Properties of Portland cement

The most important technical characteristics of Portland cement include density, fineness of grinding, water requirement, setting time, strength and corrosion resistance.

The true density p of cement ranges from 3.05...3.15 g/cm3. On average, p=3.1 g/cm3 is taken.

The bulk density of the pH powder depends on the degree of compaction. For loosely poured cement it is 1.1 g/cm3, for highly compacted cement it is 1.6 g/cm3. In calculations, the value pH = 1.3 g/cm3 is taken.

The fineness of cement grinding has a great influence on its hardening speed and strength. The fineness of Portland cement grinding is characterized by its grain composition and specific surface area. The grain composition is determined by sifting a cement sample through a sieve with very fine cells - 0.008 mm (80 microns). The main part of the sample (at least 85%) must pass through such a sieve. This means that modern Portland cement is very finely ground, i.e. its grain size is on average 20...40 microns. The specific surface of such cement is 2500...3000 cm2/g. The industry produces special cements and finer grinding.

The water requirement of cement reflects the ability of its particles to adsorb, i.e. absorb, a certain amount of water on the surface. The density of Portland cement grains is 3.1 g/cm3, water - 1 g/cm3. If you mix the cement with an excessive amount of water, then only some of it will be retained by adsorption and capillary forces. Under the influence of gravity, cement particles settle and water is forced upward. The dough begins to separate, which leads to the release of excess water on the surface of the concrete mixture or solution. The phenomenon of water separation is extremely undesirable, since water, accumulating on the upper surface of the structure, makes the concrete loose and porous. Subsequently, concrete is most intensively destroyed in these places.

The water requirement of cement is characterized by the relative amount of water (in%) to obtain cement paste of normal thickness. The water content in a dough of normal thickness corresponds to its maximum amount that cement can hold with the help of chemical and physico-chemical (adsorption and capillary) forces. Since there is no water separation in such a dough, cement dough of normal thickness, rolled into a ball, does not stick to the palm. The water requirement of Portland cement is 22...28%.

The property of water requirement of cement is of great practical importance in the manufacture of concrete mixtures and mortars. By using cements with low water demand, it is possible to produce a concrete mixture with relatively little water consumption. When cured, concrete with high strength and durability is obtained, since its porosity is low. On the contrary, cements with high water demand, in particular pozzolanic Portland cement, in which it reaches 40%, are characterized by high porosity, and concrete based on such cement turns out to be non-frost-resistant.

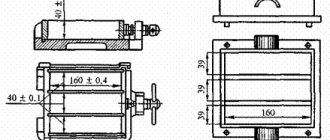

The setting time of cement characterizes the period of time during which the plastic properties of the cement paste change intensively. There is a distinction between the beginning and the end of setting. In a construction laboratory, the setting time of cement is determined using a Vicat device by the depth of immersion of a standard steel needle with a diameter of 1.13 mm into the cement paste. The beginning of setting is considered to be the period of time from mixing the cement with water until the moment when the needle, under the influence of gravity, can no longer be completely immersed in cement paste of normal thickness (does not reach the bottom of the device by 1... 2 mm). The end of setting is counted by the time elapsed from mixing until the moment when the Vicat needle is only slightly, 1...2 mm, immersed in the hardened dough or stone.

At a construction site, you can determine the setting time of cement in a simplified way. To do this, light cuts are made on the cement paste every 5 minutes with a steel knife. The beginning of setting corresponds to the moment when the cuts stop floating. Continuing to make light cuts without pressure at intervals of 15 minutes, you will notice when the knife stops leaving a mark on the surface of the cement stone. This will be the end of the setting.

In accordance with the requirements of GOST 10178-85, the beginning of setting of Portland cement should occur no earlier than 45 minutes after mixing, the end of setting - no later than 10 hours. The setting time of Portland cement is regulated by introducing the addition of gypsum. The setting speed of cement is affected by the temperature and water content of the dough. As the temperature rises, the setting time is reduced. Therefore, for concrete work in dry, hot weather, cement is used, the beginning of setting of which occurs no earlier than 1.5 hours after mixing. If the mixture is laid after the beginning of setting, then, having lost its plasticity, it will be deformed during laying with a violation of the continuity of the structure. As a result, breaks, cracks and other defects of mechanical origin form in the concrete body, which will negatively affect the strength and durability of the structure.

It is also important to ensure specified setting times when transporting concrete mixtures by concrete trucks, mobile concrete mixers, or pumping with concrete pumps. Premature setting can lead to equipment failure, and time will be wasted in bringing the installations into working order.

The setting time increases if more water is taken to mix the cement. With its excess, the volume of space in the dough increases, which must be filled with new growths. The strength of cement stone is formed at the moment when crystalline hydrates form a spatial continuous structure. To form such a structure with a larger volume of space requires more time.

It is irrational to increase the amount of water in the dough or concrete mixture in order to extend the setting time, since the strength of the hardened stone (concrete) decreases the more water is added. It is advisable to use special additives for this - set retarders.

In the practice of concrete work, false setting of cement is sometimes observed, i.e. thickening of the cement paste or concrete mixture in a time much shorter than that provided for by the standard (before 45 minutes). This is explained by the fact that the composition of such cement includes semi-hydrous gypsum, and not gypsum stone. Semi-aqueous gypsum quickly interacts with water, forming a spatial low-strength structure, which leads to loss of plasticity of the cement paste within 10...20 minutes after mixing. With subsequent mixing, especially with a small addition of water, the dough regains its plasticity and hardens as usual.

To prevent false setting, grinding and storage of cements is carried out at low temperatures. During concrete work in the hot season, the maximum cement temperature should be no more than 50 °C.

Strength is the main characteristic of cement as a material for the manufacture of concrete and reinforced concrete structures. To evaluate it, a standard characteristic of cement is used - grade. To determine the brand of cement, prepare a mixture of cement and standard quartz sand in a ratio of 1:3 by weight. Mix this mixture with water, which is taken in an amount of 40% by weight of cement. Prismatic samples (beams) measuring 40X40X160 mm are made from the mixture. The first day after production, the beams harden in humid air, and then for 27 days - in water at room temperature. After 28 days, the beams are tested for bending, and the resulting halves of the beams are tested for compression. When tested, a wide variety of strength indicators are obtained. For example, the compressive strength of samples may be equal to 40; 41.2; 43; 46 MPa, etc. These numbers, characterizing the strength, are called the activity of cement.

The infinite variety of strength values, and therefore activity, makes it difficult to compare different cements. Therefore, the strength of cement is assessed using grades. The grade of cement is a conditional characteristic, numerically equal to the minimum compressive strength of standard samples. For example, cement grade 400 means that its compressive strength is guaranteed to be at least 400 kgf/cm2. If the tests obtained strength values greater than 400 kgf/cm2 (up to 500), the grade of cement will still be 400. Standard grades of Portland cement have been established from 400 to 600 (Table 10). The higher the grade, the more durable the stone is formed when the cement hardens.

The strength of cement under appropriate environmental conditions increases over time (Fig. 25). The normal hardening conditions for cementitious materials (mortar and concrete) are:

temperature about 20°C and relative humidity 95-100%. As the temperature drops, the chemical reactions between cement and water slow down. This is expressed in a lack of strength (compare curves 1 and 2). To accelerate hardening, concrete products are treated with saturated steam at a temperature of 60...90°C. Steaming makes it possible to obtain in 10…12 hours the stripping strength of concrete, which is 70% of the design 28-day strength (curve 3). Heat treatment of products must be carried out under conditions that prevent drying of concrete, since water is necessary for the synthesis of crystalline hydrates of cement stone. .

An increase in strength over time is an important property of cement and materials based on it. This makes cement materials fundamentally different from other stone materials - natural (granite, limestone) and artificial (ceramics, glass), whose once formed strength can only decrease over time under the influence of destructive environmental factors.

Under favorable hardening conditions, cement continues to hydrate. As a result, the volume of the crystalline intergrowth of hydrate new formations increases, and the volume of spaces between them, on the contrary, decreases. Thus, the physical reason for the increase in strength is associated with a decrease in the porosity of the cement stone. By reducing porosity, its strength can be significantly increased. Thus, by hot pressing at a temperature of 250 °C and a pressure of 350 MPa in laboratories, cement stone with low porosity (only 2...4%) and very high strength is obtained - after 1 day Yaszh - = 412 MPa, after 90 days - 655 MPa. This is more than 10 times higher than the highest strength of cement (60 MPa) and concrete (60.80 MPa) obtained in standard tests. Consequently, the astringent properties of cement are far from being fully used.

Rice. 25. Curves for the growth of cement strength over time: 1 - hardening at a temperature of 5 °C, 2 - normal hardening at 20 °C, 3 - steaming at 85 °C

Due to the developed system of pores and capillaries, cement stone is relatively easily permeable to water, aggressive liquids and gases, which can cause its corrosion.

The corrosion resistance of cement stone is characterized by its relationship to chemical influences, which are divided into three main types.

Corrosion of the first type is associated with the decomposition of new formations of cement stone, dissolution and leaching (leaching) of Ca(OH)2 from it. This corrosion develops most intensively in soft waters (rain, melt) containing a small amount of salts. Under the influence of soft water penetrating into concrete, the least stable compound Ca(OH)2 dissolves. Following this, calcium hydrosilicates and hydroaluminates decompose. The most effective means of combating leaching is the introduction of additives into the cement composition that bind Ca(OH)2 into more stable compounds. Such additives, called active minerals, will be discussed in § 25.

Corrosion of the second type is caused by the interaction of Ca(OH)2 and other components of cement stone with aggressive substances in the external environment. As a result, easily soluble compounds are formed that are washed out of the cement stone, thereby weakening it. This type includes, for example, acid and magnesium corrosion.

Free acids are found in industrial wastewater. An acidic environment can also occur when moisture condenses on the surface of structures if the atmosphere contains aggressive substances - chlorine, hydrogen chloride, sulfur dioxide. This atmosphere is typical of modern industrial centers. The acid entering the concrete interacts with Ca(OH)2. The resulting calcium chloride easily dissolves in water and is washed away.

Corrosion of the third type is characterized by the fact that as a result of interaction with the environment, new solid-phase compounds appear in the pores of the cement stone, the volume of which is much greater than the volume of the initial reaction products. The crystals of these compounds, increasing in volume, put pressure on the pore walls, causing large internal stresses and cracking of the loaf.

This type of corrosion most clearly manifests itself when cement stone is exposed to sulfate water (sulfate corrosion). The likelihood of sulfate corrosion is taken into account during the construction of offshore hydraulic structures and the construction of building foundations in areas where groundwater contains sodium or calcium sulfates. In these cases, sulfate-resistant Portland cement is used.

Read more: Aluminous and expanding cements Cements with mineral additives Special types of Portland cement Setting and hardening of Portland cement Production of Portland cement Inorganic binders Various materials for plastering work Aggregates for plastering work Binders for plastering work Expanding cements

Specifications

Portland cement must comply with the following technical conditions:

- Depending on the goals, the composition of slag granules (formed by the electrothermometamorphic or blast furnace method) is 20-80%.

- The magnesium content in clinker should not exceed 5-6%, so as not to reduce the quality of concrete.

- Pure natural gypsum is added, with the addition of fluorine and phosphorus, not exceeding 5% of the clinker volume.

This material is divided into 2 types according to the speed of hardening:

- hardening at medium speed;

- quick-hardening when accelerators, mineral and volcanic additives are added - pumice, ash.

The composition of this concrete:

- slag - 5 parts;

- cement - 2 parts;

- sand - 2 parts.

The strength of hardening concrete appears after 1-2 weeks. In cool conditions, the hardening process takes longer. Therefore, heat guns or other devices are used to accelerate it.

When using heating agents, sufficient strength is achieved within a month. The more slags in the composition, the slower the mixture hardens.

The shelf life of Portland cement with slag is much lower than that of conventional dry cement mixture. The maximum shelf life from the date of production is up to 45 days.

Expired building materials are not suitable for use , because then the water resistance and strength of the concrete produced from this mixture are reduced.

What is the difference between Portland cement and Portland slag cement? These two materials differ markedly in many respects:

- Portland cement with slag is much cheaper than usual;

- the material containing slag is less dense and structures made from it are much lighter;

- slag-containing concrete becomes strong more slowly than ordinary Portland cement (after about 20 days);

- The slag-containing concrete mixture heats up less during the exothermic reaction during hardening, which complicates work at low temperatures.