- All about types of LEDs

- Main three types of LEDs

- Basic parameters of LEDs in LED lamps, strips, lamps

- Types of SMD LEDs and their features

- Rating of SMD LEDs

- How to correctly decipher the marking?

- Advantages and disadvantages of LEDs

Output LEDs SMD LEDs COB LEDs

Current Voltage Power Luminous flux Color temperature Dimensions

Single-, double-, triple-chip SMD LEDs Glow color Standard size

How to identify an LED by appearance? How to determine the polarity of an LED?

This article reveals the secrets of LEDs that are known only to specialized specialists. You will learn what types of LEDs are produced by industry, get acquainted with their manufacturing technologies and characteristics. A separate section is devoted to the features of the model range of LEDs used in ice strips and lamps.

We will tell you how to recognize the markings of light-emitting diodes, how to find out the parameters of an LED, and determine the location of the anode/cathode based on subtle signs. You will see that a regular ruler will help you find out the size of the SMD diode and then find the necessary information about it.

What is an LED: principle, device

An LED is usually called a semiconductor device that, during its operation, converts current into light radiation. It consists of a semiconductor chip placed on a substrate, a housing and an optical system. A characteristic glow appears when electrons and holes recombine in the region of the pn junction. To create a pn junction, special alloying elements are introduced into the near-contact layers. On the one hand they are acceptor, on the other - donor.

Semiconductor crystal - the basis of LED lighting

Main conclusions

LEDs with a power of 3 W are of interest for creating bright and compact lighting systems. They are good for decorative lighting and are often found in car tuning assemblies or bicycle headlights. When purchasing, you should clarify important parameters:

- supply voltage;

- color shade;

- the amount of luminous flux.

These characteristics are necessary for correct connection. In addition, they influence the choice of the purpose of the elements. State your use cases in the comments.

Types of LEDs by purpose

It is worth understanding in more detail what types of LEDs there are. Such products are usually divided into two large groups: lighting and indicator. Each type has its own advantages and possible areas of use. We suggest that you familiarize yourself with each group in more detail in order to better understand the wide range of LED products.

LEDs are different

Indicator LEDs: distinctive features

Due to their characteristics, indicator devices are widely used in color indication. They are used to illuminate instrument panels, displays, and a number of other products. With a relatively low power (less than 0.2 W), the indicator LEDs demonstrate moderate brightness.

The indicators are characterized by moderate brightness

They are usually divided into:

- DIP LEDs , consisting of a light-emitting crystal housed in a cylindrical or rectangular housing. Allows to realize a wide range of color radiation. There are single and multi-colored ones. Have a low dispersion angle;

DIP LEDs realize a wide spectrum of radiation

- Super Flux "Piranha". Ultra-bright devices with four terminals in a rectangular housing. Suitable for board mounting. Available in different glow temperatures in housings with and without lenses. The dispersion angle depends on the model and is equal to 40⁰-120⁰. Relevant for transport and advertising signs;

Super Flux "Piranha" used in advertising signage

- Straw Hat. They demonstrate a large scattering angle (100-140⁰) due to the close location of the crystal to the front wall of the lens. Similar to regular cylindrical models. They are distinguished by a large lens radius and a smaller height;

Straw Hat looks similar to DIP

- SMD LEDs. Products with standard case sizes. Often used in the manufacture of LED strips.

SMD LEDs are in demand in the manufacture of LED strips

Lighting LEDs: distinctive features

Lighting elements are included in LED lamps and strips, headlights and other products for which it is important to ensure high luminescence intensity. They have great power. Available in housings that allow surface mounting. They only come in white (cold or warm). Highlight:

- Lighting SMD LED. The most common type with a dispersion angle of 100⁰-130⁰. During the manufacturing process, the emitting crystal is coated with a layer of phosphor and mounted on an aluminum or copper substrate that provides sufficient heat dissipation;

SMD LED is mounted on a copper or aluminum substrate

- COB LEDs , consisting of a large number of crystals. They have a large dispersion angle;

Matrix for COB

- Filament LED. Often used as decorative lighting. They have lower efficiency than SMD.

Filament LED – the right lighting solution

Pros and cons of LED lighting

The main advantages of lighting LEDs include:

- energy saving, which allows you to reduce electricity costs;

- different color glow;

- availability of choice of color temperature;

- different angles of light distribution, allowing you to choose the appropriate option for any room;

- small pulsation coefficient.

LED lighting can be of different colors

Disadvantages include aging, relatively short service life and heating.

Over time, the intensity of the glow will decrease

Design and light dispersion angle

The design of a 3 W LED is practically no different from the design of other types of LED elements with similar characteristics. They are designed for direct surface mounting. SMD capacitors, resistors or other parts are installed in a similar way. The case has two (or 6 for multi-colored) short pins, which are soldered directly to the conductive traces of the board. This design allows you to create LED lamps of regular sizes, equipped with a standard base type. To replace, you do not need to change the entire lamp; you can simply use a different type of lighting fixture.

The main element of the LED design is the emitting crystal. It is attached to an aluminum base, which serves as a heat sink to dissipate the generated heat. The base is installed in a housing, the upper part of which is a plastic diffuser lens.

White LEDs actually emit blue light. It is softened by a layer of yellow phosphor. There are different formulations that produce warm and cool white. The first has a color temperature of around 3000 K, while the second has a color temperature of about 6000 K.

Interesting! The scattering angle of LEDs is a parameter that determines the degree of opening of the beam emanating from the crystal. This is one of the distinctive characteristics of all LEDs, due to the design of the crystal.

The emission of light photons occurs from the middle layer of the semiconductor assembly, tightly connected to the outer layers on both sides. Because of this, the light beam can only come out in the shape of a cone with its apex in the crystal. Different elements have a larger or smaller dispersion angle. 3w LEDs exhibit a value of 120°, which is quite an attractive value from a performance point of view.

Main characteristics of LEDs

When choosing an LED lamp, you should pay attention to the parameters of the LEDs. The ability to use the product in specific operating conditions and ensure the required level of room illumination will depend on this. Attention should be paid to power, voltage, operating current, light output, glow temperature, as well as a number of other parameters.

The characteristics of the selected lamp should be known in advance.

On-chip current

The bulk of LEDs are designed for a current consumption of 0.02 A. However, manufacturers offer products consisting of four crystals placed in one housing. Thanks to this design, the products are designed for 0.08 A, which is the sum of the 0.02 A consumed by each crystal.

The amount of LED current affects the stability of the device. With a slight increase in this parameter, the radiation intensity decreases and the color temperature increases. This is evidenced by a characteristic blue tint and premature failure.

Attention! With a significant jump in current, the LED burns out immediately.

To limit the current value, LED lamps and luminaires are equipped with current stabilizers. If they are present, current conversion is ensured to achieve the required value. To connect a separate LED, a current-limiting resistor is used, the resistance of which is calculated taking into account the characteristics of the connected product.

Advice! To select the correct resistor, you should use an online calculator to help you calculate the required resistance.

The current strength must not exceed the limit value

LED voltage

For LEDs, the supply voltage is irrelevant. An important characteristic is the magnitude of the voltage drop across the LED, which numerically corresponds to the output voltage of the product after the rated current passes through it. The characteristics are indicated on the packaging. Knowing this value, it is easy to calculate the voltage remaining on the crystal, which is taken into account in the calculations.

Manufacturers offer LEDs with different voltages, which can be recognized by the color of the glow. If the crystal is white, green or blue, the voltage is about 3 V. For red and yellow products, the desired parameter may be in the range of 1.8-2.4 V.

When connecting diodes in parallel, the characteristics of each product should be carefully monitored. Even a slight voltage jump of 0.1 V will cause a significant increase in current. As a result, such an LED will definitely burn out.

Yellow tapes have a voltage of 1.8-2.4 V

Diode resistance

Diodes are characterized by the presence of two types of resistance: differential and direct current. In the direct section of the current-voltage characteristic, the differential resistance is small and less than the direct current resistance. On the opposite side, the differential resistance tends to infinity and exceeds the direct current resistance.

Calculation of differential resistance

Light output, luminous angle: important parameters

Traditionally, when comparing luminous flux from different sources, the characteristics of the generated radiation are taken into account. An LED with a diameter of 5 mm can become a light source of 1-5 Lm (the characteristics of super-bright LEDs are higher), although a 100 W incandescent lamp will create a luminous flux of 1000 Lm. It is incorrect to make a comparison in this way, since the light from a regular lamp will be scattered, and from a diode - directional. To compare the characteristics of these light sources, you should pay attention to the scattering angle of the diodes.

Light output depends on the type of lamp

For LEDs, the dispersion angle can vary between 20-120 degrees. Thanks to their design, LEDs produce brighter light in the center, reducing the degree of illumination towards the edges of the dispersion angle. Thanks to this, it is possible to provide the desired level of room illumination with less power consumption. To increase the illumination area, the lamps are equipped with diffuse lenses.

The scattering angle of LED lamps is small

Power of LED lamps: compared with an incandescent lamp

Having decided to replace outdated incandescent lamps with LED ones, not everyone clearly understands what wattage products should be purchased. Experts recommend using the correction factor K=8. So, if a 100 W lamp was used to illuminate the room, the same level of illumination can be achieved by installing an LED analogue with a power of at least 100 W/8 = 12.5 W. To find out which incandescent lamp a specific LED corresponds to, you can use the following table:

| Power of LED lamps, W | |

| LED | Incandescent |

| 3 | 25 |

| 5 | 40 |

| 7,5-8 | 60 |

| 10 | 75 |

| 12-12,5 | 100 |

When choosing and comparing different light sources, you should pay attention to such a characteristic as efficiency. Its numerical value is determined by dividing the luminous flux (Lm) by power (W). So, for incandescent lamps this figure is on average in the range of 10-12 Lm/W, and for LED lamps it can reach 130-140 Lm/W.

With the same luminous flux, the power is less

Color temperature is a criterion that determines the comfort of perception of the light flux

Glow temperature is classified as an important characteristic. Its unit of measurement is degrees Kelvin (K). The division is made depending on the glow temperature.

The temperature of the glow varies

Attention! The comfort of perception of a particular light source mainly depends on its color temperature.

The labeling of LED lamps must include a color temperature value. It corresponds to a four-digit number followed by the letter K. When choosing an LED lamp, you should focus on the future area of use. We suggest that you familiarize yourself with the possible areas of use of an LED lamp, depending on its color temperature and glow color:

| Color temperature, K | Glow color | Recommended area of use |

| 2700-3500 | White Warm | Domestic and office premises. Products that can replace an incandescent lamp. |

| 3500-5300 | Neutral (daytime) | Workplaces in production premises. |

| more than 5300 | Cold | As a street light source and in the manufacture of hand-held lanterns. |

| 1800 | Red | Decorative and phyto-lighting. |

| 7500 | Blue | Phyto-lighting, interior lighting. |

| 3300 | Yellow | Interior lighting. |

The color temperature of LEDs can be expressed in terms of the wave nature of light. Often in the labeling of LED products, color temperature is expressed through different wavelengths. It is denoted by λ and expressed in nanometers (nm).

The color of the glow reflects the wave nature

Chip size: symbol in marking

The marking of the LED element encodes the size in the form of a four-digit number indicated on the board. Among the most popular geometric parameters of the past are the products 5050 and 3528. They have been replaced by brighter competitors 5630 and 5730.

In this symbol, the first two digits correspond to the length of the chip, and the subsequent ones correspond to its width, expressed in millimeters. So, for the 5730, the chip length will be 57 mm and its width will be 30 mm. The difference in aspect ratio is due to the different number of crystals included in the LED. The 3528 diode has one, the 5050 has three. This characteristic of LEDs for flashlights determines their design features.

The chip size is contained in the marking

Crystal size is an important parameter

The size of the crystal has a direct impact on the amount of current that can pass through it. Square models are equipped with regular 1 or 2 W crystals, having a standard size of 30mil or 45mil respectively. More powerful analogs include 10, 20, 30, 50 or 100W crystals with geometric parameters of 24 mil by 24mil, 24 mil by 44mil or 44 mil by 44mil. Low-power models can be formed from crystals of various sizes. They may include 2-3 elements connected not only in series, but also in parallel.

Description:

This LED can be used in homemade phytolamps, for example, in cases where you are going to recreate a complete light culture.

In this way, you can add missing parts of the spectra (in addition to the main peaks in the red and blue areas), as well as make the color of the glow from the lamp more natural - for example, if the task is to usefully illuminate a flower arrangement or home greenhouse, without disturbing its aesthetic beauty. The LED crystal itself is coated with a phosphor and encased in a primary lens, but if you need to focus the light from the phytolamp in a special way and create a different light geometry, then you should think about which LED lenses to choose for these purposes. And also do not forget that the back of the LED must be treated with thermal paste or hot melt adhesive before installation. And most importantly, do not forget to think in advance about how many LEDs will be in your homemade phytolamp, what spectra will be used and what current you plan to power this entire circuit with (or divide it into several electrical circuits). Based on these preferences, it will be possible to choose a power supply for the LEDs - and it is better to think about this in advance rather than looking for compromises and recalculating the number of LEDs at the final stage, because each driver can power a limited number of phyto LEDs, while it has a limit as to the minimum number of diodes, and to the maximum - for example, some drivers power from 10 pcs to 20 pcs of 3W LEDs, and some from 30 pcs to 50 pcs. Aluminum radiators are often used to cool such LEDs , because

a regular flat piece of aluminum is often not enough for proper cooling. A special white LED with a warm glow is used to add to phytolamps and lamps in a proportion of 10-30% in the following cases:

- to stimulate the flowering and fruiting stage

- in the absence of sunlight and other “white” light sources (with light culture, for example in grow boxes).

SMD LEDs: sizes and main characteristics

Manufacturers offer SMD LEDs in various sizes. Based on geometric parameters, products are usually divided into different groups, depending on color temperature, brightness and power. The marking of LEDs includes their geometric dimensions: length and width, expressed in millimeters. We invite you to get acquainted with the most popular standard sizes in order to better navigate the assortment offered by manufacturers.

LEDs come in various sizes

Main parameters of LED SMD 2835

When studying the technical characteristics of SMD 2835, it is worth paying attention to the increased radiation area. The model, unlike the SMD 3528 with a round working surface, is manufactured in a rectangular shape. This design solution, despite the smaller height (0.8 mm) of the element, provides greater light output. It generates a luminous flux corresponding to 50 Lm.

SMD 2835 is in demand in the manufacture of lamps

Due to the fact that a heat-resistant polymer is used to make the case, the product can withstand exposure to fairly high temperatures (up to 240°C). After 3000 hours of operation, the product demonstrates radiation degradation of no more than 5%. It has a low thermal resistance of the crystal-substrate transition (4 C/W). The maximum operating current is 0.18 A at a crystal temperature of 130°C.

The color of the glow can be different:

- Warm white with a temperature of 4000 K;

- Daytime white equivalent to 4800 K;

- Pure white, in the range of 5000-5800 K

- Cool white, corresponding to 6500-7500 K.

The color of the glow has a direct impact on the amount of luminous flux. This parameter of SMD LED 2835 will be greatest for products with a cool white glow and minimal for products with a warm white glow. Enlarged contact pads of the model contribute to more intense heat dissipation.

Attention! The characteristics of LED 2835 make it possible to use it when performing installation work of any type.

SMD 5050: LED characteristics

SMD 5050 involves placing three of the same type of LEDs in one housing measuring 50 by 50 mm. The technical characteristics of the red, blue and green LED sources used are similar to the crystals installed in SMD 3528. Each of the three LEDs has an operating current of 0.02 A with a total value of 0.06 A. The specified value is the limit. Exceeding the value may cause the device to fail.

SMD 5050 has the same size edges

The devices are designed for a direct voltage of 3-3.3 V with a light output (luminous flux) of 18-21 Lm. Each crystal has a power of 0.7 W, and the total value is 0.21 W. The device is capable of generating a glow of various colors from monotonous white, green, blue, yellow to multicolor.

The design and characteristics of the 5050 LEDs allow each color to be controlled separately due to the close proximity of the elements. The controllers included in the luminaires allow you to smoothly adjust the color of the glow by smoothly transitioning from one to another after a specified period of time. Often, several control modes are provided with the ability to adjust the brightness of the light.

Main characteristics of SMD 5730 LEDs

Modern products with geometric parameters 5.7×3 mm. Due to their stable characteristics, SMD 5730 LEDs belong to the category of ultra-bright products. New materials are used for their manufacture, due to which they have increased power and highly efficient luminous flux. SMD 5730 allows operation in conditions of high humidity. They are not afraid of vibration and temperature fluctuations. They have a long service life. They have a dispersion angle of 120 degrees. After 3000 hours of operation the degree does not exceed 1%.

Manufacturers offer two types of devices: with a power of 0.5 and 1 W. The first are marked SMD 5730-0.5, the second - SMD 5730-1. The device can operate on pulsed current. For SMD 5730-0.5, the rated current is 0.15 A, and when switching to the pulsed operating mode it can reach 0.18 A. It is capable of generating a luminous flux of up to 45 Lm.

SMD 5730 – appearance

For SMD 5730-1, the rated current is 0.35A, pulse current can reach 0.8A with a light output efficiency of 110 Lm. Thanks to the use of heat-resistant polymer in the production process, the device body is not afraid of exposure to fairly high temperatures (up to 250°C).

Cree: current characteristics

The products of the American manufacturer are presented in a wide range. The Xlamp series includes single-chip and multi-chip products. The former are characterized by the distribution of radiation along the edges of the device. This innovative solution made it possible to launch the production of lamps with a large luminous angle with a minimum number of crystals.

The XQ-E High Intensity series is the company's latest development. The products have a glow angle of 100-145 degrees. With relatively small geometric parameters of 1.6 by 1.6 mm, such LEDs have a power of 3 V with a luminous flux of 330 lm. The characteristics of Cree LEDs based on a single crystal make it possible to provide high-quality color rendering CRE 70-90.

Multi-chip LED devices have the latest type of power supply 6-72 V. They are usually divided into three groups depending on the power. Products up to 4 W have 6 crystals and are available in MX and ML packages. The characteristics of the XHP35 LED correspond to a power of 13 W. They have a dispersion angle of 120 degrees. May be warm or cool white.

Cree - always excellent quality

How to correctly decipher the marking?

SMD LED markings provide the user with brief information about the products. For example, we have a light-emitting diode labeled SMD 2835 UWC 5. We decipher: standard size 2835 with dimensions 2.8x3.5 mm, power 0.5 W, white tint.

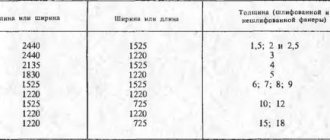

| SMD type | Number of crystals | Dimensions, mm |

| 3528 | 1 | 3.5x2.8x1.4 |

| 5050 | 3 / 4 | 5x5x1.6 |

| 5630 | 1 | 5.6x3x0.75 |

| 5730 | 1 / 2 | 5.7x3x0.75 |

| 3014 | 1 | 3x1.4x0.75 |

| 2835 | 1 | 2.8x3.5x0.8 |

How to identify an LED by appearance?

Measure the dimensions of the diode using any ruler. Look for sizes in the table, determine the type of product and see its characteristics.

| SMD type | Number of crystals | Dimensions, mm | Power, W | Current, mA | Light flux, Lm |

| 3528 | 1 | 3.5x2.8x1.4 | 0,02 / 0,06 | 20 | 5-7 |

| 5050 | 3 / 4 | 5x5x1.6 | 0,02 | 60 / 80 | 18-20 |

| 5630 | 1 | 5.6x3x0.75 | 0,2-0,4 | 150 | 58 |

| 5730 | 1 / 2 | 5.7x3x0.75 | 0,5 / 1 | 150 / 300 | 50 / 158 |

| 3014 | 1 | 3x1.4x0.75 | 0,1-0,12 | 30 | 9-13 |

| 2835 | 1 | 2.8x3.5x0.8 | 0,2 / 0,5 / 1 | 60 / 150 / 300 | 20 / 50 / 100 |

How to determine the polarity of an LED?

In the transparent body of the output LED, you can see the anode and cathode of a characteristic shape.

On SMD packages, an angular cut is visible, indicating the cathode terminal. On the back side there is a heat sink pad, shifted towards the anode.

Another indicator of polarity are the pictograms: triangle, letters P and T. The direction of the letter protrusions and the apex of the triangle points to the cathode.

Checking an LED with a Multimeter

Sometimes it becomes necessary to check the performance of an LED. This can be done using a multimeter. Testing is performed in the following sequence:

| Photo | Description of work |

| We are preparing the necessary equipment. A regular Chinese multimeter model will do. | |

| We set the resistance mode corresponding to 200 Ohms. | |

| We touch the contacts to the element being checked. If the LED is working, it will start to glow. |

Attention! If the contacts are swapped, the characteristic glow will not be observed.

LED color marking

To purchase an LED of the desired color, we suggest that you familiarize yourself with the color symbol included in the marking. For CREE, it is located after the designation of a series of LEDs, and can be:

- WHT if the glow is white;

- HEW if high efficiency white;

- BWT for white second generation;

- BLU if the glow is blue;

- GRN for green;

- ROY for royal (bright) blue;

- RED for red.

Other manufacturers often use a different designation. So KING BRIGHT allows you to choose a model with radiation not only of a certain color, but also of shade. The designation present in the marking will correspond to:

- Red (I, SR);

- Orange (N, SE);

- Yellow (Y);

- Blue (PB);

- Green (G, SG);

- White (PW, MW).

Advice! Read the symbols of a specific manufacturer to make the right choice.

Decoding the LED strip marking code

To manufacture the LED strip, a dielectric with a thickness of 0.2 mm is used. Conductive tracks are applied to it, having contact pads for chips intended for mounting SMD components. The tape includes individual modules 2.5-10 cm long and designed for a voltage of 12 or 24 volts. The module may include 3-22 LEDs and several resistors. The average length of finished products is 5 meters with a width of 8-40 cm.

Markings are applied to the reel or packaging, which contains all the relevant information about the LED strip. The explanation of the markings can be seen in the following figure:

Decoding LED strip markings

Related article:

In this material we will talk about how to implement a scheme for connecting a 220V LED strip to a network . You can install this design yourself. And we will help you with this.

What to make from LEDs with your own hands

LEDs are often used for the manufacture of non-standard products. Often models assembled on their own are many times superior to ready-made analogues. We invite you to get acquainted with ideas that you can implement with your own hands.

LEDs can be used in various applications

Current stabilizer for LEDs

The voltage stabilizer can be manufactured in the following sequence:

| Photo | Description of work |

| We prepare the necessary materials, equipment and tools. You will need a soldering iron, pliers and wire. | |

| Having previously cut off the excess length from the elements used, we tin the legs of the microcircuit. | |

| Solder the “-” diode to the left leg of the microcircuit. | |

| We solder the 100/16 capacitor “+” to the right leg of the microcircuit and “-” to the central leg. | |

| We solder the 300/16 capacitor “+” to the left leg of the microcircuit and “-” to the central leg. | |

| We solder the input contacts. |

We make DRLs from LEDs

You can make daytime running lights yourself if you want to increase the visibility of your car during the daytime. For this, 5-7 LEDs of 1 or 3 W are used for each block and aluminum board. The elements are fixed to the base using heat-conducting glue.

DIY DRL for Niva

Flashing LED Assembly

The assembly of a flashing LED is carried out according to various schemes. Depending on the goals pursued, you can choose plain elements or different colors. Most often, the “Darlington pair” principle is implemented, which involves alternate charging and discharging of two capacitors, with sequential energy transfer from one diode to another.

Flashing LED, assembled on your own

Light music with LEDs

Using LEDs, you can create light music that will add festiveness. The figure shows a detailed diagram that will allow you to achieve the desired result. The microphone included in the circuit is a source of electrical signal that converts sound. It is worth paying attention to the ultra-bright 3 volt LEDs.

The simplest light and music circuit

LED voltage indicator

You can assemble the voltage indicator yourself, following the diagram shown in the figure. This will require a number of resistors, transistors, LEDs and power supplies. If assembly is completed correctly, a green light will light up when voltage is applied, and a red light will light up when dropped.

A circuit that allows you to assemble a voltage indicator

Kinds

There are several types of high-brightness LEDs. They differ by the name of the manufacturers of these devices or by the type of installation on the supporting surface:

- Epistar. The name of these products comes from the name of the Taiwanese manufacturing company. These are compact, high-quality, ultra-bright LEDs that have a long service life. Widely used in various fields of lighting technology;

- Cree. Such lamps are the brainchild of an American company of the same name. LEDs are characterized by low energy consumption, long service life and high quality. This is the reason Cree elements are expensive;

- SMD. The name means the mounting method - directly on the supporting surface (surface mount device). This group of devices is the most common and extensive. Consists of elements in PLCC housing of various series - LN, LA, LN, LP, etc.

- STD. Standard and well-known round or oval signal-type LEDs. Series - 374, 503, 4SM, 5SM, etc.;

- P4 (Piranha). An LED resembling the shape of an SMD housing, but raised above the surface of the supporting plane to increase ventilation and heat dissipation. Series - P41, P42, P43.

LED connection diagrams

When starting to connect LEDs, you should follow certain rules. You should stick to the diagram, since the current moves in one direction.

LED resistance calculation

To find out how to calculate the resistance for an LED, just remember Ohm’s law, which describes the dependence of the desired parameter (R) on the value of current (I) and voltage (U): R = U/I. If you need to connect a 3 V LED, designed for a current of 0.02 A, to a 5 V power supply, you will have to remove the extra 2 V by including a resistor with a sufficient resistance of 100 ohms in the circuit.

Ohm's law will help you calculate voltage

Sometimes, based on the calculation results, it may turn out that the LED resistance should be increased by a non-standard value by purchasing a resistor with the nearest higher resistance value than required. The luminous flux emitted by the device will decrease slightly, although this will not be noticeable visually.

Connection diagram for LED to 220 V network

The power source used determines the selection procedure for connecting the LED to a 220V network. Possible use:

- Current limited drivers. The current strength is calculated in advance. In this case, you can dispense with the resistor. The number of connected resistors depends on the characteristics of the driver;

- Special voltage stabilizer.

Connection diagram for 220 V

Parallel and serial connection

LEDs can be connected in series or in parallel. In the first case, the required voltage will be equal to the sum of the voltage drops of each element. When connected in parallel, the current values are added together. When using devices with different parameters, the characteristics are calculated for each resistor separately.

Serial and parallel connection option

Connecting LEDs to 12 V

Connect the LED in the following sequence:

| Photo | Description of work |

| We calculate the resistance of the resistor. | |

| We solder a resistor with a resistance equal to or greater than the calculated value to the cathode of the diode. | |

| We connect the LED to the power source and check its functionality. |

Thus, it is not difficult to understand the characteristics of LEDs 3 W or more, as well as install them yourself.

Characteristics:

- Rated power: 3W

- Color temperature: 2900K

- Voltage drop: 3.0 - 3.7 V

- Maximum current: 750 mA (voltage 3.5 V);

- Recommended Power Mode: 600 mA (voltage drop 3.4 Volts)

- Light output: 220 - 240 lm

- Voltage at current: 3.1V (300mA), 3.3V (500mA), 3.4V (600mA), 3.5V (700mA)

Spectrum and phased array test.

(Read more about these indicators): Measurement of spectral characteristics: