Priming functions

Priming improves a number of characteristics of the base intended for subsequent finishing:

- A waterproofing film is formed on the surface.

- The adhesive properties of the surface are improved.

- The top of the material is significantly strengthened.

Applying a primer before filling gypsum board sheets increases the service life of the surface and significantly reduces the degree of water absorption. Some types of solutions contain antibacterial additives. Then the composition protects surfaces from the effects of fungi, mold and other bacteria.

Drywall must be primed, then the putty will apply better. Pre-treatment increases adhesion to finishing materials.

Due to the improvement in the properties of bases coated with the composition, there is a reduction in the consumption of putty for drywall, paint, and decorative plaster.

Scheme for applying primer to a plasterboard ceiling

A deep penetration primer provides drywall with many years of service without losing its properties. Antibacterial additives present in the solution improve the atmosphere in the room and prevent the development of pathogenic fungi and mold. Therefore, it is recommended to use such compounds to treat places to which access will be closed after the installation of plasterboard structures is completed (reinforced concrete floors, walls).

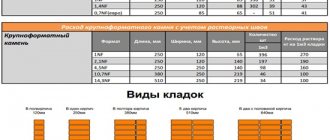

Primer consumption rates

The most important characteristic of the primer is the consumption rate per 1 sq.m. working area. For different primers and materials, this figure will be completely different. However, it must take into account the requirements of GOST.

Below are the consumption rates for the most popular types of primer:

- Concrete contact (concrete contact, concrete contact) – up to 350 g/m2. It is mainly used to prepare dense areas with low moisture permeability.

- Strengthening (deep penetration) – 0.1 kg/m2. It is used to strengthen weak, crumbling surfaces.

- Special primer for working with decorative plaster – 0.2 ml/m2.

- Alkyd primer – 0.12 kg/m2. This primer is used to treat wood, chipboard, plasterboard, and fiberboard.

- Water-dispersed – 0.1 kg/m2.

- Facade with acrylic base – 0.15 kg/m2.

- Wallpaper primer – 0.12 kg/m2.

- Primer for wood or metals before painting with enamel – 0.12 kg/m2.

- Anti-corrosion – 0.08 kg/m2. It is used to treat ferrous metal before applying paint.

- “Optimist” – 125-250 ml/m2.

- VL-02 – 0.12 kg/m2.

Consumption table for various types of primers

| Type of primer | Consumption rate | additional characteristics |

| Concrete contact | 350 g/m2 | It has a high level of adhesion (cohesion), designed for processing dense surfaces with low absorbent (absorbing) properties. Used before covering the work surface with tiles or plaster. |

| Alkyd primer | 120 g/m2 | For processing plasterboard, as well as wooden surfaces, chipboard (chipboard), fiberboard (fibreboard). |

| Water-dispersed | 100 g/m2 | Used to prepare the working surface for painting. |

| For decorative plaster | 200 g/m2 | During finishing work before plastering. |

| Specialist. primer before wallpapering | 120 g/m2 | No |

| Universal for metal and wood processing | 120 g/m2 | Used to prepare the surface for enameling. |

| Universal type "Optimist" | 125-250 g/m2 | This is a mixture of several types of specialized primers. Well suited for both metal surfaces and wooden or concrete-stone surfaces. In the instructions for use, as a rule, the proportions for each type of base being processed are written. |

| Anti-corrosion / Primer VL-02 | 80 g/m2 / 120 g/m2 | Necessary before painting surfaces made of ferrous metals (iron, cast iron, steel). |

Drawing conclusions, it is worth noting that when using a primer you need to adhere to some rules. If you are given advice that you need to buy more primers than you think, do not rush into the purchase. You can do this at any time. But if there is excess primer left, then its shelf life may be exhausted, and the money will be spent in vain and wastefully. You can always buy more primer.

When working with soil materials, adhere to safety regulations for working with such compounds. Study the detailed description of the priming work. Be sure to wear gloves when priming surfaces. Don't forget about a respirator and safety glasses. Keep the primer out of the reach of children. Treat your family with care, follow our advice and you will have a great renovation!

Types of primers

Today, various types of primers are produced. Liquids are used for different surfaces. The main types include:

- acrylic, which is universal, it can be used to cover various surfaces to be finished (concrete, brick, fiberglass wallpaper for painting), used on fiberboard, chipboard panels, wooden, plastered bases;

- alkyd is recommended for finishing wood, used on metal substrates (outside and inside), but mixtures are recommended for use inside buildings, the composition is unsuitable for processing drywall and plastered surfaces (as a result, fleecy irregularities arise), solutions are considered more suitable for impregnating untreated wood, chipboard and fiberboard;

- phenolic, which is used to coat metal and wooden substrates;

- perchlorovinyl is universal, but is used only for finishing work on the outside of buildings;

- Griftal is considered the most effective; it is used exclusively for covering the external walls of buildings;

Griftal primer for drywall sheets

- Polystyrene is used to process plastered, concrete bases, and brick surfaces; it is a toxic material, and therefore is not intended for interior work.

From all of the above it follows that the best option for processing drywall is acrylic. Video review of existing types of primers.

Consumption proportions of the main types of primer

There are no standard proportions for soil consumption per 1 m2 as such. There are several factors that invariably affect flow parameters:

- structure and type of surface being processed (wood, metal, concrete, granite, etc.);

- ambient temperature and air humidity level;

- chemical composition of the primer.

Below we will look at a calculation that we hope will help you determine the approximate primer consumption per 1 m2:

| Concrete contact | 350 g/m2 | It has a high level of adhesion (cohesion), designed for processing dense surfaces with low absorbent (absorbing) properties. Used before covering the work surface with tiles or plaster. |

| Alkyd primer | 120 g/m2 | For processing plasterboard, as well as wooden surfaces, chipboard (chipboard), fiberboard (fibreboard). |

| Water-dispersed | 100 g/m2 | Used to prepare the working surface for painting. |

| For decorative plaster | 200 g/m2 | During finishing work before plastering. |

| Specialist. primer before wallpapering | 120 g/m2 | No |

| Universal for metal and wood processing | 120 g/m2 | Used to prepare the surface for enameling. |

| Universal type "Optimist" | 130-250 ml/m2 | This is a mixture of several types of specialized primers. Well suited for both metal surfaces and wooden or concrete-stone surfaces. In the instructions for use, as a rule, the proportions for each type of base being processed are written. |

| Anti-corrosion / Primer VL-02 | 10 g/m2 / 120 g/m2 | Necessary before painting surfaces made of ferrous metals (iron, cast iron, steel). |

The above standards are not clear standards, but rather indicative. In most cases, true consumption depends on the level of damage to the material being processed. For example, several layers of primer are applied when the surrounding climatic environment quickly affects the deformation and deterioration of the surface being treated.

Primer selection

Usually the packaging indicates what kind of work the liquid is intended for and the primer consumption. To decide which composition is best to choose, it is necessary to familiarize yourself with this information. The primer must have the following basic characteristics:

- Good penetrating ability.

- Increase the adhesion of the base.

- Bind dust.

- Resistant to chemical influences.

- Not toxic.

- Ensure continued uniform application of the finish.

- Reduce consumption (per 1m2) of paint or wallpaper glue.

- Dry quickly.

It must be a moisture-resistant and heat-resistant liquid. Typically the primer is a white or colorless composition. Some white liquids become yellowish after drying. Therefore, you should know what kind of finishing the walls are planned with gypsum plasterboard.

For example, a colorless solution of Ceresit 17 is often used for priming drywall for further painting. When you plan to glue wallpaper, you can buy a white solution (if the coating is paper, then it is better to choose a colorless solution). Before painting, it is necessary to apply a colorless primer (it is recommended to choose the “Universal” option).

When choosing a solution, it is recommended to give importance to:

Indoor drywall tile primer should be used for interior work. You cannot use façade; it contains substances prohibited for work in residential and public buildings. It is not always recommended to use universal formulations. To get the best results, you should better choose special solutions.

Stages of priming plasterboard walls

The use of different types of compositions leads to the fact that less materials are wasted, and the finish lasts better. Which liquid works best and where is easily determined by the chemical composition of the solution. This factor determines the surfaces on which the composition is most effective.

Consumption of concrete contact primer per 1m2

Concrete contact is one of the new types of primers. It is used on dense surfaces with a low degree of moisture absorption. At the same time, it dries as quickly as possible, which allows you to begin subsequent surface treatment in a short time. It allows you to create a rough texture on the surface of the workpiece, which allows you to retain subsequent layers of paint, plaster, etc. The average rate of its use is primer consumption per 1 m2 of 200-500 g. We discussed the use and consumption of concrete contact primer in more detail in the previous article.

Application sequence

Acrylic primer must be applied before the next finishing stage. When carrying out work, the following tools should be used:

- a brush that is convenient for treating corners and areas near a plasterboard floor or plasterboard ceiling;

- with a roller you can quickly apply the composition to large surfaces;

- primer tray.

You can use a spray bottle. First, the seams between the plasterboard slabs and the screw heads are coated. After drying, putty is applied to the joints (tape is first applied). Dried seams should be sanded with sandpaper.

Applying primer to the seam between drywall boards

Next, you should apply a primer for drywall under the putty (near the ceiling, in the corners it is more convenient to work with a brush), and use a roller to cover the entire surface of the walls and ceiling. The primer dries on drywall within 4-8 hours. After this, the surface is covered with solid putty. The base is dried, sanded and a drywall primer is reapplied.

Again, you need to wait for the surface to dry and you can begin finishing (hanging wallpaper, painting). Sometimes it is recommended to apply two layers of solution, for example, in rooms with high humidity. It is important to thoroughly cover the entire surface. The plasterboard ceiling is primed in the same way.

A well-treated surface is ready for painting with water-based paint. Priming drywall is a mandatory and very important step (you must purchase the right solution).

Soil consumption rate

As a rule, for all building materials the consumption rate is indicated on the packaging. But this is only a preliminary calculation.

Wall primer and consumption per 1 square meter

If you watch the video tutorials on how surface priming is done, you will see that the primer is applied in 2 and sometimes 3 layers. The first layer will be almost completely absorbed by the material, and all subsequent layers will help create a base for finishing.

Also, the soil consumption calculator depends on the experience of the master and on the technique with which he applies the composition to the surface:

- brush;

- roller;

- spray bottle, etc.

On average, the material consumption calculator looks like this:

- Consumption of Betonokontakt soil per square is about 400 ml;

- the soil, which is used for preparatory work on the base for decoration, is consumed in the amount of 200 ml/m2;

- acrylic mass is consumed at the rate of 100 ml per square wall;

- consumption of alkyd substance varies around 120-200 ml/m2;

- the consumption of GF-021 soil for metal will be about 120 ml per square;

- silicate facade composition is consumed in an amount of 130-150 ml/m2;

- The smallest amount of primer is required for galvanizing - up to 80 ml/m2.

In conclusion, it is worth noting that there is no need to avoid priming the surface before applying finishing materials. The cost of primers is not so high as to save on them. If you skip such an important process, you risk encountering problems in the future that will force you to renovate from scratch.

Primers “Knauf”

The manufacturer Knauf produces all existing types of drywall, as well as related materials. The most famous solution is the colorless, quick-drying “Tiefengrun”. Drywall is processed with this material. Next, the surface is planned to be painted or wallpapered. There are no solvents in the soil. The composition can be used for interior and exterior decoration.

Knauf primer for drywall

It is necessary to observe the temperature regime; the solution cannot be used in frost conditions below -5°C. The liquid is usually packaged in containers (5.10 kg), the optimal consumption per 1 m² is 70–100 g.

Primer “Betokontakt” (especially for drywall) is used when ceramic tiles are planned to be laid on the surface. It is necessary to take into account the temperature conditions at which it is recommended to treat substrates with this type of solution (5°C–25°C). The primer is sold in packs of 5.20 kg. The average material consumption is 250-300 g/m².

Drywall should not be treated with Grundirmittel primer. When slabs are glued to the base with the Perflix mixture, it is recommended to pre-treat the surface with this solution. Knauf produces various types of primers that are used to strengthen weak, porous substrates. It is recommended to prime drywall with a solution from those produced by a German manufacturer. The products are more expensive than other brands, but the quality of the solutions is more reliable.

Knauf primer consumption per 1m2

Knauf produces not only primers, but also other building materials. Products produced by him are in demand due to their convenient price-durability ratio. Well, the costs of Knauf primers are as follows:

- Betokonakt Adhesive primer for interior use only - 350 g.

- Grundiermittel Deep primer for interior use only - 100 g.

- Isogrund Primer for cement plasters - 200 g.

- Tiefenrund Deep universal primer - 70-100 g.

- Quartzgrund Primer for decorative plasters - 210 g.

- Putzgrund Primer for decorative plasters - 210 g.

- Estrichgrund Floor primer - 150-300 g.

The Knauf company also produces insulation materials, dry screeds, aqua panels, and other building materials used by all builders.

Calculator for calculating primer consumption by wall area

Preparation of the working surface is a mandatory stage of finishing work, which is performed before applying finishing mixtures and compositions. The quality of the preparation performed directly affects the overall appearance and durability of the applied composition.

Before applying plaster and paint and varnish mixtures, the working surface is primed - this ensures increased adhesion of the liquid mixture. Below is a calculator for calculating primer consumption per 1 m2 of wall or any other surface.

When compiling the calculator, the consumption data indicated on the packaging with the composition was taken as nominal values. These indicators are regulated and were obtained during factory tests.

In practice, soil consumption differs greatly, since the structure and general technical condition of the treated surface greatly affects consumption rates.

To carry out the calculation, you must select the name of the primer in the appropriate field, enter the area of the surface to be treated and select the type of base on which the mixture will be applied.

If the desired mixture is not available, then you should select the “Other composition” value. Next, you will need to enter the consumption value declared by the manufacturer. If there is no such data, then you can use the primer consumption table located in the section below.

Main types of primers

Primer refers to the group of finishing materials applied as the first layer to a previously prepared surface. The main area of application is a wall or ceiling surface that is leveled and prepared for painting.

To produce soil, a base from both natural and synthetic components can be used. Natural components include various types of resins and minerals. Synthetic substances are represented by a number of adhesive and film-forming additives.

The main task of the primer after application is to strengthen the material being treated with the possibility of increased penetration of the finishing mixture, which will be applied as a second or third layer.

Acrylic primer is the most popular type of this composition

That is, the primer mixture penetrates and fills pores, microcracks and other voids on the surface. After drying and crystallization, a very dense film is created that prevents increased penetration of moisture. This provides improved adhesion of paint and other building mixtures.

Pre-treatment with a primer also allows you to reduce the consumption of paint and varnish products, provides antiseptic qualities and speeds up the drying time of the composition applied over it.

Among the most popular varieties, the following types of primer should be highlighted:

- Acrylic – an aqueous suspension based on acrylate-polymer binders. Used for both internal and external work. It is practically odorless, quickly polymerizes and penetrates into the structure of the treated material. Can be diluted with water without loss of performance.

- Latex is a dispersed substance based on artificial latex. Externally, the composition is similar to ordinary paint. Latex primer provides complete waterproofness, has high elasticity and strength. Used for strengthening loose bases and processing wood.

- Silicone is a highly specialized composition for treating substrates on which silicone-based plasters and paints will be applied. It has high strength, provides overall strengthening of the treated surface and further deep penetration of the applied finish.

- Silicate is a specialized mixture based on mineral components. The second name is “liquid glass”. Penetrates well into the structure of the material, fills voids and pores. After drying, it ensures tight sealing of voids. It is used only as a base for silicate paints and finishes of similar composition.

- Polyurethane – deep penetration primer based on polyurethane. Used to impart increased strength qualities. The main area of application is concrete floors and walls. Can be used for processing wood, metal and ceramics.

Before choosing and purchasing a composition, we strongly recommend that you calculate soil consumption using an online calculator or manually.

The selection of a suitable primer takes into account a number of requirements. First of all, the type of base on which it is planned to apply the composition is considered - concrete, gas silicate block, cement or gypsum plaster, wood or metal.

Next, we take into account what finish will be used in the future. For example, will a leveling plaster layer be applied, putty work will be carried out, etc.

After this, taking into account the specified requirements, any convenient composition suitable for specific working conditions is selected. As a rule, primer for exterior use has a stronger odor and is more expensive.

Regulated consumption rates for formulations

The consumption of different types of primer varies greatly and depends on the quality of the working base. The porosity of the material, chips, cracks and damage directly affect the increased consumption of soil.

The technical condition of the base directly affects the mixture consumption

The consumption rates declared by the manufacturer and indicated on the container with the primer should be taken as approximate values, since such data were obtained during factory testing of mixtures. That is, the mixture was applied on a relatively flat surface by machine.

In practice, the primer is applied to the prepared wall or ceiling using hand tools, which significantly increases the consumption of the composition. On average, the actual primer consumption is 20% higher than the declared value.

To manually calculate soil consumption, you can use the table below.

| Type of composition | Approximate consumption (ml.) |

| Acrylic | 180-200 |

| Latex | 130-150 |

| Silicone | 150-180 |

| Silicate | 150-200 |

| Polyurethane | 180-200 |

When developing an online primer consumption calculator, similar values were used with the addition of a coefficient taking into account the type of surface being treated.

Methods and technology for applying primer

Roller and tray with rolling surface

Primer application can be done using manual or automatic tools. Hand tools – brush, brush or lint roller. Power tool – spray gun or primer spray gun.

Since we are talking about treating walls indoors, it is generally customary to use acrylic compounds. They have the best price/quality ratio, have high fluidity and apply well. When using other types of soil, the use of various types of tools may be limited.

When working on a small area, it is optimal to use a lint roller with a long handle and a tray for paint and varnish mixtures. The tray must have a rolling surface to remove excess soil from the surface of the roller.

Before applying primer to the wall, it is recommended to go over the surface with a spatula. This will remove remnants of large particles of dust, plaster, putty, etc. Preparing the mixture for use is carried out according to the instructions on the packaging.

The primer is applied to the wall using a rolling motion from top to bottom. When working, you should take your time and carefully monitor drips and excess soil on the working surface.

It is better to use a brush to process corner joints and mates, since the roller treatment area does not cover small areas.

There are no standard proportions for soil consumption per 1 m2 as such. There are several factors that invariably affect flow parameters:

- structure and type of surface being processed (wood, metal, concrete, granite, etc.);

- ambient temperature and air humidity level;

- chemical composition of the primer.

That is, it turns out like this - if you choose a primer for drywall under wallpaper, then you can purchase a white solution. But here, too, an exception must be made. For example, it is better to choose a colorless option for paper wallpaper. Accordingly, the primer for drywall for painting should only be colorless.

Therefore, it is worth choosing the “Station wagon” model. Primer “Grundirmittel”. It cannot be used to process plasterboard sheets. But if they are glued to the walls using the Perflix composition, then before installation the base surface must be primed with this particular material. Do-it-yourself apartment renovation – Repair school or do-it-yourself drywall installation – All about drywall – Plasterboard putty We provide you with the opportunity to use special tables in Excel to make all the necessary calculations in just a few seconds.

You only need to know the original data (length, width, height). Next, you select the desired structure (ceilings, partitions, walls, etc.) and enter your dimensions. And the calculation is ready!

Primer consumption per square meter (1m2)

A mandatory requirement for all types of primers and other paints and varnishes is compliance with GOST. In turn, this is determined by a number of characteristics, which include color, primer viscosity, density, as well as primer consumption, drying time, etc.

Depending on the purpose and type of surface being treated, it is customary to distinguish the following types of primers: special, universal, for metal, for wood.

It is these signs that determine what the primer consumption will be per 1 m2. For a number of types of primers, the following consumption rates are established:

What primer to prime drywall

The building materials market today offers different primers that are used for different purposes. Here are the main types: I pay attention to several factors: price, expiration date and manufacturer. If the primer is from a well-known manufacturer that has already proven itself, then there is no doubt about its quality and durability. A mixture suitable for interior work is suitable for working with drywall.

Since the external one contains substances harmful to health. I liked the acrylic one the most - it is ideal for working with almost all surfaces. There are no specific rules for applying a primer to drywall.

The most important thing is to completely cover the surface to be treated. In some cases, two layers are applied. For example, in damp areas.

This is simply done to calm the soul. After all, a good primer applied in one layer is a high guarantee. Do I need to prime drywall before applying putty? Sequence and advantages of the priming process Tips for choosing a primer for the ceiling Do-it-yourself primer for old oil paint Primer for tiles, select the composition and apply it yourself Primer AK 070, characteristics and features of the material Many manufacturers write on the packaging what the primer material is intended for.

For example, there may be such an inscription - primer for wallpaper (this also means drywall) or for painting.

Primer consumption per 1 m² of wall (video)

In conclusion, I would like to draw the consumer’s attention to some things that simply cannot be kept silent about. If you have any doubts about what you think they are telling you to buy, more primer, don’t rush to do it. It’s better to buy more later than to “stock up” for future use until the next major renovation of your home. Any material – and soil is no exception – has its own shelf life. And one more thing: do not forget about safety precautions when carrying out priming work. Wear gloves, a respirator and safety glasses. Keep the soil away from children. Take care of yourself and your loved ones!

Primer consumption per 1m2

Before starting the preliminary stage of finishing work, you need to determine the primer consumption per 1 m2 in order to purchase a sufficient amount of material. This will help avoid unnecessary costs and the need to go for a new portion of the mixture without finishing the work due to its shortage. The greatest consumption of primer is required when processing porous materials that can absorb the applied mixture. To create the primary layer, a deep penetration agent is used that can ideally fill voids and further strengthen the base. In this case, per sq. per meter of surface, about 100 g of dry mixture is consumed.

When treating concrete walls, you can use the “Betonokontakt” primer. This product is consumed within 350 ml per m 2. In most cases, when working indoors on plaster and putty, an acrylic matte primer is used. It dries quickly and does not contain harmful components. On average, it is consumed about 200 ml per 1 m2. Nowadays, the environmentally friendly primer “Optimist” is very popular.

The consumption rate of this product is from 120 to 250 ml/sq.m. m. To create decorative plaster, a special mixture is used. It is consumed in the amount of 200 ml per 1 square meter of surface. There are special mixtures designed to coat wooden bases. These products penetrate between the fibers, preventing moisture from subsequently penetrating and provoking rotting processes. Such mixtures are consumed within 120 ml/m2.

After this treatment, the putty consumption per 1 m2 can be reduced. It may seem to a beginner that plasterboard surfaces do not require a layer of primer, since there is no need to level them. However, if you need to paint such walls, you need to create a perfectly smooth base that will not absorb the paint. It is the primer that allows you to achieve this result.

This coating will also come in handy before wallpapering. It will prevent the appearance of bubbles and wrinkles and ensure ideal adhesion of the finishing material to the base.

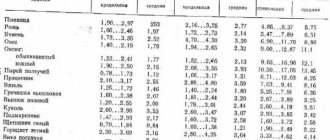

Consumption rate

The consumption of material per 1 square meter of wall depends on the type of surface on which it is applied. Consumption will be different for different walls, floors, ceilings, etc. and, accordingly, will depend on the primer itself. It is necessary to understand that one of the main criteria for choosing a product will be the surface structure. Porous ones require a mixture with a high degree of adhesiveness (adhesion) and a high degree of penetration.

On average, 1 kg of primer is consumed per 1 m2.

When applying primer, you need to consider how many layers will need to be applied. Usually apply 2-3 layers. If the wall is of medium porosity, then a universal primer will suit it. It is also necessary to take into account the future facing material. Thus, it will be possible to calculate the required amount of composition.

First of all, you must, of course, follow the manufacturer’s instructions. It usually indicates for which surfaces a given composition is suitable, how it should be applied and what the consumption will be.

To determine the amount of soil, the following factors must be taken into account:

- surface types;

- manufacturer's requirement;

- type of building materials;

- application technique (roller or spray);

- number of layers required;

On average, soil consumption per 1 sq. m. (in liters) for various primers looks like this:

| Deep penetration | Alkyd | Bituminous | Perchlorovinyl | Acrylic |

| 80-160 | 100-130 | 200-1000 | 600-100 | 120-180 |

The subtleties of applying primer to drywall before puttying

- filling small cracks and dents, which makes the surface smoother, eliminating damage caused during the installation of drywall;

If the primer is of high quality, one coat will be enough. During application, be careful to avoid material drips; if they form, the putty in this place will lie unevenly. The primer must be applied before laying the tiles , preferably in two layers. The only thing that can be lenient is not to level the putty so much, since the tile itself is a leveling material. Before you start directly priming, you need to choose the right tool with which to carry out the work.

Usually this is a soft roller, a brush for hard-to-reach places and a painting tray. Thus, we can see that priming drywall is not only a possible, but a necessary stage of surface treatment before puttying. But there are also exceptions.

Why apply primer to walls?

There are many finishing operations that require special preparation of the ceiling and wall surfaces. Preparation is carried out by applying a primer composition to the base.

Deep penetration primer is often used

The base is treated with primer in the following cases:

- before painting the surfaces of walls and ceilings;

- when finishing metal, wood and plasterboard surfaces;

- if necessary, apply protective and decorative plaster;

- to ensure reliable wallpapering.

The primer composition penetrates deep into the material through capillaries, seals the pores, increasing the strength properties and ensuring the integrity of the base.

Treatment with a primer mixture is a serious finishing operation that provides:

- deep penetration of soil into layers adjacent to the surface;

- increasing the adhesion of the finishing material to the surface;

- reduction of absorbency of the treated surface;

- significant savings in wallpaper glue and various paints;

- reliable protection against the development of microorganisms;

- long service life of the painted base;

- increasing the density and strengthening the processed base.

The primer composition ensures the integrity of the base

In order to ensure the durability of the decorative finish applied during the repair process, it is advisable to use priming compounds. They also make it possible to significantly reduce the cost of purchasing adhesive mixtures and binders. Various types of primers are used for processing wood, metal, as well as compositions and mixtures for special purposes.

Soil consumption varies depending on the type of base being treated. Using a regular calculator, it is easy to calculate soil requirements on your own.

Deep penetration primer for drywall

Before priming the drywall, it is necessary to dilute the mixture. This must be done exactly in the proportions indicated by the manufacturer on the packaging. Otherwise, the solution will lose all its properties and its use will be ineffective.

In some cases, craftsmen decide to install drywall not on a metal frame, but glue it directly to the wall. In this case, the use of a primer for drywall is mandatory, since without it the material will not adhere tightly to the base. A distinctive advantage of this composition is that it dries quickly and provides reliable protection against fungi and mold. In addition, the deep penetration primer is resistant to moisture and does not contain any toxic substances that could be harmful to human health.

GCR, which is impregnated with layers of special soil, serves for many years without losing its appearance and properties. The putty lies more evenly on the primer, since the latter improves the adhesion of various finishing materials.

- the use of a primer allows you to seal the pores of drywall, which has a positive effect on the consumption of paint and glue,

- The primer mixture has a huge number of qualities - it provides reliable protection against mold, fungi and prevents fire. In other words, the use of this solution allows you to extend the life of the wall,

- using a primer on drywall creates a smooth wall, without any defects or irregularities.

Consumption of deep penetration primer per 1m2

The consumption of deep penetration primer is much more economical in volume and comparable to the alkyd type. This primer is used for porous, highly absorbent materials to improve their processing and reduce the volume of painting and adhesive materials. Most often this is wood and its derivatives: fiberboard and chipboard. In addition, it can be cinder blocks, foam concrete and brick. Flow range from 80 to 160 g.

What is the best primer for drywall under putty?

There is another function, more often perceived as an option, giving the base surface a uniform background color. The reason for underestimating this factor, apparently, is the exaggeration of the capabilities of the finishing coating “which will hide everything.” Traditionally, a wide brush is used for processing corners and a roller with long pile for applying primer on planes. The situation with moisture-resistant drywall in this regard is even more complicated.

The greenish tint of the background will contrast with the light spots of putty. As for drywall, this is exactly the case when “you can’t spoil the porridge with oil.” All those properties that a high-quality, general construction primer has when processing gypsum plasterboard will be used and will most favorably affect the quality of subsequent finishing work.

It is almost impossible to make a specific choice knowing only these requirements, because, judging by their description, there simply are no bad primers.

Primer consumption per 1 m2 for various surfaces

The key to successful finishing work and obtaining a high-quality result is proper surface preparation. This process often includes a step such as priming. Primer is a liquid that is applied to the substrate with a brush or roller. Primer treatment allows you to strengthen the base, make it more durable, reduce water absorption, increase adhesion, prevent the appearance and development of mold and ultimately improve the adhesion of finishing materials to the base. The primer coating also helps reduce the consumption of subsequent finishing materials. Consumption for various types of primer Primer consumption per 1 m² directly depends on several factors: Material of the surface to which the primer will be applied Condition of the surface Types of primers and their concentration. In modern construction, the following types of primers are widely used: strengthening, concrete contact and for decorative plasters Type of finishing material that will be applied over the primer Weather conditions during the work Method of application. When treating a wall with a roller, the primer consumption per square meter is always higher than when using a spray gun. Strengthening primer consumption per 1 m². Strengthening primers (for example, concentrate 1:1 ilmax 4120 and concentrate 1:4 ilmax 4180) are pre-diluted with water and used on top of bricks and blocks. , concrete, cement, plasters, drywall. The coating dries in 2-3 hours and forms a transparent film on the surface. Thanks to treatment with strengthening primers, subsequent materials are applied more easily and evenly, their consumption is reduced, and the risk of cracks appearing after drying is minimized. The approximate consumption of ilmax 4120 primer per 1 m² is 50-250 ml, and the more concentrated ilmax 4180 is even lower - only 35-130 ml, depending on the type of surface to which the primer is applied. Primer consumption concrete-contact per 1 m² This primer (for example, ilmax 4175) is a ready-to-use viscous pink liquid with numerous inclusions of large particles. It is applied to smooth, dense substrates that absorb water poorly or not at all - tiles, mosaics, smooth concrete, paint, as well as chipboard, OSB, and drywall. The coating from such a primer dries in 2-3 hours and forms a pronounced roughness on the surface, which is much better “grabbed” by layers of adhesive for tiles, plaster, putty, screed and self-leveling. The consumption of such a primer per 1 m² is 200-500 ml (or 300-750 g). Primer consumption for decorative plaster per 1 m² A primer developed specifically for decorative plaster (for example, ilmax4185) is a viscous beige liquid interspersed with small particles. The coating reduces the water absorption of the base and thereby facilitates the application of decorative plasters, as it does not allow water to quickly “leave” from the mortar into the wall. Thanks to this, the master has more time to give the surface of the decorative plaster a beautiful and uniform pattern. On the other hand, a coating of such a primer creates a slight roughness on the surface, which contributes to more reliable adhesion of the plaster layer to the wall. Another bonus of treating this primer is the possibility of using it to preserve the façade insulation system for up to six months. The consumption of such a primer per 1 m² is 200-500 ml (or 300-750 g). Thus, no matter what the primer consumption per square meter is, these costs will in any case be more than recouped.

How and with what is drywall primed for different finishes?

There are several other points that may affect the choice of soil. First you need to decide on the properties of the material. They are as follows: The primer must be applied twice at intervals so that the first layer dries out. Usually wait from 12 to 24 hours. Although many manufacturers claim that 6 hours should be enough.

But it’s better not to rush, because humidity and temperature are different everywhere. The weight of ceramic tiles is quite large, so you need to make sure that they are held firmly. Tile adhesive helps with this, but you can’t do without primer. It’s not difficult to guess how to prime drywall before laying tiles.

It is worth choosing the same deep penetration acrylic primer with antifungal properties. When choosing specific products from different manufacturers, you need to make sure that they are suitable for working with ceramic tiles. It is worth paying attention to the consumption of primer on drywall per 1m2. This indicator is always indicated by the manufacturer on the packaging. You should always add about 10% to it to get a real result.

It should also be taken into account that the consumption is indicated for one layer, but you will need to apply the primer in two layers (the second is applied after the first has completely dried). Consumption usually ranges from 100-150 grams per square meter. When the question arises of what primer to use on drywall, you need to decide what types of this material exist.

It is important to choose a material based on the manufacturer, but still, you need to know about its existing varieties. The main types are as follows:

Factors influencing consumption rates

Craftsmen, seeing the condition of the surface, can quite clearly state the primer consumption per 1 m². This data is necessary when preparing estimates and calculating the cost of materials needed for repairs. You should also not purchase materials in advance, as the shelf life is limited.

Mathematical calculation

The required amount of material is calculated as follows: take the surface area and multiply by the average value (written on the label). This is how the volume of consumption per layer is calculated.

The consumption of deep penetration primer per 1 m² is determined by the condition of the base that is planned to be treated. As a rule, priming is performed in two layers:

- The first is almost completely absorbed into the material.

- The second creates a solid foundation for subsequent finishing.

Sometimes it is necessary to apply three or even four layers. Some finishing experts advise calculating the primer consumption per 1 m² of wall as follows: multiply the cost rate (the manufacturer writes it on the label) by 1.15.

Advice from the experts

Experts recommend increasing the planned consumption per 1 m² by 10-20% of the resulting figure if the walls or ceiling that are planned to be primed have significant damage or a porous structure.

In addition, it is worth paying attention to the tool with which the surfaces will be primed. When working with a roller, the primer consumption will be greater than when using a spray gun.

However, there is one more secret worth revealing. Some people prefer not to buy the entire intended amount of primer at once. This is the case when, if you don’t have enough, you can buy more material without any problems. The main thing is to take a primer of the same brand and from the same manufacturer.