Production process[ | ]

Portland cement is produced by finely grinding clinker and gypsum. Clinker is a product of uniform firing before sintering a homogeneous raw material mixture consisting of limestone and clay of a certain composition, ensuring the predominance of calcium silicates (3CaO∙SiO2 and 2CaO∙SiO2 70-80%).

The most common methods for producing Portland cement are the so-called “dry” and “wet”. It all depends on how the raw material mixture is mixed - in the form of aqueous solutions or in the form of dry mixtures.

When grinding clinker, additives are added: 1.5...3.5% gypsum CaSO4∙2H2O (in terms of sulfuric anhydride SO3) to regulate setting times, up to 15% active mineral additives to improve some properties and reduce the cost of cement.

The raw materials for the production of Portland cement are mixtures consisting of 75...78% limestone (chalk, shell rock, limestone tuff, marble) and 22...25% clays (shales, loams) or limestone marls, the use of which simplifies the technology. To obtain the required chemical composition of raw materials, corrective additives are used: pyrite cinders, flue dust, bauxite, sand, flasks, tripoli.

With the wet production method, energy consumption for grinding raw materials is reduced, transportation and mixing of the raw material mixture is facilitated, sludge homogeneity and cement quality are higher, however, fuel consumption for firing and drying is 30-40% more than with the dry method.

The firing of the raw material mixture is carried out at a temperature of 1470 for 2-4 hours in long rotary kilns (3.6×127 m, 4×150 m and 4.5×170 m) with internal heat exchange devices to simplify the synthesis of the necessary minerals of the cement clinker. Complex physical and chemical processes occur in the fired material. A wet-process rotary kiln can be roughly divided into zones:

- drying (material temperature 100...200 °C - partial evaporation of water occurs here);

- heating (200...650 °C - organic impurities burn out and the processes of dehydration and decomposition of the clay component begin). For example, the decomposition of kaolinite occurs according to the following formula: Al2O3∙2SiO2∙2H2O → Al2O3∙2SiO2 + 2H2O; further, at temperatures of 600...1000 °C, aluminosilicates decompose into oxides and metaproducts.

- decarbonization (900…1200 °C). In this zone, decarbonization of the limestone component occurs: CaCO3 → CaO + CO2, while the decomposition of clay minerals into oxides continues. As a result of the interaction of basic (CaO, MgO) and acidic oxides (Al2O3, SiO2) in the same zone, processes of solid-phase synthesis of new compounds begin (CaO∙Al2O3 is an abbreviated form of SA, which at higher temperatures reacts with CaO and at the end of liquid-phase synthesis is formed C3A), proceeding in steps;

- exothermic reactions (1200...1350 °C). In this zone, the process of solid-phase sintering of materials is completed, here the process of formation of such minerals as C3A, C4AF (F - Fe2O3) and C2S (S - SiO2) - 3 of the 4 main clinker minerals - is completely completed;

- sintering (1300→1470→1300 °C). In this zone, partial melting of the material occurs, clinker minerals pass into the melt except for C2S, which, interacting with the CaO remaining in the melt, forms the mineral ALIT (C3S);

- cooling (1300…1000 °C). Here the temperature is slowly dropping. Part of the liquid phase crystallizes with the release of crystals of clinker minerals, and part freezes in the form of glass.

You can recognize this type of cement by its appearance - it is a greenish-gray powder. Like all cements, if water is added to it, it dries into a stone-like state and does not differ significantly in its composition and physical and chemical properties from ordinary cement.

Maximum concentration in air (according to GOST 12.1.005-88): 6 mg/m3

The following types of Portland cement exist:

- fast-hardening;

- normal hardening;

- plasticized;

- hydrophobic;

- sulfate-resistant;

- road;

- white and colored;

- with moderate exothermia;

- with surfactant organic additives.

Cement activity

Then, using a caliper or metal ruler, measure the diameter of the cone along the lower base in two mutually perpendicular directions and take the average value.

The consistency of the solution is considered normal if the spread of the cone is 106...115 mm. If the cone spread is less than 106 mm or the solution crumbles when shaken, prepare a new portion of the solution, increasing the amount of water until a cone spread is 16...115 mm. If the cone spread is more than 115 mm, then the test is repeated with less water, achieving a spread of 106...115 mm. The water-cement ratio obtained when the cone spread reaches 106...115 mm is accepted for further testing. The error in determining W/C is no more than 0.01.

Rice. 4.6. Form for sample beams (c) and attachment for it (b)

Making samples. The detachable molds in which the samples are made are designed for three samples (Fig. 4.6, a). The mold parts are made of steel or cast iron with a Brinell hardness of at least HB140. The longitudinal and transverse walls of the molds, fastened with a clamping screw, are polished and fit tightly to the polished surface of the pallet.

Before filling the mold with the mortar mixture, its internal surfaces are lightly wiped with machine oil, and the joints of the outer walls with the pallet and one with the other are lubricated with technical petroleum jelly. A metal nozzle is installed on the mold (Fig. 4.6, b), which facilitates laying the solution. After this, the form is rigidly fixed in the center of the vibrating platform.

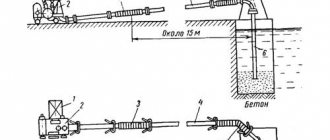

The vibration platform (Fig. 4.7) consists of a frame to which a frame with a platform installed on it is attached by springs. The oscillatory movements of the platform are created by an electric motor attached to it, on the shaft of which there is an unbalance (a load is eccentrically fixed).

The mold is filled approximately 1 cm with the solution and the vibrating platform is turned on. Then, during 2 minutes of vibration, all three cavities of the mold are filled evenly with small portions of the solution. After 3 minutes from the start of vibration, the vibrating platform is turned off and the mold is removed from it. Next, cut off the excess solution with a knife moistened with water, smooth the surface of the samples and mark them.

Samples in forms are stored for (24 ± 2) hours on table 3 in a bath with a hydraulic seal (Fig. 4.8). The samples are then carefully unmolded and placed horizontally in a bath of water so that they do not come into contact with one another. The water, which should cover the samples by at least 2 cm, is changed every 14 days. The water temperature throughout the storage period should be (20 ± 2) °C.

Rice. 4.7. Laboratory vibration platform: 1 – bed; 2 – electric motor; 3 – platform; 4 - frame; 5 - springs

Rice. 4.8. Bath with hydraulic seal: 1— bath; 2 - sealed lid; 3 - table

Rice. 4.9. Layout of sample beams on supporting elements

Samples, the strength of which after 24 hours is not sufficient for unmolding without damage, may be removed from the molds after 48 hours with a note about this in the work log.

After the storage period has expired, the samples are removed from the water and tested no later than 1 hour later.

Immediately before testing, the beam samples are wiped dry and tested for bending, and then each of the resulting beam halves is tested for compression.

When testing aluminous cement, samples in the mold are stored for the first 6 hours in a bath with a hydraulic seal, and then in water at room temperature. After (24 ± 2) hours from the moment of production, the samples are removed from the mold and some of them are tested, and the remaining ones are stored in water until subsequent tests after 3 days.

Determination of bending strength. This test is carried out on machines (clause 3.9) that provide an increase in load on average (50±10)N per second. The sample is placed on the supporting elements of the machine in such a way that its horizontal edges are in a vertical position in the machine during manufacturing (Fig. 4.9). Testing of samples and calculation of the bending strength are carried out in accordance with the instructions supplied with the testing machine. The flexural strength of the tested cement is calculated as the arithmetic mean of the two highest values of the test results of three samples.

Determination of compressive strength. The six halves of the beams obtained after the bending test are immediately subjected to compression testing on presses with a maximum load of 200...500 kN.

Rice. 4.10. Compression testing of beam halves: a - plates; b - test diagram; 1 - plates; 2, 4 — press plates; 3 – sample (beam)

In order for the test results of the beam halves to be comparable, despite the different sizes, metal plates are used (Fig.

4.10, a), through which the load from the press plates is transferred to the sample. The plates, made of stainless steel, have a flat polished surface; the surface area of the plate in contact with the sample is 25 cm2.

Half of the beam is placed between two plates (Fig. 4.10, b) in such a way that the side faces, which during manufacturing were adjacent to the longitudinal walls of the mold, are on the planes of the plates, and the stops of the plates fit snugly against the smooth end face of the sample. The sample together with the plates is centered on the base plate 4 of the press. The average rate of increase in load on the sample during testing should be (5 ± 1.25) kN per second.

The compressive strength of cement is calculated from the results of six tests as the arithmetic mean of the four highest results. The value obtained in this way is called the activity of the cement.

Determination of cement grade. The grade of cement is determined by determining the strength limits of cement in compression and bending, comparing these results with the GOST requirements for the corresponding cement.

Determination of cement strength during steaming.

Concrete and reinforced concrete products are manufactured by accelerating the hardening of concrete through its heat and moisture treatment (steaming). Therefore, GOST 10178-85 provides for determining the strength of cement during steaming. Samples for this test are prepared in the same way as for standard determinations, but their hardening proceeds according to a special regime. Forms with samples for hardening are placed in a steaming chamber at a temperature of (20±3)°C with heating turned off for (120±+10) minutes.

Similar articles: Uniformity of changes in cement volume

Navigation: Home → All categories → Cement

Notes[ | ]

- ↑ 1234

https://www.cdc.gov/niosh/npg/npgd0521.html - Portland cement market in Russia 2020: Coronavirus restrictions led to the loss of a fifth of output (Russian). Marketing Agency ROIF EXPERT

. Retrieved June 30, 2020. - Portland cement market in Russia: research and forecast until 2024. Issue: June, 2020 - Marketing research: analysis and review, forecast market indicators (Russian). Marketing Agency ROIF EXPERT

. Retrieved June 30, 2020.