What is the difficulty of installing a floor in a frame house on stilts?

Such a foundation is characterized by low cost, short installation time and versatility, i.e.

the ability to use it on any type of surface (floating soil, complex terrain, etc.). However, no one is immune from shortcomings, in this case a drafty underground. To avoid this, serious insulation and vapor barrier will be required. This will help solve the following problems:

- Will prevent the formation of fungal deposits and rotting of the floor.

- Increases the energy efficiency of the floor.

- Will eliminate the appearance of moisture on the floors.

I will also immediately note some points that will improve the quality characteristics of the future floor:

- I always treat the lower harness with an antiseptic. To do this, it is better to use a special deep penetration composition;

- I place the thermal seal between the support beams;

- I make filling for the supports, which helps reduce thermal conductivity, in order to prevent the soil from freezing under the building.

Thus, by following my recommendations, you will extend the life of the floor.

I usually use a pile foundation in the following cases:

- carrying out work on aggressive soils (rocky, marshy, etc.);

- with uneven ground surface;

- limited construction periods;

- impossibility of bringing the soil foundation into a condition suitable for construction.

This type of foundation consists of metal pipes with a metal tip installed at the edges. A cone-shaped tip is inserted into the thickness of the earth and firmly fixed in it. If the soil is loose, then I compact it additionally with soil.

To evenly distribute the weight of the structure on the foundation, the tops of the piles are cut at the same level, the caps are installed, and a circular winding is installed on top. They combine the pillars into a continuous structure.

Keep in mind that screw piles are not driven into the soil, but are screwed in manually or mechanically!

Any strapping material: steel, wood, concrete. The quality of the piping and the selected material is the basis for installing the floor of the first floor of a frame house.

While maintaining the quality and reliability of the floor covering of the first floor of a frame house, you should be careful about the selection of building materials. When choosing the load-bearing parts of a structural floor pie, you should select wood depending on the weather vagaries of the area, weight loads, aggressive room conditions (bathroom, kitchen, etc.).

We invite you to read: What is a water bath at home and how best to make it? Water bath at home

Most often used for the floor of the first floor of a frame house:

- Needles are a cheap, durable species. I use this material in small rooms.

- Aspen and oak are expensive materials, characterized by high durability and a long service life. The quality of the material allows it to be used in other rooms.

To protect the coating from moisture, many use glassine or roofing felt. Glassine is inexpensive, but it is short-lived. The reason for this is the composition, the basis is cardboard, which, under the influence of aggressive factors, is destroyed. Due to sudden changes in temperature, cracks appear on the roofing material and its protective properties are lost.

The best means for waterproofing the floor in a frame house on stilts are one or two-layer membrane materials consisting of synthetic fiber or fiberglass.

To make the work easier when performing waterproofing, I use bitumen mastics. Such mastics, according to the method of their application, are of two types - hot and cold. The first consists of mineral fiber, gypsum, asbestos, etc., the second of lime.

Frame house floor structure

When determining the necessary material for the flooring of a frame house, I pay great attention to its strength and weight. In order to prevent load on the building supports, the mass of the product is chosen to be minimal. Ideally, the material is selected from wood (aspen, oak, pine needles, etc.), which must be dry and without visible damage.

Having prepared the base and grillage, I begin installing the floor structure. To make wooden framing, I recommend using beams measuring 10x10 cm. It is better if they are made of coniferous materials, which are wear-resistant, durable and reliable.

The strapping must be strong, so for large areas, where there are more than three meters between the supports, I reinforce it with additional posts.

Next, at a distance of 50 cm, on top of the beams, I place logs with a cross section of 10x25 cm. For a small space, products with a cross section of 5x15 cm are suitable. I install landing openings along the logs.

In order for the tree to last a long time, the structure must be protected. I do this using special antifungal treatments. Then, along the bottom of the backing material, I attach cladding made of boards measuring 30 by 30 mm.

We suggest you read: How and with what to plaster a brick stove

To make the floor stronger, I use jumpers. I stuff them on top of the base at a distance of 150 cm from the base. This technique should be used when using a heated floor in a home.

Insulation materials and their properties

The floor, like the external walls, is an enclosing structure, as it separates the warm rooms of the house from the ground. Accordingly, it is also subject to the rules on the need to lay effective thermal insulation protected by anti-diffusion layers.

Basic insulation scheme

Unlike vertical structures, not only rolled mats or slabs, but also bulk or loose materials can be used to insulate the floor (methods for insulating a frame house are described in detail in our article). You just need to remember that they must be light, since the structure does not have the ability to rest on the ground. Therefore, such a fairly weighty material as expanded clay cannot be used in this case.

We suggest you read How to remove fleas from a cat at home

But what is possible? We hope that the next chapter will help in choosing the right insulation.

The use of rolled soft insulation or more rigid rectangular blocks is a traditional option for floor insulation.

Variety of materials

These materials include:

- Mineral wool (GOST 4640-2011), produced either from the melt of gabbro-basalt rocks, or from volcanic or metallurgical slag. The advantage of these wools is not only the thermal conductivity coefficient required for this design, but also its almost absolute non-flammability. According to the standard, the temperature limit for them ranges from -180 to 700 degrees (read the article about insulating a frame house with mineral wool).

Basalt slab

Cutting mat made of slag wool

Glass wool in roll

- Foam plastics (GOST 15588-2014). This term may hide slabs made of foamed plastics, two types of which are actively used in construction. One is polystyrene and the other is polyurethane. The latter is also molded into slabs, but due to the higher price in this form it is less popular among the people. If it is used, it is often in the form of foam, but expanded polystyrene is in great demand. PPS slabs come in three types: the cheapest type “P”, which is cut from one large block and has a pronounced grain structure, and “T”, formed by pneumatic, vacuum or combined methods. Both options may contain graphite, which is added to improve thermal insulation characteristics.

Eps with graphite

Extruded polystyrene, type "T"

Polystyrene type "P"

Note: Polystyrene boards may have a quarter molded edge. But here this is not required, since the slabs are not joined to each other, but are laid between the logs. Therefore, to insulate the floor inside the frame, you need to take the option with a regular rectangular edge. The sizes of these slabs are different, as are the variations in thickness.

- Ecowool (GOST 16381-77). This term is usually used to refer to cellulose insulation containing fire retardant and biocidal additives, but according to the standard, the type of ecowool raw material used may differ. That is, they can be made not only from inorganic substances, but also from organics or a combination of both. So you shouldn’t rely on the absolute environmental friendliness of this material, which is so promoted by its sellers. However, it is quite suitable for floor insulation, especially if it is not loose wool, which can lose volume, but slabs or mats.

Ecowool board

Frame house floor pie

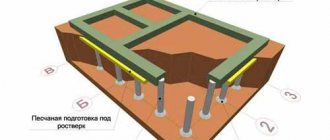

The foundation on screw piles has a distinctive feature, namely, the presence of a frame made of beams for its supports, which at the same time serves as a log. Thanks to this step, the cost of construction becomes several times less.

The floor pie in a frame house on stilts is:

- The subfloor in a frame house on stilts is the basic basis of the entire building structure. To create it, I use wood material, chipboard, OSB or plywood.

- Waterproofing layer - it is best to use a perforated membrane. Even regular film will do.

- Insulation layer - the best material here is basalt wool, expanded clay or expanded polystyrene. They are durable and high-quality materials with increased density, which is very important in floor insulation.

- Vapor barrier - prevents moisture from accumulating and prevents the insulation from getting wet.

The substrate for finishing the floor is selected based on the finishing material, i.e., when laying parquet or laminate on the floor of the first floor of a frame house, I lay plywood underneath. When decorating in the future with tiles or linoleum, I use dry screed. If the floor is water, I pour a screed under it.

Wooden floors - features

The floors of such systems are built on piles or rest on a foundation. Their complexity lies in the fact that the boards should be installed in two rows. The surface is made of tongue-and-groove boards made of pine or larch. Below it is a draft row. It is recommended to install these types of floors in the steam room, laying the space between the rows with insulating material. It is recommended to maintain a slight slope so that water flows freely to the collection and discharge point.

The main condition for a leak-proof floor in a steam room is that the logs are mounted perpendicular to the direction in which the used water flows. The main element of such a floor is strong logs resting on a beam reinforced over a columnar foundation.

It should not be forgotten that all contact areas must be carefully insulated using roofing felt material and liquid bitumen, which is used to treat the connecting areas.

If floors are laid on piles, it is recommended to use more effective insulating material - expanded clay stone, mineralized wool and others. Boards pre-impregnated with antiseptic compounds are laid on the fixed logs. If the floor is constructed of a leaky type, then gaps of several millimeters are left between the boards, through which water will be able to freely flow into the drainage hole.

Principles of insulation

I almost always use wood materials to connect screw piles. You need to know that the supports cannot be overloaded, which is why the weight of the skin is selected as light as possible. The design must protect from external factors (wind and moisture, etc.).

I use the following material for the bottom lining:

- OSB is an affordable, durable material, but does not tolerate exposure to water. Before installation, it is necessary to treat the wood with a special compound, and cover the connecting seams with sealant.

- Chipboard is an easy-to-assemble material, but it is destroyed when it gets wet. Unlike OSB, it is more environmentally friendly.

- Multilayer plywood - I use only materials marked FK and FSF; their structure contains formaldehyde resins. Thanks to them, the skin is resistant to external destructive influences.

We suggest you read: Sheathing for siding - how to make a reliable frame for sheathing

You can also use material made from ordinary wooden boards with a cross section of 5*10 cm. This is an expensive option, but more durable and environmentally friendly.

Sequence of work when insulating the floor

Step-by-step laying of materials

You should start by assembling the rough structure. To do this, wooden beams are nailed to the logs; they will serve as support. Next, boards are attached to them into the flooring. Wood elements must be treated with antibacterial impregnation.

We invite you to familiarize yourself with Prefabricated pile foundation grillage

If you plan to lay polystyrene foam or expanded polystyrene as insulation, then the subfloor can be made of mesh. But it must be strong enough to withstand the mass of insulation.

The next layer is the grillage waterproofing. It should reliably protect the insulation from moisture getting into it. For such protection, roofing material, membrane or polyethylene film are suitable. It is overlapped, leaving no gaps, with slight sagging between the joists. The joints of the film must be glued. Next comes the turn of the insulation. There should be no gaps between its sheets or strips.

A layer of film is again laid on top of the insulation to insulate it from steam. This layer will provide protection from condensation and moisture coming from inside the house. The easiest way is to fix the film with a construction stapler; be sure to overlap it.

After all this, they begin to arrange the finished floor. It can be made from wooden boards or plywood sheets; chipboards are suitable.

An affordable material is pine. More expensive types of wood are oak and aspen. These types of wood are distinguished by reliability, strength and durability. It is important that the wood is dry and has a moisture content of no higher than 20%. Otherwise, when the boards dry, cracks will begin to appear in the floor covering. For additional insulation and decoration, the floor is covered with linoleum with insulation, carpet, or laminate on a cork backing. The floors in the bathroom and toilet are decorated with tiles. You can install a heated floor system throughout the house.

Installation of the floor of a frame house on screw piles

To protect the wooden elements and also extend the life of the building, I use antiseptics and fire retardants. These are special compounds that protect wood from rodents, insects, as well as rot, mold, etc. This must be done before installing the products.

1. To begin with, I make four holes on the supports of the screw foundation, then lay a layer of waterproofing and secure it. I lay out the beams around the structure and connect them together.

2. Using self-tapping screws, I install the beams to the ends, and attach the remaining beams to the ends. I take steel staples and connect the strapping parts together.

3. Using a building level, I check that the beams are evenly installed.

4. I install the sheathing at the bottom of the beams; it will serve as the base for attaching the substructure.

5. Then I proceed to the rough finishing and laying of thermal insulation:

- First, I cover the base of the floor with a waterproofing film, which will prevent moisture from getting inside the insulation.

- I put thermal insulation between the joists. On each side I provide a margin of 0.5 cm so that the material fits snugly against each other.

- I put a vapor barrier on top of it. It should be overlapped to prevent the formation of cold bridges.

The pile-screw foundation requires the mandatory driving of the base. You can do this in one of the following ways:

- Brick - the base here is a backfill of crushed stone and sand. Then I lay the filling itself in half a brick; it is not necessary to use reinforcement here. I recommend ceramic and clinker bricks.

- From corrugated sheeting - the basis for installing corrugated sheets are the spans, which I attach to bored pillars.

- I install the material from chipboard in the same way as corrugated sheeting.

We must not forget about natural ventilation, which does not allow moisture to form in the structure. I lay out the blind area from paving slabs or paving stones or pour a concrete screed. It is important to maintain an inclination angle of 4 degrees from the house. I seal the junction of the cladding and the blind area with sealant, this prevents the accumulation of moisture and other precipitation under the base of the house.

Tags: pile, make, foundation

« Previous entry

Protective and preventive measures

The main danger to the floor in a bathhouse is high levels of humidity, constant fumes, and dampness. Waterproofing is mandatory; all building materials are treated with special compounds. If these requirements are neglected, you are guaranteed the formation of mold and mildew, which can destroy not only wood, but also concrete.

All individual elements of the floor structure must be unambiguously treated with antiseptics, which are offered in large quantities by the building materials market today. It is recommended not to skimp on this activity by treating surfaces several times. If you plan to lay insulating material in the floor, a waterproofing layer must definitely be installed.

When, for certain reasons, it is not possible to carry out all the recommendations during construction work, it is imperative to carry out certain procedures that can prevent wooden and concrete surfaces from destruction. In such cases. Wooden floors are disassembled, thoroughly weathered and dried, and places where rot has begun to appear are eliminated.