51

Isolating the foundation from groundwater and precipitation significantly increases the service life of the building. Production offers a wider choice than polyethylene or roofing felt. Waterproofing TechnoNIKOL produces all possible types of insulating materials that are easy to use. No knowledge or skills are required to work with such raw materials; the finished coating is effective protection.

Types of insulation raw materials

Types of waterproofing work with base

The complexity of the work depends on the type of insulation. There are several options for moisture protection. All materials for moisture rejection are divided into two large categories: vertical and horizontal.

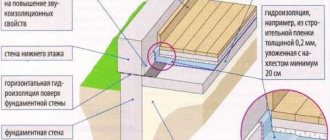

Vertical raw materials effectively protect the walls of the base, on which other materials will not hold. Horizontal products prevent contact of concrete with water on the lower and upper sides of the pour - the material is covered before concreting and covered on top after it.

Products differ in the method of application. First, you need to accurately determine the degree of protection, the number of layers, and depth. A combination of two different types of coating is possible.

The method of use can be cold or hot and is directly related to what type of mastic is used. The cold mixture is sold ready for application, while the hot mixture will have to be heated to 60-70 degrees.

You can take self-adhesive materials, on the back side of which a layer of bitumen mastic is applied. You will need a gas burner, which will be used to inject the adhesive layer before fastening.

The penetrating composition is created in a very liquid form and is designed to saturate concrete, fill concrete capillaries, preventing water absorption.

Painting or plastering compositions help simultaneously solve two problems at once - moisture resistance and decorativeness of the coating. Both options are more often used for interior work, for example, in the kitchen or bathroom.

Injection waterproofing belongs to the category of effective measures; it involves the introduction of a liquid substance through a construction syringe, which allows the desired degree of penetration to be achieved.

The material being mounted is the densest coating, which will require fastening systems, otherwise no adhesive will hold such a weight. Suitable for areas with high groundwater levels.

Characteristics and application of “hot” and “cold” mastic

Hot and cold applied coating materials produced by the company have the following physical and chemical characteristics:

- Cold applied mastic MGTN No24 – maximum shear force is 2 kN/m, adhesion strength is at least 0.1 MP, moisture absorption in 24 hours is 0.4%, temperature withstand is 80 degrees. The material consumption for processing one square meter is one kilogram. Packaging containers in the form of buckets with a volume of 3, 10 and 20 liters.

- Ready-to-use mastic TECHNOMAST No. 21 - adhesion to a concrete base of at least 0.6 MP, maximum shear force - 4 kn/m, moisture absorption in 24 hours - no more than 4%, withstand temperature - 110 degrees.

- Mastic No33 applied by cold spray - adhesive force - 0.6 MP, moisture absorption - no more than 4%, temperature withstand - 140 degrees.

- Hot applied mastic EUREKA No41 - withstand temperature - 105 degrees, adhesion to concrete base - no less than 0.8 MP, maximum shear force is 4 kn/m.

- Hot applied bitumen waterproofing AquaMast - adhesive strength - no less than 0.1 MP, moisture absorption - no more than 1% in 24 hours, temperature withstand - 80 degrees.

The foundation is cleaned and primed

Before applying coating materials, the surface to be treated is cleaned and primed with a primer. The protective coating when using hot-applied materials has good performance characteristics, but the operating technology is more complicated than when using “cold” mastics.

Range of waterproofing materials

produces insulation for different purposes and for different budgets.

There are standard professional products used by construction organizations - rolled, membrane PVC materials; heat and sound insulation; mastics; primers; foam, film coatings.

Retail items - materials for roofing, flooring, and walls of a house to protect the building from water, noise, and cold. They are easy to use, undemanding in the use of equipment and complex technologies. Suitable for self-construction of a private house or cottage.

Approximate range of finished products

The high-quality line with the “Premium” brand is made from the highest quality raw materials, which significantly improves the technical characteristics of the insulating components and increases the service life. The category includes rolls, PVC membranes, polymers, mastics, PIR.

The “Architect” line is decorative materials for building cladding, created from environmentally friendly natural components. The products are both a protective and a facing coating and differ in color and design of details.

The “Special” marking is used for a line of products for working with large industrial enterprises, roads, bridges, and other road transport and architectural objects. The products are characterized by increased parameters of resistance to abrasion, freezing, wear, moisture, ultraviolet radiation, and other destructive factors.

Areas of use

TechnoNIKOL is used for waterproofing the roof of a building and foundation.

To protect the base, a roll or paste type of product is used, but the final choice depends on the goal - simply block the concrete pores, or allow the composition to penetrate inside to block moisture.

The inconvenience of working with rolls is that the cuts need to be overlapped; it is better to immediately glue all joining edges with mastic. It will be necessary to install a finishing material that will protect TechnoNIKOL from mechanical damage - even a slight cut of the coating will compromise the integrity of the canvas.

Paste is more appropriate, the substance penetrates into the structure of the main surface, can be used as a finishing coating, and isolates inconvenient areas that cannot be covered with a roll.

Waterproofing the foundation with rolled materials - once and for all!

TechnoNIKOL foundation waterproofing - overpriced or a reasonable investment? If you are planning to build in the near future or have already started construction, the information from this article will help solve the problem of choosing an insulating material for the foundation. Waterproofing the foundation and floor of basements is one of the most important tasks in multi-story construction and the construction of individual cottages. The first thing we will talk about in this article is TechnoNIKOL roll waterproofing.

Roll insulation

TechnoNIKOL in roll format differs in technological features.

The foil layer of aluminum and polyester is characteristic of the Alpha brand, which stops water, radioactive or explosive substances in the form of gas.

Coating on a roll

Self-adhesive products are called “Barrier” and are suitable for exterior and interior use. "Barrier-Light" can only be used at temperatures not lower than +5 degrees, and the outer surface is covered with non-woven polypropylene.

Technoelastmost is suitable for situations where increased load occurs - the insulation holds its shape well, regardless of the influence of high pressure. Used as a horizontal covering for foundations.

The EPP material can be placed as desired - vertically or transversely, since the installation uses fusing technology. High-strength insulation withstands pressure up to 0.2 MPa.

Waterproofing the foundation with TechnoNIKOL roll materials

Roofing in rolls TechnoNIKOL TECHNOELAST BARRIER BO Roll roofing TechnoNIKOL TECHNOELAST BARRIER BO is a gyro-insulating self-adhesive material. The material is made by applying bitumen binder to a dense polymer film; on the other hand, the adhesive layer is protected by a siliconized film.

TECHNOELAST BARRIER is designed for waterproofing interior spaces:

- bathrooms;

- showers;

- swimming pools;

- car washes.

If you need a polyester-based material, but with slate topping, we recommend paying attention to LINOKROM EKP.

Advantages:

- tear-resistant;

- elastic and flexible (no base);

- can be installed in a closed space;

- no hot work;

- Laying on flammable substrates is possible.

Top side coating material: Polypropylene Spunbond Purpose: Waterproofing Area of material in packaging, m²: 20.0 Service life, years: 45 Heat resistance, °C: 85 Type: Bitumen-polymer Type of top side coating: Film Type of coating of the surfaced side: Film Width, mm : 1000

Packaging and storage Waterproofing material of the BARRIER series is produced in rolls measuring 20x1 m and weighing 30 kg. The product should be stored indoors, protected from direct sunlight, at temperatures from -15 0C to +30 0C.

Roll roofing material Technoelast EPP Roll material Technoelast EPP is developed on the basis of polyester, impregnated on both sides with bitumen binder. The composition of the polymer-bitumen binder includes SBS-modified bitumen and various fillers. Both sides of the material are protected with film to prevent the material from sticking together during storage and transportation.

Technoelast EPP, sold at a competitive price in our online store, is used to install the bottom layer of roofing carpet. The material is mounted by fusing onto the base or onto previous layers.

You can get acquainted with other materials for laying multi-layer roofs in the category Rolled roofing materials

Advantages:

- does not rot;

- possibility of laying material at low temperatures (down to -25);

- material thickness – 4 mm;

- provides a service life of more than 25 years.

Breaking force in the transverse direction, N/50 mm: 400.0 Breaking force in the longitudinal direction, N/50 mm: 600.0 Service life, years: 25.0, 30.0 Flexibility temperature on the beam R=25mm, °C: -25.0 Heat resistance, °C: 100.0 Type: Bitumen-polymer Type of coating on the top side: Film Type of coating on the surfaced side: Film Thickness, mm: 4.0 Width, mm: 1000

Packaging and storage Roofing material Technoelast EKP can be purchased at a competitive price in our online store. It is supplied in rolls measuring 1x10 m. One product unit weighs at least 46 kg. Products should be stored indoors, away from direct sunlight and away from heat sources. Storage in two tiers on wooden pallets in a vertical position is allowed.

TechnoNIKOL foundation waterproofing is a material popular among builders, designed to protect the foundation from the destructive effects of soil water. A distinctive feature of the company's products is their high quality and performance characteristics. It is presented in a wide range on the market. This allows you to select the optimal insulation option for a wide variety of structures located in different types of soil with different levels of moisture saturation.

Coating raw materials

TechnoNIKOL mastic exists in two formats. The difference is the heating temperature of the hot composition - you will need to heat the mixture to 180 degrees. A well-heated paste penetrates into all possible small cracks and envelops the surface of the concrete throughout the foundation.

Liquid sealants and primers

The cold solution is prepared on site. After combining the elements, an activator is added to the mixture. Adhesion to the base will be better if the concrete is pre-treated with two or three layers of primer.

Bitumen mastics No. 21, bitumen-polymer compositions No. 24 are used at temperatures of -20-+40 degrees. The liquid product is easily applied with a roller, brush, sprayer or pour with leveling.

The option is preferable; after drying, a durable protective film remains and there are no seams or joints.

Technology for using cut-off waterproofing "TechnoNIKOL"

TechnoNIKOL foundation shut-off waterproofing is used to protect the walls and partitions of a building structure from the rise of moisture through its capillaries. The product called “TechnoNIKOL-200” is manufactured in the form of conveniently cut rolls and contains polyester and polymer-bitumen binders. The rolled material is laid on bitumen mastic twenty centimeters below the basement floor and at the junction of the surfaces of the walls and the base. The protective coating has excellent performance properties, its service life is about fifty years.

Membrane and shut-off waterproofing "TechnoNIKOL"

Insulation with membrane

When ground moisture lies high or there is a lot of it, protection is used in the form of a drainage system. When assembling drainage, membrane waterproofing is used, which is created on the basis of high-density polymers.

PVC membrane

During the work process, the foundation is partially excavated, dried, covered with a primer and waterproofing, and then a membrane is installed. The purpose of the membrane sheet is to collect excess water and redirect the liquid to the drainage pipes.

The canvas is laid so that the rounded spikes remain outside. The material is resistant to cold down to -50 degrees, durable, however, does not at all interfere with the movement of air flows. Under the shelter, neither concrete nor earth will rot - ventilation proceeds almost as usual.

Purpose of the TechnoNIKOL membrane waterproofing coating

Membrane waterproofing coating is used to protect parts of a building structure buried in the ground from the aggressive effects of soil water. The main purpose of the manufactured special PLANTER Geo membrane is to waterproof the basement floor below the zero level and direct groundwater into the drainage system. This product withstands low temperatures well.

Note: it is especially pleasant to talk about high-quality domestically produced TechnoNIKOL products. We hope you will be able to appreciate it. The following video serves as an excellent addition to the material presented.

Pros and cons of the material

The type of waterproofing is chosen based on different parameters, but if several options are suitable, it is better to consider the advantages and disadvantages of each in order to make a decision.

Decorative products with a waterproofing function are resistant to direct exposure to ultraviolet radiation, dust accumulation, low and high temperatures, and precipitation. Resistance to mechanical damage, high installation speed, and low weight are noted.

Basalt or extruded materials are lightweight, very flexible, environmentally friendly, do not ignite, and do not support combustion. Prices for raw materials are affordable.

The disadvantage of the first type of insulation is instability during periods of sudden temperature changes - the elements change in size, sometimes expanding, sometimes narrowing. They are not suitable for outdoor temperatures above +50 degrees; they cannot be washed with any means - you need to choose the most gentle compositions.

Basalt is hygroscopic, with a heterogeneous structure. Vata gradually loses volume - after 10 years, at best, half of its original size will remain. Changes will lead to the formation of gaps - points of heat loss.

Benefits and methods of applying primer

Bitumen emulsion primers can be used both as independent waterproofing and as a primer for subsequent installation of roll materials. Thanks to the pre-treatment of the base with a primer, reliable adhesion of the rolled material to the foundation or other base is ensured and the protective properties of the material are increased.

The main advantages of primers are the ability to apply them to geometrically complex surfaces and reliable adhesion to the surface of the base. Another advantage is the drying speed of the primers, which is about one hour.

The material is applied using a conventional roller or brush.

Surely every person, even those unfamiliar with construction, has ever encountered roofing felt.

Since the times of the Soviet Union, this material remains the most popular when carrying out roofing work and waterproofing structures. Such popularity of the material is due to its low cost.

There are many types of roofing material brands, which differ in characteristics and scope of application.

Brands of roofing felt for foundation waterproofing:

- Rubemast . A type of built-up roofing material, which differs in the thickness of the binder composition and the cardboard base. Rubemast is used for roofing and waterproofing. It is highly resistant to cracking.

- Glass roofing felt. An analogue of rubemast, which is based on special fiberglass, which significantly improves the tensile properties of the material.

- Euroroofing material. It is made on a synthetic base on top of which a layer of polymer bitumen composition is applied. It is used similarly to all materials of this type.

Advantages and disadvantages of roofing felt

The advantages of roofing felt include its low cost and ubiquity. You can buy roofing felt at any construction market and store.

Along with several positive qualities, there are many negative properties of roofing felt that make this material not the best choice for waterproofing the foundation of modern buildings. For example, low strength characteristics and high flammability.

Another not the best property of roofing material is destruction under the influence of sunlight . After prolonged exposure to sunlight, the material becomes brittle and breaks easily.

But despite all this, roofing felt is successfully used as a material for horizontal waterproofing of foundations.

Laying technology using bitumen mastic

One of the common methods of installing roofing felt is to use bitumen mastic as an adhesive.

The mastic is applied to the foundation surface, previously cleaned of dust. After it dries, its top layer is heated using a gas burner and roofing material is laid in parallel.

Features of application

The choice of coverage requires a preliminary analysis of the situation. It is necessary to accurately establish the type of soil in the area, at what depth the groundwater lies, where the freezing line is, how much the soil swells in winter, and what load it can withstand.

If there is still 1 m left from the foundation to the ground moisture, then use coating mastic vertically and rolls horizontally. At a higher location of water, two layers of roll protection are used with mandatory gluing with mastic, but only in a dry basement. The side edges are sheathed with adhesive insulation.

An increased water level requires waterproofing from the outside, inside the structure, the fasteners are treated with anti-corrosion agents. Wooden elements are impregnated with antiseptics.

A detailed description of the principles of working with TechnoNIKOL can be viewed in the following video:

Waterproofing thickness

On the issue of the number of layers, it is advisable to consult a specialist (the water content of the areas is different). Material manufacturers also provide useful recommendations. Some general rules:

- hot mastic is applied in a layer of 2 mm;

- cold – 1 mm is enough;

- in private buildings, if the foundation depth is within 3 meters, the pasting can be done in two layers 4 mm thick;

- if the area is heavily watered, the number of layers is increased to 5.

It is not recommended to compensate for the number of layers by choosing a thicker material: it has lower ductility, it is more difficult to work with, and you will have to invite specialists.

Sectional view of the foundation

Foundation insulation

In addition to insulating from moisture, it is better to immediately insulate the foundation. Almost certainly, after the first winter, the owners will decide to cover the base with insulation - heat losses are at least 10% in the absence of a coating.

TechnoNIKOL insulation materials

TechnoNIKOL brand insulation is frost-resistant insulation with minimal hygroscopicity, steam absorption, and resistance to mechanical loads.

Products made from polystyrene foam and polyurethane foam are suitable for external cladding. The latter type of thermal insulation is recommended due to the peculiarities of the structure: foam material is sprayed onto the base, so seams and cold bridges are eliminated.

Welded waterproofing: price per 1 m2

| An object | Price |

| foundation | from 700 rub/m2 |

| roof | from 700 rubles per 1 m2 (depending on the condition of the roof) |

Price for work + material | |

| Bipole | 820 rubles per 1 m2 |

| Uniflex | 880 rubles per 1 m2 |

| Technoelast | 995 rubles per 1 m2 |

Minimum volume - 50 m2 | |