Introduction

A universal building material is concrete, the strength and other characteristics of which allow it to be used for the construction and repair of objects for a wide range of applications - from real estate to strategic objects. The anti-corrosion resistance of the material is greater than that of wood or metal; concrete perfectly resists humidity and any aggressive environment, provided that the grade is selected correctly and other parameters are calculated.

This takes into account strength, moisture permeability, material class, etc. Concrete structures best withstand compressive loads, therefore, if a tensile force is applied to a concrete surface, you have to deal with strengthening the concrete joints with other materials.

Solution parameters

Concrete class - what is it?

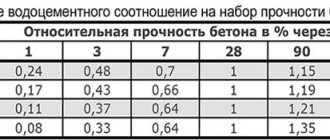

The strength property of concrete is called class. This is a parameter that means the limiting parameters for theoretical deterioration in quality if the strength is rated as standard. The class of concrete according to GOST is indicated in the design documentation for the facility. The relationship between the properties of concrete is most accurately reflected by a special reference table, which displays the strength of the concrete solution depending on the proportions of the components and the activity of the cement content.

The strength of concrete is conventionally determined in kgf/h or MPa. It is also influenced by third-party factors - water quality, sand purity and fraction, possible deviations from the technological process for preparing concrete, laying and hardening conditions. This is reflected in the fact that identically labeled concrete may differ in strength.

Dependence of concrete class on strength

Non-destructive testing procedure

Since it is possible to determine the average strength of concrete using a non-destructive method without special preparation, right on site, using modern electronic devices, we will consider just such a method, which consists of several stages:

- Stage 1. It is necessary to select a smooth edge of the product without cracks, chips or other defects. It is on this that further tests will be carried out.

- Step 2. Depending on the type of device, the following procedure may differ, but the basic principles are the same for any device. Namely, after turning on the sclerometer and selecting the required function, it is necessary to position it in relation to the surface of the concrete product strictly at a right angle, and press the corresponding button.

- Stage 3. The resulting value will be displayed on the screen. The instructions for the device will indicate the total number of times the above operation was performed to obtain the average value.

- Stage 4. If necessary, you can draw up an act of determining the strength of reinforced concrete structures using a non-destructive method, which will have legal force.

Correct placement of the device relative to the surface being tested

After determining the strength of concrete using a non-destructive method is completed, it is necessary to completely turn off the device. A very convenient “gadget” for any foreman, and even a simple craftsman. He definitely won’t “lie” about the quality of concrete at any stage of construction. You just need to remember to constantly check it.

Types of concrete

There can be as many varieties of concrete as it is possible to change the proportions of the components without losing the quality of the solution and the final product, which depends on the accuracy of the ratios of substances in the mixture. In the construction industry, the most common concrete is prepared using Portland cement grade M 400 or M 500. Varieties of concrete are classified according to their intended use and type of binder, as well as the influence of high temperatures. The tensile strength of concrete plus density also influences.

The composition can be working or nominal. Nominal concrete is mixed using dry components, the working composition is based on increasing the moisture content of the aggregates.

The main physical and operational indicator of the quality of concrete is its strength.

Heavy brands are classified into the following subtypes:

- For prefabricated reinforced concrete objects;

- For objects with rapid hardening of the concrete mixture;

- High-strength concrete mixtures;

- Mixtures prepared on the basis of fine concrete aggregates;

- Concrete for hydraulic structures.

Types of concrete

Porous aggregates are added to lightweight concrete - tuff, expanded clay, pumice, slag, agloporite, etc. Such indicators of the mixture composition are considered basic in the construction of fences and load-bearing concrete structures and make them lighter without loss of strength. The main properties of concrete affecting the strength of a structure are density and porosity. Depending on the density, concrete can be:

- Particularly light (density ≤ 500 kg/m3);

- Light (density ≥ 500-1800 kg/m3).

Light mixtures are:

- Porous mixtures, which are prepared on the basis of large-porous aggregates without the addition of sand. Porosity is achieved by introducing gas-forming or air-entraining components into all voids. The composition is also made porous by introducing foam in advance;

- Large-porous concrete is prepared with the addition of coarse aggregates, such as expanded clay, natural fine- and large-porous substances. The material is characterized by high rigidity and non-delamination;

- Cellular concrete consists of a large number of air pores (85%). Chemically produced cellular concrete is called aerated concrete, a concrete mixture obtained mechanically is called foam concrete.

Lightweight concrete

Basic criteria and parameters of concrete To classify concrete by class and grade, take the value of average strength, as well as indicators of temperature, frost resistance of the material, mobility and water resistance of the substance.

How to use a class or brand? These parameters mean that their values can be used to determine the quality and strength of the material over time.

Technical and operational parameters of concrete

Brands and classes of concrete

These characteristics depend on the volume of binder in the working composition. The higher these values, the faster the composition hardens, and the more difficult it is to lay it. The strength of set concrete is checked by laboratory tests using the non-destructive method of compressing concrete with a press on test samples.

The type of concrete used depends on the type of construction project. For example, the average grade at which the construction of a house will be considered reliable and durable is M 100, M 150. The most popular brand is M 200. When constructing monolithic foundations of structures, concrete M 350 is considered the best, since it can withstand any design loads. Such concrete is poured onto the foundations of monolithic construction sites and massive structures.

Class is the strength of the material, measured in kg/cm2 or MPa. Strength is ensured in a class of at least 0.95 for any values in the range B1-B60. During the process of gaining strength, the class may change.

Grade is a standard parameter that provides the average strength of concrete in kgf/cm2 or in MPa x 10. For heavy grade concrete, these values range from M 50 to M 800. The stronger the concrete, the higher the numbers in the grade designation.

This dependence is expressed by the following formulas: B = R x 0.778, or R = B / 0.778, provided that the strength of concrete can vary within n = 0.135, and the safety factor t = 0.95 at a temperature of 15 - 250C. As the surface temperature increases, hardening accelerates.

Physico-mechanical and deformation properties of concrete

Compliance with frost resistance and water resistance classes

| Operating parameters | Frost resistance | Waterproof | Ready-mixed concrete, grade |

| Cyclic freezing and thawing at moisture saturation and temperature: | |||

| At low temperatures ≥ -400C | F 150 | W 2 | BSG V 20 PZ F 150 W 4 (M 250) |

| ≥ -200С/-400С | F 100 | — | BSG V 15 PZ F 100 W 4 (M 200) |

| ≥ -50С/-200С | F 75 | — | BSG V 15 PZ F 100 W 4 (M 200) |

| ≥ -50С | F 50 | — | BSG V 15 PZ F 100 W 4 (M 200) |

| Cyclic freezing and thawing with periodic saturation with moisture and the influence of external factors: | |||

| ≥ -400С | F 100 | — | BSG V 15 PZ F 100 W 4 (M 200) |

| ≥ -200С/-400С | F 50 | — | BSG V 15 PZ F 100 W 4 (M 200) |

| ≥ -50С/-200С | — | — | BSG V 15 PZ F 100 W 4 (M 200) |

| ≥ -50С | — | — | BSG V 15 PZ F 100 W 4 (M 200) |

| Cyclic freezing and thawing in the absence of moisture saturation: | |||

| ≥ -400С | F 75 | — | BSG V 15 PZ F 100 W 4 (M 200) |

| ≥ -200С/-400С | — | — | BSG V 15 PZ F 100 W 4 (M 200) |

| ≥ -50С/-200С | — | — | BSG V 15 PZ F 100 W 4 (M 200) |

| ≥ -50С | — | — | BSG V 15 PZ F 100 W 4 (M 200) |

Moisture-proof properties of concrete

Each brand of concrete has limitations on water permeability, which helps to understand the degree of maximum water pressure on concrete. In individual construction, the use of the approximate water resistance of concrete is more often used. The main grades of concrete for moisture permeability:

- W 4 - normal moisture permeability, at which the level of moisture absorbed by concrete does not exceed the norm;

- W 6 - reduced moisture permeability;

- W 8 - low moisture permeability;

- Grades higher than W 8 have increased hydrophobicity.

The strength of concrete is determined by its resistance to various force influences - compression, tension, bending, shear. The same concrete has different temporary resistance under different force influences. Research has shown that strength theories proposed for other materials are not applicable to concrete. Therefore, the quantitative assessment of concrete strength is currently based on averaged experimental data, which are taken as initial data when designing any concrete and reinforced concrete structures.

The lack of regularity in the arrangement of individual particles that make up concrete leads to the fact that when testing samples made from the same concrete mixture, different indicators of tensile strength are obtained—strength scatter. In addition, it must be remembered that the mechanical properties of cement stone and aggregates differ significantly from each other; In addition, the structure of concrete is replete with defects, which, in addition to pores, are voids near the aggregate grains that arise during concrete hardening.

The axial compressive strength of concrete is considered its main characteristic, since the most valuable quality of concrete is its high compressive strength. It can be determined in laboratory conditions on samples in the form of cubes, prisms or cylinders. In our country, cubes are mainly used to assess the compressive strength of concrete.

Since concrete is a heterogeneous artificial stone material, to obtain reliable information about its strength in accordance with current standards, a batch of samples is tested and determined (average axial compressive strength of concrete cubes with an edge of 150 mm) and (average axial compressive strength reference concrete samples of prisms).

Cube strength. During axial compression, cubes (like other compressed samples) collapse due to concrete rupture in the transverse direction. The inclination of the cracks is due to the influence of friction forces that develop on the contact surfaces between the press pads and the supporting faces of the cube (Fig. 2.2a). Friction forces directed inward prevent free transverse deformations of concrete near the supporting surfaces and thereby increase its compressive strength (a cage effect is created). The holding influence of friction forces decreases with distance from the end faces of the cube, therefore, after destruction, the cube takes the form of four truncated pyramids connected by small bases. If, during axial compression of the cube, it is possible to eliminate or significantly reduce (by lubricating the contact surfaces, for example, with paraffin or cardboard spacers) the influence of the forces of supporting friction, then the nature of its destruction and strength change (Fig. 2.2b).

Figure 2.2 - Nature of destruction of concrete cubes: a - in the presence of friction along the supporting planes; b - in the absence of friction; 1 - friction forces; 2 - cracks; 3 - lubrication.

In this case, transverse deformations appear freely and the fracture cracks become vertical, parallel to the action of the compressive force, and the temporary resistance of concrete to compression is significantly reduced. According to the standard, cubes are tested without lubrication of the contact surfaces and in the absence of pads.

Experiments have established that the strength of concrete of the same composition depends on the size of the cube. Cubes with an edge of 150 mm are taken as standard (reference) laboratory samples. When testing cubes of other sizes, the results of their tests using correction factors lead to the test results of the standard cubes.

Prismatic strength. Real reinforced concrete structures differ significantly in shape and size from laboratory cubes. In them, most often one dimension exceeds two others (for example, the span is the width and height of the bending element; the height of the compressed element is the dimensions of its cross section).

Due to the fact that when testing concrete during the transition from a cube-shaped sample to a prism-shaped sample (with the same cross-sectional area), the temporary compressive resistance with increasing h

decreases (Fig. 1.3), cubic strength cannot be directly used in calculating the strength of structural elements, but serves only to control the quality of concrete in production conditions.

Reducing the temporary resistance of concrete to compression during transition; from cube-shaped samples to prism-shaped samples is explained by the fact that with increasing h/a

the influence of friction forces arising between the ends of the sample and the press plates on the stressed state of the sample in its middle height part gradually weakens, and for prisms with

h/a ≥

4 this influence is almost completely eliminated.

It is customary to determine the prismatic strength of concrete ,

the main and most stable characteristic of the compressive strength of concrete, used in calculating the strength of compressed and bending elements, on standard prisms with dimensions of 150 ´ 150 ´ 600 mm

(h/ a

= 4).

Figure 2.3 – Graph of the dependence of the prismatic strength of concrete on the ratio of the dimensions of the tested sample

Experiments have established that at 4 ≤ h/a <

8≈

0.75 .

The influence of the flexibility of the prisms is not noticeably affected.

The influence of flexibility begins to be significantly felt at h/a≥

8.

The axial tensile strength of concrete depends on the tensile strength of the cement stone and the strength of its adhesion to the aggregate grains. According to experimental data:

Where —

average limit of concrete in axial tension.

Moreover, the relative strength of concrete under axial tension kt

decreases with increasing concrete compressive strength.

The reasons for the low tensile strength of concrete are the heterogeneity of its structure, the presence of initial stresses, and weak adhesion of cement stone to coarse aggregate. Some increase (by about 15...20%) can be achieved by increasing cement consumption per unit volume of concrete, reducing W/C,

using crushed stone with a rough surface instead of gravel, and washing the aggregate.

There are several laboratory methods for determining . However, during these tests, an even greater scatter of strength indicators is observed compared to tests of concrete for axial compression, since the samples are difficult to center. Therefore, if the compressive strength of concrete is known, it is sometimes determined theoretically, for example, using the formula:

In addition, if necessary, the following are taken into account:

— strength of concrete under long-term load;

— dynamic strength of concrete;

— strength of concrete under repeated loads.

Compressive strength of concrete

The main property is the compressive strength of concrete, which is displayed in MPa or kgf/cm2 (kilograms per square centimeter). This indicator depends mainly on the following properties of the building material:

- Quality of the solution and ratios of components;

- From the cooking conditions;

- From the volume of water and the ratio of water to cement;

- On the size of the aggregates and the shape of the grain;

- From laying technology;

- From tamping technology;

- The age of concrete means its strength increases over time.

An indicator of strength for concrete is the time it lasts when compressive forces are applied. Strength is considered the most important parameter in determining the quality of concrete mixtures. So, concrete class B 15, grade M 200 means an average compressive strength of 15 MPa (200 kgf/m2), class B 25 means a resistance of 25 MPa (250 kgf/m2), etc. There is a reference table showing the compressive strength of concrete:

Tensile and compressive strength of concrete

Laboratory conditions for concrete hardening are studies of model cubes under pressure. As the pressure increases, the beginning of the destruction of the cube is noted - this will be the limit of its strength, which is the determining condition when assigning a class to concrete. After 28 days, the strength of concrete is considered initial, that is, such that its operation can begin.

By grade, compressive strength can be determined as follows: concrete M 800 has the highest strength, grade M 15 has the least. Flexural strength of concrete

The higher the grade, the higher the strength of concrete under bending forces. When compared, the tensile and bending characteristics have lower values than the load-bearing capacity of a concrete structure. Young concrete has a tensile-flexural/load capacity ratio of 1/20, but as the concrete ages, the ratio increases to 1/8, resulting in higher quality concrete.

Strength against bending forces is calculated using the formula: Rbend = 0.1 • P • L / b • h2, where:

- L is the distance between the beams;

- P – the total mass of the load and only, plus the mass of concrete;

- h and b are the height and width of the beam section;

The strength value is displayed as Btb plus a number ranging from 0.4 to 8.

Testing concrete for bending strength

Flexural strength of concrete

Each material has its own “strengths” and “weaknesses” contained in their properties. So concrete, being one of the strongest materials in terms of compression, loses in other indicators, for example, tensile or bending strength. This figure is less than for compression, approximately 8-10 times on the 28th day after pouring the composition. When bending, cracks appear on the back side of the concrete layer, which is why all reinforced concrete products and reinforced concrete structures are equipped with ribbed reinforcement bases. Bending tests of concrete are carried out using purely laboratory methods. Certain blocks of material are made, a test is carried out on them, the result of which is a specific value. This value is subsequently entered into the formula for calculating the required bending strength. It takes into account the weight of the sample and its dimensions. As a rule, with increasing grade and stiffness, the flexural strength increases. Since this indicator cannot be verified under construction conditions, it is taken into account already at the design stage and the composition of the future concrete is measured in advance.

Axial tension of a concrete sample

Such a characteristic as the axial tension of concrete is usually not taken into account. Axial tension can be used to determine the ability of concrete to withstand fluctuations in temperature and humidity without cracking or breaking the concrete.

This parameter can be calculated by stretching concrete beams using research equipment. In this case, destruction of the beam is observed under the influence of opposite tensile forces. The axial tension value can be increased by adding fine-grained aggregates to the mixture.