Cement is one of the main materials used in construction.

Not a single type of renovation carried out in a house or apartment can be completed without the use of cement. And naturally, the issue affecting the setting time of cement worries many people. It is safe to say that the hardening period of cement directly depends on many different factors and conditions under which drying occurs.

Scheme for the production of concrete blocks.

Factors influencing the hardening of cement mortar include the brand of cement used, the type and quality of the sand component. A special place among the factors influencing the hardening time of cement is the air temperature at which drying occurs.

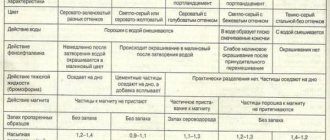

a brief description of

Cement is used to produce various concrete solutions, this is known to many. Naturally, to obtain concrete (an artificial stone material), it is necessary to have other components in the mixture, such as sand, crushed stone, and water.

To prepare a concrete solution you will need cement, water, sand and crushed stone, which are mixed in a certain proportion.

To obtain a high-quality concrete product, it is necessary to strictly follow the technology and sequence of work, which begins with the selection and mixing of components, and ends with proper care of the solution during its hardening.

The cement composition, after being prepared and poured into the formwork, begins to gradually harden, increasing its strength over time. Immediately after setting, the concrete will not have characteristics that will allow further construction work to continue. At the very beginning of the process, concrete is easily destroyed even when exposed to minimal loads.

Today, a number of different additives for cement mortar have been created that can significantly improve the quality of concrete products. For example, they can endow them with properties such as plasticity, high strength, frost resistance, water resistance and others.

The use of modern additives allows concreting work to be carried out even when the temperature outside is quite low (in winter), without using special-purpose equipment.

An excerpt characterizing the hydration of cement

Natasha saw that there was nothing to be afraid of, and therefore she was not afraid of Marya Dmitrievna. - Marya Dmitrievna? what ice cream! I don't like cream. - Carrot. - No, which one? Marya Dmitrievna, which one? – she almost shouted. - I want to know! Marya Dmitrievna and the Countess laughed, and all the guests followed them. Everyone laughed not at Marya Dmitrievna’s answer, but at the incomprehensible courage and dexterity of this girl, who knew how and dared to treat Marya Dmitrievna like that. Natasha fell behind only when she was told that there would be pineapple. Champagne was served before the ice cream. The music started playing again, the count kissed the countess, and the guests stood up and congratulated the countess, clinking glasses across the table with the count, the children, and each other. Waiters ran in again, chairs rattled, and in the same order, but with redder faces, the guests returned to the drawing room and the count's office. The Boston tables were moved apart, the parties were drawn up, and the Count's guests settled in two living rooms, a sofa room and a library. The Count, fanning out his cards, could hardly resist the habit of an afternoon nap and laughed at everything. The youth, incited by the countess, gathered around the clavichord and harp. Julie was the first, at the request of everyone, to play a piece with variations on the harp and, together with other girls, began to ask Natasha and Nikolai, known for their musicality, to sing something. Natasha, who was addressed as a big girl, was apparently very proud of this, but at the same time she was timid. - What are we going to sing? – she asked. “The key,” answered Nikolai. - Well, let's hurry up. Boris, come here,” Natasha said. - Where is Sonya? She looked around and, seeing that her friend was not in the room, ran after her. Running into Sonya’s room and not finding her friend there, Natasha ran into the nursery - and Sonya was not there. Natasha realized that Sonya was in the corridor on the chest. The chest in the corridor was the place of sorrows of the younger female generation of the Rostov house. Indeed, Sonya in her airy pink dress, crushing it, lay face down on her nanny’s dirty striped feather bed, on the chest and, covering her face with her fingers, cried bitterly, shaking her bare shoulders. Natasha's face, animated, with a birthday all day, suddenly changed: her eyes stopped, then her wide neck shuddered, the corners of her lips drooped. - Sonya! what are you?... What, what's wrong with you? Uh uh!... And Natasha, opening her big mouth and becoming completely stupid, began to roar like a child, not knowing the reason and only because Sonya was crying. Sonya wanted to raise her head, wanted to answer, but she couldn’t and hid even more. Natasha cried, sitting down on the blue feather bed and hugging her friend. Having gathered her strength, Sonya stood up, began to wipe away her tears and tell the story. - Nikolenka is leaving in a week, his... paper... came out... he told me himself... Yes, I still wouldn’t cry... (she showed the piece of paper she was holding in her hand: it was poetry written by Nikolai) I still wouldn’t cry, but you didn’t you can... no one can understand... what kind of soul he has. And she again began to cry because his soul was so good. “You feel good... I don’t envy you... I love you, and Boris too,” she said, gathering a little strength, “he’s cute... there are no obstacles for you.” And Nikolai is my cousin... I need... the metropolitan himself... and that’s impossible. And then, if mamma... (Sonya considered the countess and called her mother), she will say that I am ruining Nikolai’s career, I have no heart, that I am ungrateful, but really... for God’s sake... (she crossed herself) I love her so much too , and all of you, only Vera... For what? What did I do to her? I am so grateful to you that I would be glad to sacrifice everything, but I have nothing... Sonya could no longer speak and again hid her head in her hands and the feather bed. Natasha began to calm down, but her face showed that she understood the importance of her friend’s grief.

Main stages of hardening

Using special additives, you can slow down or speed up the hardening process of the solution, as well as give it additional technical characteristics.

So, many people know that the hardening process of cement mortar is conventionally divided into two main points. This is setting and hardening.

As for the setting stage, it does not last long, approximately 24 hours after the mixture is prepared. The most important factor influencing setting time is air temperature:

- if the air temperature is 20 degrees, this means that the cement mortar will set about two hours after mixing. And the final setting will occur after three hours. This suggests that the entire process in question will take only one hour;

- in the case when the temperature is close to 0 degrees, this same process can drag on and last about 20 hours. This is due to the fact that setting, or rather its beginning, will occur only after a period of 6 to 10 hours.

Another important factor influencing the speed of the setting process are specialized additives that either speed up the reaction or slow it down.

Hardening of cement: fig. a) – increase in cement strength depending on time; rice. b) – interaction of cement with water: 1 – cement grains; 2 – water; 3 – hydrate neoplasms; 4 – air pores.

Do not forget that the cement solution remains mobile throughout the setting period. In other words, it is still susceptible to various influences. And carrying out any actions with cement that has not yet set increases the period of the initial process (setting).

The next stage, characteristic of concrete solutions, is hardening. It occurs immediately after the end of the first stage (setting). It can be assumed that this process may last for several years.

The period, for example, 28 days specified in the instructions, only says that for this period of time the achievement of a certain grade of concrete is guaranteed. The first few days of concrete hardening are dynamic and nonlinear. To understand the reason for this feature, it is necessary to study the data describing the hydration process.

Hydration as a spatial process

Cement particles in the form of crushed hardening grains are surrounded by water, the volume of which is relatively large (50-70 percent by volume). This volume is filled with new formations to create a strong structure (cement stone). Thanks to chemical reactions with water, within a few minutes needle-shaped crystals appear both on the surface of the grains and in the water. After 6 hours, so many crystals have already formed that spatial connections arise between the cement grains. After 8-10 hours, the entire volume between the gradually decreasing cement grains is filled with a skeleton of needle-shaped crystals. It is also called “aluminate structure” because it arises from 3CaO*Al2O3. While still plastic, the mass begins to harden, and a rapid increase in strength occurs. In the remaining voids, hydration products of clinker minerals 2(3CaO*SiO2) and 2(2CaO*SiO2) appear simultaneously (but not too intensely at first). The latter form a homogeneous, extremely finely porous pile of small crystals (the so-called “silicate structure”). The importance of this structure is increasingly increasing. It becomes the carrier of the strength of the cement stone and after about a day begins to displace the aluminate structure. After 28 days (the usual test period for cement and concrete), only the silicate structure is detected.

The appearance of hydration products is considered as gelation, and hydration products are considered as gel. The speed at which these processes occur depends on:

- size of cement grains (cement grinding thickness);

- mineral composition of cement clinker;

- the amount of water with which the cement is mixed;

- hydration temperatures;

- introduction of additives

For complete hydration of the cement grain, the presence of 0.4 times (by weight) the amount of water is necessary. Of this, only 60% (that is, 0.25 mass of cement) is chemically bonded. The remaining 40% of the original water remains weakly bound in the pores of the gel. The size of the gel pores is about 3-5 nm. Their formation is inevitable; they determine the finely porous structure of the gel mass.

Hydration of cements as a chemical process. Phase composition of hardening products

When an alyte is hydrated, a reaction occurs, which in general can be written as follows:

3 CaO SiO2 + (3 ¸ x) H2O = (3 ¸ x) Ca(OH)2 + x CaO y SiO2O m H2O.

The values of the coefficients x, y, m change depending on the external conditions of the hydration reactions, mainly on temperature. Belite hydration proceeds according to a similar scheme with the formation of hydrosilicates of the same composition:

2 CaO SiO2 + (2 + x) H2O = (2¸x) Ca(OH)2 + x CaO y SiO2O m H2O.

At normal temperatures, the hydration product of alite and belite is the same hydrosilicate, designated CH(P) or C2SN2. In addition to hydrosilicate, crystalline Ca(OH)2 is formed in fairly large quantities, and during the hydration of alite, much more of it is formed than during the hydration of belite. When the temperature rises to 100-110°C, the same hydrosilicate CSH(P) is formed, but with a higher content of calcium oxide. At 70-80°C, the basicity (the ratio of the number of moles of CaO to SiO2) of hydrosilicates reaches a limit value of 2. Hydrosilicate CSH(P) is the first hydrosilicate phase formed at higher temperatures. It then turns into a hydrosilicate, designated C2SH(A), or a - C2S hydrate. The temperature range of stability of this hydrosilicate is I25 -175°C. At higher temperatures it turns into hydrosilicate C2SH(C) (g - C2 hydrate). At temperatures above 160°C, hydrosilicate C3SH2 can form. At temperatures above 125°C, hydrosilicate C2SH(B), called hillebrandite, is also formed. The sizes of hydrosilicates formed at elevated temperatures are larger than the sizes of crystals formed at low temperatures.

Thus, during the hydration of silicate clinker minerals, mainly highly basic hydrous calcium silicates are formed, having a Cao/SiO2 molar ratio of more than 1.5. However, these hydrosilicates have greater solubility and a high dissolution rate constant, so they are not optimal in terms of ensuring the durability of well support.

At elevated temperatures, the solubility of siliceous components increases, and dissolved SiO2 binds calcium hydroxide to form hydrosilicates of reduced basicity. A decrease in the content of free calcium hydroxide in the solution also contributes to a decrease in basicity. Reducing the content of free calcium hydroxide in the solution also helps to reduce the basicity of hardening products and increase their durability and strength. Therefore, to fasten intervals with high temperatures, it is necessary to introduce silica-containing materials, slag, ash, ground sand, etc. into the composition of Portland cement cements.

According to the scheme proposed by J. Skalny and J. Young, the mechanism of hydration of tricalcium silicate is as follows: C2S reacts with oxygen immediately upon contact. During the induction period, ions are exchanged between the solution and the non-hydrated solid, promoting an autocatalytic increase in the reaction rate. In this case, a large amount of hydration products with low density and increased volume compared to the unhydrated phase is deposited on the surface of the mineral covered with water. This causes an overall increase in the porosity of the system, which in turn reduces the transport of ions to the solid-liquid interface, slowing down the hydration process. This period is considered to be a diffusion-controlled stage of hydration.

At the beginning, hydration reaction occurs:

where: "C2S" is the structure of C3S.with calcium hydroxide deficiency.

At the end of the induction period - reactions:

Overall, the hydration mechanism is divided into five distinct stages.

Stage 1. When C2 comes into contact with water, hydrolysis occurs, accompanied by the transition of the O2- proton to OH-, b and Ca2+ to Ca2+ + a q. Hydrolysis occurs mainly at active sites. As a result of the transition of Ca2+ into solution in these areas of the mineral, a surface layer of reaction products is formed, which are groups of silicate ions and , interconnected by hydrogen bonds and several calcium ions. The resulting amorphous layer tends to absorb water and swell, similar to an osmotic process. Charge equilibrium is maintained by the transition of Ca2+ and OH- ions into the solution, compensating for the H+ ions present in the solution during water hydrolysis. Between the mobile ion - Ca2+ and the stationary surface, silicate ions form a double electrical layer, providing chemisorption.

Stage 2. Due to the further transfer of Ca2+ and OH- ions into solution, the surface layer formed at stage 1 continues to rupture. The resulting electrical double layer slows down the rate of its development. From groups of atoms in solution, nuclei of Ca(OH)2 or CSH crystals will form.

Stage 3. As the ions are transferred into solution, their content becomes sufficient for the growth of crystal nuclei. Initially, growth is observed when the solution is saturated with calcium hydroxide. Due to the high resistances that arise through the layer of newly formed silicon dioxide, poorly developed CSH crystals are formed on the surface.

Stage 4 and 5. At these stages, further growth of shaped CSH crystals continues. In this case, new crystals formed on previously formed CSH crystals will differ in morphology, since the content of ions in the solution changes. This determines the presence of various modifications of hydrosilicates.

The mechanism of hydration of b - C2S is similar and differs in the decrease in the degree of supersaturation of the solution with Ca2+ ions relative to Ca(OH)2 and the low exotherm of the hydration process.

The general composition and morphology of C - S - H formed from b - C2S and C3S are similar. The low degree of saturation of the solution with calcium hydroxide during the hydration of b - C2S causes the formation of larger Ca(OH)2 crystals compared to the crystals formed during the hydration of C3S.

Hydration of C3A. The process of C3A hydration is determined by the rate of diffusion of the liquid phase through the layer of C4AH13 and C2AH8 hydrates formed at the initial stage. Since the hydration of CA is accompanied by a large release of heat, these hydrates quickly transform into C3AH6.

The resulting hydrates C4AH13, C4AC5H12 and their solid solutions create an insulating layer on the surface of C3A grains, which sharply slows down, but does not stop, the flow of reacting ions and water molecules. This flow does not ensure the dissolution of the lower layer in contact with the surface, and therefore; the sequential formation of C4AH13 depletes the solution in contact with C3A grains relative to Ca2+ ions, thereby promoting the precipitation of Al(OH)3. This process is expressed:

The destruction of the insulating layer due to the transformation of C4AH13 and C2AH8 into C2AH6 will also cause, at a high content of Ca+ and OH- ions in the solution, the destruction of the Al(OH)3 layer, which will cause further hydration of C3A. The sequence of these reactions is as follows:

;

;

.

The composition of the hydration products of the aluminate components of cement also depends on the ambient temperature. At normal temperatures, the interaction of tricalcium aluminate with water occurs according to the following scheme:

.

The reaction involves calcium hydroxide, released during the hydration of silicate minerals. At elevated temperatures (more than 50 - 60°C), the main hydration product is hexahydrate hydroaluminate:

.

At low temperatures (below 10° C) during the hydration of aluminates, the formation of low-basic hydroaluminates is preferable

And .

Hydration of the aluminoferrite phase. At temperatures below 20°C, the hydration of calcium aluminoferrites is accompanied by the formation of tetracalcium aluminoferrite calcium hydrate.

At temperatures above 20 °C, this crystalline hydrate turns into cubic,

,

and at temperatures above 50°C only cubic. Calcium hydroxide present in the solution slows down the transition of the hexagonal form of the crystalline hydrate to the cubic one.

The interaction reactions of calcium aluminoferrites of various compositions are expressed as follows:

Solid solutions of tricalcium hydroaluminoferrites crystallize in the cubic system and are similar in structure to the minerals of the garnet group - grossular and andradite.

When polymineral cements containing silicates, aluminates and calcium ferrites interact with water, solid solutions of hydroalumina ferrites and aluminum iron garnets are formed according to a complex system:

In these solid solutions, one SiO2 molecule is replaced by two H2O molecules and therefore the solutions are called hydrogarnets. The entire group of compounds has a general formula:

or . Hydrogarnets increase the durability of cement stone, since they have greater resistance to many types of formation waters.

In addition to these minerals, Portland cement contains calcium sulfate in the form of gypsum, which is introduced to slow down the rate of setting of the cement paste. The slowdown mechanism is presented as follows.

The product of hydration of calcium aluminate and aluminoferrite - hexahydrate calcium hydroaluminate in the presence of gypsum forms calcium hydrosulfoaluminate of the trisulfate form according to the reaction:

,

which can be written as . This compound is called ettringite and is characterized by a strong volume increase and a high specific surface area. Rapidly forming ettringite coats the grains of clinker minerals, making it difficult for water to access them. The hydration process slows down. After all the gypsum is consumed in the chemical reaction and the concentration of ions in the solution decreases, ettringite becomes thermodynamically unstable and turns into the monosulfate form of calcium hydrosulfoaluminate. Water access to the clinker minerals opens and the hydration process intensifies.

Ferrite components in the presence of gypsum form mono- and trisulfate hydrosulfoferrites, similar to calcium hydrosulfoaluminates with general formulas:

And

At high temperatures (above 50°C), high-sulfate forms of these compounds transform into monosulfate forms, which, in turn, decompose at temperatures above 100°C to release gypsum and hydrogarnets.

The materials presented earlier allow us to conclude that the process of hydration is a special case of solvation and is a process of interaction of substances with water, in which water molecules attach to the substance without being destroyed.

The resulting compounds of a certain composition in this case are called crystalline hydrates. Hydration is caused mainly by donor-acceptor, dipole-dipole, ion-dipole interactions between particles, as well as the formation of hydrogen bonds.

There are hydration of solids with the formation of hydrates, hydration of oxides, hydration of electrolytes in solutions, hydration of molecules in solutions, as well as hydration of organic and high-molecular compounds. During the hydration process, heat is released - the heat of hydration. It is caused by wetting and reaction.

In the composition of crystalline hydrates, water molecules are included in the form of individual particles and therefore in chemical formulas water is usually written separately, for example, , etc.

Known crystalline hydrates are divided into crystalline hydrates of definite composition and undetermined ones. Firstly, there is a certain number of water molecules per molecule of a substance, for example. The latter are characterized by an indefinite number of water molecules per molecule of the substance, varying depending on temperature, water vapor pressure in space, concentration of the dissolved substance, etc. Water found in crystalline hydrates is called crystallization water. It is arranged in a certain order. Water that fills the voids and spaces of the crystal and is held by it by electrical forces is called zeolite. Its removal is accompanied by the destruction of the crystal. The water used for the formation of hydroxides is called constitutional. During their formation, water molecules decompose.

Setting and hardening of concrete

Cement is a substance that, when mixed with water, begins to harden into a stone-like material. Standard concrete mortar contains cement as a binder. The remaining fillers are most often crushed stone, sand and water. Thus, we can conclude that the essence of the concreting process is to understand the reasons and technology for hardening the binder of the concrete mixture. Understanding the essence of all physical stages of concrete allows scientists to come up with more and more new additives that affect the hardening process of this wonderful material. Today there are a huge number of different supplements, but this is a completely different story. If you need to prepare the required amount of concrete mixture of a certain brand, a concrete calculation will help you select the components.

So, the essence of concreting is to gain strength with concrete. The process of gaining strength is divided into two main stages: setting of concrete and hardening of concrete.

The first stage of the process is the so-called setting of the concrete. Setting occurs during the initial days of concrete's existence. The most interesting thing is that the time during which concrete will be exposed to this process directly depends on the ambient temperature. Moreover, the higher the air temperature, the faster the concrete mixture will set. If the temperature is kept within 20 degrees, then setting will begin 2 hours after creating the mixture and will last 1 hour. If the temperature is kept within 0 degrees, then setting can last up to 20 hours and will begin 6-10 hours after mixing the mixture. Under certain conditions, setting can be achieved in a very short time (a couple of tens of minutes), but this will require special high-thermal chambers.

During the setting process, the concrete remains in a mobile state, which makes it possible to exert physical influence on it. At this moment, the thixotropy of this material is fully manifested. The meaning of thixotropy is the ability of a material to reduce its viscosity under the influence of physical impact, and increase it in a state of inactivity. In other words, while the concrete is being mixed, it will not enter the hardening stage, which will allow the setting stage to be extended for the required period. That is why concrete is usually delivered in special rotating tanks, which do not allow the concrete to leave this stage until concreting.

Immediately after the setting process, the concrete hardening process begins. This process, just like the process of gaining strength of any reinforced concrete structure, despite the established period of 28 days, lasts not one or two months, but years. The graph of the process of concrete gaining strength is absolutely nonlinear, and is most dynamic only in the initial stages (the first two weeks).

rasschitai.ru