Carpet will become a universal covering for both residential and office premises. It has many advantages, thanks to which it has earned popularity. Is it worth laying carpet on a wooden floor and how to do it?

The material does not cause serious difficulties during installation. Almost anyone can cope with the task. But before laying carpet on a wooden floor, you need to carefully study the process technology. Only with a responsible attitude will the coating please its owner for many years.

Pros and cons of carpet

Is it possible to lay the material on wood? Is it worth choosing it as a floor covering? You can answer this question by knowing the advantages and disadvantages.

Soft coating creates visual and tactile comfort in the room

The positive aspects of using the material include:

- a wide range of colors that can be used to easily complement the interior, expand the room or smooth out imperfections;

- good sound insulation and thermal insulation;

- the material is treated with special means that prevent the appearance of ticks, moths and other organisms;

- has high resistance to fire;

- low weight allows not to overload the floors;

- lasts a long time.

The disadvantages include:

- cannot be used in rooms with high humidity;

- stains from detergents may remain;

- sunburn;

- the standard width is 4 m, which may be inconvenient for rooms of other sizes.

Is it worth installing carpet? Yes.

In most cases, its shortcomings do not have a significant impact on the operation of the material. In addition, this option will smooth out troubles from noisy neighbors. For rooms on the first floor, additional thermal insulation will not be superfluous. This floor is much more pleasant to walk on than cold ceramic tiles. In terms of heat-protective properties, linoleum or laminate cannot be compared with it.

Methods of laying carpet depending on the type of room

The method of laying the covering is selected based on a combination of factors, starting with the condition of the floor, the trafficability of the room and ending with the texture of the base material.

Methods for laying carpet are given below:

- free;

- on double-sided tape;

- on the adhesive composition;

- stretching

Let's look at the options from simple to complex. At the same time, we’ll look at how the technologies differ and whether it’s realistic to get a good result on our own.

Free laying of carpet

Ideal for rooms with small sizes and low traffic, where you can get by with one canvas.

Skirting boards act as fixing elements, securing the structure along the perimeter of the walls.

This option is the most economical, the base does not require special preparation, and the cost of consumables (backing, glue, etc.) is kept to a minimum.

True, the service life of the carpet layer with free fixation is much shorter. Inconveniences arise when cleaning with a vacuum cleaner, especially a washing one.

Rearranging furniture can cause wrinkles, creases and even damage to the fabric.

Fixing carpet with tape

Double-sided tape is used when laying floors in the vast majority of cases.

The technology of work is simple and requires only careful preparation of the base.

The method using adhesive tape is suitable for rooms of any size, but without sudden changes in temperature or humidity, which lead to deformation of the adhesive tape.

During the work, the tape is fixed to the flooring, so preparation is important for the best adhesion.

The protective film is not immediately removed; the adhesive tape itself is laid out in the form of a mesh in half-meter increments.

Laying carpet with glue

A fairly simple method to do it yourself.

Proper installation of carpet with adhesive will ensure maximum longevity and reliability for the coating.

In areas with the highest traffic, glueing the flooring with glue is a priority technology.

The disadvantage is the inability to reuse the product, which is compensated by its service life and increased wear resistance.

Adhesive fixation requires caution; if you suspect a reaction between the glue and the base (parquet, laminate), it is better to play it safe and choose another method.

Plus, it is important to accurately calculate the thickness of the fastening composition in order to avoid seepage through the carpet.

Laying stretch carpet

Carpet laying technology based on the use of gripper slats.

Application is limited by room dimensions. The dimensions of the fabric stretched along the walls should not exceed 5 meters on any side.

Without special skills, working with carpet using this technology is quite difficult, but the coating is not afraid of deformation.

The substrate, the use of which is provided for by the technology of work, is fixed once and for all.

Subsequently, changing the carpet in the room will take place without replacing the intermediate covering.

Material selection

Before laying carpet on a wooden floor, you will have to visit the store and select the right material. It can be used for different purposes: children's room, living room, bedroom or hallway. It is not recommended to install in the kitchen, bathroom and toilets - these rooms are characterized by high levels of humidity. A more practical flooring material that is easy to clean from dirt is suitable here.

Choosing the right carpet is half the success. When selecting, you should take into account such characteristics of the room as:

- the number of people in it and the frequency of walking on the floor;

- presence of pets in the house;

- interior interior of an apartment or house, area of premises;

- features of the base, its evenness and stability;

- the ability to perform regular cleaning and care for the coating material;

- budget.

The most important thing you need to know when purchasing is the size of the room.

Before going to the store, you should measure the room. Moreover, measurements are taken at several points at once. This will allow you to find the widest sections: length and width. The purchase is made based on these indicators. Plus you will need to make a reserve. It will allow you to avoid sloppy and unaesthetic inserts.

When laying a covering on a warm floor, you should choose one that has short pile and consists of natural ingredients.

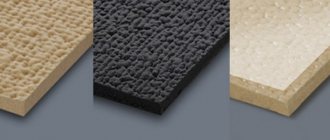

Options for heated floors under carpet

Laying carpet on a wooden floor involves the use of underlays. It is recommended to buy this material along with the main one.

The backing will hide all small defects of the wooden base

The carpet underlay is of synthetic origin. The following requirements apply to it:

- density and rigidity;

- no deformation;

- surface without damage or defects;

- thickness from 6.2 to 10 mm;

- good moisture permeability;

- ability to pass air.

A carpet underlay that meets all of the above requirements will extend the life of the material. It will not allow unpleasant odors and dampness to stagnate in the floor cake.

How to properly lay carpet on a concrete floor

Everyone knows that the final stage of renovation in an apartment is laying the floor covering, but not everyone knows how to properly lay carpet on a concrete floor. The carpet has excellent qualities and gives the atmosphere coziness and comfort.

Types of carpet

- Carpet made of natural wool. This coating is elastic, environmentally friendly and has antistatic properties. Wool carpet will not lose its color and brightness for a long time.

- Nylon fiber. The most important quality of such carpet is wear resistance. If you properly care for the coating, it will serve you for fifteen years. It is elastic and easy to clean.

- Acrylic fiber. The texture of this carpet has an imitation of wool, but differs from wool pile in that it is not elastic. Its pile is hard, and this plays a big role when cleaning it.

- Carpet is also distinguished by the type of pile. The pile can be cut, twisted, looped, two-level or single-level.

Pros of carpet

The main advantages of carpet are:

- During the production process, the carpet is subjected to a special treatment, and as a result it becomes fireproof;

- The carpet has a pile covering, which helps absorb noise;

- Can act as thermal insulation;

- This coating partially absorbs dust and there is much less dust in the room;

- It is easy to care for such a coating; you only need to clean it with a vacuum cleaner once a week;

- Carpet has a huge selection of textures, colors and textures, and this will help you choose the covering that suits your interior.

- It can be easily laid and it won’t take much time;

- Carpet can be used in any room, and even on the streets.

Getting ready to lay carpet

Before you begin laying carpet, you must first prepare the base of the floor. Check to see if there are cracks, holes, or vice versa bulges in the screed. If any of this exists, then you will have to make another screed to level the floor.

The best option for this is a self-leveling mixture, which will make your floor smooth. If you use a cement screed, it will have a rough surface, and this will affect wear resistance.

In this case, use a felt or rubber backing. The same applies to wooden floors. If the apartment already has floor skirting boards, they are removed. After this, we move on to preparing the carpet. It needs to be rolled out completely on one surface and left there for 24 hours to level it out. The main condition for this is that the temperature in the room must be at least 18 degrees.

Laying carpet correctly

After the carpet has been left for a day, it is spread out, leveled and stretched to be clamped with baseboards. This method is used for small rooms, since the carpet has every chance of moving.

There is also a way to use double-sided tape. It is glued to the floor and carpet is laid down and attached to the floor. Using tape, the cover will not move or curl, and is easy to remove.

And the last method is laying with glue. We apply glue to the floor, and the carpet is glued to it.

Laying carpet on a concrete floor

We first prepare the concrete floor, that is, we clean it of dust and dirt. Then we level it with a new screed, and as soon as it dries we prime it. When laying on concrete, it is better to use the adhesive method, as this will allow the coating to remain in place and not move.

To make the floor warmer, you can use thermal insulation in the form of a substrate. But then you will have to attach the carpeting with double-sided tape, but the base of the floor must be completely dry.

The video below provides recommendations for laying carpet on concrete:

polgid.ru

Carpet is used everywhere in apartments, private houses, cottages, and in public institutions. It is laid on concrete, wooden floors and laminate flooring. Practice shows that this is a very beautiful, comfortable, warm and practical design. You can install carpet yourself; it is not difficult if you carefully study the following information.

Composition and characteristics of carpet

From natural raw materials

In production, either pure wool or a mixture (from 10% wool and above) is used. The advantages of natural carpet include:

- Strength, elasticity, resilience;

- Low moisture permeability and thermal conductivity;

- Non-flammability;

- Practicality in cleaning and health benefits.

Disadvantages of natural carpet:

- Low wear resistance, afraid of moths;

- Ability to accumulate static electricity;

- Relatively high cost.

It is installed mainly in residential areas.

Made from artificial fibers

Carpeting made from artificial fibers is the most popular; it is practical and budget-friendly. Before you start laying carpet with your own hands, familiarize yourself with its properties.

Used in production:

- Nylon is very dense and abrasion resistant. It is not subject to deformation and retains its color and texture properties for a fairly long time. Antistatic and able to repel dirt.

- Polyester is a fireproof material, has rigidity and wear resistance. Outwardly, it is very similar to a wool surface.

- Polypropylene or olefin - has great resistance to fading and does not show stains (with the exception of oil stains), is fireproof and has good strength. But polypropylene has a significant drawback - it is brittle. Pay attention to the innovative olefin fibers - Supreme and Terklon, they are similar to wool.

- Acrylic is an elastic but abrasion-resistant material. It is used as a component in heterogeneous compositions.

Note that all these types of materials are suitable for installation on laminate, concrete and wooden floors.

Nuances of installation on various surfaces

Covering the concrete

Laying the flooring is the final stage of the renovation. When starting the main process, check:

- whether all the cracks in contact between the walls and the floor have been eliminated, and the building level will help you determine the evenness of the screed.

- then dry and clean the concrete surface thoroughly, and then be sure to treat it with a primer.

- make a drawing, carefully measuring all the protrusions and openings of the room.

- Use it to make a pattern on the main material, adding 5-7cm on each side.

There is no need to lay carpet on bare concrete. Install the backing first. It will increase the service life of the coating, insulate the floor and make it even softer, in addition to smoothing out all the unevenness of the concrete base.

Under a carpet with a textile base, rubber, felt or polyurethane-based substrates are laid; they are softer. If the base is made of rubber, then it will be enough to lay down paper. Lay the base and let it level out and rest. The carpet also needs to lie down and straighten out.

After this, a special glue is applied to the concrete using a notched trowel and the backing is carefully but at the same time carefully glued to the base of the carpet, starting from the corner. Be sure to roll it out with a roller and let it dry well.

Then the same glue is applied to it, and the carpet is attached using the same technology. Allow the carpet to dry thoroughly to take its final shape. Trim off any excess in the corners and around the perimeter, and safely attach the baseboards and thresholds.

To achieve the best possible result, you need to know how to properly lay carpet. Adhere to the following requirements (they are the same for working with laminate, concrete and wood floors):

- The glue must be applied evenly, the seams must be hidden;

- Leave an overlap of at least 5 cm on all cuts;

- Laying carpet requires a certain humidity in the workroom, otherwise air bubbles may form on it;

- When laying the pile, place it in one direction; if the joining of the canvases is intended, it is done along the room;

- Join the carpet with an overlap (so that the upper edge overlaps the lower edge by 6-7 cm), and then with a clear movement of your hand and a sharp stationery knife, make a cut;

- Start laying from the corner.

There are several ways to install carpet:

- Adhesive;

- No gluing;

- When using double-sided tape;

- Stretching (laying by tension using thin slats with two rows of nails).

Lay on laminate

Laying carpet on laminate flooring is a simple process; it can be done without the use of glue (free installation). This method is the cheapest, you don’t even have to spend money on glue and tape.

In this case, you do not need an additional substrate; the laminate will perform its role.

Step 1. Simply roll out the cut carpet onto the surface, taking into account the allowances for the walls (5-10 cm). Leave it to rest on the laminate.

Step 2. Then roll out with a roller to remove unevenness and swelling (rolling is done from the middle to the walls). After this, carefully cut out the material in the corners with a stationery knife.

Step 3. Trim the excess carpet along the contact between the walls and the floor. We fasten the plinths, they will serve as an excellent retainer, and install a threshold in place of the passage.

This way, your laminate will not fade, and the carpet can be removed at any time. The disadvantage is that when moving over it, for example, a chair on wheels, the carpet can bunch up and become deformed.

If the wooden base has aged, it is necessary to fill it with chipboard or plywood, this will also serve as a substrate. There are several ways to lay carpet on a wooden floor - with or without glue. We will focus on laying carpet on a wooden floor using double-sided tape.

Its consumption is 10 meters per 8 square meters. The width of the tape directly depends on the time of use (63 mm - 3 years; 180 mm - 7 years).

Step 1. We fasten it around the perimeter, as well as along the entire base of the wooden floor, creating cells of 60x60 cm.

Step 2. There is no need to peel off the top protective layer of the strips.

Step 3. First, spread the carpet on the wooden floor to give it a chance to rest and take the desired shape.

Step 4. Then we bend half of the covering towards the middle, peel off the top protective layer from the strips of adhesive tape and, using a roller, roll the covering over the wooden floor with lathing.

Step 5. We do the same with the other half of the carpet. Finally, we attach the baseboards and metal thresholds.

The disadvantages of adhesive tape are that when using the carpet, unevenness or bubbles may appear, and sudden temperature changes may cause it to become deformed.

We hope our recommendations will help you when laying carpet on concrete, laminate or wood floors. Create comfort in your apartment, private or country house with the help of this interesting coating. Doing this, as you can see, is easy and simple, even with your own hands.

Preparing the base

Before laying carpet, you will need to carefully examine the surface of the wooden floor. There should be no cracks, dents, or strong differences in height. All these troubles will lead to the fact that the laid carpet will eventually take the shape of the base or begin to tear.

Nails and screws are the easiest ways to eliminate squeaks

The next stage is filling small cracks and gaps with mastic.

To fill cracks, use a special wood putty

If the floor has only slight unevenness, then it may well become the basis for a carpet. Here it will be enough just to check the flooring for protruding nails or screws, and recess them into the wood if necessary. Then they do it with a special machine or plane.

Grinding stages

If serious defects are found during the examination, it is recommended to do this. For work, it is advisable to purchase moisture-resistant material. Plywood is laid in two layers. Between the rows you need to make an offset, as in brickwork. It is impossible for four corners of different sheets to converge at one point. Fastening is done using PVA glue, and then with self-tapping screws.

Plywood will help create a smooth and durable surface

After leveling, the underlay is laid under the carpet. It is not needed when installing the coating on a heated floor system. The material must be laid so that bubbles and unevenness do not form.

Laying carpet with double-sided tape

A mesh of adhesive tape is made over the entire area of the room, the cells of which will be 55 X 55 cm

The installation technology is not much different from that used with the adhesive method. Instead of glue, double-sided tape is used. The base on which the tape will be placed must be degreased with primer or another compound so that it sticks well. Try to avoid waves on the carpet. A mesh of adhesive tape is made over the entire area of the room, the cells of which will be 55 X 55 cm (approximately, maybe a little more or less). The top protective film is not removed immediately, but as the material is laid.

Make sure that it lies evenly along the walls, use the same gradual work. After gluing the canvas to one side, carefully align it around the room so that there is no free space that could later form wrinkles or bubbles. Also prune gradually. The tape also needs time to “set.”

Disadvantages of this method:

- insufficient strength,

- inability to use a washing vacuum cleaner,

- Wheels on furniture will wrinkle the coating.

Fastening technology

Once the deficiencies of the flooring have been eliminated and the underlay for the carpet has been laid, you can proceed directly to work. There are several ways that allow you to correctly lay the material on a wooden base:

- securing the whole web;

- gluing fragments;

- attaching carpet to slats.

Regardless of the technology, after the material is brought from the store, it is spread on the floor and allowed to smooth out within a couple of days. The entire process must take place at room temperature.

When using only one color, it is wise to choose a method that involves laying a whole canvas. In this case, the fastening can be adhesive or non-adhesive. The second option is suitable for small spaces. It consists of unrolling the roll on the floor, leveling it and securing it with a plinth. You should start with baseboards along the length of the room, then fix the sides along the width.

For a glueless connection, it is best to secure the edges and joints of the canvases with double-sided tape

Adhesive fastening is performed in the following order:

- the canvas is laid out on the floor for several days, after which it is rolled up to the middle;

- part of the surface near the roll is covered with an even layer of adhesive solution;

- roll out the carpet a little, press it tightly with a heavy roller;

- In this way, fix the first half of the coating, and then the second;

- trim off excess around the edges;

- fix the baseboards.

Installation with glue makes sense in rooms larger than 20 sq.m.

If a composition of different materials is laid on the floor, the fragment method is used.

In this case, parts are cut, the edges of which must be treated with a special seam. These parts are glued as close to each other as possible, taking into account the pattern and direction of the pile. The resulting joints must be sealed with colorless glue, which will prevent moisture from getting under the material.

Carpet underlay is a given when purchasing; we will look at this below for those who have doubts.

Carpeted floor coverings have been used for a long time, and what's more, they have become popular. There was a time when it was quite difficult to get a beautiful and large carpet for the floor and carpet was considered almost a luxury item. Now available to everyone. Rolled carpets or simply carpet are produced and sold in huge quantities. The soft covering can have not only a printed pattern, but also complete scenes. Carpet has earned its popularity solely for its affordable price, ease of installation and practicality.

How to lay

There are no problems with laying the material.

Each of the layers can be laid either dry or with glue. But preparatory work with the subfloor is necessary in any case! To work, you will need a minimum set of tools: a cutting knife, glue if rigid installation will be carried out, the substrate itself and a waterproofing film, if required by technology. Also don't forget construction tape to secure the seams.

Whether or not to level the base before laying the underlay and carpet is a question that those who want to complete the renovation as quickly as possible ask themselves. In this case, it all depends on what material will be placed between the finishing coating and the rough base.

For very dense substrates, it is imperative to level the base! If you place a cork on a “humped” floor, it will also begin to “hump”; if you lay carpet on such “waves”, nothing good will happen.

For more elastic materials, it is permissible not to thoroughly level the base, but it is necessary to knock down the bumps and fill the holes with cement mortar. If the difference in level is more than 2 cm per 1 meter, you will have to pour a concrete screed.

If the carpet underlay is placed on concrete, the order of work is as follows:

- Clear the concrete slab of debris.

- Perform rough leveling.

- You remove the dust.

- Divide the floor into squares if the room is large, or into two equal halves if it is small.

- Mix the self-leveling concrete mixture with water.

- Pour it into the selected square, roll it with a needle roller to remove air bubbles.

- Do the same with the remaining cavities. After a couple of days, remove the delimiters, fill the holes with cement mixture and carefully level them.

- Allow the surface to dry thoroughly.

If you are installing a carpet underlay on a wooden floor, it is not advisable to pour a self-leveling concrete screed. Use leveling using sheets of plywood. This will give additional rigidity to the rough base. Remove debris and dust from the floor and check the level of deviation from the horizontal. Calculate the thickness of the plywood. In places where the surface level is slightly lower, thicker sheets will be needed.

The ideal option is to lay plywood in two layers. The bottom layer is placed with a mandatory spread of vertical joints (like brickwork), fixation is done with nails or self-tapping screws. The second layer is also laid in a bandage, but above each seam of the first layer there should be a whole sheet of the second. Fixation is similar. The preparatory work has been completed.

Let's look at ways to install a carpet underlay on the floor:

- Laying the substrate in a floating manner. A simple option, but it risks the fact that the material will wrinkle somewhere if the carpet is installed unsuccessfully. Installation is carried out from the far corner along the long side of the room. Rolls of material are rolled out and allowed to rest so that it does not roll back into a tube. When the substrate has straightened out, minimize the joints and connect the panels using construction tape. A plastic film with a thickness of 200 microns or more must be placed under the cork.

- Laying the substrate on glue. Before such work, you need to carefully remove all dust from the base. It is best to fix material that is prone to wrinkling, i.e. not very dense. The installation technology is simple: unscrew half the length of the backing, apply glue to the base, put the material back and carefully level it with your hands. To consolidate the result, roll something heavy on top. Carry out these steps with each of the rolls. Secure the joints with construction tape.

Important! Select the glue based on the backing material, otherwise there is a high probability of shrinkage and the appearance of gaps between the rolls.

To lay carpet in a free-flowing manner, you need to know some tricks. First, if it is not possible to cover the floor in one piece, the joint is glued. There is no way without this. The simplest option is to fix the joint with double-sided tape. Two strips of double-sided tape on both sides of the seam.

You need to cut the carpet with a sharp knife, placing a board or plywood underneath

Second. You cannot lay only material brought from the store. We bring the carpet into the house and let it sit for several days - at least two for sure. Next comes the actual carpet installation. First, we measure the exact dimensions of the room. We assume that there should be a gap of 5-8 mm to the walls. This is the so-called compensation gap.

So, we cut the carpet to the required size and lay it out in the room. That's not all. There are a few more steps.

- They laid it down and checked the size of the gap. We left it for another 2 days.

- Checked the width of the gap. If it gets a little bigger, it doesn’t matter. Up to 3 cm can be covered with a plinth. If it’s more, you’ll have to order a special one. But the gap becomes larger if the carpet was brought in from the cold and was not allowed to rest.

- If the distance between the edge of the covering and the wall is less than 5 mm, cut it so that it is less than 8 mm.

Loose laying carpet is suitable for rooms no larger than 12 square meters. With an area of up to 20 squares, you can glue it with tape. It must be glued around the perimeter and in stripes every meter. Additional stripes at the junction.

We use tape

The technology for laying carpet on tape is not too different. We start work after it has rested for several days, cut it a little smaller than the size, wait a couple of days. If the gap remains within the desired limits, we begin to fasten it. We turn the covering away from the walls towards the center. We fix the tape in the designated places and along the walls.

Laying carpet under the baseboard is suitable for small rooms up to 12 square meters in area

If necessary, roll the covering and apply tape in the previously occupied area. Then remove the protective tape and roll out the coating. It's simple

You can also use a large spatula.

The structure of carpet resembles ordinary carpets, but in general it has nothing in common with them. This versatile, durable, easy-to-clean covering covers entire subfloors, whereas regular carpet only covers an area of the floor, with a regular finish underneath.

Do not think that carpet is boring and monotonous - this is far from the case. Nowadays all kinds of coating variations are produced - with long and short pile, soft and quite dense.

Available carpet colors

Carpet - operation and care

Laying can be done on any type of substrate - the material feels great on a concrete or wooden floor, on plywood or gypsum fiber flooring, etc. The carpet is suitable for installation both in an office and in a residential building, its features help it not to lose popularity and is often used for interior decoration.

- The material has increased thermal insulation and retains heat well in the house.

- Carpet has soundproofing properties. And the larger the pile, the quieter the steps when moving on this type of coating.

- The coating has high fire safety indicators, as it is treated with special compounds during production.

- Carpet absorbs dust and prevents it from floating in the air. The smallest particles settle in its pile.

- The material is easy to clean - sometimes you just need to use a vacuum cleaner to remove dirt.

- Carpet has a wide variety of textures and colors.

- Installation of the material is very simple and can be done by anyone who is even a little familiar with tools.

- Carpet provides warmth and comfort in the home.

Carpet in room design

Before starting work, the required amount of carpet is calculated. It is best to take a whole canvas for the room, but if its size is not enough, then the pieces can be joined together. The material is taken in such a way that there is a margin of about 5-8 cm for the walls; the excess carpet can then be cut off.

READ MORE: Which underlay for parquet boards is better and why a comparative review

Carpet can be laid on almost any base: concrete screed, tiles, wooden floors, on stairs, there is tiled carpet, the main thing is that the floor is smooth and clean.

If you have a concrete base, then carefully level it using putty, let it dry and completely remove the dust.

The wooden base can be leveled using chipboard sheets, the joints are sealed with putty and everything is opened with a primer.

There is another way: first, the nail heads are pushed down, then the surface is scraped, primed and filled with a self-leveling mixture for wood.

If you do everything yourself, follow these recommendations:

- lay the carpet on the floor and let it lie for at least a day until it is completely level;

- there should be no draft in the room, otherwise folds may form on the coating;

- instead of a primer, you can use a mixture of PVA and water;

- During work, the room temperature should be at least 17 degrees and humidity within 10-65%.

Very often, home craftsmen ignore laying underlay under the carpet, but experts recommend using it.

Substrate

Laying the underlay improves the heat and sound insulation characteristics of the specified coating, it gives it strength and elasticity.

Using a backing almost doubles the service life of the carpet. For this, foamed polyurethane or rubber is usually used.

In the hallway it is better to use a thin and durable underlay, but in the bedroom and nursery you can lay thicker material. At the next stage, the carpet is laid, its excess is cut off, and it is pressed using baseboards.

Tile carpet

Tile carpet is produced in the form of squares with a side size of 50 cm, it has a denser base, and thanks to its precise dimensions, its installation is carried out practically without seams.

- Gluing.

- Installation with construction double-sided tape.

- Free flooring with material pressed around the perimeter using skirting boards.

- Stretching.

Laying on tape

Why is carpet underlay needed?

Helpful information:

The large selection of carpet underlays is due to the fact that the demand for carpet itself is quite significant. Why is underlay so necessary for carpet? Let's look at the properties:

- The service life of a carpet with a backing increases several times. This once again proves that it is necessary to lay additional layers under it. The substrate will take on all the loads and the carpet will not wear out, maintaining its qualities.

- The underlay can give the carpet additional softness. Any underlay, even a thin one, will turn a thin coating into a fleecy and thick carpet.

- Can increase sound and heat insulation. If you have a floating floor, then thanks to the underlay it will not creak. A substrate of only 5 millimeters can perfectly level the surface.

As a result, you can see that it is the underlay that helps preserve the appearance of the carpet longer, as well as improve some of the defects of the floors.

What functions does it perform?

The quality of the carpet will improve if you use a backing when laying it. Without it, the carpet will deteriorate just a few months after use. The use of a substrate is effective by reducing the contact of the flooring with the concrete base, because concrete has a rough surface. And as a result of walking and load on the covering, friction occurs and the carpet loses its original characteristics. Thus, the additional layer acts as shock absorption and provides comfort and softness when walking. To create this layer, a variety of materials are used, the choice of which depends on the type of decorative coating.

Before purchasing a substrate, you must first carefully study the properties of the substrate and what material it is made of.

The quality of carpet laying depends on the thickness, elasticity and density of the interlayer. It is recommended to lay a thin, elastic and durable underlay that can provide complete sound insulation and make the room feel warm. Do not forget that the base for decorative flooring must have a smooth surface and be extremely level.

When choosing a carpet, they opt for a covering that already has a backing, but it is often purchased separately in specialized stores. In any case, the underlay for carpet is beneficial and justifies the cost, because it increases the service life of the decorative covering, as well as strengthens its structure and increases the comfort of use.

How to choose a carpet underlay

When purchasing a carpet backing, carefully study the characteristics and properties of the material from which it is made. It should not be loose, it should be dense and slightly springy. If you squeeze the backing with your fingers and it doesn’t regain its shape, it’s better not to buy it. Thickness ranges from 0.70 millimeters to one centimeter. When choosing, be sure to take into account such properties as air conductivity. Otherwise, an unpleasant smell of dampness may subsequently appear - the floor will rot and become damp.

Polyurethane foam

Used in hotels, apartments, offices. It perfectly levels the floor and improves sound insulation. This underlay must be laid evenly, joint to joint, on dry floors. Has a base and top made of polyethylene. If you want to lay carpet using the stretching method, then this type of underlay is perfect for you. This substrate is the most popular.

There are substrates with a paper, felt or polyurethane base. Their properties are soft, they also remove uneven floors well, and also make the floor warm.

Rubber

Carpet backings made from rubber crumbs are solid. They are used exclusively for carpet, which has a high-quality and natural base. With such a backing, your carpet will delight you for a long time, and the comfort and sound insulation of the floor will also improve.

Cork

Cork is made from natural raw materials, it does not emit unpleasant odors, and does not cause allergic reactions. This material is able to absorb excess moisture and release it back into the atmosphere in dry air. Cork can be used equally well as a backing for carpet on concrete or on a wooden floor; its manufacturing technology prevents the development of mold or fungi on the surface.

Any craftsman knows that flooring is laid using a certain technology. For laminate or linoleum, stores sell related materials, the purpose of which does not raise questions for the buyer. But to the question: how to lay carpet, what technologies are available, not everyone can answer something definite. Despite the similarity with carpets, it is impossible to simply cover a floor, especially a concrete one. Carpet, just like other types of coverings, is laid using a certain technology using special accompanying materials.

Covered the substrate

Once the primer or leveling mixtures have dried, you can begin laying down the underlayment material. There is an opinion that carpet underlay is not necessary. It is motivated by the fact that, as a rule, carpet has a large thickness and a “built-in” backing layer of felt or foamed PVC. Indeed, the carpet has a bottom - the main layer (not the main one, but important), but it is not enough to prevent moisture from being drawn out from the base and relieving stress between the materials.

The most reliable substrate is felt with a thickness of 4-6 mm. If it is made of synthetic materials, it is most likely treated with water-repellent impregnations, so your carpet will not be in danger of becoming damp.

You can choose a polystyrene foam substrate with a thickness of 2-3 mm, but, firstly, it will wear out much faster than felt, and secondly, it will not be able to adequately compensate for unevenness of the base. The advantage of a synthetic substrate is its inertness to moisture.

When covering the substrate, try to lay it in one piece so that there are no places where moisture and cold from the base can come from. If the substrate consists of several parts, glue it joint to joint using construction tape, and not overlapping.

The underlay should have an overhang of 15-20 mm onto the walls, since it will settle under the pressure of the carpet.

When you have laid the backing, smooth it with a roller to release the air and leave it for several hours.

Selection of material and preparation of the base

If for a subfloor with a flat surface in an apartment, laying material with pressure using baseboards is suitable, then laying on concrete should be carried out according to the following rules:

- First of all, it is the right choice of carpet. Not every type is suitable for laying on concrete. Natural carpeting is not recommended. The best choice is a synthetic material with olefin fiber. This material will last a long time on concrete. It is not recommended to use carpet with a jute base, as it absorbs moisture.

- Remove doors that open inside the room. After completion of the work, the laid carpet will raise the floor level, and it may be necessary to adjust the dimensions of the door leaf.

- Ensure low humidity of the base and atmosphere (not higher than 65%). The concrete must be dry (a fresh screed takes a month to dry). Check the old screed for possible sources of moisture and waterproof it. Heated household fans are used to dry the air in the room.

- The concrete base must be level. It is inspected for cracks, bumps, potholes and crumbling areas. Defects are repaired.

- To prevent fungal growth, treat the screed with antiseptic impregnation. The final stage will be treating the concrete with a primer for absorbent substrates.

Substrate

The main difference between the technology of laying carpet on concrete and flooring on a rough wooden floor is the mandatory use of a backing.

Polyurethane foam backing

For laying carpets on a concrete base, the following types of underlay are used:

- Polyurethane foam. Inexpensive and high-quality material that will smooth out unevenness and serve as additional hydro- and thermal insulation. Material thickness up to 6 mm. Polyurethane foam substrates are easy to install: they are sold in rolls. Simply unwind the lining and cut the strips to the required length. After this, the cut strips are removed, the base is coated with glue and the backing is rolled out onto the glue.

- Polyurethane. This type of substrate has a protective layer of polyethylene film. Due to this, the surface of the material is slippery, so they use stretched carpet for stretching. If you are using short-pile carpet, you can lay a polyurethane backing with a felt top.

- Made from pressed rubber crumbs. The base of this backing is made of polyjute. Of all materials it has the highest elasticity. Allows you to obtain a springy surface that is comfortable when walking.

Crumb backing

- Cork substrates are not used for laying on concrete, as additional work is required to waterproof the base.

The underlay for carpet on concrete is used for the following purposes:

- Compensating the load on the carpet, which will extend its service life.

- Creating a soft and comfortable coating.

- Reliable adhesion of carpet, eliminating shifting of the covering.

- Creating a barrier to the flow of cold air from the concrete base.

- Smoothing out uneven surfaces of the base.

Important! All types of carpet underlay are laid with glue.

Carpet screed

Carpet flooring, according to most consumers, is very difficult to maintain and requires the use of expensive detergents.

However, with proper use, as well as with proper installation of such a floor covering, the carpet will serve you for many years and will not require special care. To increase the service life of the carpet, you need to prepare the base of the floor for its installation. It should be perfectly even and smooth. Then follows the laying of the base - floor screed. A good option for this is the semi-dry screed method, which will help save money and speed up the process of installing the floor base.

Advantages of semi-dry carpet screed

- When installing a semi-dry screed, a small amount of water is used, which speeds up the drying process and prevents the penetration of water and moisture onto the lower floors and through the floors.

- The mortar mixture does not shrink during the process of strengthening the concrete solution. The risk of cracks appearing on the base is also reduced.

- When using fiber microparticles, such a screed becomes quite durable and does not require the application of a large layer of cement-sand mortar. When using a small amount of water, the screed is light in weight and does not place large loads on the load-bearing structures of the building.

- The semi-dry screed method involves the use of inexpensive materials, which makes it possible to save your money.

Work on laying carpet on a floor screed

Before carrying out construction work, it is necessary to clear the base of debris. It is also necessary to treat the surface with special means for waterproofing and increasing the strength of the future screed. Processing is carried out using impregnations based on acrylic or acrylic silicone. A film is laid on the removed and treated base, which is capable of retaining moisture in the cement-sand mixture for better hydration of concrete. Polyethylene also prevents premature drying of the semi-dry screed. Then it is possible to lay waterproofing and soundproofing materials.

The prepared solution is supplied to the site using pneumatic injection machines, which are capable of delivering the solution to a distance of 120 meters vertically and 200 meters horizontally. The mortar mixture is laid on prepared beacons, which are installed using a laser level. The gradual supply of concrete is accompanied by leveling the mixture using a rule and cutting expansion joints.

Next comes the stage of grinding the concrete surface using trowels and trowels. After grouting and creating a perfectly flat surface, the floor is covered with film to create the desired microclimate and better hydration of the concrete solution. After drying and gaining the necessary strength, you can begin laying the carpet. Carpeting work.

Several methods can be used:

- Laying carpet without using adhesives. Suitable for work in small spaces and using a single sheet of material. The carpet is laid in the room with a margin of 5 centimeters in each direction and leveled with a roller from the center. The excess is cut off and the edges are fixed using skirting boards.

- When using adhesives. This method is used when laying carpet in large rooms or when using carpet tiles. Double-sided tape or glue is used. There is a need to treat the concrete base for better adhesion with tape or adhesive.

It should be remembered that before starting work, the carpet should be placed in the room for a kind of acclimatization of the material.

We are engaged in installing semi-dry floor screed under carpet. By contacting our company, you receive a smooth and durable floor screed on which carpet can be easily laid.

- Forward

Laying technology

Laying carpet on a screed or concrete floor can be done in the following ways:

- Gluing.

- Installation with construction double-sided tape.

- Free flooring with material pressed around the perimeter using skirting boards.

- Stretching.

Important! When joining several carpet sheets, the seam is made along the light flow in the room (for example, perpendicular to the window). In this case, even a sloppy seam will not stand out.

Laying on tape

The advantage of this technology is its simplicity of execution and the ability to quickly dismantle the coating without damage. To perform this method, the base must be dry and clean.

Working with tape

- The adhesive tape is applied in a continuous strip around the perimeter.

- Then a mesh with a cell size of 50x50 cm is formed on the floor from adhesive tape. The protective layer of adhesive tape is torn off during the process of rolling out the carpet roll.

- Starting from the wall, the carpet is rolled out, removing the protective layer of tape. As you move, the material is smoothed out and pressed against the base for reliable fixation on the adhesive layer.

- Excess covering is cut off and baseboards are installed.

Bonding technology

To install carpet, dispersion or two-component adhesive is used.

Dispersion adhesives

A common glue of this type is PVA, but it is not used on concrete bases. Acrylic-based dispersion universal adhesives are popular.

Two-component reactive adhesives

You can lay carpet on a concrete floor using polyurethane adhesive specially developed for this purpose. The adhesive is mixed with the hardener immediately before starting work, when the carpet has already been rolled out. The initial setting time of this composition is 1 hour. This is enough to correct detected defects (shifts) in the installation.

Advantages:

- The setting of the adhesive occurs as a result of a chemical reaction between the components, and not as a result of evaporation of the solvent. This process does not depend on the presence and concentration of moisture in the air.

- Elasticity of the material after hardening.

- Possibility of using glue in a wide range of ambient temperatures and base surfaces.

When working with two-component glue, remember that the hardener is toxic until the glue dries. Therefore, when working with glue, it is necessary to ensure continuous ventilation of the room.

Applying glue

Work order:

- The carpet sheet is rolled out on the floor. Primary (rough) trimming of the material is carried out with an approach to the walls of 6-8 cm.

- The work is carried out in two stages: first one half of the room, then the other. To do this, first, the rolled out carpet is pulled up to half, folded in half.

- The open half of the floor is coated with glue using a notched trowel. It is necessary to avoid applying a thick layer, as the glue will either protrude along the edges and stain the pile, or it will saturate and ruin the fabric.

- In accordance with the instructions for the glue, wait a period of time, and only after that the raised half of the covering is unrolled.

- You can press the carpet with a rule or use a rubber roller. The material is rolled from the center to the walls without strong pressure.

- The same procedure is repeated with the second half.

Video of professional installation with glue:

Important! In a situation where it is necessary to make a joint, two pieces of coating are laid overlapping. The joint area is not coated with glue. After gluing the main part of the carpet sheets, a long metal ruler (usually) is applied to the joint and cut through two layers of covering. The trimmings are removed, the joint is coated with glue, the edges are pressed to the base and rolled with a rubber roller. The joint will be smooth and invisible.

Stretching method

This is a complex technology that requires professional skills and the use of special tools. This method is used for laying carpet in a large area.

Laying is done on a gripper rail. This is a thin (up to 1 cm thick) strip into which short nails are driven through in two rows. The lath is stuffed around the perimeter of the room with the points of the nails facing upward. They serve as hooks to hold the stretched carpet.

This method allows you to lay the underlay without glue, since the carpet will not be attached to the plane of the base, but along the perimeter.

Gripper rail

To work you will need:

- Power stretcher. A special tool with two needle soles connected by an extendable rod with a lever mechanism. Used to stretch from wall to wall.

- Knee stretcher. Used for working in corners.

- Shovel for padding carpet. With its help, the edge of the carpet is tucked behind the gripper strip.

- Iron and tape for heat-sealing seams.

- Seam clamp.

- Scissors.

After filling the slats, the carpet is pinned into studs along one wall. After this, using a power stretcher, it is stretched along the length step by step and fixed on the nails on the opposite side.

The work of merging joints using seam clamps and thermal tape requires professional skills, so this work is entrusted to experienced specialists.

Laying without fixation

The usual method used by most home craftsmen: rolling out carpet, trimming, installing baseboards. The carpet is pressed and held only by the baseboard. Sometimes the carpet is additionally secured around the perimeter with nails. This is justified when laying carpet on a small (up to 20 m2) area in rooms with low traffic intensity.

In rooms with high traffic or over a large area, more reliable fixation is necessary, since the floor carpet will stretch and crawl along the base. This will lead to premature wear and damage to the carpet.

Available substrate: 5, 6, 7, 10, 11mm. Available to order: any thickness from 5 mm.

We work with regions. Delivery throughout Russia.

Any modern floor covering must combine an aesthetic appearance and the ability to withstand high operating loads. The most common type of covering in apartments and houses today is carpet, which is comfortable for long-term use, easy to install, and also creates an atmosphere of unique comfort and warmth in the home. It is not for nothing that builders and craftsmen recommend using underlays for carpet, since this material extends the life of the floor covering, increases wear resistance and, of course, ensures hygiene. Underlay is a material that is placed under the carpet to achieve the necessary elasticity and maximum comfort.

Underlay for carpet on concrete: types, installation (how to lay it correctly)

› Construction from monolithic concrete › Floors

31.01.2020

Underlay for carpet on concrete is a material that must be used before laying the finishing coating in order to protect, extend its service life, increase thermal insulation characteristics and improve a number of other properties. There are many types of substrates on the market today, and they all differ in installation features, technical characteristics and appearance, but perform the same functions.

Before laying carpet on a concrete floor, it is advisable to take care of the underlay. Despite the increase in flooring costs due to the need to purchase and lay an additional layer, in the future this solution will pay off both in terms of ease of use and a significantly longer service life of the carpet.

Main functions of carpet underlay:

- Extending the service life of the finishing coating - the backing absorbs most of the load and protects the carpet from abrasion.

- The ability to make the floor covering softer - even the thinnest underlay makes the carpet more comfortable to use.

- Increasing the level of sound/heat insulation - the floor will not creak, the substrate will absorb all sounds, making the base warmer.

- Correction of small defects - if there are minimal potholes or bumps on which carpet cannot be laid, you can do without pouring a rough screed and fix everything with a thick backing.

Laying technology

When thinking about how to properly attach a substrate to a concrete base, you need to take into account the type of material and operating conditions of the room. You can attach the backing with double-sided construction tape or glue. Stretching technology is also used; it is possible to lay the flooring freely, pressing the material with skirting boards around the perimeter.

Laying on tape

This technology is very simple to implement, makes it possible to carry out work quickly, and, if necessary, easily and quickly dismantle the coating. The base must be clean and dry before starting work.

How to attach the backing to the tape:

- Scotch tape is glued exclusively in the form of a continuous strip.

- On the concrete floor you need to form a grid with tape with a cell size of 50 by 50 centimeters.

- The protective layer of tape is removed as the carpet roll is rolled out.

- The carpet is rolled out, starting from the far wall, moving towards the exit, the material is smoothed and pressed, trying to achieve maximum fixation.

- The excess covering is cut off, then the baseboards are installed.

Bonding technology

It is possible to glue the substrate to various compositions, but their choice must be approached very responsibly. Not all adhesive bases are suitable for concrete monoliths. Just as not every glue is suitable for the selected type of substrate. It is advisable to follow the advice of professionals, read the instructions on the packaging of the adhesive (there, among the materials with which the adhesive can be used should be the one from which the backing is made).

Dispersion adhesives

The most common glue from this group is PVA, but it is better not to use it for a concrete base. Acrylic-based dispersive universal adhesives are much more suitable for completing the task. A distinctive feature of this type of composition is that the substrate must be glued to them immediately after applying the glue.

Two-component reactive adhesives

There is a special polyurethane adhesive used for laying underlayment on concrete floors. The glue includes two components: the adhesive itself and the hardener, mixed right before work (the carpet must already be rolled out). Initial setting occurs in about an hour, during which installation defects can be seen and eliminated.

How to choose a carpet underlay?

Initially, you should decide on the technical characteristics of the floor covering itself. Typically, the thickness of the substrate should range between 5 and 10mm. In this case, the substrate must have the following parameters: high strength, elasticity, which allows it to restore its original shape. If the backing wrinkles and remains deformed for a long time, then you have a low-quality material, so you should take the choice of backing for carpet seriously. There is a risk of purchasing a substrate with an unpleasant odor and dampness in the living area, for this reason it should be slightly porous.

Carpet underlays and their types:

Each type has its own characteristics and, accordingly, advantages. The modern domestic flooring market offers a wide range of materials used for laying under carpet. Many carpet manufacturers produce both artificial and natural options.

Polyurethane foam materials for carpet.

These materials are very popular when used in offices, hotels, municipal institutions, and business centers. They make it possible to hide all imperfections and irregularities as much as possible, and increase noise insulation in the premises. There are certain rules that should be followed during installation: 3 mm - maximum difference; maximum density of the material to the floor. Polyurethane materials for carpet. The thickness of these materials is greater than that of polyurethane foam products, which allows them to be used on concrete floors. They also have an additional layer of polyethylene, which gives the substrate moisture-proof properties. By the way, the top layer can be felt, providing high noise insulation. The polyurethane material is based on paper or artificial jute. Rubber crumb backings for carpeting. The distinctive properties of this material are density and hardness, which is not noticeable under the carpet. Of course, it has noise, moisture and heat insulation and is perfectly combined with floor coverings. Rubber underlay can be used with both wood and concrete flooring.

Why you should buy carpet backing in our online store:

- ◆

A luxurious range of carpets from leading manufacturers.

◆

Our own delivery service will ensure timely transportation of orders on favorable terms for you.

◆

Huge sales on all products.

◆

High quality customer service.

◆

The most affordable prices in the city for carpets and accessories.

Kinds

Today, the range of the market is huge, but despite this, there are types of materials that are used as a layer under carpet. The most common ones are:

- polyurethane foam;

- polyurethane;

- rubber;

- cork;

- polystyrene foam.

Polyurethane foam

Polyurethane foam backing for carpet.

In rooms with high traffic, polyurethane foam materials are used for carpeting. After all, this type of layer allows you to level the surface and provide sound insulation. Before laying polyurethane foam layers, dry the work area. The flooring is used for polyurethane foam masonry with no height differences of more than 5 mm. By using such material, the room is provided with thermal insulation and protection against water penetration.

The process of installing polyurethane foam layers does not cause difficulties, however, there should be no air bubbles when laying it.

Polyurethane

Polyurethane backings, the base and surface of which are made of polyethylene, are attached to the decorative flooring using a gripper strip, which facilitates precise fixation of the carpet. The polyethylene layer provides high strength and resistance to moisture. Also, polyurethane layers can insulate floors at low temperatures.

Rubber

When using a rubber layer, you do not use whole material, but its crumbs. You can lay the rubber layer yourself, since this method of sealing the decorative coating does not have any particular installation difficulties. Just like polyurethane and polyurethane foam, a rubber base increases the service life of carpet made from natural materials and hides its errors.

Cork

This type of interlayer is the best type of decorative coating due to its environmental properties. The cork layer cannot be deformed during operation, is resistant to rotting, and also has sound insulation. Using additional flooring made from pressed cork, uneven surfaces on the concrete base are leveled out. It is often used in children's rooms due to the inherent shock absorption of the substrate, which ensures safety for babies. Cork can also protect the carpet from the heavy weight of furniture and provides warmth and comfort to the floor in the room.

For many floor coverings, the use of underlayment material is strictly necessary. This includes carpet. A special underlay for the carpet is needed to ensure its proper service life.

The latter causes heated debate. Many argue that carpet does not need an additional layer, because it itself is warm and soft. But contrary to this, professionals say that you need to follow the established installation technology.

Carpet flooring is comfortable, but installation technology must be followed

The substrate improves the performance:

◆ thermal insulation (saves energy resources

)

◆ noise insulation from 24 dB

◆ acoustics (echo disappears when talking)

◆ comfort (relaxes your legs when walking)

◆ hides unevenness and differences in the floor

◆ significantly extends the life of the carpet due to self-straightening of the pile

◆ the backing protects the carpet from deformation and trampling

◆ carpet underlay does not shrink

◆ sound disappears when walking on carpet

◆ thin carpet becomes soft and easy to clean

◆ Vacuuming is more efficient, providing maximum cleaning power and less damage to the carpet

Prices for all products are valid and are adjusted daily!

You can order delivery and pickup of the substrate daily. The warehouse is open seven days a week.

If you approach the installation of flooring wisely, it will last much longer. Properly means using certain tricks that extend its service life and allow you to save on repairs. For example, when laying carpet, a trick is to use underlay. Its presence allows the use of thinner coatings, which are easier to maintain and cost less. The underlay enhances sound insulation, prevents moisture from appearing on the reverse side of the carpet, enhances the spring properties of the covering, and adds softness to it.

Walking on such a floor is more convenient and comfortable.

Peculiarities

The peculiarity of any type of substrate is that it extends the service life of the coating and, depending on the material, increases it by two or even three times. This is achieved due to the high shock-absorbing properties of the substrate, which takes on the bulk of the load and distributes the rest evenly over the carpet area approximately 1 m2 from the person’s foot. Without a backing, all carpets take on the entire friction load and wear out faster.

With it, there are no traces of furniture left on the carpet, the pile rises faster and more completely.

The second feature is giving the flooring additional softness.

A pad placed between the floor and a thin carpet makes it comparable in softness to a long-pile carpet.

It’s not even worth mentioning that a short-pile or looped carpet is much easier to care for than a fluffy carpet.

If the thickness of the substrate is not less than 0.5 cm, then it is not necessary to additionally level the surface (lay a new screed on top of the old one). If the floors are wooden, then the underlay prevents the effect of a “floating” floor and prevents the floor covering from swelling and sagging.

Another characteristic is a high level of sound insulation,

increasing the thermal properties of the carpet and, most importantly, increasing hygroscopicity. Thanks to the interlayer, the coating will not mold from accidental moisture, which often occurs on a concrete screed in the off-season, neighbors below will not complain that elephants are running around your house, and in winter your feet will be warm even without socks.

DIY carpet installation on wooden floors

Laying carpet on a concrete floor is carried out according to certain rules. First you need to select a suitable material, study its properties, requirements for the installation method, then prepare the base and only then begin work.

It is important to choose carpet that can be laid over concrete. After all, if the material does not involve interaction with the concrete surface or does not provide the required level of comfort, the substrate will not save it. Natural types of carpet are not recommended for use on concrete floors.

Before starting work, you need to remove the doors that open into the room. It is worth considering that after laying the underlay and carpet, the floor level will rise by approximately the sum of the thickness of both materials, so there is a possibility that it will be necessary to adjust the dimensions of the door leaf. To prevent this from happening, it is better to lay the carpet on the floor while performing other finishing work, before installing the door.

Before laying the carpet, you also need to ensure optimal air humidity (no more than 65%), make sure that the concrete is completely dry (28 days have passed since pouring). If the screed is old, it needs to be checked for defects and sources of moisture. If necessary, lay a layer of waterproofing, and to dry the air, use household fans equipped with heating.

The concrete base must be level - minimal defects are allowed, there should be no significant bumps, cracks, potholes, areas with crumbling or peeling coating. All defects must be eliminated. To eliminate the possibility of fungus spreading under the substrate or carpet, it is advisable to treat the concrete floor with a special antiseptic impregnation. Ideally, the final stage of preparation would be to coat the concrete with a primer for absorbent substrates.

Laying on tape

This technology is very simple to implement, makes it possible to carry out work quickly, and, if necessary, easily and quickly dismantle the coating. The base must be clean and dry before starting work.

How to attach the backing to the tape:

- Scotch tape is glued exclusively in the form of a continuous strip.

- On the concrete floor you need to form a grid with tape with a cell size of 50 by 50 centimeters.

- The protective layer of tape is removed as the carpet roll is rolled out.

- The carpet is rolled out, starting from the far wall, moving towards the exit, the material is smoothed and pressed, trying to achieve maximum fixation.

- The excess covering is cut off, then the baseboards are installed.

It is possible to glue the substrate to various compositions, but their choice must be approached very responsibly. Not all adhesive bases are suitable for concrete monoliths. Just as not every glue is suitable for the selected type of substrate. It is advisable to follow the advice of professionals, read the instructions on the packaging of the adhesive (there, among the materials with which the adhesive can be used should be the one from which the backing is made).

Dispersion adhesives

The most common glue from this group is PVA, but it is better not to use it for a concrete base. Acrylic-based dispersive universal adhesives are much more suitable for completing the task. A distinctive feature of this type of composition is that the substrate must be glued to them immediately after applying the glue.

There is a special polyurethane adhesive used for laying underlayment on concrete floors. The glue includes two components: the adhesive itself and the hardener, mixed right before work (the carpet must already be rolled out). Initial setting occurs in about an hour, during which installation defects can be seen and eliminated.

The main advantages of this type of glue:

- Setting occurs due to a chemical reaction between the two components, but not due to the evaporation of the solvent. The process occurs regardless of the temperature/humidity in the room and does not involve toxic fumes after completion of work.

- After hardening, the material becomes elastic.

- The glue can be used if there are minor defects in the base, which it eliminates.

It must be remembered that the hardener is toxic until the glue dries, so during the work it is advisable to constantly ventilate the room, and after that there is no need to be afraid. This type of adhesive is suitable for laying underlay or carpet directly onto concrete.

How the work is performed:

- The fabric to be laid is rolled out on the base, a rough (primary) trim of the material is made, extending onto the wall by about 7 centimeters.

- They lay the coating in two stages: first they work on one half of the room, then on the other. The already rolled material is lifted and folded in half.

- Using a notched trowel, coat the exposed half of the concrete floor with glue, being careful not to make the layer too thick, since then the glue may protrude along the edges and add problems.

- Maintain a certain time (specified in the instructions), unroll the raised half of the covering, carefully fix it with pressure on the floor using a rubber roller. You need to roll in the direction of the center/wall, do not press too hard.

- Do the same with the other half of the room.

Stretching method

This method is quite complicated and requires professional skills and special tools. Typically, it is not the underlay that is laid in this way, but carpet in rooms with a large area. The coating is placed on a gripper strip - a thin (about 1 centimeter thick) strip into which 2 rows of short nails are driven through. These nails act as hooks that hold the stretched carpet.

After stuffing the slats, the carpet is carefully pinned onto nails along the wall, then stretched using a power stretcher gradually along the length, and fixed to the nails on the opposite side. But splicing joints using thermal tape and seam clamps requires professional skills, so it is better to entrust the process to experienced craftsmen.

This method is used to lay the material by most home craftsmen who do all the work with their own hands. The underlay or carpet is rolled out, trimmed, laid, and baseboards are mounted on top, which act as the only fastening element. Additionally, you can secure the material with small nails around the perimeter, especially if we are talking about small areas with minimal loads.

High loads (where traffic is high) require better and more reliable fastening of materials.

- The humidity level in the room where the flooring is planned should be from 20 to 65%, and the temperature - 18 to 35 degrees.

- Before installation, the material must acclimatize - it must be brought into the room and left for 1-3 days.

- Make sure the concrete base is completely dry.

- After drying, seal all cracks and remove defects.

- Treat the cement screed with chlorine solution to prevent the appearance of fungus.

- Apply primer to the surface and wait until it dries completely. Thanks to it, the concrete base will become strong and will not crumble.

- On glue. The carpet is glued to the concrete floor using special or regular PVA glue, or Bustilat.

- With double-sided tape. Optimal for small spaces. The screed under the carpet must be perfectly flat.

- Perimeter fastening. The canvas is held in place only by the baseboards. Suitable for small spaces.

- Stretching. A method of attaching carpet to special slats installed around the perimeter. Mainly used for large rooms. A special tool is required to tension the fabric.

READ MORE: Installing an electric heated floor under a laminate - which system and laminate to choose

Next, we will consider each method of installing carpet on a screed in more detail.

And one more piece of advice: if several panels are laid, the joint between them should be perpendicular to the window opening, so it will be less noticeable.

A simple and fairly quick installation method. Another advantage is the ability to dismantle the coating and use it again. Step-by-step description of the process:

- First we glue double-sided tape around the perimeter of the room.

- Next, we glue the tape in the form of a grid with a pitch of approximately 50 cm (do not tear off the outer protective layer).

- Carefully lay the carpet against one wall and gradually unwind the roll and remove the outer protective layer of tape. Carefully smooth and press down the material.

- Trim excess parts, install skirting boards, thresholds, etc.

The next installation method is with glue. To choose the best way to glue carpet to concrete, read the article about this consumable.

- After following the above recommendations, roll out the canvas around the room.

- We lift one side up to half and fold the material in half.

- Coat the freed surface with a thin layer of glue. You can use a notched trowel for this. Don't apply too much glue or excess glue will come out around the edges.

- Let the glue sit for 10-15 minutes (according to the instructions on the package).

- Now you can lay the carpet, carefully smoothing it so that there are no bulges or folds.

- We do the same with the second half of the canvas.

- We install skirting boards, thresholds, etc.

Find out more about carpet skirting boards.

This method is the most difficult, it requires experience and the use of a special tool - a stretcher. But you can lay the underlay under the carpet without gluing it to the surface of the concrete floor. We advise you to contact specialists if the coating is installed using this method in a room with an area of more than 20 sq. m.

- Gripper slats with two rows of nails driven into them are installed along the perimeter of the room.

- First, the material clings to the slats on one side of the room, then, using a special tool, it is pulled onto the slats on the other side of the room.

- Next, the baseboards and thresholds are installed.

- The assembly of the interlayer depends on the quality of the base.

- Laying is carried out based on the technical characteristics of the carpet and the base on which it will be laid.

- The type of carpeting is directly related.

Laying on tape

- First of all, it is the right choice of carpet. Not every type is suitable for laying on concrete. Natural carpeting is not recommended. The best choice is a synthetic material with olefin fiber. This material will last a long time on concrete. It is not recommended to use carpet with a jute base, as it absorbs moisture.

- Remove doors that open inside the room. After completion of the work, the laid carpet will raise the floor level, and it may be necessary to adjust the dimensions of the door leaf.

- Ensure low humidity of the base and atmosphere (not higher than 65%). The concrete must be dry (a fresh screed takes a month to dry). Check the old screed for possible sources of moisture and waterproof it. Heated household fans are used to dry the air in the room.

- The concrete base must be level. It is inspected for cracks, bumps, potholes and crumbling areas. Defects are repaired.

- To prevent fungal growth, treat the screed with antiseptic impregnation. The final stage will be treating the concrete with a primer for absorbent substrates.

Tile carpet

- Why does a carpet need underlay?

- Polyurethane foam backing

- Polyurethane backing

- Rubber backing

- Cork backing

- Polyethylene foam backing

- Expanded polystyrene backing

- Methods for laying underlay under carpet Fixing the underlay with glue

- Attaching the backing with double-sided tape

The peculiarity of any type of substrate is that it extends the service life of the coating and, depending on the material, increases it by two or even three times. This is achieved due to the high shock-absorbing properties of the substrate, which takes on the bulk of the load and distributes the rest evenly over the carpet area approximately 1 m2 from the person’s foot. Without a backing, all carpets take on the entire friction load and wear out faster. With it, there are no traces of furniture left on the carpet, the pile rises faster and more completely.

The second feature is giving the flooring additional softness. A pad placed between the floor and a thin carpet makes it comparable in softness to a long-pile carpet.

If the thickness of the substrate is not less than 0.5 cm, then it is not necessary to additionally level the surface (lay a new screed on top of the old one). If the floors are wooden, then the underlay prevents the effect of a “floating” floor and prevents the floor covering from swelling and sagging.

Another characteristic is a high level of noise insulation, increased thermal properties of the carpet and, most importantly, increased hygroscopicity. Thanks to the interlayer, the coating will not mold from accidental moisture, which often occurs on a concrete screed in the off-season, neighbors below will not complain that elephants are running around your house, and in winter your feet will be warm even without socks.