev walls

Load vector. In order to hang something on the wall, you need to choose a fastening method, and in order to choose a fastening method, you need to understand the load vector, i.e.

understand what load the connection will have to bear when breaking or breaking.

If the upcoming load involves a “lever” load, as for example in the case of a horizontal bar, where the center of gravity will be placed far from the attachment point, then you should choose the most reliable and proven fastening methods, for example, anchor or through pin fastenings, where it is necessary to make a through hole and install a long hairpin with a metal insert on the tail. In all other cases, where the load is not large, less radical methods of fastening are suitable.

Method number 1. Fastening with dowels in old sand walls

If your design involves a “break” type of load, then you can use high-quality plastic dowels with a larger diameter than the dowels and screws supplied in the kit.

If the mounting loops of your design do not allow you to install larger self-tapping screws, then simply buy high-quality dowels of the same diameter. Don’t even think about using a standard dowel-nail in old sand walls; you’ll be redoing it.

Before inserting the dowel into the drilled hole, remove any dust from the hole that always remains during drilling. If the dowel fits in without much effort, i.e. If you stuck it in with one finger press, then it definitely won’t be able to stay in such a loose wall.

The dowel should fit tightly into the hole under light blows of the hammer; in addition, it is advisable to dip the dowel in PVA glue or drop any assembly glue, for example, “liquid nails” into the hole. A more reliable method for wall kitchen cabinets.

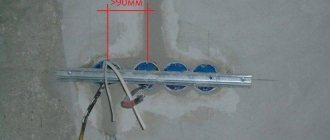

Take a wood bit with a diameter the size of a socket box or larger, such a bit will easily cope with a “sandy” wall, drill out the intended fastening points for the cabinets with it, this diameter will allow you to screw in half the long screws on the sides of the wide hole and they will serve as a reinforcing base.

Moisten the prepared holes with water or PVA glue diluted to a liquid state, then fill them with cement-sand mortar and put them under the wall level with a spatula, wait until they dry completely and you can drill drills with the diameter you need for hanging cabinets and shelves. Of course, this method is time-consuming, but you don’t have to worry about the reliability of the design and risk not only expensive sets, but also your health and the health of your loved ones.

Method number 2. Fastening with a metal anchor

Perhaps a metal anchor is the most effective method of fastening that exists. But in the case of sand walls, the anchor may not live up to the expectations placed on it. You shouldn’t have high hopes for it if you have a Khrushchev building with sandy walls.

The most unpleasant thing that can happen is that the anchor pin turns in the wall when it is almost tightened, you will have no other choice but to cut it off with a grinder and leave it in the wall, the anchor bolt in this regard looks simpler, you can dismantle it even if it turns .

Therefore, when installing a structure on an anchor bolt or stud, pay special attention to proper drilling.

When driving in the anchor pin, make sure that the thread is not deformed, otherwise you will not be able to tighten the anchor with the nut, since the anchor pin will rotate with the nut due to the deformed thread.

Method number 3. Fastening with chemical anchor

Relatively recently invented, and already quite popular, the chemical anchor has earned universal recognition for good reason. The once expensive and rare product is now gaining popularity and becoming more accessible.

Its advantage is ease of use and reliable connection. Today I know of 2 types of packaging for chemical anchors, which are used differently, in tubes and glass flasks.

In the case of old, loose walls of Khrushchev-era buildings, I recommend using a chemical anchor in a tube.

You drill a cone-shaped hole in the wall, clean it from dust, then fill it with a chemical anchor, insert a pin, and after 25-60 minutes (depending on the manufacturer and personal instructions) you can fasten the structure.

Drilling. If you have the same sand walls as described above, then you need to drill such walls with a regular drill in non-impact mode. I advise you to replace the standard dowels included in the kit with dowels and screws of increased diameter, if your design allows it.

I recommend using Fischer dowels; this is not advertising, but a reality proven by time.

Ideally, the diameter of the drill should be 0.5 mm smaller than the dowel, but such a drill is not always available. Knowing this nuance, the fischer company produces dowels of a slightly larger diameter so that when driving the dowel, sufficient density of the mounting hole is maintained.

When drilling, choose a position that is comfortable for you and try to hold the drill as level as possible relative to the plane of the wall, observing the angle of entry of the drill so as not to expand the diameter of the hole.

By the way, at the extreme points of attachment it is better to increase the angle slightly in order to create additional resistance, i.e. make it not 90 degrees, but 91-95 degrees. After the hole is drilled, be sure to remove dust from it; this can be done using a vacuum cleaner or a can of compressed air.

Well, if you are still not confident in your abilities or something is not working out for you, then we are ready to offer you ours.

Source: https://www.uvasnachas.ru/statya/5/rihlie-pesochnie-steni.html

Difference from dowels

To ensure expansion of the wall, a self-tapping screw is inserted into the dowel. The functioning mechanism of both elements is based on the expansion of the wall material. The dowel fastening system is simpler: a self-tapping screw is screwed into them or a large nail is driven in. With anchors things are more complicated. Their fastening system consists of two parts. At the moment of screwing into the spacer, its “petals” open in the cavity of the wall. This ensures reliable adhesion.

In terms of purpose, both types of fasteners do not differ. They are used to secure heavy objects. The only difference is that the anchors can withstand heavy loads: from 100 kg. A through fastening system on a load-bearing wall is implemented.

If you use special fasteners

Perhaps such methods will seem very exotic. Then, to save effort and time, it is better to use special dowels:

- “butterfly” is used for fastening in hollow walls;

- the spacer dowel will distribute the load not only along, but also perpendicular to the fastening element, increasing the pressure zone and, accordingly, reducing the weight at the fastening point itself;

- dowels for foam concrete are intended for walls made of fragile building materials;

- The spring dowel, or umbrella, is distinguished by its overall versatility: it is suitable for almost all types of loose or loose walls.

The main advantage of special dowels is fast and hidden installation. In addition, if necessary, it is much easier to dismantle.

Varieties

Anchors differ not only in size. There are design features of technical parameters. Anchor products for brick walls are divided according to their intended use. A specific type of hardware is used for certain installation work.

Important! To ensure reliable fixation of an object in a brick wall, it is recommended to take a responsible approach to the choice of anchor products.

Driven type

Allows you to secure critically heavy weights. Made from high-strength material or carbon steel. It is treated with a specialized anti-corrosion coating, which ensures an increase in service life. The product is manufactured in one piece, which increases the reliability of the fasteners. A popular type of hardware is the collet anchor.

Drivers

The anchor is driven into the brick with a hammer. Its working part becomes wedged. This way the element is securely fixed in the wall. Then the bolt or stud is screwed in.

Wedge type

The scope of application is identical to the hammer type analogue. The method of installation in a stressed and unstressed concrete plane is allowed. Refers to reliable fastening elements. Capable of withstanding high loads. Used in dry rooms.

Made from various types of steel. Differs in specific execution. On one side there is a stud with a metric thread, onto which a nut is screwed. On the other hand, there is a spacer system in the form of a coupling with an internal shank.

Wedge

MSA type

Brass products, the outer side of which is characterized by the presence of a special sleeve with a large notch. The design allows you to increase the density of fixation of fasteners in the wall cavity. The permissible intra-sleeve cross-section is in the range of 8-10 mm.

Chemical principle

The external design is a cylindrical tube. Inside there are two ingredients - organic and inorganic. Reacting with each other, they harden and provide the required degree of strength.

Chemical

Important! Chemical-type fastening structures are in high demand because their use is allowed in places with high humidity, in porous substrates. Even in such extreme conditions, they are able to hold the elements together.

The name of the hardware was given in view of the chemical principle of operation - a chemical reaction. Has no smell. It is an environmentally friendly product. Does not harm the environment and the human body.

The negative aspects of using the product include the high price and different setting times of the composition. The latter depends on the variety of adhesive mixtures.

With ring

The peculiarity of the product – the presence of a ring – ensures its scope of application. It is convenient to install suspended structures on wall and ceiling surfaces. In construction it is used for securing scaffolding. Allowed to be used for bricks with a dense internal structure - only solid ones. In porous and hollow materials, fasteners lose their effectiveness.

With ring

Double-spacer

Additionally, a spacer sleeve is provided that opens simultaneously in two places. The first spacer element does not come into contact with the solid masonry surface. The reliability of fixing the product in the wall increases. The sample shows good results in the tensile test, therefore it is used in difficult operating conditions.

Double-spacer

How to fix an anchor in a hollow brick?

Metal dowels for hollow foundations

If previously the walls of houses were built exclusively from solid bricks, then with the advent of well masonry technologies, multi-slot bricks, as well as porous ceramic blocks, began to be used for this purpose. In this case, the walls are hollow, which is very good for their thermal characteristics. However, the question immediately arises: “Which masonry anchors should be used in this case?”

This question has a double meaning: what types of anchors are used to attach the cladding to the main wall; and what fasteners can be used to hang something on a hollow wall in everyday life.

In one case, you need anchors for brick cladding, and in the other, an anchor for hollow bricks.

These are completely different things, and we, using the video in this article to help, will consider options for both categories of work.

Features of lightweight brick walls

Walls are hollow for two reasons:

- First : when slotted brick is used for masonry.

- Second : when the walls of a building are lightened by constructing cavities-wells inside the masonry, which are then filled with heat-insulating material. When making well masonry, both hollow and solid bricks can be used, so a variety of anchors may be needed in the work.

Well cavities in brick walls

Well-type masonry consists of two parallel walls connected to each other by transverse diaphragms - which is what we see in the photo above. It is they who perform the role of anchors in this case. Thanks to them, vertical wells are formed, which, in order to increase the thermal properties of the enclosing structure, are filled with either foam insulation or loose insulation.

As an option, concrete-anchor masonry can be performed. What is she?

In principle, this is a type of well masonry, only here cellular or ash concrete is used as insulation. Since it hardens and forms a strong monolith, the means to achieve maximum structural rigidity here is anchor brick.

Anchoring lightweight masonry with bricks

This intriguing name hides the most ordinary bricks, which are laid into a row of spoons with pokes. This is done so that the protruding edges form teeth in the internal cavity of the wall.

During the hardening process of the concrete poured into the wells, the anchor bricks will be firmly fixed in it.

In the above picture, even without words, you can clearly see how in this case the anchoring of the brickwork is carried out.

Fastening the facing masonry to the wall

From all that has been said above, it is quite clear that when constructing lightweight masonry, the anchor for a brick wall is the brick itself. So, when it comes to ordinary masonry, no fastening elements are needed. But to fix decorative (facial) masonry to it, completely different technologies are used.

Flexible connections

In general, when performing cladding, an anchor for brickwork can be any available metal material. Many masons believe that all means are good for this.

To anchor the facing masonry, which is carried out simultaneously with the construction of the main wall, they use pieces of steel rods and strips of plaster mesh, and even manage to make improvised anchors with their own hands from scraps of aluminum profiles.

Anchoring with steel rods

Note! There are many types of anchors specially designed for fastening brick cladding, which are called flexible ties.

Why flexible? Yes, because part of the anchor rod is made of flexible polymer or composite material.

This makes sense: thanks to the movable connection with the load-bearing wall, when the foundation shrinks, cracks do not form on the facing masonry.

Composite rods and dowels

The most common are anchor rods and facade dowels with a flexible connection, made of basalt plastic or fiberglass. The rods are used for monolithic cladding - in cases where it is not possible to connect to a load-bearing wall.

For example, when the pattern of the facing masonry is formed only by rows of spoons. The rod anchors, which are shown in the picture below, can also be used when constructing a decorative wall with a ventilation gap, but without insulation.

Brick anchor: fiberglass rods for monolithic cladding

Anchors in the form of a facade dowel with a flexible connection, which you see in the photo below, are equipped with a spacer washer. They allow you not only to connect two walls together, but also to simultaneously fix the heat-insulating boards. Therefore, they are used to connect three-layer insulated walls, while simultaneously serving as disc-shaped dowels for insulation.

Basalt plastic anchor rods

This concludes all the differences between rods and dowels. All of them can withstand prolonged exposure to high temperatures and are extremely durable. By the way, in this indicator, basalt plastic is even ahead of steel.

It is also important that it has a low thermal conductivity coefficient, and reduces to zero the possibility of the formation of cold bridges. This is precisely the main disadvantage of metal rods, since they accumulate condensation and succumb to corrosion, which leads to breaking of bonds.

Perhaps someone will think that since the rod is flexible, it can be easily pulled out of the wall. However, this is not at all true. The force that needs to be applied for this corresponds to 408 kgf (4000 Newton). Such an impact only occurs during an earthquake, but when the walls themselves collapse, it is unlikely that anyone will worry about the cladding.

How to install an anchor in brickwork

- The diameter of the anchor sleeve intended for brick walls is usually 6 mm. The length varies significantly, which, in fact, determines the price of the product: from 6 to 14 rubles. a piece.

- The length of the dowel is selected so that it fits into the facing brickwork by at least 9 cm (three-quarters of the width of the brick).

- Its anchor part is always 6 cm. Clamps for insulation are sold separately and purchased as needed.

- There are also options for flexible connections for attaching brick cladding to other types of foundations: monolithic, cellular concrete. The exact number of connections is determined by calculation, and depends on the presence or absence of insulation in the wall pie.

- Its type also matters. For example, mineral wool needs to be fixed more often than polystyrene foam. But on average, the consumption of composite anchors is 4 pieces per 1 m2. Additionally, they are installed at corners, around openings, in places where expansion joints are located, and the fastening spacing is no more than 300 mm.

Fixing brick cladding to a concrete wall

What else are flexible anchors good for when building a brick wall with brick cladding? Because they allow you to connect two walls even when the horizontal joints of the masonry do not coincide.

A flexible connection can also be placed in a vertical seam, which cannot be done in any other case. To prevent the fastenings from loosening, before attaching the brick anchors, install the thermal insulation with glue, and then, stitching it through, install flexible connections.

Anchors for hollow foundations

The instructions given in the previous chapter were focused on anchoring the walls themselves during their construction and brick cladding. Now we will look at which brickwork anchor can be used when you need to hang a cabinet, lamp, CCTV camera, etc. on the wall.

Types of fasteners

There are no problems with solid brick walls: they simply drill holes in them and install dowel-nails. But for walls built from slotted bricks or porous ceramic blocks, this technology is not suitable. Due to the hollow structure of the base, a regular dowel will not hold - for this you need anchors for hollow bricks.

Fastening rules

Expert recommendations:

- Holes for anchors are made exclusively into the body of the brick. It is strictly prohibited to make them into inter-masonry butt joints. Such fasteners are not capable of holding a heavy object. On the other hand, damage to part of the seam joint negatively affects the load-bearing capacity of the wall, weakening it.

- Installation of fasteners is carried out in strict perpendicularity to the plane of the brick. Even minimal deviation is not allowed. The technological process is disrupted. The fixation becomes unreliable.

- When calculating the depth of the hole to be made for the fastening element, it is imperative to take into account the thickness of the finishing layer. The surface can be puttied or plastered. Fixation of hardware should be carried out exclusively in the plane of the wall, and not in the plane of the facing or decorative material. Incorrect calculation of the depth of the fastener will cause it to fall out.

- After drilling, the hole is cleaned of dust and dirt, particles of brickwork, and plaster. Use a special construction brush, vacuum cleaner or other available means.

Following the recommendations of specialists will allow you to create a high-quality fastening and guarantee its reliability.

How to fix an anchor in hollow brick

Metal dowels for hollow bases

If earlier the walls of houses were built exclusively from solid bricks, then with the advent of well masonry technologies, multi-slot bricks, as well as porous ceramic blocks, began to be used for this purpose. In this case, the walls are hollow, which is very good for their thermal characteristics. However, the question immediately arises: “Which masonry anchors should be used in this case?”

This question has a double meaning: what types of anchors are used to attach the cladding to the main wall; and what fasteners can be used to hang something on a hollow wall in everyday life.

In one case, you need anchors for brick cladding, and in the other, an anchor for hollow bricks.

These are completely different things, and we, using the video in this article to help, will consider options for both categories of work.

Installation features

In the practice of modern construction, anchors are in demand. They provide a reliable way to install equipment and fix massive objects and structures on the walls and ceilings of a building. It is important to choose the right hardware for the job.

Fastenings for solid bricks will not provide the necessary adhesion to hollow material. Therefore, it is important to first determine the base raw materials from which the enclosing structure was erected.

Sequence of work:

- The plane is marked. The work is done with the utmost care. Hollow ceramic bricks are fragile. If you make two holes with a small interval between them, the material will most likely be deformed.

- The hole in the brick is made with a specialized drill. The cross-section of the anchor element and the depth of its placement are taken into account. The perpendicularity of the hole produced is a guarantee of high-quality work.

- After creating the hole, it is cleaned of dust and debris. Depth accuracy is checked.

- When inserting the anchor, make sure that the gap between it and the wall is minimal. If it turns out that the product is loose, it is better to take larger hardware. It should be selected according to the diameter of the resulting hole.

Important! Installing a hammer-type product is the same painstaking process as installing a spacer analogue. If you apply excessive force when hammering, not only the fastener itself will be damaged, but also the wall.

Expansion anchor

In difficult situations, it is advisable to use expansion anchors that provide strong fastening of suspended structures. Such anchors are made of brass, carbon steel and other durable metals. The design includes a hollow sleeve with longitudinal cuts and petals that expand during installation using a spacer mechanism. At the end of the anchor there is a thread with a washer and a nut for adjustment. The anchor is driven into a hole pre-drilled in the wall, after which the required item is hung and secured with a nut. The use of expansion anchors ensures reliable fastening and stability of hanging shelves and other elements.

Thus, attaching a shelf or other hanging object to a crumbling wall is not particularly difficult. If you use the above recommendations and choose the optimal fastening method, you can ensure reliable retention of the suspended structure even on a hollow and loose surface.

Fixation to the roof base

The product is used to ensure reliable fastening of the rafter system. The Mauerlat, presented in the form of a beam, allows you to evenly distribute the load on the walls of a permanent structure. The procedure for fixing roofing material is carried out using several methods. Each of them involves the use of special fasteners. Ankera is no exception. Moreover, the resulting fastening is characterized by increased reliability, strength and durability.

To the roof

The main disadvantage of the technique is the high cost of hardware. But, if you compare the durability and the absence of the need for repairs for several years, the investment pays off. It is justified to use a mechanical fastening method. The option is popular.

Step-by-step instructions for performing the work:

- Waterproofing is first carried out along the perimeter of the walls of the capital structure. This can be roofing felt or other material that protects against moisture and contact between the wall material and the rafter system.

- Subsequently, the Mauerlat is arranged and holes are made in the right places. It is recommended to make the markings immediately on the wooden plank, making it easier for yourself to work in the future.

- The beam is mounted on the anchor. Providing improved strength parameters is achieved by subsequent screwing onto bolts with washers.

What is a fastener for hollow bricks?

Nowadays, there are many modern construction technologies that use fasteners for hollow bricks. Small private houses and multi-storey buildings are built from this material. Even a self-taught mason can lay brick walls.

For hollow bricks, it is necessary to choose special fastening systems.

It is important to securely secure the blocks in the assembled structures.

About types of bricks

Brick blocks are divided into:

Types of bricks.

- Hollow.

They have good durability. With the help of such products, facing work is carried out. The voids inside them range from 13 to 50% of the total weight of the block. Such bricks are made from fusible clay. Many single red brick blocks are formed. There are cases of using white silicate hollow blocks. - Full-bodied. Buildings are erected from them. These bricks are strong and durable. The main disadvantage of bricks is that they do not retain heat well.

Hollow bricks have a number of positive features. They:

- retain heat well, so a building lined with such material on the outside retains heat well even during winter cold;

- hollow brick is an excellent sound insulator: such blocks cope well with various climatic conditions, quite high frosts;

- hollow brick has a good appearance, the modern building materials market has a wide range of beautiful facing bricks, which differ in color shades and texture;

- since the weight of the hollow brick is small, you do not have to build a deep and strong foundation;

- such blocks cost less than solid ones, therefore, construction from hollow bricks will cost 1/3 less;

- Since hollow bricks are not very heavy, they are easier to transport.

About fasteners for hollow bricks

fasteners for hollow bricks are necessary in cases where communication lines are pulled through the block. Many different practical types of fastenings are used. this is about:

The dowel fastener is the most budget fastening option.

- dowel fasteners. they are the most common and cost-effective segments. The dowel has two uniform thickenings. thanks to them, the product has a non-standard shape. The most popular fastener for hollow bricks is called a “butterfly”. Special locking screws are screwed into special sleeves.

- anchor fasteners. there are also a couple of thickenings here. When developing this fastener, all the characteristics of hollow blocks were taken into account. At the base of the anchor there is a threaded rod. it is long enough to erect thick structures. fixation is ensured by a spring, ensuring high-quality fastening.

- chemical fasteners.

This is the most modern and creative type of fastening for hollow blocks. the finished substance is introduced into the hole. After the anchor has completely hardened, the structure can be considered strengthened. - If there are no fasteners, then you can use screws and nails instead.

Products successfully cope with light loads. In addition there are:

- rivet fasteners, they are used to fasten many glass objects that should be handled with care;

- corner fasteners. they can be used to secure shelves or other, not too heavy hanging objects, however, such fasteners should be handled carefully, because if too much pressure is applied, the brick can be damaged.

It is recommended to use drills to make holes in the body of hollow-core bricks.

advantages of the Fisher anchor

According to experts, the most modern and comfortable means of fixing hollow bricks is the Fisher anchor. This type of fastener is used in many areas of architecture. "Fisher" copes well with:

Fisher anchor is the most durable and strong type of fastener.

- hollow concrete blocks;

- hollow bricks;

- silicate blocks;

- lightweight concrete briquettes;

- hollow silicate products;

- bricks with vertical voids;

- lightweight concrete.

Fisher fasteners are convenient and practical. in particular, it is used for fastening:

- all kinds of structures and objects made of steel;

- fences and handrails;

- consoles and various stairs;

- gutters for laying cables;

- machine tools;

- flights of stairs;

- gate;

- facades;

- window elements;

- shelving;

- awnings

types of autonomous equipment

The chemical anchor can withstand enormous loads and fits perfectly into any construction projects.

Fisher chemical anchors have many positive qualities that deserve attention:

- they go well with any building materials.

- The operating principle of this fastening system is quite simple and universal. Therefore, Fisher chemical anchors are suitable for any construction projects.

- With the use of non-expansion anchoring, it is possible to reduce the edge and axial distances.

- Such fasteners are represented by a large number of modifications. they are used in all sorts of devices.

The loads that Fisher anchors can handle should be discussed separately. Speaking about brickwork, it can be noted that this type of fastening can cope with any loads that fall on structures made of hollow brick blocks. The same situation is observed with aerated concrete structures.

For compressed concrete, consideration should be given to which threaded rods it will be used with.

The Fisher fastener is a chemical device divided into a pair of separate chambers. the first container is filled with a chemical solution, and the second with a hardener. Before using the anchor, you need to thoroughly mix the ingredients and then squeeze the suspension into the prepared recess.

//www..com/watch?v=wufxbegxa6q

instead of a conclusion

When choosing the right type of fastener, you need to clearly determine how much weight you will have to attach to the wall. It is advisable to analyze these conditions and settle on the most convenient, acceptable and economically accessible type of fastening.

Visor

The hole for fixing the visor above the entrance is made with a drill. Steel or wooden brackets holding the structure are subsequently secured with anchors.

Important! Construction stores sell special drills for fragile building materials that do not destroy its structure.

Drilling is done carefully and carefully. First, markings are made for the desired height of the visor. There is no need to drill into seam joints. The canopy may collapse.

Anchor products have improved properties compared to other hardware. Provides an increased degree of fixation of heavy objects. This is subject to the purchase of products in specialized construction stores with quality certificates for the existing product. It is important not to skimp on fastening. Such a mistake can be costly.

Fastening dowels for a brick wall - a practical recipe

Whatever the universal fastener, in practice, a home craftsman, encountering such a device for the first time, often makes mistakes, and the fastening simply turns out to be fragile. We, in turn, want to reveal to you one very effective method of installing dowels for a brick wall, based on practical application. This method is used by installers of heavy structures, so it is more than effective.

Before starting work, prepare all the tools and material that we will need for the work, and this is: a hammer drill, a drill bit for a hammer drill of the required diameter, tile adhesive in the form of a dry mixture, the dowel itself . You will also need a set of rubber spatulas, and perhaps an electric drill, in order to drill a neat mounting hole without breaking it.