Screw piles today are increasingly used for the construction of the foundations of private houses and in the construction of larger-scale industrial facilities. Supports of this type experience enormous loads and, after the construction of the building is completed, continue to be subject to the destructive effects of environmental factors. That is why many are now wondering whether it makes sense to use screw piles or whether the service life of these widely available building elements is too short?

A little history

Screw-type piles appeared about 200 years ago. All this time, they were widely used in the construction of bridges, piers, towers, power lines and many other serious objects. There is a lot of evidence that the service life of screw piles can be up to 150 years. For example, the pier, which has been standing in sea water on similar supports for more than a century and a half, has not yet collapsed.

There are entire museums where visitors can personally examine the tips of the very first screw piles. However, this does not mean that metal structures will last forever. Negative reviews about the service life of screw piles are quite justified, since the supports made using handicraft methods actually collapse quite quickly. The manufacturing technology of building structures has a lot of nuances and features. If production standards were violated, then the finished piles will not last even a third of the declared period. Therefore, it is very important to pay attention to these subtleties when choosing structures for the foundation.

How does it improve the performance characteristics of screw supports?

For the employees of our company, the production of screw piles is not only about achieving a competitive advantage over other companies. The most important aspect of the work is that the company bears full responsibility for both the erected foundation and the screw piles themselves. In this regard, our employees are making significant efforts to improve the technical characteristics of manufactured piles and increase the service life of screw foundations. Among the measures taken, the main ones can be noted:

- When manufacturing screw supports, our company strictly adheres to all technical standards. To do this, we purchase materials that comply with standards, for example, we use only seamless pipes. We also make sure to maintain the stated thickness of the walls of the barrel and blades. In the case of welding work (production of welded screw piles), careful control over their quality is carried out. This allows the production of piles with a long service life.

- Application of anti-corrosion coating to screw piles. Studies have shown that good anti-corrosion protection extends the service life of screw piles by 7 - 15, and with hot-dip galvanizing - up to 20 years. We produce cold galvanizing of welded screw piles. And we apply a special two-component protective coating to the cast supports. These measures make it possible to increase the service life of screw piles.

- Geological exploration and test screwing of the screw support. Handicraft crews neglect these works. However, without them it is impossible to obtain data on the optimal depth for screwing piles, and also to use additional protection methods, for example, when high acidity of the soil is detected. Geological exploration allows you to make a decision about how and which piles need to be loaded in each specific case.

- The builders of our company constantly monitor the quality of the work performed. First of all, this is the correct choice of the piles themselves:

- Diameter;

- Height;

- Type of anti-corrosion coating;

- Number of blades;

- Tip type (cast or welded), etc.

An important point is the screwing of the support, because even a slight deviation from the screwing axis can affect not only the service life of the screw pile, but also lead to significant problems with the overall design of the base. The manual immersion of supports is especially carefully controlled, since the so-called human factor is present. It is not the fact that important stages of work are performed that are controlled, but their quality.

Service life according to GOST

According to government regulations, the service life of screw piles ranges from 60 to 120 years. GOST also indicates the following data:

- Electromechanical corrosion of metal in soil develops at a rate of 0.02 to 0.05 mm per year.

- The thickness of the walls of the screw and the support itself is at least 5-6 mm.

- The walls of the pipes decay at a rate of 5 mm/0.5 = 100 years.

In addition, the piles are coated with special two-component polymer compounds that retain their properties for 7-15 years. This allows you to increase the service life of screw piles under the foundation. If these conditions were violated during the manufacturing process of the supports, the products will be less reliable and durable.

Structural characteristics of pile pipes

Screw piles are a structural element that performs load-bearing and strengthening functions. They are used as a basis for a building and take on the load. Supports strengthen the structure of the building, make the foundation stronger, and increase its service life.

Piles are tall metal pipes with blades at the bottom. The pillars have a certain diameter, which is determined depending on the type of soil and building. The supports are equipped with a hole on top through which an iron rod is passed to screw the pile into the ground.

Scheme of a screw pile for a foundation

The service life of piles is more than 50 years. This effect is achieved thanks to special production technology, the use of anti-corrosion protection and proper installation. In order to save money, many lay the foundation on pile structures themselves, without resorting to the services of specialists. This often causes damage to elements, for example, seams coming apart.

Before purchasing building material, invite an expert to the site to assess the condition of the soil and determine the required number of piles. This will help avoid problems when building a house.

Is there a difference between cast screw and welded pile caps?

There are no significant differences between these products. Cast tips are made from standard steel marked 35L. The main difference between these support elements is that the screw lines are not welded to the pile cones, but are immediately cast together with them. However, few people know that cast ends are actually welded to the pipe. This means that when using them it will not be possible to avoid welds.

If we talk about the disadvantages of cast tips, then during their production it is necessary to control the level of casting quality. In addition, their production is impossible without the use of ultrasonic equipment. The fact is that the material from which the product is made may contain small cracks, pores and voids, which will significantly reduce the strength characteristics and service life of screw piles.

Welded tips can be checked independently, since even with a visual inspection it becomes possible to assess the quality of production of the products. Piles with cast lines cost almost 25% less.

History[ | ]

Pile foundation construction has been known since ancient times, but for many centuries its use was limited by the material from which the piles were made (wood) and the method of driving them (driving). In the 20th century, wooden piles were replaced by reinforced concrete ones, which expanded the scope of application of pile foundations, but the immersion method remained the same, although it received a number of improvements.

Invention of screw piles

Solving the problem of constructing offshore structures on soft soils such as sandy reefs, mud terraces and estuaries, civil engineer Alexander Mitchell (1780–1868) invented and patented in London in 1833 a new device called the “screw pile.” . For his invention he received the Telford Medal and membership of the Institution of Civil Engineers.

Screw piles were originally used for ship berths and consisted of a metal pipe with an anchor screw at the end. They were screwed into the ground below the silt level by the efforts of people and animals using a large wooden wheel called an anchor capstan. Up to 30 men were hired to install screw piles ranging from 20 feet (6 m) in length with a 5-inch (127 mm) shaft diameter.

The first technical document Mitchell wrote regarding screw piles was “On Subsea Foundations. Screw piles and piers in particular”[1]. In his work, the engineer stated that screw piles can be used to provide load-bearing capacity or resist pull-out forces. In his opinion, the load-bearing capacity of a screw-pile foundation depends on the area of the screw blade, the nature of the soil into which it is screwed, and the depth at which it is located below the surface.

In 1838, screw piles formed the basis for the foundation of Maplin Sands Lighthouse on the unstable coastal soil of the River Thames in Great Britain. To strengthen sea piers, the technology of screw piles was first used by the architect and engineer Eugenius Birch[en] (1818-1884). From 1862 to 1872, 18 sea piers were built.

The expansion of the British Empire contributed to the rapid spread of technology throughout the world. Thus, from the 1850s to the 1890s, 100 lighthouses were built on screw piles along the East Coast of the United States and along the Gulf of Mexico alone.

In the period 1900-1950, the popularity of screw piles in the West decreased somewhat due to the active development of mechanical piling and drilling equipment, but in subsequent years the technology began to develop rapidly in the field of individual, industrial and large-scale civil construction.

Development of screw pile technology in the USSR and Russia

Technology came to Russia at the beginning of the 20th century. Then screw piles became widespread in the field of military construction, where their advantages were fully appreciated - versatility, the ability to use manual labor, reliability and durability, especially in heaving, waterlogged or permafrost soils. These advantages were proven thanks to the works of the Soviet engineer Vladislav Dmokhovsky (1877-1952), who conducted comprehensive research in the field of pile foundations (the theory of conical piles).

The theoretical basis for the use of screw piles and the technology for carrying out work were developed in the USSR only in the 1950-1960s. At the same time, installations for screwing them were designed and manufactured. Significant contributions to the systematic study and experimental development of the use of screw piles in construction were made by G. S. Shpiro, N. M. Bibina, E. P. Kryukov, I. I. Tsyurupa, I. M. Chistyakov, M. A. Ordelli, M.D. Irodov and others. The works of these authors contain valuable information necessary for determining the technical parameters and geometric shapes of screw piles, solving structures and selecting materials for their manufacture.

The researchers obtained extensive materials on the bearing capacity and movement of screw piles in different soils, and determined the influence of the size of the blade and the depth of its immersion on the bearing capacity of the piles. The experience of driving a large number of screw piles of various sizes and materials made it possible to develop a technology for driving them into the ground, determining the rotation speeds, the magnitude of torques and axial forces required for driving. In 1955, “Technical guidelines for the design and construction of foundations for bridge supports on screw piles” (TUVS-55) were published; then - “Guidelines for the design and construction of masts and communication line towers made of screw piles,” which was the result of the implementation, testing and trial operation of communication line towers up to 245 m high in 1961-1964.

One of the first scientists to consider screw pile foundation technology through the prism of scientific experience was Doctor of Technical Sciences, civil engineer V. N. Zhelezkov[2]. Scientists have proven that screw piles are not only a full-fledged alternative to traditional types of foundations, but also have a number of advantages over them, for example, when it comes to difficult geological conditions.

V.N. Zhelezkov also developed a method for determining the load-bearing capacity of piles based on the magnitude of the torque for both compressive and pull-out loads. In 2004, he published the monograph “Screw piles in the energy and other industries”, which collected valuable experimental data on determining the bearing capacity of screw piles for compressive, pull-out and horizontal loads.

The intensive introduction of screw piles into construction and energy began in the mid-1960s. This was facilitated by the expansion of work on the reconstruction of buildings and structures, the implementation of construction work in cramped urban conditions or in industrial areas, which required the development of deep pits in close proximity to existing foundations. Another reason for the development of the technology of pile-screw supports was the increase in the volume of installation work in construction. The installation of heavy structures for chemical, metallurgical, and energy facilities required the development of new types of foundations and expansion of the scope of their use. Screw supports are most widely used in the communications and telecommunications industries (fastening power line supports).

In Russian low-rise and individual housing construction, screw piles began to be widely used at the end of the 20th - beginning of the 21st century [ source not specified 372 days

].

Difference between Russian and Western approaches

The development of screw piles in the USSR was carried out independently of the research of Western scientists, with high speed and ease of driving in high-density soils becoming the priority tasks. These requirements were met by a deaxial steel screw pile with a cast tip and one blade of 1.25 turns, starting on the beveled part and gradually increasing in width, the design of which was developed by V. N. Zhelezkov. This pile, despite the relatively small amount of torque, does not require the use of additional loading force when screwing. However, being universal, it has a low load-bearing capacity, to increase which it is necessary to increase the diameter of the trunk and blade, which leads to increased construction costs. Nevertheless, such a pile is still used quite widely in Russia and the post-Soviet space.

Western developers, on the contrary, have focused on providing the necessary load-bearing capacity with a minimal increase in material consumption. This led to the abandonment of fastening the blades to the pile cone, and to increase the load-bearing capacity, the designers resorted to increasing the diameter of the blade and the number of blades. Due to the introduction of new technologies, pile-screw foundations have become widely used in the field of civil engineering. According to the International Society for Soil Mechanics and Foundation Engineering (ISSMGE), in 2010 screw piles already occupied 11% of the Western market, gradually displacing driven piles.

Is there a difference between painted and galvanized pile caps?

The main difference is the resistance to corrosion. According to numerous reviews, the service life of screw piles treated with paint and varnish material is significantly lower due to the influence of an aggressive environment. The protective coating lasts for a maximum of 15 years, after which metal products begin to rust quite quickly.

Piles that have undergone hot-dip galvanizing do not corrode for 40-50 years. However, it all depends on the aggressiveness of the soil. Thanks to the hot-dip galvanizing method, a layer 0.2 mm thick is formed on the surface of the piles, which does not wear out over a long period of time. In addition, the protective zinc layer will not be erased during the process of screwing the support.

It is also worth paying attention to the cost of the products. Supports that have undergone hot-dip galvanizing will cost 25% more than products treated with paint and varnish material.

Types of pile foundations, materials and features

Foundations of this type can have different configurations, piles are made of different materials and differ in shape.

Pile foundation layout

According to the design solution, the pile foundation can be represented by:

- single piles;

- pile bushes;

- pile tapes;

- pile fields.

Single piles , as a rule, are used as foundations for columns and racks, the load on which does not reach large values. This foundation design can be used for power line supports, as well as other mast or tower structures erected on unstable, weak-bearing soils.

Pile bushes are several piles driven close to each other, united by an overlying structure - a grillage. Like single piles, bushes are foundations for columns. But the reliability and load-bearing capacity of such a foundation will be significantly higher than that of a single pile. For any design solution for a pile foundation, the minimum distance between piles is valid - it should not be less than three nominal diameters of the pile section.

Pile strips are usually installed as foundations for walls. Piles are driven in one or more rows, forming elongated ribbons. In this case, a beam-type grillage is used.

Pile fields are designed as foundations for multi-story buildings, as well as structures that transfer significant loads to the foundation. A distinctive feature of the pile field is the location of the piles under the entire building and the arrangement of a common slab grillage that follows the contour of the building.

An analogy can be drawn between the design solution and layout of shallow and pile foundations: single piles and bushes correspond to columnar foundations; pile strips - strip, pile fields - slab foundations.

Grillages

A grillage is an element of a pile foundation that ensures the joint operation of a group of piles. Suitable for pile bushes, strips, fields. Depending on the way it interacts with the ground, the grillage can be low or high.

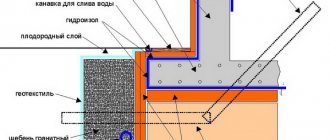

Img Photo by Random Sky on Unsplash

A low grillage is immersed in the ground; when designing it, the same principles apply as when designing shallow foundations. The main ones are: the bottom of the grillage must be below the freezing depth of the soil ; it is also necessary to ensure waterproofing of the foundation. The main feature of a low grillage is that the load from the overlying structures is transferred to the base not only along the surfaces of the piles, but also along the base of the grillage. It can be considered as a shallow foundation and taken into account in the calculation.

A high grillage is installed above the planning level, so it does not come into contact with the ground. This solution is recommended for use in swampy areas, as well as on foundations with a high groundwater level.

Rack piles and hanging piles - differences, features

According to the method of interaction with the soil, piles can be divided into:

- hanging piles;

- piles-racks.

Friction piles transfer load to the foundation due to the frictional and adhesion forces that arise between the side surfaces of the pile and the foundation soil. For such a solution to the foundation, a settlement calculation is required, since the piles are located in compressible soil in a free state and are not connected to strong engineering geological layers of the base. Suspended piles are used in cases where, during engineering surveys at a construction site, no soil was found at an accessible depth that could become a supporting layer for rack piles.

Rack piles transfer the load from the building to a strong incompressible base layer, which serves as a support for them. The task of the rack pile is to go through the unreliable upper layers of the soil and ensure that the foundation rests on the underlying layers, if they have the required load-bearing capacity. The classic case of installing rack piles is a geological situation in which under a weak-bearing compressible top layer of soil there is a strong layer, represented, for example, by rocky soil. Often this type of foundation is arranged for bulk foundations: the piles pass through the bulk layer of soil and reach the underlying pillar, which is represented by dense loam of natural origin.

Soils that can serve as a load-bearing layer for rack piles:

- rocky;

- coarse clastic;

- dense clayey.

When calculating foundations on rack piles, in most cases the friction forces on the side surfaces of the pile are neglected. It is necessary to ensure the strength of the pile: in terms of the type of work under load, this type of pile resembles columns. In most cases, only calculation of the strength of piles is necessary; calculation based on deformations - foundation settlement is not required. This fact is also a characteristic feature of this type of pile foundation.

Methods for driving piles into the ground

Due to the wide variety of design and technological solutions for constructing a pile foundation, there are many ways to install piles in the design position. The main ones:

- driving;

- printed;

- drilling;

- screw.

These methods can be divided into two categories: with and without excavation. Driven and cast-in-place piles are installed without excavation, while drilled and screw piles are installed with excavation.

Driven piles

Driven piles are driven into the ground using diesel hammers, vibratory hammers, vibratory pressers and other similar mechanisms. Basically, driven piles are made of reinforced concrete and have a fairly large cross-section. The length of driven piles depends on the cross-sectional area. The most common piles are with a cross section from 300x300 to 500x500, the length of which ranges from 3 to 14 m. The possibility of constructing composite piles of greater length is provided.

Advantages of the method:

- relative ease of performing the work;

- no auxiliary excavation work required;

- possibility of carrying out work in winter;

- Concreting of piles in the ground is not carried out.

Flaws:

- creating vibration that can disturb the foundations of neighboring buildings;

- excessive consumption of reinforcement, since the pile is required to withstand transport and installation loads;

- a significant percentage of broken and unfinished piles.

To install the driven pile in a vertical position, a special mechanism is used - a pile driver. Driving piles is most often done using a hydraulic hammer. The pile is driven to the required depth and can be stopped if the pile fails - the distance to which it has sunk in one blow - is less than the specified value.

Driven and drilled piles

They are installed in pits made using a removable pile or an inventory pipe (blank). The resulting well is filled with concrete mixture. Wells of bored piles are carried out using auger drilling installations, immersion of retrievable and non-retrievable casing pipes. The diameter of piles of this type is 0.5-1.2 m, length – up to 25 m.

Advantages of the method:

- no need to deliver large prefabricated elements to the construction site;

- optimal use of reinforcement;

- the possibility of installing inclined piles, as well as piles with an expanding heel.

Flaws:

- low speed of work due to the presence of additional operations;

- complex concreting process;

- It is not recommended to install cast-in-place piles in soils that are aggressive to concrete.

Bored injection piles can be successfully used in the reconstruction of dilapidated buildings. This method does not create vibration; drilling can be carried out in close proximity to the building. The drilled well is filled with a special solution. This method was used to reconstruct historical buildings built on wooden pile foundations.

Screw piles

The installation of screw piles is a special case of drilled piles. A distinctive feature of the method is the material and shape of the pile itself. Screw piles are made of metal; at their end there are special blades that provide the ability to screw in the pile, as well as a large friction area and a supporting heel. The length of such piles can reach 12 m. Screw piles are often used for homestead construction in swampy areas or on weak, unstable soils.

Advantage of the method:

- relatively simple and fast installation technology;

- possibility of carrying out work in winter;

- good resistance to settlement and pulling out of the foundation.

The disadvantages of drilled piles include the need for thorough anti-corrosion treatment. The piles must be screwed in carefully so as not to damage the protective layer.

Pile material

Depending on the installation technology and site conditions, the following materials can be used to make piles:

- precast reinforced concrete – for driven piles;

- monolithic reinforced concrete – for castings, drilling

- cement mortars – for drilling injection;

- wood - for driving;

- metal – screw, driven piles.

Prefabricated reinforced concrete piles are manufactured at specialized enterprises according to standard catalogs and series. Due to the correct hardening technology, the concrete of such piles has greater strength and is less susceptible to destruction in aggressive environments.

Monolithic reinforced concrete is used to fill drilled or squeezed holes. The technology for properly concreting such piles is quite complex: it is necessary to supply the concrete mixture to a considerable depth, preventing it from falling from a great height, otherwise the concrete will delaminate. Injection solutions have a fine filler; a significant amount of modifiers is added to them for better filling of deep wells of small diameter.

Wooden piles are used for temporary buildings in regions where wood is an available common material. Such piles require additional treatment with compounds that prevent the material from rotting.

Driven piles can be made of steel, either from rolled sections or in the form of composite sections. The most common are screw metal piles.

Pile sections

Piles can have the following cross-sectional shapes:

- rectangular, square;

- tee, I-beam;

- round.

Reinforced concrete driven piles have mainly a rectangular cross-section. Friction piles can be designed in T- and I-sections to provide more lateral surface area. This cross-section provides greater rigidity and bending strength. Drilled piles have a circular cross-section.

According to the type of longitudinal section, piles are divided into:

- rectangular (prismatic);

- pyramidal;

- trapezoidal;

- with an extended heel.

The last three types are best suited for installing suspended pile foundations in a compressible foundation.

What affects the decrease in durability

The service life of a foundation on screw piles can be significantly reduced due to the following factors:

- Impact of moving soils. Under normal conditions, soil has minimal impact on screw piles. However, if we are talking about extreme conditions and increased soil mobility, this may affect the performance characteristics of the supports.

- Thermal impact. Due to seasonal temperature fluctuations, the metal constantly contracts and expands, its structure is disrupted. The bearing capacity of the supports is significantly reduced as cracks and pores appear in the material. When using high-quality piles, the number of freezing and defrosting cycles of which is enough for up to 120 years, this does not happen.

- Chemical corrosion. If the acidity level in the soil is exceeded, then rust on the piles will spread much faster.

- Electromechanical corrosion. Such damage occurs when piles are severely oxidized due to stray currents that may be part of the soil. Most often, supports located near underground cables or various industrial facilities suffer from electromechanical corrosion.

Calculation and installation of a pile-screw foundation

Based on the fact that even piles of not the largest diameter have sufficient load-bearing capacity, it is considered optimal to install them along the perimeter of the building, under load-bearing walls and at their joints at a distance of 2-3 m. The depth of their installation should also be determined based on such a parameter as soil freezing in winter.

Laying out the pile field

The places where the piles are screwed into the soil are preliminarily marked with pegs, guided by the plan of the future structure.

Screwing in piles with your own hands

When screwing in piles, which, by the way, can be done by several workers with their own hands using a lever, you should control the even vertical position of the pile relative to the horizon. The wider the diameter of the pile, the more difficult it will be to screw in. Of course, you need to use a lever, it is inserted into the top hole of the pile, the wider you make the lever, the less effort you put in, it is recommended to make the lever 2-3 meters.

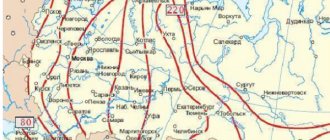

Piles are always screwed in below soil freezing, the average value in Russia is 1.3-1.5 meters. At the end, the pile reaches hard soil and the pile enters the soil very difficult, almost impossible.

Driving piles using special equipment

Also, if the construction budget allows or there are not enough workers, you can use the services of special equipment.

Leveling the pile foundation to level

After all the piles are installed in the ground, the pile-screw foundation, like any other, is checked and leveled. The most convenient way to do this is with a hydraulic level or nevilir. If necessary, the piles are tightened or the protruding part is cut off with a grinder.

Pouring piles with concrete

After leveling, a concrete mixture is poured inside the piles, which is designed to protect them from corrosion from the inside.

Installation of a grillage on a pile-screw foundation

At the final stage, the grillage is installed, i.e. the very foundation for the future home. For lighter structures, for example, houses made of timber or logs, it is possible to install a grillage made of thick timber. For houses made of bricks or blocks, it is better to make the grillage using reinforced concrete.

A pile-screw foundation will not require any time for shrinkage; construction of the house can continue immediately after installing the grillage. Now you can begin installing the frame of your house. The foundation is ready for loading and full use.

Where to buy piles and what is the price?

Go to the Leroy-Merlin online store=>>

BUY screw piles=>>

How to increase the service life of screw piles

There are several ways that will help extend the “life” of a foundation installed on supports of this type:

- Use piles with thickened walls. Every millimeter of metal increases service life by approximately 15 years.

- Use supports made only from alloy steel. Piles must be treated with special compounds that prevent chemical corrosion.

- If the products are not protected from rust, you must coat them yourself with anti-corrosion compounds.

- Concreting the inner shaft. Thanks to this procedure, you can protect the structure from moisture and increase the load-bearing capacity of the support.

It is not recommended to use impact equipment during the installation of piles. This will preserve the structure of the products and increase their service life. If the piles were installed in accordance with the regulations, the supports will last up to 100 years.

Advantages of screw piles

Despite the problems that can arise with the operation of supports of this type, they are still very often used for the construction of foundations and the construction of other structures. This is explained by the following advantages of screw piles:

- A medium-sized foundation can be erected in the shortest possible time (no more than 1-2 days).

- The cost of the foundation is almost halved, making the construction of the entire structure much cheaper.

- Screw piles are optimally suited for use on unstable soils.