Cement-sand screed (CSS) is used to level stone and concrete floors and create a base for a final coating. At the same time, it improves the sound and heat insulation properties of the base.

The use of this leveling method is limited by the large specific gravity of the DSP. With a screed thickness of 10 mm, its weight per square meter can reach 20 kg. Taking into account the fact that its minimum thickness cannot be less than 30 mm (this thickness avoids cracking of the screed and its crumbling), and also taking into account the weight of the thermal insulation and the finishing coating, one square meter of floor will weigh about 70-75 kg. This is the weight of the floor at the minimum permissible thickness of the DSP. A 50 mm thick layer with tiles as a finishing coating will increase this value to 130-140 kg. Therefore, cement-sand screeds are used to level floors in buildings where the structure of load-bearing floors is designed for a payload of 300-400 kg/m².

The large weight of the DSP structure is, to a certain extent, its main disadvantage. Another disadvantage of cement-sand screed is the significant time required for it to dry completely. 40 mm thick DSP dries in 7 days, but each subsequent 10 mm thick requires an additional 15 days for each of them to dry.

Cement-sand screed: composition, methods of execution

In terms of its composition, CPS can be a regular cement-sand mortar or made from dry mixtures. The composition of such ready-made mixtures varies for different types of screed.

The solution for the cement paste is mixed from a mixture of cement (1 part) and sand (2.5-3 parts) with the addition of water (0.5 liters per 1 kg of cement). Plasticizers, modifiers and fillers are added to such a solution. The addition of these components to a cement-sand mortar eliminates the threat of cracks, increases the ductility of the screed and promotes rapid strength gain compared to a mortar mixed without additives.

In construction, ready-made dry mixtures are mainly used to prepare mortar. The packaging of the finished mixture indicates the volume of water required to prepare the solution and the consumption of the mixture per unit area for different screed thicknesses.

Requirements for the composition of mortars are determined by GOST 28013-98 “Construction Mortars”.

There are the following methods for constructing a DSP:

- Wet. A ready-made mixture is used for screeding.

- Semi-dry. The mixture is mixed at the work site.

- Dry. Dry backfill is used and then covered with sheet materials.

The popularity of semi-dry DSP is explained by the ability to significantly reduce surface hardening time. Typically this time is several hours. The use of semi-dry screed minimizes the risk of subsequent cracking and avoids leakage of water from the solution through the floors.

How to choose material for screeds?

When choosing a material for two-layer screeds, you need to ask what the binder base of these mixtures is. Modern dry mixes are produced using the following binders:

- Cement;

- Cement-polymer;

- Plaster;

- Gypsum-polymer.

An important factor is the compatibility of materials. For example, if the rough leveling layer of the screed is made from dry mixtures on a cement binder, the final layer is made from dry mixtures on a gypsum binder, then a primer layer must be laid between these layers. The reason lies in the fact that cement binders promote a mild alkaline reaction, while gypsum binders promote an almost neutral reaction.

The result of using dissimilar materials in two layers of one screed is gypsum leaching. You can put gypsum on the cement layer of the screed, having first applied a primer, but cement will not work on the gypsum layer, because gypsum, even hardened, will not withstand moisture, raw cement will turn it into mush.

When choosing a material for a screed, the following nuance is also taken into account: screeds based on cement binders are shrinkage. In other words, cracking is possible during setting. To prevent cracking from occurring, polymer additives are added to dry mixtures. Screeds based on gypsum binder do not shrink, are more environmentally friendly and are vapor permeable.

The latter quality means that the screeds absorb excess moisture from the air, and release it in a dry room. If the floor is wooden, then it is better to make gypsum, since such screeds are only suitable for dry rooms. Cement screeds are suitable for various premises. If polymers are added to the gypsum, then the screed will become more tolerant of moisture, and it can be used in rooms where the humidity is moderate.

When preparing to start work, it is important to calculate your material needs. Thus, the volumetric weight of a cement-sand screed in dry form is 1800 kg/m³. Typically, the solution is mixed in a ratio of 1:4, so the weight of a cement screed of 1 m3 will consist of 0.25 m³ of cement and 1 m³ of sand.

Among other things, various components are mixed into the screed. To improve adhesion and moisture resistance - methylcellulose additives (culminals, tylose and natrasols). Accordingly, the specific gravity of the cement screed varies depending on the amount of impurities.

Features of semi-dry DSP with fiber fiber

Our method of installing cement-sand screed is relatively new. In addition to plasticizers and modifiers, fiber fiber is added to the mixture of cement (in this case Portland cement is used) and fine quartz sand. As a result, the structure is reinforced using this component of the solution and traditional mesh reinforcement becomes unnecessary.

This technology (also called German) provides additional advantages:

- The cost of installing a cement-sand screed with fiber fiber is less than the cost of installing a screed with conventional reinforcement.

- The installation of such a screed takes significantly less time due to the reduction in the drying time of the surface. This is achieved by reducing the volume of water used when mixing the solution. The screed is ready for laying the topcoat after 4 days.

- The DSP device with fiber fiber results in a completely flat base surface. This is achieved using a trowel, which eliminates all microdefects on the surface of the screed.

- In terms of impact resistance, such a screed fully complies with SNiP 22.03.13-88.

Features of working with different types of screeds.

The basis of the semi-dry screed solution is a classic cement-sand mixture. To reduce the proportions of water in the mixture, when mixing the solution, a special polymer composition, fiber fiber, is added to it. Adding this composition allows you to reduce the proportion of water and make the screed semi-dry.

The solution for semi-dry screed must be mixed mechanically. Fiber fiber is added at the last stage of mixing, according to the instructions received when purchasing it.

The best solution for semi-dry screed is obtained by mechanically mixing the solution in special installations. After mixing, the solution is supplied through a pipeline to the desired floor of work.

Different types and types of screeds imply individual characteristics of their installation.

1) The strength of the screed based on cement binder for all types of floor coverings should not be less than 150 kg/cm²;

2) If it is necessary to level the screed with self-leveling mixtures - at least 200 kg/cm²;

3) The strength of gypsum screed for all types of floor coverings should not be lower than 100 kg/cm²;

4) For polymer “self-leveling” - no less than 200 kg/cm².

The screed for self-leveling mixtures is usually made the strongest, because the “self-leveling” mixture sets the fastest, which contributes to the development of high internal stress. There will be no cracks, but a weak bottom tie may be “pulled” and torn from the base.

You also need to take into account that a complete replacement or installation of a new screed will put all its weight on the reinforced concrete floor slabs. Reinforced concrete floors in old houses have limitations on load-bearing capacity, which is equal to 400 kg/m² - permanent load and plus 150 kg/m² - temporary load.

If it is necessary to increase the thickness of the screed or replace the screed material with one that is heavier, everything will have to be coordinated with the load-bearing capacity of the floor, and therefore approved by local authorities.

Old house, the floors were wooden, we removed the joists and boards, we want to fill the screed.

It turns out you need a thickness of 10 cm, perhaps even more.

Is it possible to pour screed of this thickness in an apartment?

What kind of floor slabs are installed in your house, for example, these

https://www.youtube.com/watch?v=upload

But there are floor slabs with a permissible load of 800 kg or more per sq.m.

The age of the house, it is advisable to conduct a construction examination in order to know exactly the permissible load on the floor slab; the older the house, the lower this figure.

Screed weight, cement-sand screed weighs on average 220 kg sq.m.

The weight of the finishing floor covering, for example, tiles with glue, weighs much more than linoleum or carpet.

The weight of the furniture (this is a constant load).

The weight of the users living in the apartment (not a constant load, but it must also be taken into account).

Next, the floor slab is affected not only by your screed, but also by the weight of the ceiling plaster of the neighbors below.

That is, go down to your neighbors and determine how they repaired the ceiling.

The presence of partitions 9 in the same room (this is also a load on the floor slab), if there is a partition, then what kind, for example, a partition made of brick weighs much more than a partition made of gypsum board.

Further, when raising the floor by 10 cm, problems may arise with the heating radiators, or more precisely with the distance from the floor to the radiator; they will have to be raised higher.

Reinstall interior doors, otherwise the door leaf will touch the tie when opening.

Taking all this into account, a decision is made.

https://www.youtube.com/watch?v=ytaboutru

If we are talking about a house from an old housing stock, then most often there were joists on the floors and then a floorboard; here you can do without reinstalling the doors and raising the radiators higher; the boards were removed, the joists were removed and the screed was poured.

If the load on the floor slab is acceptable, then in principle it is possible to pour a 10 cm thick screed in the apartment.

Screeds of this thickness are reinforced and do not forget about waterproofing under the screed and installing a damper tape around the perimeter of the room before pouring it.

Before laying the final floor covering, the screed must be completely dry and gain maximum strength.

To create the right base, you need to take into account the weight of the material. So, the rough base weighs within 90 kg/m² – i.e. has a significant mass. At the beginning of work, it is important to analyze the load-bearing capacity of the structure. The most suitable would be a concrete and stone base.

We invite you to read: Installation of beacons for floor screed

The process of creating a monolith provides for mandatory technological features: layer thickness – from 3cm to 7cm.

If the first condition is not met, the structure will crack. Increasing the thickness is not effective for economic reasons and is characterized by high material consumption. The approximate weight of 1 m2 of cement screed is 22 kg. The table below shows the weight depending on the thickness of the screed. Weight of 1 m2 of sand screed depending on thickness

| Thickness of cement-sand screed | Weight m2 of sand screed (kg) |

| 1 cm | 22 |

| 2 cm | 44 |

| 3 cm | 66 |

| 4 cm | 88 |

| 5 cm | 110 |

| 6 cm | 132 |

| 7 cm | 154 |

| 8 cm | 176 |

| 9 cm | 198 |

| 10 cm | 220 |

| 11 cm | 242 |

| 12 cm | 264 |

| 13 cm | 286 |

| 14 cm | 308 |

| 15 cm | 330 |

Installation of cement-sand screed

To obtain a high-quality screed, compliance with the technology of its construction is required.

Surface preparation

The surface under the screed device is thoroughly cleaned beforehand, pieces that flake off when tapped are removed. The surface to be prepared should be swept and, if possible, cleaned with a vacuum cleaner. Technological holes in the base and potholes are sealed with mortar and leveled.

Then the surface is primed. Using a primer will increase adhesion between the screed and the base. The primer eliminates the possibility of displacement of the lower layers of the screed during operation. The primer is applied in two layers, the second layer should be applied after the first has dried.

The damping tape is laid around the perimeter of the room after the applied primer has dried. The tape serves to seal the room and protect the screed.

Screed level marking

Marking is faster and more convenient to do using a laser level. Do not forget that the thickness of the cement-sand screed cannot be less than 30 mm, otherwise the screed will crumble and crack. The thickness of the screed in a particular room is determined by the design or, in its absence, by the need to solve specific problems (hide communications, level the level of the base with a large slope, etc.). The laser level is installed on a base in the center of the room and marks are made on the walls at the desired height. The point where the laser level is installed should have the maximum height in the room.

Installation of beacons

Beacons are the guides along which the surface of the screed is leveled. Accordingly, the quality of the cement-sand screed directly depends on the correct placement of the beacons.

To install screeds, ready-made metal or mortar beacons are used. The use of ready-made metal beacons greatly simplifies the work process.

The beacons are laid out strictly parallel along the surface. The width between the beacons depends on the length of the rule used and should be 200 millimeters shorter. If the rule has a length of 2000 mm, the beacons are laid out at a distance of 1800 mm from each other.

After marking the level, the beacons are raised to the required height and fixed using the mortar from which the screed will be made, building plaster or alabaster. Important! Beacons should not have deflections along their entire length. In places of deflections, gaskets are installed so that they are at the desired height, and the beacons are fixed.

Very important ! If there is no door installed in the room, the level of the screed installed should not overlap the level of the future door. This can be avoided by starting work from the doorway.

Mixing the solution and installing the screed

After the solution under the beacons has dried, the surface of the base is moistened with water. An ordinary cement-sand mortar is mixed based on the proportion of 1 part cement to 3 parts sand with the addition of water at the rate of 0.5 liters per 1 kg of cement. The solution is mixed using a mixer or a drill attachment.

The solution from ready-made dry mixtures is mixed according to the instructions on the package. Plasticizers and modifiers are also added according to the instructions.

Important ! Work on installing the screed begins from the most inaccessible places in the room, from the wall opposite the entrance, and is carried out towards the door to the room.

The solution is poured onto the base and pulled out using the rule.

Leveling the surface of the screed can be done with a trowel or manually. In the second case, a grouting mixture is prepared (in a ratio of 1 part cement to 1 part sand). The result should be a smooth surface of the cement-sand screed.

Important ! The horizontality of the screed is checked after completion of work on its construction. You can use a laser or regular construction level.

After completing the screed installation, its surface should be moistened with a wet roller and covered with plastic wrap for a day. Repeat the procedure a day later. The drying time of the cement-sand screed is determined based on the thickness of its layer: 7 days for complete drying of a 40 mm thick layer, plus 15 additional days for drying of each next 10 mm of screed layer.

Adding modifiers and plasticizers to the solution will significantly reduce the time between completion of the screed and the start of finishing work on the floor in the room. In addition, the screed will not crack.

Additional recommendations

It should be borne in mind that each individual mixture may contain a different number of components and their ratio or quality. Thus, it is quite difficult to accurately determine the weight; only approximately take as a basis the average statistical data based on the brand of the mixture.

Not only the amount of sand matters, but also its fraction. Fine-grained sand is heavier than coarse sand. An increase in voids, with a large fraction, leads to a lighter weight of the entire solution. It is generally impossible to calculate a solution prepared by yourself, since each batch will be slightly different from the previous one.

Similarly, with a larger brand, less mixture will be needed per 1 m2. So, when filling the site, you can use other brands instead of M300, both M200 and M400, the results will differ slightly.

The freshness of the cement plays an important role. If the cement was produced more than 1 month ago, then its characteristics are slightly reduced, by approximately 10-15%. Thus, a little more cement is added to the solution.

Drying the solution from the moment of preparation takes about 1-1.5 hours. Subsequently, it ceases to be suitable and begins to form into a single whole. Even adding water will not restore the proper elasticity of the mixture.

Cost of cement-sand screed

The cost of the DSP device consists of the cost of the materials used and the cost of work. In Moscow, the cost of installing one square meter of central heating station starts from 400-430 rubles. True, we are talking about large volumes.

Ready-made dry mixtures are usually packaged in craft bags weighing 25-50 kg. Manufacturers claim that the consumption of dry mixture is about 20 kg per device of 1 m² of screed with a thickness of 10 mm. The cost of the bag varies depending on the composition of the mixture. Prices start from 130 rubles/bag (sand concrete).

Cement-sand screed

used for leveling unevenness on stone, concrete foundations and floor slabs with level differences from 40 to 150 mm. and creating a base for installation of any type of finished floor covering. Cement flooring is resistant to significant exposure to mineral oils, organic solvents, water and other neutral liquids, and to a lesser extent to alkaline solutions (with a concentration of up to 8%) and substances of organic origin.

The weight of the screed per square meter is 5 cm = 100 kg.

Weight is a very important parameter that affects the design of load-bearing floors. In modern construction, on average, the payload on floor slabs is about 300-400 kg/1 sq.m (if possible and necessary, this figure should be clarified in the building design). For example, in a light frame building, in large rooms with a large pitch of load-bearing beams in the floors, it is difficult to make heavy concrete screeds, and in such buildings, as a rule, wooden lathing is used and the voids for sound insulation are filled with soft mineral or glass wool to absorb sound, and the lathing is twisted through polyethylene foam gaskets to decouple the structure and reduce sound transmission throughout the structure.

The weight of the screed per square meter is 5 cm = 100 kg.

If you make a heavy screed, then placing heavy household items, partitions and arranging a storage area in the middle of the room becomes unsafe. Typically, a square meter of concrete or DSP screed 5-6 cm thick for thermal insulation with tiles weighs about 130-150 kg/sq.m. The weight of the screed itself (approx. made of cement and sand) with a layer thickness of 10 mm. is 20 kg per 1m/sq. Considering the distributed load on the floor slabs (or monolithic floor), this weight is quite normal for living. Various extreme examples of the operation of premises (the presence of a forging hydraulic hammer, a metal warehouse, a helipad, a swimming pool, etc.) are calculated and taken into account as part of the project, where everything is clearly regulated, from what and how.

PROFESSIONAL CONSTRUCTION OF CEMENT SEMI-DRY FLOOR SCREED WITH FIBER - EXPERIENCE SINCE 2002

When laying various communications on the floor, with very uneven floors, the thickness of the screed is especially large. Achieving an ideal surface can be very difficult, and semi-dry production has recently been brought in to help builders. Using the technology of laying semi-dry screed, the customer receives the following advantages.

Firstly, the result of the work is a perfectly flat base, which is completely ready for laying parquet, linoleum, cork, etc. The use of a trowel during screed production eliminates the formation of voids and cracks on the surface of the screed.

Secondly, the production of screed using this technology significantly speeds up the floor production process. It is possible to lay up to 250 m2 of screed per shift. After twelve hours, people can walk on the floor, and after four days the floor is completely ready for laying the finishing coating. And all this thanks to the minimal amount of water in the sand-cement mortar.

Thirdly, in the production of mortar and its installation, it is possible to use various modern construction equipment from concrete pumps to pneumatic blowers. And the quality and composition of the solution allows it to be supplied to a height of up to eighty meters and a distance of up to one hundred and fifty meters.

And fourthly, the production costs of this type of screed are very competitive. And all thanks to the low cost of materials used in production and. Cement, sand, fiberglass for reinforcement are all much cheaper than leveling polymer mixtures and steel mesh or reinforcement.

Thermal insulation is carried out with dense, load-bearing, effective thermal insulation materials, which are mainly polystyrene foam and mineral wool. The density of mineral wool for use in floor screeds should be at least 140-160 kg/cub.m., the density of expanded polystyrene should be at least 35 densities. Soft mineral wool (and glass wool), various thermal insulation fills (expanded polystyrene, perlite, ecowool, mineral wool) are used in floors made on logs. Expanded clay chips are not an effective insulation material, since, for example, to obtain the same insulation coefficient as 10 cm of expanded polystyrene, it is necessary to make 25-35 cm of backfill.

Ease of use: Screeds based on wet processes, where the mixture must be mixed with water, have some inconveniences in operation - they are dirty, work only at positive temperatures above +5 degrees, and the likelihood of leakage through cracks in the lower floors.

In prefabricated screeds, factors such as the delivery of materials to the site should be taken into account - gypsum fiber boards, wood chipboards, oriented strand boards, plasterboard, cement bonded particle boards, plywood boards are very inconvenient to lift to the upper floors in standard production sizes, but they can be assembled with self-tapping screws at subzero temperatures, but at high temperatures. Room humidity can cause such slabs to deteriorate and create operational problems.

It is very difficult to find and bring in big cities. Loading cement generates dust that must be cleaned up. Also, all this is quite difficult to move, especially to high floors and long distances.

If cement screeds fail, they are much more difficult to fix; in most cases, dismantling is necessary. Prefabricated screeds can be disassembled and reassembled with minimal loss of material other than flooding due to leakage. In such cases, the floor cannot be repaired.

Answer:

The theoretical determination of the weight of a cube of mortar is complicated by the fact that solutions can have several components (complex solutions), different ratios of these components, as well as different types of sand according to grain density.

The weight of 1 cube of solution directly depends not only on its components, but also on humidity. According to GOST, based on average density, solutions are divided into light and heavy. Light mortars include mortars with a volumetric weight of less than 1500 kg/m 3 . Heavy solutions, accordingly, include solutions with a volumetric weight of more than 1500 kg/m3. Heavy mortars are prepared using aggregates with a volumetric weight of more than 1200 kg/m3 and, when hardened, they have greater strength and density. Lightweight solutions, due to the presence of many air pores, have lower thermal conductivity. The weight of a cube of solution also depends on the size of the filler grains, as well as on the granulometric composition - the ratio of the filler grains by size. The greatest volumetric weight of the filler and, as a consequence, the solution will be if a certain ratio is observed between the number of grains of different sizes. For example, 1 m 3 of sand with grains with a diameter of 1 mm weighs about 1400 kg, and a mixture of grains 0.15-5 mm already weighs 1600-1700 kg. And if we take into account that sand is not the only type of filler, then we can conclude that the weight of a cubic meter of a complex solution can only be determined experimentally, by weighing vehicles, or approximately using tables:

Price of semi-dry screed

The weight of one square meter of floor on which a semi-dry floor screed is made is 17-19 kg.

- A semi-dry screed is made on concrete bases or an earthen floor with appropriate preparation (a cushion of sand, crushed stone and a rough concrete layer).

- A layer of polyethylene or other rolled waterproofing material is laid on the rough subfloor.

- A damper strip is laid along the perimeter of the room to the height of the screed. It separates the screed from the walls of the room and “transfers” it to the class of floating screeds.

- In apartment rooms, semi-dry screed does not require expansion joints. It is enough to make transitional seams between rooms in the doorways.

- The screed solution is supplied through a pipeline to the apartment and scattered over the area of the room;

- Next, the solution is compacted (usually with feet);

- For semi-dry screed, there is no need to install profile beacons. The level of the screed is measured, and beacons of the screed itself are made according to the level;

- The compacted solution, or rather not a solution, but a mixture, begins to be leveled using the rule. As a rule, you need to apply constant pressure and, as it were, press the solution.

To level the mixture of semi-dry screeds, special tamping slats are produced and made by hand. For compacting industrial floors, there are special leveling units.

- Pedestrian load on a semi-dry screed is possible after 12 hours.

- Finishing work in the room can begin after 72 hours.

- Complete drying of the semi-dry screed, after which the floor can be finished, takes 3 weeks.

In a semi-dry screed, it is possible to lay any utilities in compliance with the installation technology: electrical wiring in pipes or electrical corrugation, water supply in solid pipes (without connections) made of cross-linked polyethylene. There must be at least 3 cm of mortar from the top level of communications to the top level of the screed.

Typically, the price of a semi-dry screed with material is 20 USD. per meter The maximum height is usually 16 floors. Productivity is 180-200 meters per working day.

Related materials

- the thickness of the semi-dry floor screed (layer height), like any other, should be at least 20 mm (but even then, it is advisable to reinforce it with fiber fibers, otherwise there is a very high risk of cracks);

- the weight of a semi-dry screed per 1 m2, with a height of 50 mm, will reach about 100 kilograms (with the help of simple calculations, you can calculate the real indicators, and the indicated mass can actually be reduced by adding polystyrene foam granules);

- the strength of a semi-dry floor screed varies from M150 to M180 (without taking into account the addition of plasticizers, reinforcement and other impurities; this value is quite sufficient for most purposes, but exceptions may be industrial premises and areas where heavy equipment passes);

- The density of semi-dry screed must be in the range of 2000-2100 kg/m3 (with the standard preparation method).

The option when the base is organized not by pouring, but by laying materials intended for this purpose, deserves special attention. Here the criteria are somewhat different and very much depend on which components are used:

- the thickness of the dry floor screed is directly related to the sheet covering used - chipboard, gypsum, OSB, and so on (the level of its elevation must be calculated in each case separately - the indicator is determined by many factors);

- the weight of the dry screed per 1 m2 (load) is minimal (also depends on the characteristics of the consumables used, but it is significantly less than the lightest concrete pouring option);

- the strength of dry floor screed is much lower than cement screed (but it is used mostly in residential premises, where it is more than enough);

- the density of the dry screed should be calculated from the same properties of the sheet special material (OSB, gypsum and plywood have different values, but you are unlikely to find critical differences, because each of them was manufactured for the same purpose).

We suggest you familiarize yourself with: Thickness of screed on a wooden floor

As for the most common capital method of organizing a coating, the characteristics here are virtually the same as those made using the semi-dry method. And the point, of course, is that the same cement and sand are used here and the addition of the same impurities is allowed. So:

- the thickness of the cement-sand floor screed should not be less than 2-2.5 centimeters (the larger limit can vary to significant values from 100 mm or more if reinforcement or plasticizers are used);

- the weight of cement-sand screed per 1 m2 with a minimum layer is 40-50 kg (higher ones can be lightened with various additives, for example, polystyrene foam granules);

- the strength of the cement-sand floor screed is enviable, like that of any other capital structure (the tabular indicators of a conventional mortar after hardening are from M150 to M180 - this is quite enough even for moving heavy equipment);

- the density of the cement-sand screed (thermal conductivity) is on average 2000 kg/m3 (if everything is done in compliance with the necessary details).

All of the above indicators are completely optional for people whose professional activities are far from construction. Contact us and entrust all calculations to our specialists. You can be sure that they will offer the most profitable and technologically advanced solutions in any specific case. Everyone who contacts us will always have the opportunity to take advantage of:

- attractive prices;

- prompt execution of work;

- many years of experience of employees;

- professional consultations;

- official quality guarantee.

The screed is done with the purpose of leveling or stiffening the surface, ensuring heat absorption of the floor, and creating a slope in the floor on the floors. Pipelines are covered with screeds.

Screeds are made as the final surface or as an intermediate layer on which the final coating is laid.

https://www.youtube.com/watch?v=https:accounts.google.comServiceLogin

Considering the design, couplers are:

- Solid single-layer. Placed in one layer over the entire thickness;

- Solid multilayer. They consist of several interlocking layers that are made sequentially;

- Prefabricated. They are prefabricated elements that are completely ready for installation.

Screeds made from cement-sand mortar are a thing of the past, since such work took a lot of time. While the solution gained strength and dried, more than one week passed. If the finishing coat was applied to a solution that was not completely dry, the quality of the work decreased.

Modern quick-setting cement-sand mixtures with polymer additives have simplified the process of screed formation. Instead of several months, it now takes only a couple of days for the fill to reach the required humidity for laying parquet. A modern screed is a construction of 2 layers. The first layer is leveling, rough, the second is thin, finishing.

According to SNiP, the maximum thickness is not regulated.

- So in residential premises, the screed using classical technology should be at least 20 mm. This thickness provides sufficient abrasion resistance. If it is necessary to install pipes for heated floors in the floors, close utility systems, or lay soundproofing material, the thickness will naturally be greater.

- Strength in the wet method is ensured by the physical properties of the binder components. If cement grade M150 or M200 is used, then the strength of the screed is 15 MPa and 20 MPa, respectively. This strength allows it to withstand even heavy equipment.

- The density of the screed is within 2000 kg/m3 and depends on the density of the constituent components of the wet mixture.

- Weight - 40-50 kg per 1m2 of screed with minimum thickness. When using fillers such as polystyrene foam granules, the weight of the screed can be changed, which means reducing the load on the floor.

To fully “mature” the screed using the wet method, you must wait at least 4 weeks. The standards stipulate technical indicators where the screed layer must withstand 15 MPa in compression and a surface slope of no more than 0.2%.

A semi-dry floor screed will speed up construction, as it contains a half-dry cement-sand mixture. And it takes much less time to mature. The strength of the coating is guaranteed by reinforcement with mesh or polypropylene fiber. It takes 4 days for the coating to fully set. Water is introduced into the composition in a minimal amount to start the crystallization process. This way we get a surface without shrinkage and cracks. The semi-dry flooring method is characterized by the following criteria:

- The density is 2000-2100 kg/m3 if the mixture is prepared according to the standard.

- The strength is sufficient for various premises, except warehouses and garages for heavy equipment within M150-M180.

- The weight of a semi-dry screed per 1m2 is 100 kg, with a height of 50 mm. To reduce weight, polystyrene granules can be added to the mixture.

- The thickness of the semi-dry screed is 20 mm. To prevent cracks, it is advisable to reinforce with fiber fibers.

One of the modern technologies is dry screed, or bulk floors. This technology insulates and significantly increases the sound insulation of the room. Quartz sand, expanded clay or slag and two layers of gypsum board sheets are used as bulk material. Installation of bulk floors is simple, and their installation can be completed in 1-1.5 days. Criteria that a dry screed must meet according to SNiP:

- The density is the same as the materials used for dry screed.

- Strength – 200 kg point load per 1 m2.

- The thickness must be at least 6 cm. Depending on the covering material, the thickness of the dry floor screed varies.

- The weight of a dry screed is not large compared to the wet method. The amount of load per 1 m2 depends on the materials used.

We suggest you familiarize yourself with: Screed thickness for water heated floors

A floor laid on a dry screed is more expensive, but also warmer, stronger and more durable.

Knowing the features of different floor screed methods, you can decide which screed you need. Contact . All the worries about calculating the necessary materials and the installation of the floor itself will be carried out by professionals with extensive experience.

We guarantee:

- Consultation with specialists,

- Personal approach to each client,

- Completion of work in a short time,

- Nice rates,

- Quality guarantee.

We are waiting for your calls.

The choice is the right choice.

Table Weight of 1 cube of solution depending on the type of binder and fillers

| Name of solutions | Weight of 1 cube |

| Cement-sand mortar | 1800 |

| Complex mortar (sand, lime, cement) | 1700 |

| Lime-sand mortar | 1600 |

| Cement-slag mortar | 1400 |

| Cement-perlite mortar | 1000 |

| Gypsum perlite solution | |

| Porous gypsum perlite solution |

Installing a larger number of floor coverings requires a leveled, smooth surface. And the most popular method is to fill the floors with concrete screed. This process is labor-intensive and requires: skills and experience; use of quality materials; holding for a certain period of time. Despite the long drying time, it is DSP that is popular in our country. Let's talk in more detail about the types and design of floor screed.

Varieties: cement screed

- Messenger

. Typically used in high-rise buildings - the DSP here serves to level the floor slabs. To create a reliable base, you need good adhesion - connection - between the poured layer and the old one. That’s why the type of screed is called – connected. Its minimum layer is 3 cm. - Incoherent

. With this type of base, the new layer is not bonded to the old floor. For example, installation on a concrete base that has been previously polished or on a layer of insulating material. The minimum thickness of the screed is 5 cm. - Floating

. If the floor needs to be made warm, it is impossible to achieve a rigid adhesion of the screed to the base. When the insulating material changes its dimensions, the concrete layer placed above also lowers/raises. That’s why this screed is called floating. To create rigidity, which requires a minimum thickness of the cement-sand mass in this version of the screed, at least 6.5 cm.

All of these types of CPS have their own installation characteristics, but they are united by the use of sand-cement mortars. Sometimes, to increase reliability, reinforced fibers are added to the composition. This is usually fiberglass; there are additives from small parts of steel wire, but they are not used often. Reinforcement of the solution is required when the concrete layer is large.

Chaotically arranged fibers significantly increase the strength of the base and practically no cracks appear in it.

According to building rules, the minimum thickness of the screed is 3 cm. With the thinnest layer during the period when the mortar dries, the canvas will crack and the base will be unreliable. At the same time, concrete has a lot of weight: per 1 m2, a 10 mm layer weighs approximately 20 kg. And since the minimum thickness is 3 cm, then the minimum weight of 1 m2 of screed will be 60 kilos. Not every foundation is capable of supporting such a load without consequences. This can cause the foundation to shrink and crack. To reduce the weight of the screed, light binders, for example, expanded clay, are included in the solution. The mass of 1 cm of expanded clay concrete is 16 kilos. With volumetric footage being poured, the difference is significant.

SNiP dry screeds

There are a large number of ways to make such a screed. However, we can distinguish the main ones - tied and untied screeds and floating.

Types of floor screed

The bonded screed method is used if the permissible leveling layer can be up to 4 cm thick. The base becomes one with the floor and walls. This type of screed requires careful preliminary preparation of the rough foundation - all large holes, cracks, cracks in the floors are sealed, all significant irregularities are removed as much as possible.

The solution for pouring the screed should have the consistency of sour cream or cake cream. It turns out quite liquid and about 20 minutes after pouring it will begin to gradually harden. Therefore, you need to have time to fill and arrange the screed during this time.

The solution for pouring the screed should have the consistency of sour cream

You can carefully walk around the room the next day, but the drying time for such a screed is long - up to 40 days. It is important to properly dry such a base - the water cannot quickly evaporate from the layer, it must come out gradually, so it is recommended to moisten the fresh screed with water and cover it with film.

There is an untied screed, which, on the contrary, is mounted on a perfectly smooth surface. In this case, the base should not have water-absorbing properties, so as not to draw moisture out of the screed. The thickness of such a layer can reach 5 cm. The main difference from the previous type is that a primer is not used before pouring such a screed. Also, no methods are used that can increase the adhesion strength of the solution and the rough base.

Floor screed - mortar and grout

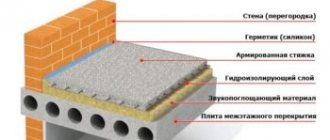

A so-called floating screed is also often installed. It is usually used if its thickness should be 5-7 cm. The design of such a layer is different in that it does not even directly come into contact with the rough base - on the contrary, layers of hydro- and thermal insulation are laid between the solution and it, various materials that simply will not give the solution will adhere to the ceiling.

Fiber fiber for floor screed

Fiber fiber mixture

Due to its large thickness, such a screed could have the maximum weight, but it is poured using the so-called semi-dry technology. That is, the solution is mixed using a small amount of water and resembles the structure of wet sand.

We suggest you familiarize yourself with Installing a damper tape when installing a screed

fiberglass for screed

Semi-dry screed over heated floor

Depending on which screed option is chosen, the composition of the mixture for its manufacture is also determined. The proportions of the two main components are selected depending on what brand of cement will be used and what quality of sand. To install a screed in an apartment, it is enough to use M200 cement.

Screed mortar

It is very important to choose the right sand to create the solution. It should not contain (or at least contain) various inclusions - silt, clay, etc. These components negatively affect the strength characteristics of the finished screed. It is best to use washed river sand. Quarry sand is also suitable, but its quality is somewhat worse than river sand due to the angular shape of the sand grains.

Table. Mixture compositions according to GOST when using M400 cement, wt. h.

| Brand of solution | Cement | Water | Sand |

| 150 | 1 | 0,55 | 3 |

| 200 | 1 | 0,48 | 2,8 |

| 300 | 1 | 0,4 | 2,4 |

You can prepare the solution yourself, or you can buy a ready-made mixture. The building materials market is rich in such offers. They are simple to use - just like when creating a regular solution, water is added to the dry ready-made mixture - all the necessary components are already mixed in the required proportions, often with the addition of plasticizers. These substances can reduce water consumption without losing the quality of the solution.

Dry mixes for screed

Handmade cement floor screed in a bathhouse

To level the floor slabs, use a tie screed. In apartment premises, the floors between floors are usually made of reinforced concrete slabs. This sand-cement screed is also suitable for a bathhouse building on a slab foundation. But only when waterproofing and insulation are not needed.

This type of screed is also suitable for

:

- Porches;

- Tambura;

- Verandas, etc.

The main task of preparation in this case is to create the best possible adhesion of the concrete layer to the base. To do this, you need to very well clean the surface of debris and dust. It is better to do this by using a vacuum cleaner - a brush cannot remove all the dust. There is no need to level out uneven areas; on the contrary, if there are smooth areas, it is necessary to make grooves/pits in them. Correctly seal only very deep cracks, and do not even out the surface. After all dirt has been removed, the surface is generously primed.

The primer can be poured onto the floor, and then treated with a brush.

The primer must be allowed to dry for at least 8 hours; drying time depends on the humidity and temperature conditions in the room. After drying, you can install the beacons and pour the mixture (cement, sand) with your own hands. In order to prevent the destruction of the screed or vertical surfaces due to different amounts of expansion when changing temperature conditions (different densities), a damper tape must be installed around the perimeter of the room. This especially plays a role when the vertical surfaces are wood, which is almost the rule in bathhouses.

The tape must be rolled out and attached to the walls. It is usually larger in height than the screed, but when the cement sets, it must be cut to the level of the floor. If waterproofing of the DSP is required, it will no longer be cohesive. Here the preparation is different. Waterproofing material is placed on a clean and flat surface. If the base is uneven, for example, the surface of the foundation slabs in a bathhouse, then it must be leveled. For this purpose, the leveling connection DSP described above is used.

After drying it, you need to lay out the waterproofing and pour another layer of concrete (a special tape will also be required). Due to the fact that the base does not absorb moisture during such installation, cavities and pores may appear. Therefore, the solution must be processed with a vibrator. By increasing the thickness of the floor surface screed to 100 mm, the problem resolves itself, but the costs and weight are greater. It is important that the filling technology is followed.

Work order

Actions must begin by preparing the foundation.

To do this, the floors are cleared of the previous floor covering, the room is cleared of construction debris and construction beacons are placed, having determined the horizon using a level.

The installation of a sand-cement screed is possible in any room where the base temperature does not fall below +5 ͦ Celsius.

Having installed the beacons, start pouring the screed from the farthest corner

The beacons are installed on a pre-laid layer of waterproofing, which can be used as a polyethylene film. The edges of the canvas are placed on the wall so that they protrude at the level of the screed.

They begin to pour the screed from the most inaccessible places in the room, but if it has a door, then it is important to make sure that the doorway is not blocked.

After the solution on which the beacons are installed has hardened, the prepared mixture is poured onto the base, filling one strip with it. Using the rule, the solution is leveled, and only after the first strip is ready, they begin to pour the solution into the second. After 12 hours, the beacons are removed and the resulting space is filled with a solution, which will take about 15 hours to completely harden.

Now prepare the grout mixture and perform the manipulations associated with grouting the surface. You will need a dry or wet mixture consisting of equal parts of sand and cement. Rub the surface using special equipment or manually using a floor polisher or grater. For all the details of the process of pouring concrete on beacons, see this video:

After completing all the work, you will get a smooth, slightly rough surface, which must be rolled with a damp roller and covered with plastic film. Moisten the screed for at least seven days, after which the film is removed.

Very often the deciding factor when choosing the type of screed is its weight. This nuance can be quite significant if it is necessary to make the floor level in an apartment with large differences in height along the base. Roughly speaking, if the floor slabs lie very unevenly: in one room you need to make a screed 4-5 cm high, and, for example, in a corridor the thickness will be from 8 to 10 cm. It turns out that in some rooms the weight of the screed will be very large . And such a load may exceed the permissible one.

For example, let’s compare two rooms with an area of 14 square meters and a screed thickness of 8 cm:

- cement screed has a mass of about 2400 kg

If desired, the weight of the cement screed can be reduced by using large expanded clay, polystyrene foam or expanded polystyrene as a substrate. The layer of such a substrate can be 4 cm in this case. In this way, we will reduce the weight of a traditional cement-sand screed by almost half. If we neglect the mass of expanded clay or other bulk material, then it will all look like this:

- cement screed has a mass of about 1200 kg

dry screed weighs about 650 kg

It is not recommended to make a cement screed less than 4 cm thick, so we considered its minimum weight. Similarly, dry Knauf screed is performed with a minimum layer of 4 cm. To make it more convenient for you to use these data by square meters, we will highlight them separately:

- weight of cement screed per 1 sq. meter with a layer of 4 cm will be about 85 kg; each additional 1 cm will add about 21-22 kg.

weight of dry screed per 1 sq. meter with a layer of 4 cm will be about 30 kg. Each additional 1 cm will add about 4-5 kg*

*Since with a minimum layer of dry screed the majority of the mass is the floor element, and the dry backfill weighs very little, then after 4 cm an increase in thickness will have a slight increase in mass.

Here we looked at examples of the simplest designs of dry and cement screeds. The weight of 1 square meter may differ when using various floor designs (using additional lightweight materials, laying an additional layer of gypsum fiber reinforced concrete, etc.). But we hope that the principle itself will be clear to you.

If you need an individual calculation of the weight and thickness of the dry screed, then call us, we will answer all your questions and perform high-quality installation of the Knauf screed floor.

We work in Moscow and the nearest Moscow region.

When replacing and laying floors, concrete screed is most often used. It allows you to level the surface, make the base strong for static and dynamic loads, this is the most used method of installing floors in residential buildings and industrial facilities. All known floor coverings can be laid on it, while it can act as the top layer of the floor.

Installation of floating cement-sand screed

This type of screed can usually be found when making floors in country houses and baths. Floating CPS is also used when installing water-heated floors and some types of electric floors. It is this that makes it possible to make a floor surface in a bathhouse on the ground. The thickness of the layers of the cake and building materials are selected individually, based on the climate in the region, but the principle is the same.

There can be many and varied layers here, but the main distinguishing feature is that there is no connection with vertical surfaces or the base. Such a floor does not react to shrinkage of the foundation or timber frame. Therefore, these are the right floors to install in a newly installed bathhouse. Although, it is still better to wait until the shrinkage is carried out.

Experts give some advice

:

- The recommended minimum thickness is 65 mm.

- First of all, you need to lay a layer of 2 cm and leave it for 24 hours.

- Leveling the rest of the part will not be difficult, since the first layer will be compacted under its own weight.

To increase strength, a high screed should be reinforced before cementing. Fiber fiber is often used. For baths, the consumption of a mesh with a cell of 200 mm is quite suitable. After the screed has set, you can install tiles on the floor or make a wood floor - pourable (unsealed) or sealed. During installation, it is important to follow the rules of SNIP and the proportions according to the diagram. If you are laying tiles, then grout is needed.

Semi-dry cement-sand mixture for floor screed

If additives/reinforcing additives are included in a standard DSP screed, less water will be needed for the concrete to gain strength. Additives or additives make this process faster.

They come in different varieties and impart different qualities.

:

- Additives for frost protection. They accelerate the maturation of the screed, while at the same time reducing the freezing temperature of water. They are used if the temperature drops below +5 °C.

- Fiber fiber or pieces of steel wire increase the strength many times over, and even under heavy loads the DSP will not crack.

- For water repellent qualities. They are suitable for pouring DSP in the washing room and steam room of a bathhouse, bathroom, toilet room or kitchen.

- The instructions on the packages indicate how many additives to add. They vary between 0.3-10% of the cement mass. That is, per kilo of cement you need to add from 3 to 100 grams of additives.

When creating a semi-dry screed, much less water is needed. First, mix the dry ingredients well, then add water. But the solution should be like moistened sand. If you take it in your hand and squeeze it, moisture should appear, but the water should not flow, it should remain a lump in your hand. This is the correct consistency of the solution. Due to the fact that such a solution is not so plastic, its leveling is difficult: more labor will be required. When laying the mixture between the guides, it must be compacted. This can be done using special surface vibrators for concrete, or you can simply crush it with your feet. There are special additives that make the mass self-compact.

Weight of cement-sand screed per 1m2

On average, 1 cm of central fiber has a specific gravity of 22 kilos. To calculate the consumption, you should multiply the height of the screed by 22 kg, then multiply the resulting amount by the total meters of the room. The resulting result must be compared with the capabilities of the main floor. If the mass is larger or comes close to the reserve, it is necessary to reduce the layer height or not use the DSP. This could cause an accident. Dry weight of CPPS is 1800 kg per m3. This is the standard.

We must remember that the volumetric weight also includes various kinds of additives that

:

- Increase adhesion;

- Improves moisture resistance;

- Makes the structure stronger.

Based on their quantity, the specific gravity also changes. Coated thread is suitable for marking while working. Screed grade M150 is well suited for pouring. Also an excellent solution for baths is the leveling mixture CPR.

Cement floor screed (video)

It is possible to do the floor screed in an apartment, house or bathhouse yourself. It's not very simple, but it's not that difficult either. The main thing is to understand the technology and gain first experience.

To create a high-quality and durable foundation for any finishing floor covering, it is necessary to determine the load-bearing capacity of the entire structure.

The weight of the screed is quite large, and therefore it puts a lot of pressure on the base of the structure.

In cases where the work is not carried out using a ready-made mixture purchased in construction stores, but a composition prepared independently, accurate calculations should be made taking into account the characteristics of the materials used.

Fiber reinforcement

Today, the so-called fiber cement screed is often practiced, in which the role of metal wire is played by fibrous plastic strands with a length of 3 to 18 mm and a diameter of 20 microns. Polypropylene fibers are added to the working mixture at the mixing stage and are evenly distributed throughout the entire volume of the solution. They are very successfully used for screeds with increased or fluctuating loads in new buildings, where the likelihood of shrinkage is higher than in other cases, while significantly reducing the total mass pressing on the floors.

Fiber fiber can be used in combination with other concrete additives (for example, sawdust and cement screed). As a result, wear resistance, ductility and complete drying time of the coating significantly increase.

Such a screed is somewhat similar in its characteristics and quality to a base made of sawdust and cement. It can be classified as a light type of concrete pavement; the weight of 1 m³, as a rule, does not exceed 450 kg.

The minimum rate of adding fiber to the working solution is from 300 to 500 g per 1 m³ or 40-50 g per 1 m2 of surface. Translating this expense into a monetary equivalent, it is not difficult to see that the use of this type of reinforcement is more economical compared to the use of metal elements.

The main nuance when making a mixture using fiber reinforcement is that the fibers are added not to a liquid solution, but to a dry powder.

Water is added last.

It is important to prepare the correct mixture for floor screed. Today in the retail chain you can find dry compounds designed for any type of work. A big advantage of such mixtures is the exact proportions of sand and cement. The optimal ratio of all ingredients plays an important role in saving material for the screed and in shaping the working qualities of the solution.

Which cement is better? The grade of material must be at least 200. The sand used is either river, fine fraction, or quartz. In addition, as a rule, the factory packaging of a concrete mixture assumes the presence of additives in it. They are needed to prevent the cement screed from cracking.

The use of various plasticizers and additives significantly speeds up the drying time. The total time required for its production depends on how long the cement screed dries.

Often builders are faced with the task of screeding a wooden floor. In such cases, first of all, it is necessary to evaluate the stability and safety of the wood on which the cement screed layer will be poured. It must be strong, able to withstand the load, shock-absorbing elements must be replaced. Next, a layer of waterproofing is laid on the boards. This is necessary in order to prevent interaction of the “wet” solution with the wood.

After this, experienced builders recommend installing a layer of lightweight self-leveling floor (3-5 cm), on which beacons can be installed. At the same time, such material levels out all the unevenness inherent in wooden floors. After the latter has dried, you can arrange the coating in the usual manner, observing the proportion of cement and sand for the screed.

Screed on a wooden floor, despite the apparent simplicity of execution, requires increased attention and additional costs.

To create a high-quality and durable foundation for any finishing floor covering, it is necessary to determine the load-bearing capacity of the entire structure.

The weight of the screed is quite large, and therefore it puts a lot of pressure on the base of the structure.

In cases where the work is not carried out using a ready-made mixture purchased in construction stores, but a composition prepared independently, accurate calculations should be made taking into account the characteristics of the materials used.

Selection of materials and mixture preparation

DSP or cement-sand screed is a necessary and fairly simple way to level surfaces. To create it you need sand, cement and water. The quantity of each component depends on their characteristics.

So, for example, if you take cement grade M150, then you will need three times more sand. If M500 grade cement is used to prepare the mixture, then sand is taken in accordance with the proportion of 1:5.

For a 50 kg bag, take 150 kg of sand

It is considered optimal to use cement grade M 150, therefore for this material weighing 50 kg you will need 150 kg of sand. As for the amount of water, it depends on the moisture content of the sand.

You can prepare a high-quality solution by taking:

- 1 bag (50 kg) of cement;

- 15 ten-liter buckets (150 kg) of dry sand;

- 27 liters of water.

The addition of wet sand will reduce the volume of water to 25 liters.

The weight of the cement-sand screed determines the pressure it will exert on the base of the structure. Accordingly, before starting work, it is necessary to clarify the thickness of the poured layer.

The screed must be at least 30 mm thick

The minimum thickness of the screed is 0.3 cm. Otherwise, after the solution hardens, the surface will become covered with cracks. Exceeding the maximum thickness of 0.5-1 cm leads to exceeding the permissible load on the base.

If this value reaches 8-10 cm, then the weight of the cement screed for each square meter will be about 150 kg. This is unacceptable and therefore experts recommend not to exceed the established parameters.

The density of the mixture depends on the quality of the material

When creating a cement-sand screed with a thickness of 1 cm, its consumption will be at least 20 kg per square meter. In this case, per 1 cm² its weight will be from 15 to 20 kg.

When creating a cement-sand screed, it is necessary to take into account the density of the composition, which depends on what materials are chosen by the craftsmen.

According to this parameter, compositions are divided into:

- Lightweight, the density of which does not exceed 1400 kg/m³.

- Heavy screeds, the indicated value of which is significantly higher than 1400 kg/m³.

If the technology is strictly followed, the specific gravity of the sand-cement screed, depending on the given characteristics of the sand, will not exceed the permissible limits.

In accordance with GOST 8736-77, one cubic meter of sand should contain no more than 1600 kg, and its specific gravity should be 1550 to 1700 kg/m³. For more information on how to make a solution, watch this video:

You can calculate the consumption of materials using the existing formula and reference data. When working with cement grade M 400 to construct a screed 3 cm thick in a room with an area of 50 m², you will need the amount of cement and sand that a simple calculation will help you find out:

The volume of water is determined at the rate of 0.5 liters per 1 kg of cement. Accordingly, 4875 × 0.5 = 2437.5 liters will be required.

Compliance with all these standards will allow you to perform the work efficiently and create a strong and reliable base for the finishing coating.

Calculation of sand-cement dry mixture for screed

The thickness and process of laying cement-sand screed are regulated by regulatory documents (SNiP and GOST). According to them, the minimum thickness of the mortar layer can be 3 cm; at lower values, the screed will simply crack due to the high tension inside the material that will appear when drying. And the maximum thickness of the screed, according to the documents, is only 7 cm, although in some cases it may be more.

Floor screed

It is easy to calculate the solution consumption per 1 m². To do this, you need to take into account that on average 1 m³ of cement and sand solution has a mass of about 2 tons. The composition includes 1350 kg of sand and 450 kg of cement. Thus, we find that for 1 m² of screed layer 1 cm thick, you will need 20 kg of mixture, which contains 13.5 kg of sand and 4.5 kg of cement. Knowing the thickness of the screed and the dimensions of the room, calculating the amount of mortar is very simple.

The quantity and cubic capacity of consumables for plastering a wall is quite difficult to determine. The reason is that the walls are rarely even, they usually have protrusions, recesses, and the layer in each area is slightly different.

It is necessary to determine the average depth of the layer in order to calculate the volume of the cement-sand mixture. For example, per 5 mm layer there is 7 kg of mixture per 1 m2.

Calculation for plaster

The thickness of the plaster ranges from 5 to 30 mm. When plastering, it is worth considering the number of additional components; slaked lime is often added.

For large volumes of work, a batch is made consisting of:

- 4 bags of cement;

- 40 kg of slaked lime;

- 550 kg of sand;

- 100 liters of water.

So many ingredients comply with regulatory rules per 1 m3.

Plasticizers, liquid soap and the like should not be taken into account, since their proportional ratio is insignificant. It is not recommended to make large batches at once, since the solution may harden if it is not possible to spread it within 1-1.5 hours.

The screed is characterized by the presence of increased pressure on the finished site. This characterizes the increased need for screed strength. Therefore, a mixture of M300 or M400 should be used. In some cases, M200 is also used, but only where high strength is not required.

It is necessary to calculate the number of DSPs after forming a platform from bulk materials, if one is planned.

The required amount of materials can be calculated based on the parameter 1 m3. The area and depth must first be converted into this value. A room with an area of 50 m2 and a screed depth of 20 cm will require 50 m2 * 0.2 m = 10 m3.

Calculation for screed

Next, by selecting the grade of mixture required for the task, usually M200 or M300, you can determine the amount of material to be purchased. In addition to the brand, the weight per 1 m3 also depends on the manufacturer and the components that were used.

For M200 per 10 m3, it is necessary to use a flow rate of about 600 kg/m3 * 10 m3 = 6000 kg, while taking into account a draft of 1 to 1.4. That is, you should acquire 8400 kg of mixture for 10 m3 of screed.

For M300 the volume is slightly different: 650 kg/m3 * 10 m3 = 6500 kg. Taking into account some settling when preparing the mixture, the volume becomes approximately 9100 m3.

Let's start our acquaintance with the physical properties of the structure in question with the fact that the thickness of the floor screed in an apartment is not allowed to be less than 20 mm. Otherwise, its destruction is inevitable due to poor wear resistance. That is, you should calculate it at the lowest point so that it is even thicker.

A completely different matter is the thickness of the screed for a water heated floor. There should be enough here to hide the pipes. In addition, it is recommended to make a heat-insulating pillow from expanded clay. Accordingly, the level increases significantly.