Creating your long-awaited home, which has a basement floor, may be a lengthy undertaking, but it is respectable and often necessary. The appearance of a private house will become representative, and the additional space obtained from the constructed basement can be used at your discretion. For example, the ground floor can then be converted into a room, where it is quite possible to spend time profitably.

The basement floor can be made from the following materials: ceramic brick, monolithic concrete and the most optimal and less time-consuming option - concrete blocks.

Features of expanded clay concrete

Today, expanded clay concrete blocks are very popular in European countries and North America. The material is actively used in the construction of various buildings in Germany, France, Sweden, Finland and a number of other countries. Expanded clay concrete blocks have become widespread in the CIS due to the fact that they are a high-quality and reliable building material.

Expanded clay and expanded clay concrete.

The use of expanded clay concrete blocks can significantly reduce energy costs during the heating period of the house. In addition, the need for the number of workers is significantly reduced when you build a house from this material or individual structural elements of the building (for example, the same base).

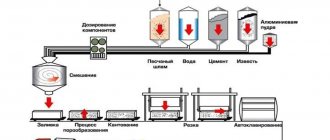

The basis of the blocks is the most common expanded clay, which during the manufacturing process goes through a foaming procedure. As a result, a foamy substance hardens inside each granule. After firing in a kiln, the granules acquire their hardness and other performance characteristics. In most cases, the density of expanded clay concrete varies from 300 to 2000 kg/m3. m.

Advantages and disadvantages of the material

Of course, like any other material, expanded clay concrete blocks have their advantages, as well as negative aspects, which often force one to abandon the use of this building material.

Any building material has its advantages and disadvantages.

By the way, there are many more advantages and they look more solid:

- When compared with other types of cellular concrete, expanded clay concrete blocks are more durable and have higher thermal insulation properties.

- The use of expanded clay concrete allows for a higher level of sound insulation of the room.

- The main advantage of this modern material is its enviable strength.

- Compared to bricks, blocks are more affordable in terms of price.

- Expanded clay concrete blocks are resistant to moisture and chemical attack. These characteristics are better than those of cement blocks.

- Expanded clay concrete has a relatively small specific gravity.

- Expanded clay concrete blocks can be used both for the construction of a basement and load-bearing walls. However, in recent years, expanded clay concrete has been used specifically for the construction of basements.

Expanded clay concrete blocks are an excellent alternative to brick and concrete. The versatility and ease of installation suggest that this material will continue to be used in the future for all kinds of construction work.

As already mentioned, any building material has its drawbacks, so let’s note them for expanded clay concrete:

- Blocks have a high level of porosity (a huge number of pores inside the block), so in terms of their physical and mechanical characteristics (in most cases) they are slightly inferior to heavy grades of concrete.

- Expanded clay concrete blocks are more fragile than ordinary concrete, so the scope of use of the material is somewhat limited (for example, they are not suitable for building a foundation).

- Blocks are subject to direct physical impact. For example, if one is accidentally touched or pierced by something, it will be damaged and will need to be replaced.

Brick selection

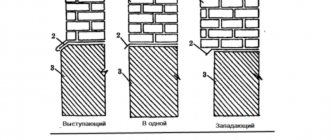

Solid ceramic blocks are best suited for laying a plinth

Not all types of bricks are suitable for arranging a connection between the foundation and walls. For example, it is definitely not recommended to make a plinth from sand-lime brick. Although this material is aesthetically pleasing, its performance qualities when applied to this design leave much to be desired. This is due to low load-bearing capacity and absorption of large amounts of moisture.

A good option would be solid ceramic blocks. Such bricks are not too expensive, but their operational parameters are best suited for this task. The use of hollow material is acceptable when working on a light construction, but solid options are preferable due to their load-bearing qualities. Sometimes you can find recommendations to use clinker bricks for the basement floor, explained by its almost zero hygroscopicity. This characteristic has both pros and cons. For good adhesion to the mixture, the ability to absorb moisture is necessary. Otherwise, the seams begin to do this. When they freeze, they increase in size, which leads to damage to the brickwork of the base.

Using expanded clay concrete for the plinth

If you decide to make the base from expanded clay concrete, then you need to take into account the fact that this part of the building will experience very high loads during operation. Therefore, the decision to use expanded clay concrete blocks for the basement is relevant in cases where the height of the house does not exceed 1–2 floors, because this building material can begin to collapse under heavy load.

Expanded clay concrete blocks have high thermal insulation properties.

In addition, it is necessary to make high-quality waterproofing of the material after the blocks are laid. It is recommended to apply vertical and horizontal waterproofing. Horizontal waterproofing will prevent water from penetrating into the basement and other interior spaces. For this purpose, roll insulating materials are used. For vertical waterproofing, as a rule, bitumen mastics, protective varnishes, synthetic resins, rolled materials and other waterproofing agents are used.

It is also recommended to make a high-quality thermal insulation layer, although you shouldn’t be too zealous either, because expanded clay concrete blocks themselves are good thermal insulators.

Horizontal waterproofing is done using rolled materials.

It was already said above that when using expanded clay concrete blocks it will be possible to save money on heating in the winter. This is achieved due to the fact that the blocks are an excellent thermal insulator, which, in combination with other thermal insulation and waterproofing materials, provides the highest level of protection for the basement of the building from the penetration of moisture and cold air.

General information

Norms

According to the standards, the ceiling height of the ground floor must be no less than 250 cm. The deepening of the ground floor is limited by the level of groundwater - with a high occurrence of perched water, as well as in wet places, its underground part is usually small. In an area with deeply located groundwater, the base is deepened almost completely, and this will reduce heating costs. So, we should consider the features of the construction of the basement floor.

Arrangement of the ground floor

The base is a continuation of the base, and therefore it can be made of the same material as the foundation itself, or using the material of the wall surfaces. Typically, monolithic concrete, brick or ready-made blocks are used to build the ground floor. The thickness of the basement walls is determined by a special calculation.

The role of the floor on the ground floor is played by a concrete slab, and it is produced by pouring or even ready-made reinforced concrete slabs are laid. Floors of the ground floor can be made of slabs, concrete, or even wood. Given the huge above-ground height of the plinth, windows and doors can be made in it, and it is important to place them on the east, south or even west side. The location of the window frames on the northern wall of the basement can lead to excess snow accumulating and possibly even pushing through the window frames. Basement walls require mandatory waterproofing, and the deep part of the base is recommended to be treated with waterproofing materials both outside and inside in order to increase reliability. It is permissible to waterproof the above-ground part only from the outside.

Phased construction of the basement

Work on the construction of a plinth made of expanded clay concrete blocks is carried out in the following sequence:

- First of all, a layer of roofing material is laid out, which will act as horizontal waterproofing. In principle, here you can choose any roll-type waterproofing material, but roofing felt is best suited.

- Next, we prepare the concrete solution in accordance with the instructions. The solution must fully meet the requirements for laying expanded clay concrete blocks. A regular cement-sand mortar may not be suitable.

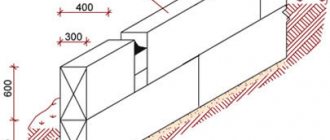

- Laying the first row should begin from the corner of the structure. First, the first row is laid along the perimeter of the building, after which a metal reinforcing mesh is placed on the blocks. It is recommended to take a mesh with a cell size of 50x50 mm.

- Then we apply the solution to the first row of blocks and lay out the second row according to the same pattern. It should be noted that small holes (windows) must be made in the masonry of the base for ventilation. The holes should be spaced in increments of 2.5–3 meters, the size of each window is 20x20 cm. Often, windows for ventilation of the ground floor or basement are made in the third row of masonry (this is optional).

- After the installation of the second row is completed, attention should again be paid to waterproofing. Again we take roofing felt and carry out horizontal insulation of the basement structure (it is recommended to lay roofing felt in two layers).

- The third row is laid using mortar (reinforcing mesh is not used here). After laying the third row, the metal mesh is installed again.

- Finally, the fourth row of blocks is laid. Once all installation work has been completed, final horizontal and vertical waterproofing must be done. This time you will need to insulate the entire base part. As a rule, bituminous materials and mastics are used for vertical waterproofing. The choice of one or another waterproofer will depend on the specifics of the work, the capabilities and wishes of the owner of the house. It is recommended to use traditional hot bitumen mastic, which is applied in two layers. After the vertical one, you need to do horizontal waterproofing again: glue the roofing material to the top of the base (again in two layers).

- The final stage is to install waterproofing over the entire subfloor area. Any sheet-type insulating material can be used here. The sheets should be laid overlapping each other by 10–15 cm. A ten-centimeter layer of sand is poured on top and thoroughly compacted.

For the construction of the base, solid expanded clay concrete should be used (photo courtesy of the site skb21.ru).

It should be noted that this work is not as simple as it might seem at first glance. Therefore, if you do not have proper experience in carrying out construction work, then it is best to entrust the matter to professionals. If you have some experience, then you will not find anything complicated in laying expanded clay concrete blocks. By and large, this is very similar to standard brickwork, although there are some characteristic features that must be taken into account when carrying out work of this type.

For the plinth, you should choose high-density expanded clay concrete blocks that will successfully withstand the load of the building, as well as other negative influences (for example, climatic).

Making a pillow

Due to the fact that the ground floor will serve as a foundation, its construction must be taken with full responsibility. Sand is poured along the entire perimeter of the pit, at least 15-20 cm thick. It is moistened and compacted thoroughly to prevent the formation of voids. Medium-fraction crushed stone is poured onto the sandy bottom of the pit so that the layer thickness is 15-20 cm.

After leveling, a metal mesh is laid on top of the sand and crushed stone cushion, which will serve as reinforcement. Concrete is poured (M400 cement) and distributed evenly over the entire base of the pit. To remove air from the mixture, special tampers and vibrating plates are used. In order for the pillow to acquire its load-bearing capabilities, it needs to stand for 2 weeks at positive temperatures.

Attention! In our case, the previous owner was involved in creating the pillow. In order to save money, he did the following. Markings were made along the entire perimeter of the pit in accordance with the design documentation, after which trenches were dug and formwork was installed. Sand and crushed stone were poured into the bottom of the trenches; after compaction, reinforced mesh was laid and concrete was poured. We made excavations in different places to assess the quality and condition of the pillow. During the research, it was revealed that it extends beyond the supporting structure by about ¼ of the size. The depth of the pillow, taking into account the sand and crushed stone layer, is 40 cm.