Airborne noise

Sound is a physical phenomenon produced by the vibration of particles in various media, including gaseous and liquid substances. All sound vibrations have operating parameters of frequency and amplitude that affect human audibility.

The average noise frequency for individual events is as follows:

- The noise of the forest varies depending on the wind strength within 10-24 dBA.

- A conversation between two people is about 65 DBA, while a child's cry is already 78 DBA.

- The operation of music centers and other audio systems for similar purposes is about 85 dBA.

- Active road traffic, depending on the number and type of vehicles, is within 78-92 dBA.

In general, noise standards are 40 DBA during the daytime and 30 DBA at night. People's tolerance to increased noise varies. For example, in noise conditions up to 60 dBA, some people may experience discomfort. At the same time, a stable noise level within 70-90 dBA contributes to the emergence of various types of diseases of the nervous system. Exposure to noise of more than 100 dBA negatively affects a person’s hearing and can lead to partial or complete loss of it.

Soundproofing walls in the house

Attention customers - permanent promotions to reduce the price of blocks can be found here

WE do low-rise projects of any complexity from Itong gas blocks with foundation calculations based on IGI. Prices are reasonable.

Soundproofing in the house

The issue of sound insulation, which excludes the penetration of noise from the street and sound insulation of partitions inside the house, is a very important issue that directly affects the comfort of living conditions in a house or cottage and its importance is no less than the issue of the same thermal insulation of a wall or partition or their vapor permeability.

Before we give recommendations for the use of Ytong aerated concrete blocks as a soundproofing material, let's try to understand what sounds (noises) there are that affect a person during the operation of a house or cottage built from Ytong aerated concrete blocks, Mozhaisk plant of aerated concrete blocks and lintels or aerated concrete blocks, Maloyaroslavl plant of aerated concrete blocks Gras . There are two types of them in nature - shock, which occurs when a blow is struck on a structure with a shock wave transmitted through the structure of the material (it is also called structural), for example, on a wall, on a ceiling (walking on a floor, children jumping on a floor, hitting a ball or toys on the ceiling), on the window (knocking on the window), on the roof (the sound of rain, hail) and the second type is when sound is transmitted through the air by a sound wave - this is household noise, dog barking, music in the courtyards, train noise , conversation inside the house, a baby crying, sound from the TV…. All sounds have a certain vibration frequency and amplitude. (material on sound insulation is also posted on this page)

Minimum audibility = 0 dB. You can understand whether this is a lot or a little by comparison, for example, the forest makes noise with a force of 11-23 dB, people talking -62-67 dB, when a child cries, the sound intensity can reach 80 dB.

You need to understand that constantly raising the sound can lead to serious nervous and psychological diseases. Normal sound intensity is considered to be no more than 40 dB during the day and about 30 dB at night. With a systematic sound intensity of about 90 dB surrounding a person, nervous health disorders are possible; with a sound intensity of more than 100 dB, hearing loss and deafness may occur.

To reduce sound, that is, aerated concrete or foam concrete is good as a sound insulator due to the presence of its porous structure, which well absorbs and dissipates sound energy carried by a sound wave. Sound insulation requirements are standardized by SP 23-103-2003 standards for the design of sound insulation of enclosing structures and SP 51.13330.2011 noise protection.

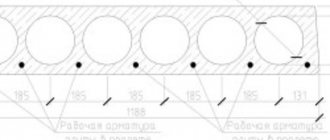

If we consider the aerated concrete block Ytong of the Mozhaisk Aerated Concrete Blocks Plant, then for it the calculated insulation indices R w of airborne noise for walls are indicated in the table below in D B for densities of 500 kg/m3 and 600 kg/m3 in the numerator the size of the unplastered wall is indicated in the denominator plastered with two sides of the wall with plaster thickness = 10mm.

| Density kg/m3 | 150mm | 200mm | 250mm | 300mm | 375mm | 500mm |

| 500 | 41/44 | 46/48 | 50/51 | 53/54 | 56/57 | 61/62 |

| 600 | 43/46 | 48/50 | 52/53 | 55/56 | 58/59 | 63/64 |

Based on the standards DESIGNING SOUND INSULATION OF ENCLOSING STRUCTURES OF RESIDENTIAL AND PUBLIC BUILDINGS, you can select the appropriate thickness of the wall from ytong aerated concrete blocks or partitions to ensure comfortable sound insulation.

For all questions regarding the calculation and selection of sound insulation materials, please contact our specialists by calling the numbers listed on our website.

advertising: buy Itong aerated concrete blocks in Mozhaisk, price for Ytong aerated concrete blocks, on request price of Ytong aerated concrete lintels, buy aerated concrete lintels in Mozhaisk, buy Ytong aerated concrete lintels from the Mozhaisk aerated concrete block plant, cost of 1m3 of Itong aerated concrete blocks, buy Ytong aerated concrete blocks at the price..., Buy Ytong aerated concrete lintels at a price, price of aerated concrete blocks in Mozhaisk, buy Itong foam block, price of Ytong foam block in Mozhaisk at the Itong aerated concrete plant.

Soundproofing methods

You can improve sound insulation performance in two different ways. Firstly, by reducing the level of noise production, and secondly, by providing additional barriers to its spread.

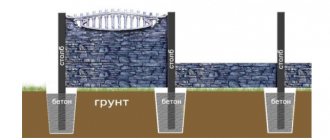

To soundproof fences, two main methods are also used:

- Reducing the volume of fluctuations. This is achieved by increasing the severity of the obstacle. The more massive and heavier the structure (wall), the less susceptible it is to vibration processes, and the more it protects the interior space from penetrating sounds.

- Absorption of sound waves. It is achieved through the use of multilayer structures, including those with porous materials, which promote wave dissipation inside the barrier due to its physical properties.

It is aerated concrete that has increased sound absorption capabilities. Its porous structure is much more capable of scattering sound waves than materials with smooth surfaces. Due to these properties, aerated concrete blocks are actively used for internal masonry in industrial enterprises, where it is necessary to ensure reliable isolation of production premises from the surrounding infrastructure.

Soundproofing of aerated concrete

Although sellers of gas silicate blocks talk about high sound insulation performance, they greatly exaggerate. Even a standard block 200 mm thick conducts sounds and noise well, and thinner partition blocks even more so.

Comparative characteristics of sound insulation of partitions made of different materials

According to standards, the sound resistance of partitions should not be lower than 43 dB, and it is better if it is higher than 50 dB. This will provide you with silence.

Sound insulation standards for different rooms

To get an idea of how “noisy” gas silicate blocks are, we present a table with standard indicators of sound resistance of blocks of different densities and different thicknesses.

Sound absorption coefficient of aerated concrete blocks

As you can see with the block, at 100mm thick it falls slightly short of the lowest requirement. Therefore, when finishing aerated concrete, you can increase the thickness of the finishing layer in order to “reach” the standard. If normal sound insulation is required, the walls are additionally sheathed with mineral wool. This material is not soundproofing, but it reduces noise by approximately 50%. As a result, sounds are almost inaudible. Specialized soundproofing materials have the best performance, but when choosing them, you need to look at their vapor permeability characteristics so as not to trap moisture inside the gas silicate.

If you need absolutely “quiet” walls, experts advise installing two thin partitions with a distance of 60–90 mm, which should be filled with sound-absorbing material.

Modern society lives at a frantic pace. Therefore, a person experiences discomfort from the environmental situation, stress and noise. A number of innovative materials can solve the latter problem. Builders suggest using gas block. The sound insulation of the material is at the level. It will cope with airborne and structural noise. The indicator depends on the thickness of the layer and the brand of material.

Design Guidelines

For internal walls, it is optimal to use continuous jointing when there are no internal cavities. The top of the walls must be plastered (on both sides). When designing, special attention should be paid to the joints of structures in order to prevent the appearance of cracks. In cases where cracks and crevices have formed during the operation of the structure, they must be immediately eliminated using sealants, filling the cavities to their full depth without leaving voids.

Internal walls

An effective way to improve sound insulation is to build double walls that touch each other at certain points using lintels. The distance between the walls should be 40mm or more. When using frame-sheathing type partitions, the sheathing must be fastened to the frame at a distance of at least 300 mm. When using a two-layer structure, gluing two sheets together is not allowed. The frame posts in such structures are installed at a distance of 600 mm from each other or slightly more.

The quality of sound insulation when using a frame-sheathing structure can be improved by using soft sound-proofing materials that fill the interior space. In addition, designs in which each side of the cladding uses its own frame, and the cladding is made in a multilayer design, have increased soundproofing capabilities.

The most common cladding materials are plasterboard, fiberboard sheets and other materials for similar purposes. Their installation is carried out using “beacons” or wooden slats hammered onto the wall surface. Between the wall and the cladding materials, the size of the air cushion must be at least 50mm, which provides an increased level of protection against sound penetration. The resulting cavity must be filled with insulating materials (glass wool, mineral compounds, and so on).

Device and features

If aerated concrete partitions are installed during the renovation and redevelopment of apartments or houses, markings must first be applied. The line is upholstered around the entire perimeter: on the floor, ceiling, walls. The easiest way to do this is with a laser plane builder. If it doesn't exist, it's better to start with a stream:

- Mark a line on the ceiling (two points on opposite walls). A painting cord, painted with blue or some other dry dye, is pulled between them. With its help they beat off the line.

- The lines on the ceiling are transferred with a plumb line to the floor.

- Then the lines on the floor and ceiling are connected by drawing vertical lines along the walls. If everything is done correctly, they should be strictly vertical.

The next step in constructing aerated concrete partitions is waterproofing the base. The floor is cleaned of debris and dust, waterproofing roll material is laid (any: film, roofing felt, waterproofing material, etc.) or coated with bitumen mastics.

Vibration dampening strips

To reduce the possibility of mother-in-law formation and increase sound insulation characteristics, a vibration-absorbing strip is laid on top. These are materials with many small air bubbles:

- hard mineral wool - mineral wool cardboard;

- polystyrene foam of high density, but small thickness;

- soft fiberboard.

The first row of blocks is laid on this strip with glue. Glue thickness is 2-5 mm, consumption for a thickness of 1 mm is 30 kg/m3. Next, the construction of partitions occurs using the same technology as load-bearing walls. Read more about the technology of laying aerated concrete walls here.

On short spans - up to 3 meters - no reinforcement is done at all. On longer ones, a reinforcing polymer mesh, a perforated metal strip, as in the photo, etc. are laid.

Aerated concrete partitions can be reinforced if desired

Connecting to a wall

To ensure connection with adjacent walls at the masonry stage, flexible connections are placed in the seams - these are thin metal perforated plates or T-shaped anchors. They are installed in every 3rd row.

Connecting the wall and partition using a T-shaped anchor

If a gas silicate partition is installed in a building where such connections are not provided, they can be fixed to the wall by bending them in the shape of the letter “L”, inserting one part into the seam.

When using anchors, the connection with the wall is rigid, which in this case is not very good: a rigid rod due to vibrations (wind, for example) can destroy the adjacent adhesive and the body of the block. As a result, the abutment strength will be zero. When using flexible connections, all these phenomena will not affect the blocks so much. As a result, the bond strength will be higher.

Joints

When designing joints, including between partitions and load-bearing structures, the likelihood of cracks that negatively affect the quality of sound insulation must be completely eliminated.

Filling the joints between floors and walls is carried out using concrete or mortar, and at the joint there must be the necessary cavities that are to be filled with a cement-based composition. In addition, it is necessary to limit the possible movement of structures as much as possible, for which individual elements are welded, fastened using dowels, and so on. In turn, all parts used for connection should not become an obstacle to filling the cavity and contribute to the appearance of voids. The optimal material for performing such work is expanding concrete.

In the process of carrying out design work at sites using prefabricated structures, it is necessary to provide such a configuration of joined parts that will ensure maximum ease of use of sealing compounds (in cases where they are provided for by construction standards).

How to attach

KNAUF-Acubord does not require any frame - it is attached to the gypsum partition with self-tapping screws, and to the aerated concrete structure using dowels and screws. However, to achieve the desired effect, to install one panel measuring 1200 x 1500 mm, it is necessary to use at least 16 screws at even intervals. It is due to the tight contact of the panel with the partition that increased sound insulation is ensured. Like regular drywall, shelves and cabinets can be attached to the panel, the surface can be painted, or wallpaper can be glued to it.

Alexander Boganik technical director of Acoustic Group

This is truly a unique, promising and, given the scale of construction of partitions made of tongue-and-groove slabs and aerated concrete, a necessary product. According to the subjective sensations of the consumer (by ear), it doubles the sound insulation of the structure without eating up space. KNAUF-Acubord will appear in stores in the near future; additional information about it can be read on the KNAUF and Acoustic Group website.