Mesh reinforcement. Price in estimate.

Before choosing a price in the estimate for reinforcement, it is important to study the technological and design data and requirements necessary for the correct and safe construction of a particular facility.

During the construction of a facility, when carrying out concrete work and erecting structures made of concrete, brick, stone and many other materials, there is often a need to reinforce the structures being built. Reinforcement is performed with the aim of strengthening the structure in relation to destructive external factors such as temperature changes, soil shrinkage, changes in humidity and many others. Reinforcement of wall, floor, and ceiling structures can be made from various materials, for example, reinforcing steel, anchors, and mesh. The choice of material for reinforcement directly depends on what the reinforced structure is made of and what loads it will bear during operation. All this data must be indicated in the design documentation of the construction project, with an exact indication of the brands, manufacturers, volume and other indicators of all materials for this type of work.

One of the most commonly used materials for reinforcement is reinforcing mesh. Meshes are made from different materials, each of which has its own advantages and disadvantages. Thus, metal reinforcing mesh is the most durable and stable, especially if you need to strengthen and secure load-bearing monolithic structures. However, the metal mesh is susceptible to corrosion over time, and the lack of flexibility and ductility can cause the destruction of the concrete structure itself. In this regard, in construction, meshes made of polymer and fiberglass materials, as well as fiberglass, are often used to reinforce structures. At the moment, there are many manufacturers of reinforcement mesh on the market, which differ not only in the material from which they are made, but also in the size of the cells, production method and other indicators.

What is concrete reinforcement and what are the design features of this type of reinforcing structures?

Nabetonka is an increase in the cross-section of a concrete slab in a horizontal plane in order to increase its load-bearing capacity and increase the strength characteristics of the structure as a whole. This option is often the only solution if it is necessary to strengthen the structure without carrying out large-scale work to replace the floors.

But, despite its apparent simplicity, this method of amplification requires certain nuances, which we will consider in this review.

In the photo - this is what the diagram of the reinforcing layer looks like

Basic requirements for work

Let us note right away that not all builders know what a concrete paving device is and what criteria should be taken into account when carrying out work, so it is important to scrupulously follow the technology, otherwise the resulting effect will be much lower than planned. It is important to know the following rules:

| Why is amplification done? | The main purpose of the work is to remove the payload from the plate; the resulting system should work like a monolith |

| How it works | An additional concrete layer helps to increase the leverage of the internal force pair, thereby increasing the load-bearing capacity |

| Conditions for achieving high results | The real effect is achieved only with perfect adhesion of concrete to the base; any shift negates all efforts |

| Feasibility of application | This option makes sense to use if it is impossible to solve the problem in other ways, since the requirements for the quality of work are very high |

Important! It should be remembered that strengthening slabs using this method significantly increases the weight of each element, which creates additional load on all supporting structures and the foundation of the structure. This factor must be taken into account when repairing old buildings.

For example, consider this option: if you lay 40 mm thick concrete on a 100 mm thick slab, the load-bearing capacity will increase by approximately 1.4-1.5 times.

The large weight of concrete causes additional load on the base and load-bearing elements

Work technology

As noted above, to achieve the best result, it is very important to carefully follow the technological process and perform work in strict accordance with the requirements that will be set out below.

Using pins or dowels

Concrete construction without any additional retaining elements is quite risky, since even a minimal shift of the layers relative to each other removes the monolith effect completely. In this case, the bearing capacity will be the sum of the combined deformation of the layer and the slab, and this value is much lower.

The work process itself has the following features:

- To achieve the best effect, it is important to use only heavy concrete, grade M250 and higher . In this case, strength is of fundamental importance; the price of these options is higher, but the quality is disproportionately higher.

- The second very important element is reinforced reinforcement . It makes the structure several times stronger, in addition, the reinforcing belt reduces the shrinkage rate, which also contributes to stronger adhesion of materials and provides additional stability.

It is necessary to use durable reinforcement with a diameter of at least 10 mm

- Surface preparation is also an activity that must be taken into account . The work is simple, but the adhesion of concrete and slab largely depends on it: first, remove debris and stains if any, then it is recommended to blow off the surface with compressed air. The last stage is to moisten the surface, but it is worth remembering that there should be no puddles.

Advice! If you have an industrial vacuum cleaner, then all contaminants can be removed with its help; the power of such equipment is usually enough to thoroughly clean the surface of all contaminants.

With the help of a construction vacuum cleaner, preparing the base with your own hands will not be difficult.

- One of the most common ways to prevent shear of the concrete is to install pins of low-height reinforcement . They are inserted into holes drilled in the slab at regular intervals and act as dowels, preventing the slab and the reinforcing layer from moving relative to each other. This option involves very labor-intensive work of drilling concrete and driving rods.

- There is another, simpler way to prevent the layer from shifting: holes about 5 cm deep are drilled at regular intervals across the entire surface . During the process of pouring concrete, the solution fills all the voids, which, after hardening, makes it possible to create unique keyed connections that make the reinforcing layer and the slab a single whole.

Due to the fact that the layer thickness can vary within 10 mm, during design a layer of at least 50 mm is laid. Based on this, it is necessary to calculate how much the load on the structures will increase, and whether it is advisable to carry out a set of measures.

Creation of a reinforced structure

Sometimes none of the above options are suitable due to the fact that the slabs are thin-walled and it is quite difficult to install pins in them or make holes for dowels.

In this case, there are several options with which you can add additional strength to the concrete structure:

- If there is such a possibility, then you can place metal supports under the slabs, which are either inserted into the walls and reinforced with struts, or placed on racks. The beams are placed in the transverse direction, thanks to which the load on the span is divided into 4-5 points instead of two.

Metal beams help strengthen the system

- Another great way is to open several voids along the entire length and introduce a flat cross-section stiffener into them. This method allows you to significantly strengthen the reinforcement and increase the area of contact between the concrete and the slab, because all exposed voids are filled with the solution.

Filling voids with concrete eliminates its displacement

Conclusion

If this review is used as a guide, you will be able to avoid many common mistakes. The video in this article will help you understand some of the nuances even better.

Concrete reinforcement. Price in estimate.

Most often, the price in the estimate for concrete reinforcement is provided as part of the work for the construction of concrete structures. As can be seen in Figure 1, welding and installation of reinforcement in a reinforced concrete structure is a necessary condition for the correct execution of this type of work without violating building codes and safety regulations. Reinforcement is one of the most durable and resistant materials, and therefore it is used to strengthen and protect against destruction load-bearing monolithic structures, foundations, floors, ceilings, that is, structures whose operation is associated with heavy loads and unfavorable external conditions.

The reinforcement, as a rule, is supplied in 11.7 m rods, then cut directly on the construction site to the required lengths and laid in the concrete structure. Reinforcement comes in different classes and brands, the choice of which also depends on the design data and concrete parameters. Therefore, the use of prices in estimates for concrete reinforcement requires careful analysis.

Figure 1. Reinforcement as part of the work within the prices.

A similar method should be applied if a quote is needed in the estimate for reinforcement of concrete slabs. When applying a particular price in this case, it is also necessary to analyze and compile a lot of data, including the method of performing the work, the parameters of the materials used, etc. For example, the thickness of the reinforcement should be selected based on the thickness of the concrete; depending on the brand of concrete and additives in its composition, the price in the estimate for reinforcement, etc., should be selected. .

Floor reinforcement. Price in estimate.

When approaching the choice of prices in the estimate for floor reinforcement, just as when reinforcing any other structure, it is necessary to rely on sheets and diagrams of the project for the construction of a specific facility. When reinforcing the floor, reinforcing bars or reinforcing mesh are most often used. In cases where serious loads are expected during the operation of the floor, for example, the movement of technological transport, installation of heavy equipment, aggressive environmental conditions, etc., it would be advisable to use reinforcement or metal mesh to strengthen and strengthen the floor. If the loads are moderate, it is possible to lay plastic or fiberglass mesh and fiberglass when installing the floor screed.

It should also be noted that when installing a floor screed, the price in the estimate for reinforcing the floors with mesh is also usually part of the scope of work. It is necessary to clarify that reinforcement is not always a prerequisite for floor installation work. For example, in the case of the construction of private buildings, garages, verandas, etc., it is possible to exclude reinforcement from the scope of work. However, as noted above, reinforcement is a way to increase the service life of structures and protect them from destruction. Therefore, most often, the estimate and design still provide for reinforcement, especially in cases of construction of civil and industrial construction projects.

In addition, reinforcement is necessary when constructing multi-layer floors. If, before pouring the floor with concrete, it is necessary to carry out work on installing layers of waterproofing and thermal insulation, then in the case of direct application of the screed to these layers, instability of the entire structure may occur, and subsequently its destruction. Therefore, floor reinforcement will be a way to eliminate unpleasant consequences after the facility is put into operation.

How to arrange a protective layer of concrete for reinforcement

Comments:

Rating: 45

Of particular importance for monolithic structures is the protective layer of concrete for the reinforcement, which ensures the strength and durability of the entire structure. Regardless of the functional load, be it a paving slab, a base for a swimming pool or a foundation, it is necessary to maintain a clear sequence and coherence of actions.

A protective layer of concrete is necessary to protect the reinforcement from aggressive environmental influences.

The slightest failure to meet deadlines or use of the mixture in the wrong proportions can lead to serious consequences. Moreover, destructive processes will begin later than the warranty period for these works. That is why it is important to control each process and perform all actions in strict sequence.

Many people build their own houses or country cottages on their own and do not even think about such a thing as a protective layer of concrete. And incorrectly laid reinforcement in the foundation can lead to the destruction of the entire house.

Definition and main features

Table of protective soya concrete.

The concrete cover is the distance in millimeters from the reinforcement tie to the surface. It performs the function of protecting the metal in concrete, and also ensures a safe relationship between these two elements under the influence of the environment. Even a slight change in external weather conditions or humidity levels can affect the structure if the concrete is not poured correctly.

A layer of concrete that is too thin will cause the metal to deteriorate due to penetrating moisture, while a layer that is too thick can be very expensive. To determine what thickness of layer is necessary and sufficient to protect the reinforcement, it is important to consider:

- type of structure (foundation, slab, support, base for the pool);

- load on the structure;

- reinforcement section size;

- environment (open air, room, high humidity, contact with the ground).

Based on this, the requirements for the protective layer of concrete for reinforcement are formed:

Table of thickness of concrete mixture layers.

- protection from aggressive interference of external factors (weather, natural phenomena);

- corrosion protection;

- interaction of metal and concrete.

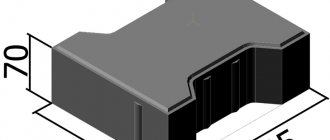

It is enough to cite as an example the square slabs with which all the central squares of large cities were decorated. Many of them have not yet been modernized. But each slab lives its own life. One developed a chip, another cracked diagonally, and the third crumbled, exposing the metal bond. In order for all slabs or other concrete structures to last for more than one year, it is necessary to initially correctly calculate all the parameters.

Return to contents

At the state level, special norms and regulations (SNiP) have been calculated and developed to determine the correct thickness of concrete:

- inside buildings and structures at normal or low humidity levels - 20 mm or more;

- inside buildings and structures with high humidity levels (without any additional protection) - 25 mm or more;

- outdoors (without additional protection) - 30 mm or more;

- in soil (without additional protection) - 40 mm or more;

- in foundations - 40 mm or more;

- for concrete in constant contact with the ground (maximum value), 76 mm or more.

Reinforcement prepared for pouring concrete.

Additionally, the values for frames and clamps with the presence of transverse metal elements are specified in the norms and rules. Here it is necessary to use a concrete layer thickness of 10 mm for a reinforcement section height of less than 250 mm and 5 mm more for a height greater than a given value.

If it is not possible to control the work, there is a method for checking the reliability of filling with a layer of the required thickness using magnetic sensors, which are the basis of special measuring instruments.

Return to contents

The most demanding among all concrete structures is the foundation, since it is this that influences the future strength of the entire building. Mistakes made when working with the foundation are almost impossible to correct. Many factors influence its stability: moisture, frost changes, spring groundwater, gravity of the walls, snow on the roof in winter.

It is very important to follow all the rules for working with reinforcement in order to avoid problems in the future, since metal is afraid of moisture, and its function is to control the adhesion of the concrete bond around the perimeter.

Diagram of reinforcement elements: support reinforcement; concrete; crown; rods.

The frame of the house will last a long time while minimizing the interaction of metal with water and soil. Therefore it is important:

- the lower part of the reinforcement tie should not touch the bottom of the foundation trench (for this you need to use bricks or other supports);

- the upper part of the reinforcement ligament must comply with the requirements of SNiP;

- at the corners, all elements must be bent or cut so that there is at least 5 cm to the outer edges of the frame.

Return to contents

As a result of operation, a violation of the protective level design may occur due to accidental exposure to factors.

This may happen:

- When the load on the structure increases (for example, the construction of another floor, the use of special equipment).

- While maintaining the same loads (for example, under the influence of aggressive weather and natural phenomena).

In these cases, restoration of the protective layer of concrete is required, consisting of:

- sealing of formed cracks;

- restoration of crumbled areas with possible modernization of the reinforcement structure;

- strengthening the existing structure due to transverse elements.

This method does not consider repeated and systematic damage in the upper level of a concrete structure, since then a mandatory complete restoration of the entire layer with duplication or restoration of the reinforcing ligament is required. The standard restoration procedure involves plastering with a dense cement-sand mortar in a ratio of 1:2.5 or 1:3.

Return to contents

Without a special tool, the protective layer of concrete cannot be made high-quality and durable:

- tape measure (3-5 m for small structures and at least 10 m for foundations, etc.);

- water level (convenient when working with liquid concrete);

- knitting wire;

- pliers;

- welding machine (for monolithic structures of long-term construction, where large sections of reinforcement are used);

- grinder (for cutting reinforcement);

- reinforcement mesh clamps in fixed places.

Every builder knows that carrying out construction or renovation work using concrete requires maximum responsibility. Therefore, in pouring concrete, every stage is important, especially the final or protective layer. It should be evenly distributed in a liquid state with minimal accumulation of water in one place. Literally every centimeter of the upper level must protect metal from corrosion and concrete from destruction.

tolkobeton.ru

Reinforcement of masonry walls. Price in estimate.

By analogy with the reinforcement of concrete structures and floors, it is possible to reinforce masonry walls. It is noteworthy that reinforcement of walls is possible if the walls are made not only of concrete and concrete structures, but also of brick, stone, concrete and aerated concrete blocks. For example, as can be seen in Figure 2, the price in the estimate for the reinforcement of masonry walls is part of the scope of work even when laying the facing layer. In addition, the use of reinforcing mesh is often used for wall finishing work such as surface filling. These methods are used in the same way as when reinforcing other surfaces, in order to protect and strengthen the finish, and its long-term service.

Figure 2. Wall reinforcement in price

Thus, reinforcement is an important element in the construction of structural elements of buildings and structures. Therefore, the correct and correct application of prices for the reinforcement of structures directly affects the correctness of drawing up estimate forms and the cost of construction of the facility as a whole.