About the building material

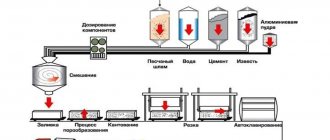

Expanded clay concrete blocks, as the name suggests, are made from expanded clay, sand and cement. Expanded clay is a coarse aggregate for lightweight concrete, produced by firing pieces of clay. During the production process, expanded clay becomes porous, which subsequently ensures low thermal conductivity of the block. The expanded clay concrete mixture is molded, giving the blocks the same size and configuration. They can be full-bodied or hollow. Large voids that provide additional heat and sound insulation are created during the molding of products.

Expanded clay concrete blocks

Construction of bath walls from expanded clay concrete

It is necessary to install a wooden or steel frame on the foundation, which will serve as a fastening reinforced belt, as well as a base for securing the floors. Then the subfloors are laid taking into account the placement of the furnace. Beacons are installed in the corners of the building and a rope is pulled over them along the future walls. They will serve as a guide for laying expanded clay concrete blocks.

The first row begins to be laid out on cement mortar with constant monitoring of the location of each block relative to the horizon and the alignment of the walls. Any deviations cannot be corrected subsequently, and the walls will lose strength and reliability. The first brick is placed in one of the corners on a thin layer of mortar previously applied with a trowel. It is pressed down on top and then gently tapped on top with a wooden hammer. The solution that appears on the sides is removed. Next, apply the solution to its end part and to the place where the second brick is laid. The second expanded clay block is pressed against the first with pressure on it from above so that it completely falls into place. It is then leveled in the same way and pressed into the seat. This is how the first row is laid out.

The second row should be placed with the first one tied half the length of the expanded clay block. To do this, the laying begins from the starting corner, but in the opposite direction. Every two to three rows, the structure must be strengthened by adding a reinforcement grid with a rod diameter of at least 2 mm. If it is necessary to form a window or door opening, non-standard block sizes may be needed. To cut them carefully and not damage the end part, use a grinder with a concrete disc installed.

Suitability of blocks for baths

Traditionally, bathhouses and houses were built from wood, using coniferous logs for felling. The resin they contained helped protect against rotting.

Expanded clay concrete blocks are not susceptible to biological pests and are therefore quite suitable for the construction of bathhouses. Low thermal conductivity is an important positive point, and low weight will allow you to save on the choice of foundation design and ensure fairly rapid construction of walls.

Of course, like any material, expanded clay concrete has both pros and cons. For example, blocks cannot be as environmentally friendly as wood. It all depends on the deposit in which the clay for expanded clay and cement was mined. All products made from it, even porcelain, may have a small amount of radiation.

However, all certified products must comply with sanitary standards, and certification for building materials is mandatory. In addition, when purchasing blocks, you can use a dosimeter to check the presence of background radiation. As a rule, it is absent or negligible.

The seams between the blocks have a higher density and can become “cold bridges”, so additional insulation will be required.

However, judging by reviews on the network, more and more developers prefer this particular material, which is also inexpensive compared to others. Owners who have had the opportunity to use buildings made of expanded clay blocks are satisfied with the quality of the material used.

Internal insulation of a bathhouse made of expanded clay concrete blocks

The complex of works for insulating a bathhouse made of expanded clay concrete blocks from the inside includes thermal insulation of the floor, walls and ceilings. Each of these structures deserves special attention.

Floors

Insulation begins from the floor, the pie of which can be structured in several ways. We present three main ones.

Option 1 – on logs with expanded clay screed

The floor in a bathhouse made of aerated concrete can have a frame structure. In this case, the floor is based on beams with a square or rectangular cross-section resting on a strip or column foundation. Skull blocks are nailed to their side faces, which serve as support for rough flooring made of boards, cement-bonded particle boards or wood-polymer boards.

Expanded clay is poured between the logs (and 10 centimeters above them), on top of which a concrete screed is then made. If desired, water pipes for underfloor heating are laid in the concrete layer, which can be organized from a boiler installed in the bathhouse (or in the house). Make a screed with a slope towards the drain hole, install a wooden ladder on top with gaps between the boards so that water can drain.

Scheme of laying expanded clay on rough flooring

Option 2 - on logs with a screed on sheet material

In the second case, slab insulation (foam plastic or mineral wool) is laid between the joists, and instead of screed, two layers of cement-bonded particle boards (CPS) are mounted directly over the joists. Then the slope is formed in the same way using a concrete screed placed on top.

Note: Bulk and slab insulation materials are inferior in efficiency to foamed polyurethane, which ensures complete tightness of the structure. But this option will also be the most expensive.

Scheme with slab insulation between the joists

Option 3 - monolithic

In the third case, the floor is laid on the ground. It consists of two inclined planes leading to a small rectangular tank with a sewer pipe connected to it. Brick pillars are installed on top of the concrete screed, on which a wooden ladder can be supported. If necessary, the insulation can be laid under a concrete slab - the same expanded clay or rigid slabs of extruded polystyrene foam.

Ground floor diagram

Insulation of bathhouse walls made of expanded clay concrete blocks

Before you begin insulating the walls of a bathhouse made of expanded clay concrete blocks, it is necessary to prepare their surface. To do this, the enclosing structures are cleaned and plastered to a smooth state. Further work proceeds in this order:

- Using a building level, a wooden sheathing made of timber is installed on the walls using pre-laid waterproofing.

- The distance between its vertical elements should be 2-3 cm less than the width of the insulation boards. This will allow the insulation to fit tightly to the sheathing and hold onto it on its own.

- The frame cells are filled with basalt wool slabs.

- A vapor barrier layer made of a foil membrane made from kraft paper is laid on top of the insulation. Its reflective side should be directed inside the steam room. The membrane sheets are overlapped by 15 cm, the joints between them are taped with metallized tape. It is attached to the sheathing using a stapler.

- Then, in a direction transverse to the beam, a counter-lattice is attached on top of the vapor barrier layer. It is necessary for installing external wall cladding and creating a ventilation air gap under it, which will provide the foil with a heat-reflecting effect and remove condensation from its surface.

- At the final stage of insulation, the outer cladding is performed. The material used in the steam room is natural wood.

Bathhouse ceiling and roof made of expanded clay concrete

Compared to the thermal insulation of other building structures, the insulation of the ceiling of a bathhouse made of expanded clay concrete blocks is of paramount importance. It operates in extreme impact mode at the border of high and low temperatures. In order not to heat the air around the bathhouse, but to retain precious heat in the steam room, the ceiling is insulated in two ways - closed and open. The open insulation option is used for baths in which the attic space does not have a floor. The wooden ceiling lining is covered with a waterproofing foil membrane and covered with a granular heat insulator with a layer of more than 25 cm. Another open method of ceiling waterproofing has been used for a long time, but is still relevant today. It consists of using instead of a membrane a layer of oily clay 3-4 cm thick with the addition of sawdust; after drying, it is covered with oak leaves and dry soil. The method is very effective and has proven itself in work. Its only drawback is the increase in the weight of the floor - an additional calculation of the cross-section of the ceiling beams is required. However, expanded clay is more often used for backfilling. Another waterproofing layer of roofing material or polyethylene film is laid on top of the insulation; they are attached to the beams using a stapler. The closed method involves installing a flooring made of boards on top of the thermal insulation, which makes it possible to use the attic space for economic purposes. The flooring is nailed to the joists. The insulation cushion underneath consists of three layers in succession: a vapor barrier made of foil material, insulation made of mineral basalt wool and waterproofing made of roofing felt. The standard rules for installing a warm roof for a residential building also apply to bath buildings. The choice of materials for its insulation depends on the functionality of the attic space. Mineral wool, as an absolutely environmentally friendly heat insulator, is used to insulate recreation rooms or billiard rooms. To insulate warehouses, you can choose glass wool, saving 20-30%. How to insulate a bathhouse made of expanded clay concrete - watch the video:

Brick and stone are “cold” materials. Therefore, the better you insulate a bathhouse made of expanded clay concrete blocks, the less heat loss can be expected in its premises. With proper organization of labor and adherence to technology, you can do it yourself.

Design and calculation of materials

When building a bathhouse, no matter how simple a structure it may seem, it is necessary to take into account all the subtleties and nuances even before starting work. Developing a project, even independently, will help you avoid mistakes.

Bathhouse project

It should include the location of the bathhouse on the site, the layout of the premises, the need for materials, and their storage locations.

When developing the layout, you must take into account how the bathhouse will be used and how many people can stay in it at the same time.

In a building that is being built only to accommodate the necessary bathing procedures, ensuring hygiene, a minimum set of premises will be sufficient: a dressing room, a wash room, a steam room. Sometimes the last two rooms are combined into one.

If you plan to hold events related to relaxation in the bathhouse, and even in company, you can, for example, provide a bathhouse with a gazebo under one roof.

Bathhouse made of expanded clay concrete blocks with a gazebo

Depending on the purpose of the bathhouse, the roof structure is also designed. In the first case, it can be an ordinary gable with an attic, and in the second, it is already possible to provide an attic room under the roof for guests to relax.

It is better to deliver most of the materials to the site in advance to avoid subsequent time and financial waste. It is not difficult to make a preliminary calculation if you know the range and prices of products in the region. At the same time, clarity immediately appears even for a person who has never been involved in construction. For example, to build a 4x6 m bathhouse from expanded clay concrete, only 600 blocks are needed for the walls, that is, about 8.5 m3 of material.

The finished project will be a kind of step-by-step instruction for the future owner if he decides to carry out construction on his own.

A little about the choice of expanded clay concrete blocks

When people think about building a bathhouse, the source of information about the quality and performance properties of materials is reviews from more experienced builders. According to many owners of buildings made of expanded clay concrete blocks, the main thing is to find a good supplier. The material is inexpensive, so there are many cheap, low-quality analogues on the market. It is difficult to distinguish them by appearance, but it is still possible. If the block crumbles in your hand or splits when struck, then you need to look for another, more durable and reliable block block.

The second way is to pay attention to color. The more cement there is, the darker the shade of gray the block has.

Photo from our reader - a bathhouse made of expanded clay concrete on a summer cottage

There are practically no negative reviews of expanded clay concrete - the owners are almost always satisfied with the structure, noting that the bathhouse turned out to be warm, easy to use and maintain.

Construction stages

The construction of a bathhouse on the site can be divided into several stages:

- choosing a site for construction;

- project preparation;

- construction of the foundation and installation of communications;

- construction of walls and partitions;

- installation of roof structures and roof installation;

- installation of floors and finishing inside and outside;

- installation of necessary equipment and inventory.

Construction of a bathhouse from expanded clay concrete blocks

Selecting a location

When choosing a place where a bathhouse will be built, you have to take into account many factors, especially if the area of the site is large and the following options are possible:

- It is necessary to take into account the standards for placing buildings on the site. For almost all outbuildings, and the bathhouse is one of them, it is required to maintain a distance of at least 1 m from the border of the site.

- If the area is small and gardening is carried out on it, the bathhouse should be located on the north side in order to shade the area as little as possible.

- Provide for the possibility of arranging future communications. It is good if the site has centralized water supply and sewerage. Then it is enough to take into account only the financial side of the construction of supply networks. If all life support systems are autonomous, you will have to make a separate sewer system for the bathhouse, especially if there is a bathroom. Then it is better to place the bathhouse at the lowest point of the site’s relief.

Location of the bathhouse on the site

The ideal option would be to place a bathhouse on the shore of a natural or artificial reservoir, if there is one on the site. This is where there is freedom for lovers of a traditional bathhouse with buckets, rockers, watering cans and swimming in an ice hole in winter. The water supply problem will also be largely resolved.

Of course, it will not be possible to take into account all factors and meet all requirements perfectly. Based on the conditions of future use, the most compromise solution can be found.

Foundation structure

Since the material of expanded clay blocks does not tolerate tensile loads, the walls should not be subjected to even the slightest bending. Such forces can occur when the foundation moves unevenly. It can sag due to soil heterogeneity, exposure to high groundwater and due to frost heaving in winter.

Shallow strip, pile, and column foundations on most soils are not suitable for block walls.

Shallow strip foundation

Their structures do not have sufficient spatial rigidity, and the walls will simply crack. As an exception, such foundations can be used on rocky or permafrost soils, where vertical movements will be minimal.

For walls made of expanded clay concrete blocks, a strip foundation with a base buried below the freezing level or a solid (slab) foundation is ideal.

The technology of a recessed strip foundation is quite difficult for DIY construction. In addition, when designing it, it is necessary to have knowledge of the composition of the soil and the height of groundwater, as well as the depth of soil freezing in winter.

Perhaps the most acceptable option when building a bathhouse from expanded clay concrete blocks with your own hands is a slab foundation. It is practically universal, can be erected on any soil, and its base area will provide high load-bearing capacity.

Slab foundation

The foundation is a monolithic reinforced concrete slab lying directly on the ground or on a layer of insulation. Of course, a preparation of well-compacted sand must be made under the slab. Formwork work will require a minimum of materials and time. It is enough to install boards made of boards 20-30 cm wide around the perimeter of the foundation. Next, you need to build a reinforced frame, which you can also make yourself, and pour in the concrete mixture, compacting it well using a vibrator.

Building walls

The construction of walls must begin with the installation of horizontal waterproofing of the foundation, otherwise moisture from the soil, seeping through the foundation, will quickly destroy the expanded clay concrete.

The blocks are laid using ordinary cement-sand mortar. The thinner the layer, the better the quality of the masonry. Correct block sizes facilitate quick installation.

Laying expanded clay concrete blocks

Do not forget about the need to reinforce the masonry to compensate for tensile forces with reinforcement, which can arise not only from the movement of foundations, but also from the effect of wind load on the walls. Reinforcement is made with steel reinforcement. Corners must be reinforced. In this case, the reinforcement should bend and not be laid crosswise.

Roof

The roof of the bathhouse can be of any design. The main requirement that is worth paying attention to is the maximum use of non-flammable and difficult to ignite materials. All parts of the rafter system and sheathing must be treated with fire retardant compounds.

Where chimneys pass, it is better to insulate wooden products with non-combustible sheet materials. Good ventilation must be provided in attics. The simplest option is to install dormer windows in the gables. Windows must open.

Chimney pipe passage through the roof slab

Wall decoration inside and out

Finishing a bathhouse made of expanded clay concrete blocks is not difficult. The wall material holds any fasteners well; its strength is sufficient for the installation of any finishing coatings.

The inside of the bathhouse is traditionally decorated with wood. For this purpose, lining, timber simulator, and decorative wooden panels are used. In the steam room, where the temperature reaches high values, the use of coniferous wood is not allowed due to the high resin content. Most often, aspen or linden materials are used for finishing.

The washing room can be finished with glazed ceramic tiles. At high humidity, this option will be the most rational.

Decorating the walls of the washing room

Externally, expanded clay concrete blocks can be plastered and then painted, or covered with one of the types of artificial coatings for outdoor use. A bathhouse made of expanded clay concrete blocks, lined with an imitation log frame, looks impressive.

Floor installation

The floors in the bathhouse are either planked on wooden joists or tiled on a concrete base.

The joists can rest on foundation ledges or be installed on brick pillars. The boards in the washing room are mounted with a gap to ensure water drains through the floor.

All wooden products must be insulated from stone and concrete structures to avoid moisture in contact areas.

Tiled floors on a concrete base must be insulated. To do this, penoplex is laid over the concrete and a screed reinforced with steel mesh is installed. Tiles are laid on it. Water flows through special sewer receiving devices and drains connected to the sewer system.

Pros and cons of the material

A comparison with wood shows that expanded clay concrete is at least not inferior to it (if you focus on the whole range of properties). It has a good level of thermal insulation (other things being equal, it transmits 2–3 times less heat to the outside than brickwork). At the same time, expanded clay concrete blocks are lightweight; even parts measuring 40 x 30 x 24 cm are not a problem for adults to lift. Other advantages include:

- Reduced work time (since one block easily replaces an average of 12 brick rows).

- Possibility to carry out work on a continuous cycle. The structure should not be allowed to settle before installing the roof and starting finishing.

- The ability to use a standard solution of cement and sand during construction. Sometimes it is replaced with mounting adhesive foam.

- Formation of extremely smooth walls.

- Cost savings (when building a bathhouse, for example, measuring 5 by 5 m, the costs are 25–50% less than with classic wooden construction).

- Possibility to limit yourself to a strip foundation with shallow depth.

The weak points of the expanded clay concrete bath are the inability to build more than three floors, as well as the insufficient resistance of the blocks to mechanical damage. If the part falls or is hit, it will be broken. The cost-effectiveness is not that great: it is necessary to install cladding inside and outside the building. These shortcomings can be safely ignored. All the same, the quality of the expanded clay concrete bathhouse is noticeably superior to the wooden options.

Insulation, ventilation, communications

There is no need to insulate a bathhouse that is used only for washing. Expanded clay concrete blocks will provide sufficient thermal insulation for the duration of use, and the heat will be provided by the stove. Heat loss from wall structures can be ignored if the bathhouse will be used periodically - several hours a week.

If the duration of your stay in the bathhouse is planned to be quite long, then it is better to insulate the enclosing structures. And there are some subtleties here.

Despite the fact that external insulation is recognized as the most effective, it is better to insulate a bathhouse from the inside, given the periodic heating regime. This way it will warm up faster, especially in winter after a week's break.

Insulation of a bathhouse from the inside

The fact is that expanded clay concrete blocks have some thermal inertia. If they cool down very much, then the air in the bathhouse will take a long time to heat up, because there are ice walls around. Interior decoration will not improve the situation much. If there is insulation on the inside of the wall, the air will warm up much faster, despite the fact that the blocks will remain cold.

Ventilation in the bathhouse is carried out either naturally - through slightly open windows, or through ventilation ducts. They can be installed parallel to the chimney in one brick riser. Drying the bath after use is carried out in the summer through the windows, and in the winter through the stove pipe, for which the valves are left open.

Electrical wiring in the bathhouse must be waterproof. In wet rooms - washrooms and steam rooms, the supply voltage should be no more than 12 V. To ensure this, a step-down transformer can be installed in the dressing room or vestibule.

Electrical wiring in the bathhouse

All lamps in the bathhouse must be protected from splashes. The degree of protection is not lower than IP54.

Preparatory work before the construction of an expanded clay concrete bath

During preparatory work, the selected plot of land is marked around the perimeter with wooden pegs, and then the fertile layer is cleared off and the area is leveled. Depending on the type of foundation chosen, appropriate excavation work is carried out. Since expanded clay blocks are relatively light in weight, any base design can be suitable for them. For a strip type, they dig a trench around the perimeter with a depth below freezing of the soil, but not less than 50 cm, and for a columnar type, separate holes of the required size to a dense layer. If it is necessary to install a brick or stone oven, you will need to make a separate foundation from the main one.

Before the start of construction work, pipe communications should be installed, especially when concreting is carried out. This is due to the fact that subsequently the waterproofing layer can be damaged and the service life of the foundation can be significantly reduced.

Sauna stove options

The “heart” of the sauna is the stove. There are many varieties of electric or gas stoves, but a real sauna needs to be heated with wood. They can be made of brick, stone, or metal. Some designs include tanks for heating water.

The placement of stones in the furnace can vary. More often there are options when the stones are located on a metal sheet, heated from below by firewood burning in the firebox. Such a stove can be heated during the bath procedure. They are called constant firing furnaces.

Wood burning stove

The design is closer to the traditional one, in which the stones are located inside massive brickwork, and all the heat from the firebox goes directly through the heater into the chimney. Such stoves are heated before the bathhouse begins to function. The stones are heated until they turn red and their self-cleaning effect occurs. After this, the stove is extinguished and closed with a valve in the pipe - a view. Then you can take a steam bath. These furnaces are called batch furnaces.

In modern life, a bathhouse has long ceased to be an urgent need, but the physical benefits of the procedures and the good spirits after visiting them still make it one of the most popular types of recreation and pastime.

Bathhouse projects made of expanded clay concrete blocks

The standard layout and design of a sauna building made of expanded clay concrete is not very different from traditional buildings made of cinder block or foam concrete. The most popular solution is the design of a bathhouse with a 6x4 attic made of expanded clay concrete.

The standard layout of such a bath looks like this:

- On the ground floor there is a relaxation room and a steam room with a washing area;

- There is a guest room in the attic;

- The bathroom or boiler equipment is removed outside the building.

A sauna building made of expanded clay concrete will look more natural if the façade and gables are covered with clapboard polished to look like a log, and the walls are lined with white siding.

What will you need to build a sauna from a ceramic block?

In addition to the main bathhouse box, it is necessary to carry out all communications that will ensure the uninterrupted operation of all systems. In addition to ventilation, you need: water supply, electrical networks, sewerage. The water supply can be supplied from a centralized network on the site. If there is none, you can use a nearby well or borehole.

To heat water you will need a reliable and economical gas boiler. The sewer system must be autonomous, not connected to the house’s drainage system. Electricity can be obtained by connecting to a centralized power grid or using generators. All communications and their location must be discussed at the project creation stage.

Before starting construction work, you should take care of purchasing everything you need: building materials and auxiliary equipment.

For DIY construction you need:

- expanded clay blocks;

- cement;

- sand;

- crushed stone;

- water;

- thermal insulation, roofing material;

- cladding;

- bitumen mastic;

- mineral wool.

Tools you will need:

- reinforcing mesh;

- rafters;

- shovel;

- building level;

- Master OK;

- roulette;

- pegs and anchors;

- bucket.

After preliminary purchases, you will not have to waste time on additional calculations and purchases. Baths made of expanded clay blocks are reliable and will delight your family with their warmth for many years.