Characteristics

The concrete mixture is required to be workable. This concept is very important; it characterizes the ability of the prepared concrete mixture to be placed into a structure with the least effort. The concept of concrete workability is difficult to characterize unambiguously. This is a scientific definition that includes different components. The main property of concrete is fluidity, which depends on the water-cement ratio. Such a solution must pour well into the mold, fill the mold under the conditions of a certain work that must be done to achieve complete compaction.

If the concrete mixture, under the influence of certain mechanisms and techniques, easily fits into the mold, is compacted and does not delaminate, then it is considered workable.

The workability of concrete can be achieved by adding water using plasticizing additives. Closely related to the concept of workability is the concept of mobility. Concrete spreads and is characterized by fluidity. Mobility is the consistency of the solution. But workability and consistency are not the same thing. With the same consistency, workability varies.

Since the solution is heterogeneous, each composition has its own characteristics of cement paste, its own characteristics of fillers, and contains different additives, workability must be determined in each specific case.

Method for determining mobility

Determination of the workability of a concrete mixture: a) a device (cone) for determining the mobility of a concrete mixture: 1 – rigid mixture; 2 – mobile mixture; 3 – cone settlement; b) a device for determining the hardness of a concrete mixture: 4 – test diagram.

There are several methods for determining workability. None of the methods directly determines workability, since this concept is conditional and in practice is characterized for different concretes by either the property of mobility or rigidity. There are common instruments that can more or less accurately determine the workability of concrete.

For movable mixtures with low rigidity, a method has been adopted for determining the workability of concrete by the cone slump. Mobile solutions fill the pouring form under the influence of their own gravity. A certain device, which is a truncated cone, described in the Russian standard (GOST 10181), is filled with solution and then slowly rises. During the rise of the cone, the solution “settles” to a certain height. The height of the draft is measured in the middle of the cone. This settlement, measured in millimeters, characterizes the property of mobility.

The cone is usually made of sheet steel with a height of 300 mm. At the lower base it has a diameter of 200 mm, the upper base has a diameter of 100 mm. It is installed on a fairly smooth sheet, then filled in three even layers with concrete, carefully compacted by bayoneting with a metal rod, that is, it is simply pierced with a rod 25 times after laying each layer. Then, when the concrete is laid, the excess is carefully cut off. The cone must not be allowed to skew during its lifting.

Conducting experiments

As already mentioned, there are several methods to determine the exact result.

The work order can be described separately, in more detail.

- With the cube method, an area of 10 or 15 centimeters is filled. Thanks to this, the grade of concrete mixture is determined more quickly based on workability.

They wait for some time until the material takes a cubic shape. After the base has completely hardened, it is sent to the laboratory. This method has a lot of disadvantages; it takes too much time and requires money. The solution is unlikely to be justified in low-rise construction.

- A plastometer is another option, but it also has a high price. And it changes the workability of the concrete mixture.

The purchase and use of such a device will be justified during a large construction project, when tests are carried out constantly. Another thing is low-rise construction, when owners encounter the relevant work only 1-2 times in their lives.

The cone method is the simplest option available to any user ( according to GOST 10181-2014 Concrete mixtures. Test methods. ), even with minimal skills and training. You need to take a cone, usually made of metal. Industrial and civil production require the use of products with standardized dimensions. There are separate factories that specialize in the production of equipment.

To determine the mobility of a concrete mixture, use:

- normal or enlarged cone;

- metal ruler;

- loading funnel;

- trowel type KB;

- stopwatch;

- a smooth hard sheet with dimensions of at least 700x700 mm made of waterproof material (metal, plastic, etc.);

- straight metal smooth rod with a diameter of 16 mm, a length of 600 mm with rounded ends.

The workability grades of concrete P4 and P5 (the most common grades for ready-mix concrete) are determined by filling the cone in one step and bayoneting it 10 times in a normal cone, and 20 times in an enlarged one.

At the last stage, the cone is turned over onto a flat surface. The structure is removed from the mass. The concrete dough begins to settle under the pressure of its own weight. The mobility of the material is determined by how much shrinkage has occurred in centimeters.

Hardness index

Scheme for determining the mobility (slump value of the cone) of a concrete mixture.

Rigid mixtures that need to be laid by vibration are tested for workability with another device - a technical viscometer. A technical viscometer consists of metal molds and a vibration platform with certain parameters. At the site, the amplitude of vertical vibrations per minute is 0.35 mm, the number of vibrations is approximately 2800-3000. A standard cone is placed on the platform and filled to the top. First, a standard compaction is performed by bayoneting (as for determining mobility), and then the final compaction is performed by vibration until the cement paste appears on the surface of the cone and under the lower base.

Scheme of possible stratification of the concrete mixture: a - during transportation and compaction; b—after compaction; 1 - direction in which water is squeezed out; 2 - water; 3, 4 - fine and coarse aggregates.

Compaction is carried out over a certain period of time (from 5 to 30 seconds). After compaction, the concrete mixture is carefully cut flush with the cone and raised. A device disk with a rod is installed on the surface of this concrete cone, then the vibrating platform is turned on again.

Under the influence of vibration, concrete settles to a certain level. Once the desired draft is achieved, the vibration stops and the stopwatch turns off. Workability is measured in this case in seconds and is no longer characterized by an indicator of mobility, but by an indicator of rigidity. This method of measuring workability is used if filler with a grain size ≤ 40 mm is taken.

Cone slump of concrete mixture GOST table

To prepare the cone and fixtures for testing, all surfaces in contact with the concrete mixture should be cleaned and wiped with a damp cloth. The cone is placed on a smooth metal sheet and filled with concrete mixture through a funnel in three layers of equal height.

The cone must be pressed tightly against the sheet during filling and bayoneting. After compacting the concrete mixture in the cone, the funnel is removed and the excess mixture is cut off with a trowel flush with the upper edges of the cone. The cone is smoothly removed from the molded concrete mixture and installed next to it. The time taken to remove the cone should be s.

Mobility (P)

The settlement of a concrete mixture cone is determined by placing a metal ruler edgewise on the top of the cone and measuring the distance from the bottom edge of the ruler to the top of the concrete mixture with an error of up to 0.5 cm. If, after removing the cone, the concrete mixture falls apart and takes on a shape that makes it difficult to determine its settlement, the measurement is not perform and the test is repeated on a new sample of the concrete mixture selected in accordance with GOST. The value of the slump of the concrete mixture cone, determined in an enlarged cone, is reduced to the value of the slump of a regular cone by multiplying the value of the concrete slump of the enlarged cone by a conversion factor of 0. The slump of the concrete mixture cone is determined twice.

The total test time from the beginning of filling the cone with concrete mixture during the first determination and until the moment of measuring the cone settlement during the second determination should not exceed 10 minutes. The cone settlement of the concrete mixture is calculated, rounded to 1.0 cm, as the arithmetic mean of the results of two determinations of the cone settlement from the same sample, differing from each other by no more than:.

If there is a greater discrepancy between the results, the determination is repeated on a new sample selected in accordance with GOST. The test results must be entered in a journal in which they indicate:. If calculated in accordance with the instructions given in paragraph. The stiffness of the concrete mixture is characterized by the vibration time in seconds required to level and compact the preformed cone of the concrete mixture in a stiffness determination device.

Super hard solution

Diagram of the device and the sequence for determining the hardness of the concrete mixture: a - installation of the device and loading of the concrete mixture, b - installation of the disk on the surface of the concrete cone, c - the moment the tests are completed; 1 - cylindrical ring, 2 - reference cone, 3 - funnel, 4 - tripod, 5 - disk with holes, 6 - rod, 7 - vibrating platform.

If the solution contains coarse aggregate, the grain size of which reaches 70 mm, the hardness indicator is less than 100 seconds (medium hardness), then workability is measured in a simplified way. A metal mold in the form of a cube with an internal rib size of 200 mm is installed and secured on the vibration platform. A standard cone is installed inside the mold, first the standard laying is done without vibration, then it is vibrated as standard until the concrete dough appears. After this, the dough is cut flush with the surface of the cone. Then it is removed in the standard way, and the concrete is subjected to vibration again until the solution fills all four corners of the cubic shape. The time it takes to level to a horizontal state is measured (in seconds). In this case, the rigidity is characterized by the leveling time, which must be multiplied by a factor of 1.5.

INFORMATION DATA

1. DEVELOPED by the USSR State Committee for Construction, the USSR Ministry of Construction Materials Industry, the USSR Ministry of Energy and Electrification, the USSR Ministry of Transport and Construction

DEVELOPERS

A.S.Dmitriev, Ph.D. tech. Sciences (topic leader); L.A. Malinina, Doctor of Engineering. sciences; I.I. Kostin; V.I.Savin, Ph.D. tech. sciences; Yu.M.Romanov; B.A.Usov, Ph.D. tech. sciences; V.G.Dovzhik, Ph.D. tech. sciences; V.A.Piskarev, Ph.D. tech. sciences; L.I.Levin; E.N. Leontiev, Ph.D. tech. sciences; E.V. Friedman, Ph.D. tech. sciences; V.A. Dorf, Ph.D. tech. sciences; A.G. Malinovsky; V.B.Sudakov, Ph.D. tech. sciences; Ts.G. Ginzburg, Candidate of Technical Sciences sciences; V.A. Karysheva; G.V.Morozova; E.A. Antonov; L.V.Bereznitsky, Ph.D. tech. sciences; A.M. Sheinin, Ph.D. tech. sciences; E.R. Pinus, Ph.D. tech. sciences

INTRODUCED by the Research Institute of Concrete and Reinforced Concrete (NIIZHB) of the USSR State Construction Committee

2. APPROVED AND ENTERED INTO EFFECT by Resolution of the USSR State Committee for Construction Affairs dated December 31, 1980 N 228

3. INTRODUCED FOR THE FIRST TIME

4. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

| Designation of the referenced technical document | Item number |

| GOST 427-75 | 2.1 |

| GOST 10180-90 | 3.1.2, 3.2.2 |

| GOST 10181.0-81 | 1.1, 3.1.8, 3.2.6 |

| GOST 10181.1-81 | 2.1, 3.1.2 |

| GOST 10181.2-81 | 2.1, 3.2.2 |

| GOST 22685-89 | 2.1 |

| GOST 24104-88 | 2.1 |

| OST 16.0.801-397-87 | 2.1 |

5. REPUBLICATION. May 1997

This standard applies to concrete mixtures prepared with mineral binders, dense and porous aggregates and establishes methods for determining their delamination in terms of solution separation and water separation.

Delamination of concrete

Diagrams of instruments for determining the rheological properties of cement paste and concrete mixture: a - by changing the speed of flow of the mixture through the hole; b – by measuring the penetration depth of the cone; c – according to the speed of immersion of the ball; d – by pulling force; d – by the rotation force of coaxial cylinders.

In addition to the characteristics of rigidity and mobility, the solution is characterized by medium density and porosity. Porosity is the ratio of mass to volume. The property of porosity is used in concretes having porous fillers. Each type has a porosity characteristic determined by the volume of air in the concrete. For such concretes, porosity is determined by the volume of pores in the filler. An important indicator is the property of concrete to delaminate. The concrete mixture sometimes becomes heterogeneous and separates into individual components. Delamination is characterized by water separation and solution separation.

The dynamic effect causes larger particles of aggregate to fall down under the influence of their weight; water tends to rise upward, since water is lighter than stone and sand. Water separation is normal for normal concrete mixtures and does not cause any negative changes to the concrete. After all, water sometimes evaporates and reduces the water-cement ratio, which increases the strength of concrete. If delamination occurs during transportation, accompanied by water separation, then this phenomenon is negative.

Dense and light consistency

Determination of the workability of a concrete mixture in a simplified way: a – general view of the device; b – concrete mixture before vibration; c – the same, after vibration; 1 – cone; 2 – cube shape; 3 – concrete mixture; 4 – vibration platform.

Delamination is caused by careless transportation or improper installation. Preparation technology also affects the subsequent shelf life of the concrete mixture. In this regard, if the solution is prepared with a minimum cement consumption, exceeding the size of the aggregate, then the shelf life is weak, it is short-lived and does not correspond to the quality in terms of density or mobility. The density of concrete is not a simple characteristic. There are concretes of different densities: light, heavy, and also especially heavy. Density is measured by the weight of concrete relative to its volume. The density of the lung is in the range of 500-1800 kg/m3. Concrete is heavy - 1800-2500 kg/m3.

It is possible to increase the density of concrete by using expanding Portland cement, pozzolanic Portland cement. Particularly dense concrete is widely used during the construction of nuclear power plants, as they protect against the effects of ionizing radiation. The load-bearing capacity of concrete depends on the filler and density characteristics. Lightweight concrete with low density has low load-bearing capacity. General characteristics are improved with the help of plasticizers. These are additives that can increase its density, prevent delamination, and improve the workability of hard concrete with coarse filler.

Standards for delamination and workability

Types of concrete mixture structures and their influence on the water demand of a uniform mixture: I – a mixture with floating aggregate, II – a mixture with dense packing of aggregates, III – a coarse-porous mixture with a lack of cement paste.

The tendency to delamination can be compensated for by placing it in formwork directly at the place of preparation. If concrete is transported through chutes, especially from a great height, or due to a change in the direction of the chute, it often delaminates. Settlement of the mixture often occurs when workability is poor, when the vibrator is used for a long time. Delamination of concrete is easy to notice, but the degree of delamination is difficult to measure. The degree of delamination is clearly visible during plasticity tests, when a concrete cube is vibrated for 10 minutes and then breaks. With excessive vibration, delamination is visible by how the coarse filler is distributed in the cube.

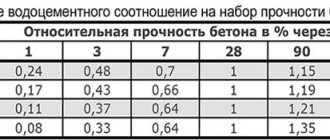

The norm of stratification for different mixtures is characterized by the values of water separation and the values of solution separation (in percent) specified in GOST 7473. Table 1 of this standard contains information on the norm of workability, Table 2 characterizes the norm of stratification. Table 1 of the standard contains quantitative measurements of the workability norm for different grades of concrete according to workability: super-rigid mixtures, rigid mixtures and flexible mixtures. For hard and super-hard mixtures, the table shows the hardness in seconds, for flexible mixtures - the mobility value in millimeters.

Application in construction of mixtures with different cone drafts

Depending on the mobility indicator, the purpose of concrete solutions may be different. Thus, mixtures of categories P2 and P3 are used for monolithic filling. But mixtures with increased mobility with a cone draft of 16 to 21 cm and an indicator of P-4 and higher are used for pouring narrow formworks and columns, structures with a frequent reinforcement design. The latter solutions are also called cast concrete; it is used where it is difficult to use vibrating rammers and compactors.