The density of expanded clay concrete quite often becomes a subject for discussion, let’s not guess, just figure it out and find out what it really is, because expanded clay concrete wall blocks are used for building houses, and, of course, you want to be sure of the reliability of your home.

Related articles:

- Consumption of reinforcement for the foundation

- Concrete work in winter

Expanded clay concrete wall blocks, despite the fact that they are quite light, they are still durable and their strength depends on the density of expanded clay concrete from which the blocks are made. The density of expanded clay concrete is measured in kg/m3 and starts from 350 kg/m3 and reaches 1800 kg/m3. Such a relatively low density is easily explained by the expanded clay included in the solution. Despite all this, expanded clay concrete comes in different categories and different qualities. For example, large-porous expanded clay concrete is made without the use of sand.

See also: Expanded clay concrete: Brand weight

Density of expanded clay concrete kg m3

I think it’s not difficult to guess that the density of expanded clay concrete primarily depends on expanded clay, or rather its weight, or more specifically, on its density, which varies with the degree of porosity. Secondly, it depends on the proportion of expanded clay and concrete in expanded clay concrete. Since expanded clay has the lowest density among all the components included in expanded clay concrete, this means that the more expanded clay there is, the lower the density of expanded clay concrete will be.

Here you need to decide what the expanded clay concrete will be used for; if for the construction of walls made of expanded clay concrete or various floors, then only dense concrete must be used, with a lower content of expanded clay, which has strength many times higher.

Expanded clay concrete comes in 3 types:

- Structural expanded clay concrete

- Thermal insulating expanded clay concrete

- Structural thermal insulation expanded clay concrete

Related articles: Correct blind area

Certification of expanded clay concrete

Expanded clay concrete is one of the types of building materials that consists of cement and expanded clay. A document such as a certificate for expanded clay concrete is not considered mandatory in our country, but you can order and receive it on a voluntary basis from us. To purchase a certificate for expanded clay concrete, the first thing you need to do is contact the certification center with an application for certification.

Next, you will be provided with free consulting services, during which you can find answers to your questions. A voluntary certificate of conformity for expanded clay concrete will add many advantages to your business, which will give you the opportunity to distinguish your product from competitors.

Structural expanded clay concrete

Structural expanded clay concrete is used in the construction of load-bearing walls and other buildings that need to withstand fairly high loads. The density of structural expanded clay concrete ranges from 1200 to 1800 kg/m3; for this type of expanded clay concrete, the compressive strength starts from 100 and reaches 500 kg/cm2. This expanded clay concrete has advantages, such as high frost resistance, up to 500 cycles, as well as significantly lower weight when compared with classic heavy concrete.

Related articles: Screed with expanded clay

Types and classification of expanded clay concrete

Depending on its type, purpose, density and other properties and characteristics, expanded clay concrete has its own classification.

By product type

Expanded clay concrete can be produced in the form of blocks, panels and slabs.

- The blocks have the form of building elements of the correct shape and with standard parameters. They consist of expanded clay, sand, water and cement. The role of the binding component is played by Portland cement of a grade not lower than M400. To increase water-repellent properties, hydrophobic cement can be added to blocks

- Expanded clay concrete panels Their dimensions can vary within the following range: length from 30 to 720 cm, height from 30 to 810 cm. They are usually used for mounting the external part of the wall and creating partitions indoors. They can also be used to fill the frame of reinforced concrete structures.

- slabs have received good reviews; they are a monolithic structure reinforced with a steel frame. They are highly durable and therefore are actively used in the construction of buildings with high loads.

Next we will tell you about structural thermal insulation blocks,

By granule density

Based on the density of the concrete used, the building material is divided into three types:

- Dense expanded clay concrete . It has a high density (up to 2000 kg/m3). The main area of use is the creation of foundations and various load-bearing structures, which must have high strength.

- Sandless or large-porous expanded clay concrete . It consists of fractions of expanded clay gravel and crushed stone up to 2 cm in diameter, Portland cement M300-M400 and water. Due to the absence of sand in the composition, the density of the finished material decreases by 600 kg/m3 and is about 1800 kg/m3. It is actively used for the construction of monolithic structures and wall blocks.

- Painted expanded clay concrete Depending on the scope of application, it is divided into:

- Thermal insulation (density about 400-600 kg/m3). It is actively used for thermal insulation of enclosing structures.

- Structurally – heat-insulating (density about 800-1200 kg/m3). Designed for the production of large blocks and single-layer panels.

- Structural (density 1500-1800 kg/m3). Used for the construction of load-bearing structures, various building structures and in shipbuilding. High strength and reliability have led to its widespread use.

The strength of the material depends on the strength of the expanded clay and cement used.

By application

Depending on the scope of application for which expanded clay concrete is made, it is divided into:

- wall blocks have received positive reviews and are used for the construction of walls in low-rise construction.

- Foundation blocks intended for the construction of the foundation of any building and structure. Due to bearing large loads, they are more durable than wall ones.

- Partition blocks are used to organize internal partitions and ceilings.

- Ventilation blocks made of expanded clay concrete deserve positive reviews; they are a porous material that prevents the appearance of fungus and mold.

Next, we will consider the comparative characteristics of monolithic expanded clay concrete, the thickness of the walls made from it, and we will also tell you how to make a monolith from expanded clay concrete with your own hands.

By solidity

Monolithic expanded clay concrete is a fairly common type. The material is formed by combining expanded clay with lime, cement or gypsum.

The result is an environmentally friendly material that is not inferior in its technical characteristics to ceramic bricks and makes low-rise construction from monolithic expanded clay concrete simply ideal.

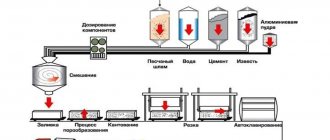

To create monolithic expanded clay concrete, it is necessary to observe the proportions and all the technology for its production, as well as use the necessary components.

- To begin with, 1 part of cement is placed in a concrete mixer, then 2 parts of sand.

- These two components are thoroughly mixed together, after which 1 part of water and 3 parts of expanded clay are added, then they are mixed again. The mass should be quite moist. Water is added until the dissolved cement covers all the expanded clay granules.

- The resulting mixture is poured into the formwork.

In this case, the finished mixture should be isolated from slabs, bricks and other materials. Otherwise, monolithic expanded clay concrete will give up its moisture to another material. For these purposes, polyethylene, mastic or special emulsions are used.

The monolithic crystalline hydrate sets on the second day, at which time the finishing layers can be made. Monolithic expanded clay concrete itself will fully gain its strength within a month. To regulate its microclimate, the structure is covered with a film or its surface is regularly moistened.

You will learn which brand of expanded clay concrete is better in terms of strength, reliability and other parameters in the next section.

The following video will tell you in sufficient detail about monolithic expanded clay concrete:

Expanded clay concrete m150: advantages, composition, technical characteristics

Low-weight concretes occupy a special place in the building materials market. Expanded clay concrete m150 is included in this group of products. The material is practical, so it is in great demand. With its help, strong and reliable structures are obtained. They are safe and environmentally friendly. People stay in them for a long time without harm to their health. Inside, it is possible to prevent sudden changes in temperature at any time of the year. The cost is in an acceptable range, so the material occupies a leading position in sales. The quality passport confirms the presence of the necessary technical characteristics of expanded clay concrete m150. It contains the main technical characteristics of the material. They are verified through a series of studies.

Advantages of expanded clay concrete

The material contains clay granules. They are pre-fired and foamed. Expanded clay is thoroughly mixed with the binder. Additionally, the structure includes gypsum, cement, lime. Synthetic and chemical materials help improve wear resistance. They are selected based on the characteristics of future operation.

Expanded clay concrete according to GOST is characterized by advantages in comparison with brick. It is light weight but high strength. It manages to effectively retain heat indoors. The necessary sound insulation is also achieved. The positive qualities fully justify the price of the product.

Advantages of the material:

- High thermal conductivity is combined with the strength of the walls. Thanks to this, it is possible to create warm load-bearing walls.

- Possibility of preparing blocks and mortar with your own hands.

- The material is relatively cheap. At the same time, it is not inferior in properties to expensive analogues.

- Expanded clay concrete is suitable for creating a rough floor. It perfectly combines strength and warmth.

- The duration of use has already been set. Materials that have recently gone on sale cannot boast of this.

- Does not contain harmful impurities and additives that emit toxic smoke when ignited.

- Low weight. The product contains air inside. This makes the blocks easy to lift and install. Transportation is not difficult either. Preparation and pouring of the solution is carried out with a minimum set of equipment.

Expanded clay concrete has excellent vapor permeability and sound insulation. Many modern building materials cannot boast of these properties. The solution is actively used in construction and reconstruction work. It dries quickly and gains strength. The coating will withstand high loads, so it is used as a base for floors.

Key Features

Expanded clay concrete m150 has the following technical characteristics:

- Frost resistance of the coating ranges from F75 to F100.

- Strength from B10 to 12.5.

- W4 - water resistance efficiency.

- Density ranges from D1000 to D1500.

The material is practical. It is due to structure. It accumulates the required amount of moisture. Expanded clay concrete consists of natural components. It combines the best properties of stone and wood. During operation, no additional effort is required to preserve the surface. The material does not suffer from open fire for several minutes.

Scope of use

Expanded clay concrete blocks M150 are actively used for various construction purposes. They produce walls with good heat and noise insulation. The material can be used to create roofs in any type of room. It is suitable for new buildings and renovation of old buildings. A wide range of uses increases the popularity of the material. It has advantages, especially when compared with concrete.

Key differences

Brand M150 is used as a filler. Additionally, it was possible to reduce the intensity of heat conduction and weight. However, the surface strength remains in the same range. Thanks to this, the material can be used in the process of creating basic structural elements. The type of room does not matter.

Concrete of this brand is characterized by optimal heat conductivity. This strength and density are much higher than the classic version of the product. Improvement was achieved through a cellular structure. Expanded clay concrete has an increased ability to insulate sound and resists the accumulation of moisture in the surface. It cannot be negatively affected by alkalis and carbon dioxide. The surface remains the same even during periods of sudden temperature changes. The structure and other properties do not change.

GOST requirements

Expanded clay concrete is a material that is further divided into grades. Each of them has a number of key indicators. BSL expanded clay concrete m 150 is characterized by the highest. For example, it does not suffer from frost, and the density of the walls is maintained for at least 20 freezing cycles. The walls in load-bearing structures are strong, but allow air to pass through and do not interfere with natural air circulation. The benefits of the design will be felt by people who suffer from dust allergies.

Brand M150 - made from natural ingredients. It does not have a negative effect on the human body. The material has thermoregulatory properties and prevents moisture from accumulating inside. Aggressive chemicals do not destroy the outer layer. Expanded clay concrete is widely used in construction. The liquid version helps to form panels, blocks and various structures for engineering purposes. The strength of the material is high, so load-bearing structures are created from it.

High quality concrete can be purchased at an affordable price. It is lightweight, so transportation is not a problem. If the material complies with GOST, then its quality is high. It is confirmed by the presence of the necessary documents. Expanded clay concrete fully complies with international quality standards. It is recognized as a safe coating for human health.

betonov.com