Is glassine a vapor barrier or a waterproofer?

When independently building a private house, the owner has to select materials on his own. When it comes to installing a vapor barrier, the owner often wonders whether glassine is suitable for this work, or is it still necessary as a waterproofing material? The answer is quite simple. The material is suitable for both types of work. Using the example of a roofing “pie,” you can see that bitumen sheeting is used as a vapor barrier for insulation on the side of the room, as well as as waterproofing under the roof covering. There are three schemes for laying the material, where it plays a different role.

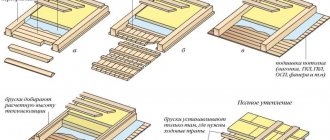

Schemes of roofing “pies”

In this roofing “pie” scheme for a flat roof, glassine is used for vapor barrier:

- concrete floor slabs;

- double layer of glassine;

- thermal insulation layer;

- cement-sand screed;

- roofing covering.

The following scheme involves the use of material as waterproofing for a pitched roof with a cold attic:

- rafters covered with solid wood sheathing;

- double layer of glassine;

- roofing material.

In the latter scheme, glassine serves as a waterproofing and vapor barrier. This “pie” is used for gable roofs with a warm attic:

- internal lining of the attic with gypsum plasterboard sheets;

- rafter system;

- glassine vapor barrier layer on the attic side;

- thermal insulation layer;

- counter-lattice;

- glassine waterproofing layer;

- roofing covering.

From the considered diagrams we can conclude that glassine is not a roofing covering. Although, many are mistaken in these matters and use the material to cover sheds and other outbuildings. Naturally, the result of illiteracy is a leaking roof within a year.

Scope of application of glassine as a vapor barrier material

Before you find out the scope of application of the material, you need to understand two concepts. Vapor barrier and waterproofing are the protection of the thermal insulation layer from moisture. It can exist in two states: as steam followed by the formation of condensate, or liquid. So, a vapor barrier will save you from penetration of vapors into the insulation, and waterproofing prevents the penetration of liquids. As a vapor barrier, bitumen sheet can be used in the following situations:

- The bottom lining layer of the roofing pie.

- Protection of the thermal insulation layer outside and inside the room from condensation. Preventing moisture penetration will extend the life of the insulation.

- Insulation from condensation between chipboard slabs and reinforced concrete base of the building.

- The use of material for packaging metal products prevents the penetration of condensation, which causes corrosion of the metal.

Glassine is well suited for vapor barrier in the construction of winter baths.

But you can’t use it for a steam room. When exposed to high temperatures, the material begins to emit an unpleasant odor containing toxic substances. Glassine is a rolled material and is mostly laid on top of insulation under a solid roof covering, such as slate or tiles. The elastic structure allows the material to be used on pitched roofs. Experts categorically do not recommend using glassine under a soft roof, for example, bitumen shingles. This is due to the difficulty of providing proper insulation in difficult areas such as ridges or valleys. Also, poor fastening of the substrate to the base will lead to the tiles slipping along with the vapor barrier. Wooden structures are covered in places of contact with concrete or soil. This protects the wood from rotting. A vapor barrier between two surfaces of dissimilar composition prevents the formation of condensation. It turns out that glassine is used more as a vapor barrier. It is vital to protect and increase the service life of the thermal insulation layer.

Areas of use

Thanks to its improved technical characteristics, lining glassine is used in the following areas:

- Construction of all-season baths and saunas. When used with mineral wool or other heat insulator, it is mounted on the base of the log house. Provides protection for the bathhouse from cold penetration in winter and helps maintain the microclimate in summer.

- Vapor barrier of floors and walls. Suitable for laying on wooden, reinforced concrete, cement, wood-chip base. Construction tape or mastic is used for fastening.

- As a roof vapor barrier. Designed to protect the roof from the penetration of vapors from the inside of the building, it is located in the lower layer of the roofing pie.

- As a roof waterproofing agent. In this case, the material is laid on both sides of the heat-insulating layer, protecting the structure from atmospheric moisture.

Glassine is used not only for roofing - it is good as an insulator for wells, pipelines, foundations, bridges, septic tanks, and floors. Sometimes it is used to form a temporary shelter for stacks of building materials, and also to create packaging containers.

What is glassine and its varieties

Glassine is cardboard impregnated with special bitumen solutions. It is produced according to two standards: GOST and TU. This material differs in cardboard density and roll length. For example, the P-350 brand according to GOST has a density of 350 g/m2 and a web length in a roll of 20 m. The indicators of a similar brand produced according to specifications respectively have 180–200 g/m2×15 m. Naturally, the material produced according to GOST has better characteristics, but its cost is more expensive. At the moment, manufacturers offer three brands:

- P-250 is resistant to moisture for up to 10 hours.

- P-300 will not allow moisture to pass through for 20 hours.

- P-350 has a water absorption level of up to 20% by weight. This material is used to create a vapor barrier during roofing work.

It should be noted that of the presented brands, P-250 is not produced according to GOST at all, and P-350 is no longer produced according to GOST, since the material is considered obsolete and is becoming a thing of the past.

Advantages and disadvantages of the material

Before you decide to use a material to make a vapor barrier, you need to know all its pros and cons.

The material has the following advantages:

- The main advantage that attracts private developers is the low price compared to modern materials intended for these purposes.

- The canvas can be called universal. It is used as a vapor-waterproofing barrier, and installation can be carried out even by an inexperienced builder. Depending on the base, the sheets are secured with staples, gluing or construction tape.

- Light weight does not require reinforcement of the roofing system or the foundation of the building.

- A canvas that has become unusable can quickly be replaced with a new one; of course, to do this you will have to dismantle the top finishing coating.

- It has moderate water absorption and tensile strength.

In addition to many advantages, there are still significant disadvantages:

- Although glassine is moisture resistant, it should not be laid on a wet surface;

- Installation at low temperatures will cause sheets to break;

- Sun rays are detrimental to the structure of the material, so it cannot be used on an open surface;

- High temperatures cause the bitumen impregnation to melt, which is accompanied by the release of toxic substances and an unpleasant odor.

Having weighed all the pros and cons, before using the material, it would not hurt to get additional advice from construction specialists.

Glassine or vapor barrier – which is better to choose?

The desire to live in comfort is human nature. That’s why we try over and over again to improve our homes, to decorate them inside and out, and to protect them from heat and frost. Fortunately, there are no problems with the latter, since the modern building materials market offers customers a wide range of different products, including vapor barrier films. Despite the large selection, some builders and zealous home owners, out of ignorance, habit, or a desire to save money, buy glassine. But is this the right decision? Will the savings turn into even greater waste? Let's try to find out which is better - glassine or vapor barrier.

Glassine

Essentially, glassine is cardboard impregnated with a protective composition with a bitumen base. Depending on the thickness of the cardboard layer, there are several grades of glassine: from 250 to 350. The higher the grade, the greater the weight of the material.

It is used for vapor barrier of outbuildings, sheds, garages, change houses as waterproofing, but only in combination with other protective materials, and also as a substrate for a “soft” roof, as a temporary protective covering.

This material is captivating with its price, as it is somewhat cheaper than budget vapor barrier films and membranes. It is easy to install, has a relatively low weight, if necessary, damaged areas can be easily restored, and has good strength.

However, when purchasing, some people ask themselves: is glassine a vapor barrier or a waterproofing agent? Here the answer lies in the main material of manufacture - cardboard. Whatever the impregnation, the paper remains paper. Therefore, glassine waterproofing is very poor. As well as vapor barrier in wet rooms.

Disadvantages of glassine:

- destroyed by exposure to UV;

- if there is insufficient ventilation, it can cause the insulation to get wet and rot the internal structures;

- flammable material;

- efficiency decreases when installed on a damp base or in bad frosty weather; low temperatures make glassine brittle;

- bitumen impregnation releases toxins into the air, so it is better not to use glassine in residential areas.

Glassine brand P 350

The most dense and durable of the three options. The price, although higher than that of previous representatives, is still acceptable for the buyer. Withstands a force of 25 kgf, and also retains moisture for more than 22 hours.

The denser the glassine cardboard, the more bitumen it absorbs, becoming elastic and durable, and its water-repellent properties increase. Its high strength is due to the fact that it is used as the bottom layer in the roofing structure, which is not susceptible to strong mechanical loads. Glassine (what it is is described above) is distinguished by another property, such as heat resistance. Possessing a high melting point, it easily tolerates summer heat. Due to its elasticity, it is not susceptible to cracking in winter cold. The service life of glassine is at least 10 years. It is very easy to install and can be handled by one person due to its lightness. All these properties can be called advantages. The final chord is its low price, which deprives it of almost all competitors. The most famous glassine is roofing glassine. The company assures that it has brought the material to perfection, endowing it with even better properties than those provided for in SNIPs and GOSTs. Thanks to the high quality that the manufacturer provides glassine, customer reviews of it are only positive.

Despite all its advantages, glassine is not used as a separate element for roofing, since it does not have its own protective layer with which it can protect itself from aggressive environmental influences: precipitation, high and low temperatures, especially from their sudden changes , from direct sunlight, as well as from all kinds of mechanical damage. By studying the technical characteristics of a material such as glassine (what it is, what it is made of), we can formulate the conclusion that its main area of application is the implementation of the hydro- and vapor barrier protective functions of the roof as a substrate. As a rule, glassine is laid on top of the insulation to protect it from moisture and condensation vapors, and then the roofing covering itself is laid, be it slate, metal profiles or tiles. Most often it is used on pitched roofs, due to the fact that it is very elastic, lightweight and has excellent protective properties. Glassine is produced in rolls with a width of 1, 1.025 and 1.05 meters. The weight of 1 roll is 15 kg (20 m2) or 30 kg (40 m2).

Vapor barrier

Specialized vapor barrier films are usually two-layer. They do not allow moisture and water vapor to pass through. When installed correctly, they provide complete tightness. Special reinforcement increases the strength of the films. Some types (for example, foil film) can, in addition, reflect thermal radiation.

The films are environmentally friendly, easy to install, lightweight and affordable. The only thing that is important to know is that the vapor barrier must be laid with the correct side facing the insulation and do not forget about the necessary air ventilation, otherwise condensation will wet the thermal insulation material.

We hope that we were able to convey to you the idea that vapor barrier is much better and more effective than glassine. We will be grateful if you share this article on social networks.

Our services:

- Cesspool for a cottageCesspool for a cottage When you live in a city apartment.

- Aluminum heating radiator Rifar Alum 350 8 sectionsAluminum heating radiator Rifar Alum 350 8 sections The exact cost of work and equipment is specified by the engineer +7 (495) 744-67-74 The cost depends on.

- SRO Pravda MoscowSRO or self-regulatory organization is an association of entrepreneurs or organizations by type of activity. It turned out that for the people.

- What are stormwater treatment plants? Atmospheric precipitation in the form of rain, hail and snow brings with it a large volume of water, which, falling on the ground, often leads to flooding in low-lying areas. In addition, large streams of water flowing down the streets almost always absorb garbage and dirt, which can cause significant harm to the environment, causing serious environmental disasters. To prevent this from happening, there are special stormwater structures designed not only to collect rainwater, but also to properly purify it, so that the water can easily drain into the ground.

- Thermal power of Global radiators Global bimetallic radiators The exact cost of work and equipment is clarified with an engineer. The cost is influenced by factors: no.

- PentaxServices for installation of heating water supply LLC DESIGN PRESTIGE In addition to fast and high-quality repair of heating pipes, we provide.

- HajduServices for installation of heating water supply LLC DESIGN PRESTIGE In addition to fast and high-quality repair of heating pipes, we provide.

- Review of Butakov stoves: reviews from owners, installation and DIY production Organizing heat for a country house and dacha can be a difficult task. Previously, the only option was to hire a special oven.

- Bimetallic heating radiators Global series Style Plus 500 Bimetallic heating radiators Global series Style Plus 500 The exact cost of work and equipment is clarified with an engineer Cost.

- Aluminum heating radiators Global series ISEO 500 Aluminum heating radiators Global series ISEO 500 The exact cost of work and equipment is clarified by the engineer +7 (495) 744-67-74 The cost is affected.

- Wall-mounted gas boiler with built-in water heater De Dietrich MS 24 BIC Built-in 40 l cylinder water heater Can operate on natural gas.

- Construction of a cesspool for a modern house Construction of a cesspool for a modern house In modern houses, everything is bigger.

- Cesspool for a houseCesspool for a house There has always been one sewer system in a private house.

- Do electric vehicles have a future? The catastrophic state of the atmosphere in megacities is forcing the authorities of many countries to stimulate demand for electric vehicles. And electric cars are back in fashion: every self-respecting automobile company strives to release a “battery-powered car.”

- Choosing a polycarbonate carport Specialized carports are quite a useful thing, especially if you have a private house or a summer cottage. Thus, carports made of polycarbonate are very easy to use and install, and all materials and fasteners can be purchased at any specialized store. The shape of such a canopy depends on your skills and imagination. With the right approach [. ].

- Gas tank 4850 l. City-Gas (standard) 4850 l. City-Gas, Bulgaria - RUB 204,400. (houses up to 300 m²) Capacity 4850 l. Shut-off valves Reducing block.

- Snow retainers will increase the safety of the roof. Modern quality standards for construction work include such assessment criteria as ease of maintenance of the facility after its completion. Clearing roofs of snow is one of the services that shows how far the contractor has deviated from acceptable standards. If at the project development stage conditions are created for the installation of snow and ice barriers, then the roof and people are relatively safe. The main threats have been neutralized. [. ].

- The construction of low-rise buildings in the new Moscow is gaining momentum. The commissioning rate of low-rise buildings has increased 2.3 times (up to 135.7 square meters) compared to 2020, reports the Moscow Department. Low-rise housing is becoming more in demand among residents of the capital. “The share of low-rise residential real estate in new Moscow is not only not decreasing, which would be understandable in the current economic situation, but is also growing. If three years ago we spoke with caution about 20-25% of “low-rise housing” as a very good forecast, now we are boldly including up to 30% of low-rise housing in our plans,” he said.

- High-quality water heating of a private cottage from an old company High-quality water heating of a private cottage from an old company. ► DESIGN PRESTIGE LLC ► 8(49)744-67-74 ► Ours.

- Floors in the Hoff store in the shopping center "GOOD" Sign up on the website expresspol.ru for floor installation, semi-dry floor screed, vibratory laying of tiles. Recording Floors in the Hoff store in the GOOD shopping center for the first time.

WE GUARANTEE HIGH QUALITY WORK

DESIGN PRESTIGE LLC was founded in 1999. The company's employees are all experienced, have Moscow registration and Slavic origin, payment is made in any convenient way, if necessary, equipment and work are provided on credit. Autonomous heating and full winter water supply.

The company's office is located near the districts: Mitino, Tushino, Strogino, Shchukino.

Nearest metro stations: Tushinskaya, Skhodnenskaya, Planernaya, Volokolamskaya, Mitino.

Nearby are the following highways: Volokolamskoe Highway, Pyatnitskoe Highway, Leningradskoe Highway.

Why do you need a vapor barrier - basic requirements

Vapor barrier coatings eliminate the possibility of condensation forming on materials that are used to insulate various parts of building structures - in particular, roofs and floor foundations. If you do not protect the insulation, it will very quickly become saturated with moisture. This will lead to the loss of its operational properties and its subsequent destruction.

The penetration of condensate into the thickness of the thermal insulation material causes an increase in the thermal conductivity of the latter. Because of this, significant heat loss and the formation of vapor (a mixture of small water droplets with warm air) will be observed in the premises of the building. Such suspensions will constantly look for a way out. They will find it in ceiling and floor surfaces. Over time, water vapor will destroy the surfaces of the ceiling and floor. A vapor barrier is installed precisely to prevent such a situation.

Installing a vapor barrier on the ceiling

Thanks to materials that act as protectors of building structural elements from condensation, floor and ceiling surfaces last much longer.

There are a number of special requirements for modern vapor barrier products. The vapor barrier should:

- Meet fire safety regulations, having specified reliability and fire resistance.

- Effectively prevent the accumulation of condensate in building structures, have low water absorption and high moisture resistance.

- Do not emit compounds negative for humans into the atmosphere - be clean from an environmental point of view.

- Do not allow shrinkage, which leads to the formation of cold bridges.

- Be flexible and as frost-resistant as possible.

An “ideal” vapor barrier must be characterized by a low thermal conductivity. The lower this indicator is, the thinner the layer of protective material can be laid. The moisture-technical properties of any modern structure or residential building can be called optimal only if the vapor barrier coating for their structural parts is selected and installed competently and professionally.

Advantages

- Simple installation - easy to process; the installation process does not require special equipment or significant effort.

- The material has high plasticity and can bend in any direction without changing its structure.

- High frost resistance.

- Increased degree of protection against water vapor.

- Thanks to bitumen additives, it has significant heat resistance and does not lose its properties and other characteristics with increasing temperature.

Glassine – how good is the vapor barrier?

The material discussed in this article is a modern product made on the basis of thick cardboard, which is treated with special compounds (bitumen). After their application, glassine acquires increased strength and a number of unique characteristics. This gives it the ability to withstand quite serious mechanical loads.

Note that in the manufacture of the described vapor barrier, special cardboard is used. It has a density of 250 to 350 g/sq.m. This type of cardboard is called roofing cardboard. It consists of many (up to 40) layers of straw, cotton, all kinds of rag masses, wood, and flax. Additionally, non-woven materials in the form of highly crushed particles are added to its composition. This is done so that the bitumen compositions easily penetrate into the base of the material.

After treatment with special solutions, glassine is pressed. It is performed using special equipment that produces pressure of up to 300 grams for each square of material being processed. Such pressing gives the finished product the highest strength, minimizes the risk of damaging the integrity of the vapor barrier, and allows it to withstand significant loads.

Today glassine is produced in four varieties - P-400, P-350, P-300 and P-250. The numbers in the material marking indicate the density of the cardboard that was used to produce the vapor barrier. This indicator is of great importance. The higher the density, the better the performance characteristics of the final glassine.

The key advantages of the roll vapor barrier material under consideration are the following:

- Low weight, ease of processing with all cutting devices used today, ease of use.

- Excellent moisture resistance.

- Increased elasticity. Glassine easily bends without the slightest damage at almost any angle.

- High-quality ventilation of water vapor.

- High strength, durability, frost resistance, resistance to cracking under the influence of natural factors and low temperatures.

In addition, glassine is a very heat-resistant material. Even at high ambient temperatures, it does not soften and does not lose its special properties. This is due to the fact that the described vapor barrier for the floor and ceiling is impregnated with bitumen.

Glassine - what is it?

Glassine is a roofing material used to protect not only roofs, but also walls from wind, moisture and condensation. It is made by impregnating cardboard with bitumen with a low softening point of 45-50 degrees.

The basis for glassine is a special roofing cardboard consisting of 20-40 layers of wood fibers, straw, cotton, and cellulose. It also contains non-woven materials that provide better ability to absorb moisture. To achieve excellent technical characteristics of glassine, its cardboard base is passed through a press with a pressure of 300 g/m2.

About the disadvantages of glassine - how can we live without them?

When laying the vapor barrier we are interested in on damp substrates, the effectiveness of the coating is significantly reduced. This should be taken into account when performing work with its help. Glassine also has other disadvantages, it:

- It is characterized by limited resistance to fire, which is due to the bitumen impregnation of the material and its paper base.

- It has insufficient resistance to temperature changes, since it does not have a protective outer layer.

- Capable of releasing harmful compounds when the outside air temperature rises. Therefore, it is undesirable to use it in areas located in hot climate zones.

- Breaks down at extremely low temperatures (-40°).

- Destroyed by exposure to ultraviolet radiation. In this regard, glassine is never used without subsequent coating with additional material to protect the roof.

- Has a limited service life. The vapor barrier from it must be replaced regularly.

One more important note. The moisture that collects on glassine for the floor and roof over time causes the development of rotting of structural elements made of wood, which is transmitted to other parts of the structure. Therefore, when installing this vapor barrier, it is necessary to take care of organizing a high-quality and stably functioning ventilation system.

Video: using glassine

- The main thing is the low price. Brand P-250 costs (in rubles/roll) from 76, P-300 – from 115, P-350 – from 143 (web dimensions 20 x 1 m). Rolls of 15 m2 are also available for sale.

- Installation is so simple that you do not have to resort to the services of hired specialists. Fastening is done in different ways, depending on the base material - by gluing, using construction tape, or fixing with staples. In this regard, glassine can be considered universal.

- Light weight, which allows the product to be used for roofing without additional measures (strengthening the foundation, rafter system).

- Good maintainability. Replacing the canvas is quite easy and can be done even by a person without experience in such work.

- Sufficient tensile strength – from 15 to 25 kgf. Therefore, minor temperature deformation of structural elements does not lead to damage to the material. High-quality impregnation gives the canvas the necessary elasticity.

- Moderate water absorption - no more than 15 - 20% of the total mass of the material.

Flaws

- The reliability of the coating decreases sharply if installation is carried out on a damp base. In addition, at low temperatures the material breaks down. Therefore, it will not be possible to work on the roof in any weather (as well as during the season).

- Ultraviolet radiation destroys glassine, which makes it impossible to use it “openly” (like) without surface coating with another material.

- It burns well (like cardboard, don’t soak it, but the base remains the same – paper).

- Reliable natural ventilation must be ensured. Moisture condensing on glassine provokes the development of putrefactive processes in other materials (walls, insulation, sheathing).

- During operation, products are capable of releasing harmful substances (as the ambient temperature rises).

Despite the large range of products intended for use as protection (wind, steam, hydro), many developers still choose glassine (either out of habit, or not knowing that there is a practical analogue) . Modern industry produces the product BUB-120 (bitumen paper). The only difference from glassine is that this material is thinner (and therefore lighter), which makes it, with all other characteristics being equal, preferable.

When organizing the storage of glassine, you need to take into account that its rolls should only be placed VERTICALLY (installed “on the butt”). When using this material, it is necessary to focus on the maintainability of this part of the surface. The service life of glassine guaranteed by Manufacturers, even under the most favorable operating conditions, is no more than 8 - 12 months. Consequently, almost every year, at least partially, the canvas will have to be changed.

Although some sources indicate that their service life is tens of years. When purchasing, you should familiarize yourself with the product certificate, including this indicator.

That’s why you need to carefully calculate everything - either buy this cheap material and spend time and effort on updating it, or use more expensive products, but do less repairs.

You can find recommendations for glassine finishing of saunas, baths, and residential buildings for waterproofing. How justified this is can be judged by the structure of the product. We must not forget that its base is cardboard, and that says it all. It is unlikely that, taking into account this “nuance,” it would be advisable to use this material in places exposed to excess humidity in this particular capacity. Although it is quite suitable for a cold change house and the like.

When purchasing glassine, you need to pay attention to such points. Firstly, smooth edges of the roll. Secondly, the absence of grease stains on the canvas. If at least one of these conditions is not met, this is a clear sign of a low-grade product, in other words, a bad fake.

In any case, we should not forget that, first of all, Manufacturers position glassine as a material for constructing vapor barriers. Therefore, when using it for other purposes, you should compare all the pros and cons, and only then make a decision.

Glassine is a modern vapor barrier produced in rolls. It is used to protect structural elements of buildings from the appearance of condensation on their surface.

Vapor barrier coatings eliminate the possibility of condensation forming on materials that are used to insulate various parts of building structures - in particular, roofs and floor foundations. If you do not protect the insulation, it will very quickly become saturated with moisture. This will lead to the loss of its operational properties and its subsequent destruction.

The penetration of condensate into the thickness of the thermal insulation material causes an increase in the thermal conductivity of the latter. Because of this, significant heat loss and the formation of vapor (a mixture of small water droplets with warm air) will be observed in the premises of the building. Such suspensions will constantly look for a way out. They will find it in ceiling and floor surfaces. Over time, water vapor will destroy the surfaces of the ceiling and floor. A vapor barrier is installed precisely to prevent such a situation.

Installing a vapor barrier on the ceiling

Thanks to materials that act as protectors of building structural elements from condensation, floor and ceiling surfaces last much longer.

There are a number of special requirements for modern vapor barrier products. The vapor barrier should:

- Meet fire safety regulations, having specified reliability and fire resistance.

- Effectively prevent the accumulation of condensate in building structures, have low water absorption and high moisture resistance.

- Do not emit compounds negative for humans into the atmosphere - be clean from an environmental point of view.

- Do not allow shrinkage, which leads to the formation of cold bridges.

- Be flexible and as frost-resistant as possible.

An “ideal” vapor barrier must be characterized by a low thermal conductivity. The lower this indicator is, the thinner the layer of protective material can be laid. The moisture-technical properties of any modern structure or residential building can be called optimal only if the vapor barrier coating for their structural parts is selected and installed competently and professionally.

The material discussed in this article is a modern product made on the basis of thick cardboard, which is treated with special compounds (bitumen). After their application, glassine acquires increased strength and a number of unique characteristics. This gives it the ability to withstand quite serious mechanical loads.

Note that in the manufacture of the described vapor barrier, special cardboard is used. It has a density of 250 to 350 g/sq.m. This type of cardboard is called roofing cardboard. It consists of many (up to 40) layers of straw, cotton, all kinds of rag masses, wood, and flax. Additionally, non-woven materials in the form of highly crushed particles are added to its composition. This is done so that the bitumen compositions easily penetrate into the base of the material.

After treatment with special solutions, glassine is pressed. It is performed using special equipment that produces pressure of up to 300 grams for each square of material being processed. Such pressing gives the finished product the highest strength, minimizes the risk of damaging the integrity of the vapor barrier, and allows it to withstand significant loads.

Vapor barrier "Parchamine"

Today glassine is produced in four varieties - P-400, P-350, P-300 and P-250. The numbers in the material marking indicate the density of the cardboard that was used to produce the vapor barrier. This indicator is of great importance. The higher the density, the better the performance characteristics of the final glassine.

The key advantages of the roll vapor barrier material under consideration are the following:

- Low weight, ease of processing with all cutting devices used today, ease of use.

- Excellent moisture resistance.

- Increased elasticity. Glassine easily bends without the slightest damage at almost any angle.

- High-quality ventilation of water vapor.

- High strength, durability, frost resistance, resistance to cracking under the influence of natural factors and low temperatures.

In addition, glassine is a very heat-resistant material. Even at high ambient temperatures, it does not soften and does not lose its special properties. This is due to the fact that the described vapor barrier for the floor and ceiling is impregnated with bitumen.

When laying the vapor barrier we are interested in on damp substrates, the effectiveness of the coating is significantly reduced. This should be taken into account when performing work with its help. Glassine also has other disadvantages, it:

- It is characterized by limited resistance to fire, which is due to the bitumen impregnation of the material and its paper base.

- It has insufficient resistance to temperature changes, since it does not have a protective outer layer.

- Capable of releasing harmful compounds when the outside air temperature rises. Therefore, it is undesirable to use it in areas located in hot climate zones.

- Breaks down at extremely low temperatures (-40°).

- Destroyed by exposure to ultraviolet radiation. In this regard, glassine is never used without subsequent coating with additional material to protect the roof.

- Has a limited service life. The vapor barrier from it must be replaced regularly.

Laying a vapor barrier

One more important note. The moisture that collects on glassine for the floor and roof over time causes the development of rotting of structural elements made of wood, which is transmitted to other parts of the structure. Therefore, when installing this vapor barrier, it is necessary to take care of organizing a high-quality and stably functioning ventilation system.

The roll vapor barrier in question was originally created exclusively as a material for protecting the roofs of houses and buildings from condensation. Glassine served as a substrate during the conduction. And now it is mainly used as a roofing material.

It is usually mounted on top of a heat insulator, after which it is covered with metal profiles and other products. Glassine is ideal for pitched roof structures. It is lightweight and elastic, which allows it to be mounted on steep roofs and roofs with complex configurations.

Also, with the help of glassine, various wooden structures are reliably protected from condensation in those areas where they come into contact with concrete or ground. Vapor barrier material perfectly protects wood from swelling and excessive moisture, significantly increasing the service life of wood structures.

Glassine is actively used in the construction of saunas and baths, standing apart from other buildings and structures. In such situations, the described vapor barrier is installed around the perimeter of these buildings in several layers. Thus, saunas and baths are guaranteed truly effective vapor protection.

Other areas of application of the material:

- vapor barrier of curtain and ventilated facades;

- protection of car garages and basements of residential buildings from moisture;

- vapor protection of walls and plinths of apartment buildings, as well as their foundations.

The use of "Parchamine" for protection against moisture

Recently, glassine has been increasingly used as an excellent vapor barrier for floors. In this case, it is laid on the floor base along with hot bitumen. The recommended scheme for making a cake for floor vapor protection looks like this:

- bitumen (hot);

- a layer of glassine;

- bitumen again;

- glassine;

- and once again hot bitumen.

Note! Glassine for flooring is used exclusively after waterproofing of the floor base. Moreover, a layer of material for waterproofing must be placed 10–15 cm on the wall.

In addition, the corners between the wall and floor surfaces are pre-smoothed using a chain-link mesh for these purposes. It is attached with bitumen or construction staples, and then treated with cement-based plaster. After this coating has dried, you can begin installing glassine on the floor. The top of the vapor barrier layer should be covered with reinforced plaster.

The standard layout of glassine looks like this:

- Thoroughly clean the base of the floor or roof.

- Roll out the vapor barrier material over the surface.

- Cut the rolled product to the required size and attach it using a stapler (if the base is wooden), tape or bitumen mastic (if you are working with concrete surfaces).

- Install all subsequent rows of material with a 15-centimeter overlap.

To get a really high-quality vapor barrier layer, the gaps between individual rows of glassine should be coated with mastic.

King of the table: cream cheese sauce

12.07.2020

Recipe for quick preparation of cucumbers in mineral water for the winter

12.07.2020

Dolma from pickled grape leaves

12.07.2020

Areas of application of the material – a very popular insulator

The roll vapor barrier in question was originally created exclusively as a material for protecting the roofs of houses and buildings from condensation. Glassine served as a substrate when waterproofing the roof. And now it is mainly used as a roofing material.

It is usually mounted on top of a heat insulator, after which it is covered with slate or metal tiles, metal profiles and other products. Glassine is ideal for pitched roof structures. It is lightweight and elastic, which allows it to be mounted on steep roofs and roofs with complex configurations. Also, with the help of glassine, various wooden structures are reliably protected from condensation in those areas where they come into contact with concrete or ground. Vapor barrier material perfectly protects wood from swelling and excessive moisture, significantly increasing the service life of wood structures.

What is glassine

Construction glassine is made on the basis of roofing cardboard. The material is impregnated not with carcinogenic tar, like the once irreplaceable roofing felt, but with petroleum bitumen. The advantage of glassine is that during its production process it is not required:

- special waste disposal, since cardboard is easily recycled (this item does not apply to already impregnated material);

- the presence of running water – eliminates the appearance of dirty drains;

- implementation of additional measures to clean up harmful emissions.

Of course, the stage of impregnation of glassine in working baths is accompanied by the occurrence of natural evaporation of hot bitumen. But workshops must be equipped with forced ventilation, which prevents the spread of vapors within the premises. They are successfully brought out.

Glassine is used as a vapor barrier and also as a waterproofing agent. Its functionality depends on the location of the layer. For example, rolled material laid on the underside of the roofing pie protects the insulation from rising damp vapors. If glassine is laid out between the heat-insulating layer and the roofing, then you should keep in mind the waterproofing that prevents the penetration of precipitation.

Glassine is produced in 20 or 40 meter rolls with a width of 1-1.05 m. It is recommended to use grade P-350 as a roofing vapor barrier. Less dense material is intended for other purposes or is laid with more layers. Depending on the length of the rolls, their weight is 15 or 30 kg. In terms of dimensions and weight, small deviations in one direction or another are allowed, and by agreement with the customer, the area of the canvas can be changed to the required dimensions.

The finished strips have good strength characteristics. They are quite difficult to tear and stretch. But this vapor barrier material is afraid of punctures, which can cause moisture to penetrate into the insulation. Therefore, work should be performed with extreme care.

Deformed areas of glassine require additional treatment by gluing patches to cover the holes that have appeared, or coating the areas with bitumen mastic.

Glassine: technical characteristics

Roofing cardboard , from which glassine is made, consists of 40 or more mixtures of various materials: wood, flax, cotton, etc. During the process of impregnation with bitumen and other additives, the cardboard mass is pressed under high pressure.

The resulting material has high strength and durability, it can withstand fairly high loads. There are several types of vapor barrier - P250, P300, P350, P400. The marking indicates the density (thickness) of the product. Manufacturers produce glassine in rolls 1.025 x 1.05 m wide and weighing from 15-30 kg.

Another type of vapor barrier material is liquid glassine, which is a polymer composition. This is a universal product that can be used for waterproofing concrete and wooden structures.

Application area

Glassine is used as a vapor barrier in the construction of buildings. The product is used as a waterproofing substrate in roofing or floor construction. So, when installing a roof, insulation is laid as the first layer, followed by a vapor barrier, which is covered with a finishing material: metal profiles, metal tiles or slate.

The product is widely used for the installation of complex structures with unusual shapes. Thanks to its properties - elasticity and low weight, it can be easily and quickly installed on almost any surface (walls, floors, roofs).

The material is primarily used to protect wooden structures from condensation. As a result, the wood does not deform and the service life of such coatings increases. Vapor barriers are successfully used in the construction of baths and saunas. For efficiency, the product is laid in several layers around the entire perimeter.

Another area of application is protecting the foundation from moisture. The product is used when installing foundations of multi-apartment buildings, plinths and walls.

When installing a vapor barrier on the floor, a layer of glassine is alternated with hot bitumen, which is laid as the last layer. This design guarantees reliable protection against water vapor for a long time.

Installation of vapor barrier protection for basements, car garages and curtain facades is carried out. The insulator is used in the construction of heating mains, where it is mounted using clamps, wire and adhesive tape.

Pros and cons of glassine

Insulating material has a number of advantages, namely:

- light weight;

- versatility;

- reasonable cost;

- maintainability;

- moisture resistance;

- flexibility;

- frost resistance;

- durability – under favorable conditions.

But along with the advantages, it is necessary to highlight the disadvantages of glassine. One of them is poor heat tolerance. At high temperatures, bitumen begins to melt, also releasing an unpleasant specific odor. The second significant disadvantage is that the material should be worked at ambient temperatures above +5 degrees. At lower values, the fabric loses flexibility, which leads to brittleness of the vapor barrier material.

In addition, glassine is a flammable material. Its water absorption is 20% after daily soaking, while more modern vapor barriers achieve similar values in three to four days. Another disadvantage of the material in question is the absence of a protective layer on its surface, which is fraught with destruction of open areas.

The quality of glassine can be determined by its appearance. Light stripes or spots indicate uneven impregnation. Uneven roll edges indicate improper storage or careless transportation of the material. It should be understood that the ideality of the edges is very important for the correct construction of the insulating layer.

Kyiv highway, 1 km from the MKAD market "StroyMaster"

Glassine P-250 is a soft rolled roofing covering, which is a cardboard grade 250 impregnated with petroleum bitumen, made from wood, cellulose and semi-cellulose, rag pulp, natural flax and cotton. The composition of cardboard 250 is similar to cardboard of grades 300 or 350, but there are differences in such parameters as density, strength and, accordingly, quality: the higher the grade, the more reliable and durable the cardboard. Despite the fact that glassine P-250 is the most economical material in the line of products for vapor and waterproofing, its quality is not in doubt. To impregnate cardboard, petroleum bitumen is used, which has such qualities as viscosity, plasticity, heat and water resistance. The combination of these properties of bitumen allows the use of glassine for hydro- and vapor barrier purposes.

The popularity of glassine P-250 is due to the fact that it is the lightest, most inexpensive and easiest to use vapor barrier and moisture insulation material, as well as the fact that it is easy to transport, store and use.

Areas of application Glassine P-250 is used in several areas, including vapor barrier, waterproofing and as a wrapping material for various products.

When used for vapor barrier, glassine P-250 is laid in places where metal, concrete or brick bases come into contact with wooden structures. It is used to cover wooden parts of windows, doors, beams, joists, that is, those structures that will subsequently be hidden in brickwork or concreted. In many cases, glassine P-250 is placed at the junction of the concrete foundation and the walls of a wooden structure, for example, a log house, log house, change house, outbuilding or bathhouse. Thanks to the use of glassine, the wooden parts of the structure are reliably protected from condensation and fumes, which, in the absence of protection, lead to premature rotting of the wood, damage to it by mold, mildew and other unpleasant consequences.

The obvious fact is that when wet, the most common insulation materials, such as mineral wool, significantly lose their physical insulation properties. Glassine P-250 as a vapor and waterproofing agent protects thermal insulation from moisture penetration and significantly extends its service life. In this form, glassine P-250 can be used to protect insulation on pitched roofs and under external cladding on facades, when installing ventilated facades, laying underground communications that require insulation (heating mains, water supply), or laying floor coverings on concrete bases.

Reasons for popularity : strength. If you cut a strip 50 millimeters wide from a sheet of glassine, it will withstand a tensile force equal to 250 newtons; waterproof. Glassine P-250 remains absolutely waterproof under a pressure of 0.01 atm. within 10 minutes, and during the day the water absorption of P-250 glassine does not exceed 20%; elasticity. With a bending radius of 5 mm at 18°C. glassine is resistant to cracks and breaks and retains its integrity; resistance to temperature changes. The softening temperature for using petroleum bitumen, which is an impregnation for P-250 glassine, exceeds 45°C. This guarantees the absence of melting and spreading of the material even in hot summer weather, and due to its frost resistance in cold weather, P-250 glassine retains all its qualities and does not crack; ease of use. When working with glassine, no special skills are required; non-toxic. When heated, glassine does not release any substances that pose a danger to human health; price. Glassine P-250 is one of the most affordable vapor and waterproofing materials on the market

The technology for laying glassine P-250 is very simple and is no different from the method of using glassine of other brands. The basic rules are that the glassine is laid with an overlap of 100-150 mm, while the joints are glued with mastic. For better vapor and waterproofing, experts recommend 2-layer installation.

Laying vapor barrier

According to GOST 2697-83, vapor barrier made from building glassine is defined as a lining layer for roofing pies. It is used in the construction of roofs of residential buildings and outbuildings. In other cases, the material rather performs the function of waterproofing or protection against condensation.

The glassine is rolled out over the entire area of the ceiling, laying the sheets with an overlap of 10-15 cm. Vapor barrier, as a rule, is made no thinner than two layers. The material is attached to wooden surfaces using a stapler. Glassine is glued onto flat areas. The seams are covered with construction tape or coated with mastic. The main thing is to ensure the tightness of the layer.

Decorative cladding is installed on the side of the house, aesthetically covering the vapor barrier.

If repairs are necessary, damaged areas of glassine are cut out, and new patches are placed in their place, overlapping each other. If the roof does not leak from above, the bottom layer can be updated by laying on new pieces without removing the old vapor barrier. In each case, the issue is resolved individually, based on the conclusions of specialists.

“Liquid Glassine” Jar 2.4l. Application with a brush.

PLEASE WATCH THE VIDEO Clips.

This product detailed description in English is available here - https://nippon.technology/liquid-glassine.

Technical Support & Container Logistics. Please feel free to contact

Waterproofing Polymer Water Displacing Composition

"Liquid Glassine".

“Liquid Glassine” is a water-displacing polymer composition, specially designed to protect wood from rotting during the construction of log houses, the construction of bathhouses and the construction of wooden houses, as well as to protect concrete during waterproofing of the foundation. This composition is used for floor waterproofing, basement waterproofing and bathroom waterproofing, to protect aerated concrete from moisture and rotting.

It can be used as an effective substitute for wood impregnation to protect wood from rotting and protection from moisture, especially when treating hidden cavities in which the process of wood rotting is most intense. The frozen composition resembles the consistency of soft rubber or chewing gum and is black in color. When protecting wood or protecting concrete, the surface can be armored with sand or colored screenings to increase durability and add decorative properties.

“Liquid Glassine” covers cracks, capillaries and pores of wood with micro plugs of hardened polymer. Treated wood acquires the properties of planks, which last much longer than regular sawn boards. As you know, all the pores of a plank are closed by numerous blows of an ax, which stops the penetration of moisture and oxygen into the wood, prevents the development of microorganisms and ensures high durability. This Polymer Composition is used to protect wooden structural elements (beams, lower crowns, mauerlats, rafters) from rotting, as well as in yacht and shipbuilding.

“Liquid Glassine” already contains a primer and is applied equally well to both dry and clean surfaces and dusty and damp surfaces. The composition has high capillarity, and the porous layer of wood, concrete or aerated concrete will be deeply impregnated, which provides long-term protection of wood from rotting and reliable waterproofing of concrete. The protection of wood from moisture and the waterproofing of aerated concrete will not be compromised even with minor damage to the outer layer of the coating, since all capillaries and pores of the treated material are blocked with polymer micro plugs.

“Liquid Glassine” provides long-term protection of sheet building materials from rotting, mold and swelling caused by the penetration of moisture into the porous structure of the materials. Plywood, MDF, plasterboard and OSB treated with this Polymer Composition will last much longer, as they acquire permanent protection from moisture. All their pores and capillaries are deeply impregnated and reliably covered with polymer microplugs. Typical structures treated with Liquid Pergamin are partitions in basements, roof slopes and valleys before laying roofing material, subfloors, walls of bathrooms and restrooms before laying tiles, walls of garages, gazebos and sheds.

The recipe for “Liquid Glassine” already includes a complex of several fungicides that are safe for humans and animals, which provides long-term protection of wood from rotting during the construction of log houses, construction of bathhouses and construction of wooden houses, as well as protection of concrete from biodegradation during waterproofing of the foundation. When building bathhouses on river banks, you should avoid getting the composition into the water, as it is unsafe for fish.

“Liquid Pergamin” is a promising product for the wooden house-building market and, according to our data, is the only waterproofing material in Russia that was specifically designed for moisture insulation of wood, and not adapted for these purposes from another area (most water repellents are created for concrete surfaces and are used on wood as more or less suitable). The composition imitates the properties of the sap of a living tree and can rise up the capillaries to a height of more than a meter.

“Liquid Pergamin” penetrates deeply into the pores and is applied equally well to both dry and clean and wet and wet surfaces, since it contains a special water-displacing additive that removes water when waterproofing concrete and aerated concrete or impregnating wood. Water rolls into balls like mercury, without interfering with processing. This composition can be effectively used for waterproofing a bathroom, waterproofing a floor or waterproofing a basement, as well as impregnating wood, for example for painting elements of fences and fences, or when constructing fences for beds.

“Liquid Glassine” can be applied at temperatures down to – 15 C, and there should be no layer of ice or clay on the surface. Ice should be removed, as it is not subject to impregnation and reduces the degree of protection of wood from rotting and protection of concrete from moisture.

“Liquid Glassine” is an opportunity to simultaneously buy impregnation for wood and aerated concrete, a primer, an antiseptic and a fungicide. Quick repairs are possible even in rain and snow.

Now you can work in any weather.

“Liquid Glassine” - Highly elastic Capillary-Osmotic impregnation for wood with a plank effect.

As is known, at the micro level, a tree consists of many fused capillaries through which moisture rises from the roots to the crown. Tes has much greater durability than sawn wood. The reason is that all the pores of the plank are blocked by numerous blows of the ax, which ensures high durability. When sawing or rough processing, the capillaries open. This leads to the free penetration of water and air into the inner layers of wood and the development of anaerobic microorganisms that destroy the wood.

Liquid Glassine" is a Water-displacing Polymer Composition with a board effect based on a super-elastic synthetic polymer. The composition has both high capillary permeability and osmotic effect (membrane permeability), that is, it can spread through the capillaries of wood, like the sap of a living tree.

Apply Liquid Glassine in two layers without intermediate drying to ensure deep penetration of the polymer into the porous internal structure. Impregnation covers capillaries and cracks with polymer microplugs, preventing moisture and air from entering the inner layers of wood. The development of microorganisms that damage the wood stops, which ensures the durability of the sawn wood. A material with such properties is necessary when processing floor logs in bathhouses, constructing piers, waterproofing and repairing the lower crowns of log houses, and is used as a water-displacing adhesive for laying flexible tiles in any weather.

Unlike paints, the protective layer created by “Liquid Glassine” does not crack or collapse even when the wood dries out, freezes and receives strong impacts, due to the ultra-high (up to three thousand percent) extensibility of the polymer. The absence of phenols harmful to health makes the Polymer Composition environmentally friendly. It can be used for both external and internal work.

For clarity, let’s place a wooden block in a container with “Liquid Glassine”. The frame clearly shows that the Polymer Composition quickly penetrates the porous structure of the wood, making it moisture-proof. At the same time, the less dense layers of wood that are most susceptible to rotting are impregnated deeper and faster. When processing wet wood, it is recommended to leave palm-sized gaps in places protected from moisture through each linear meter of logs or beams. For example, on the underside of the floor joists in a bathhouse or on the upper side of the crowns of a log house. After the wooden structure has dried, the holes can be painted over or left open, provided that water is guaranteed not to penetrate into the wood through them. If you split a section of lining treated with Liquid Glassine, you can also see that the looser areas of the wood are impregnated to a greater depth, which provides better protection in problematic, least dense areas.

The polymer composition contains an environmentally friendly complex of fungicidal additives based on natural resin (a natural protective substance of wood) and food preservatives that are harmless to humans.

"Liquid Glassine" - durability of wooden structures in the most unfavorable environment.

"Liquid Glassine" can be seen on the pages of manga (traditional Japanese comics).

マンガ Manga (18+) - Japanese comics.

We can deliver the required batch of material to any city in Russia.

Delivery to the terminal in St. Petersburg is free,

You pay for the services of the transport company yourself upon receipt of the cargo.