Correctly calculated overlap of reinforcement during tying affects the final quality of the structure. The reliability of this method is difficult to challenge, however, there are certain nuances in the work process, if not observed, the result of the connection may turn out to be fragile and short-lived. This can also affect the rate at which the concrete hardens, causing the base to become very soft.

Why is it necessary to comply with reinforcement overlap standards when knitting?

When pouring the foundation of a house or when erecting any other concrete structure (column or monolithic block), the issue of strength and durability of the structure remains pressing.

Subject to compliance with all building codes, an additional metal frame will greatly strengthen the structure and make it durable, and the base unaffected by natural conditions and time. If the rules are not followed, the foundation of the house may soon collapse, which will lead not only to the loss of a large amount of materials, but also to human casualties. This is due to the fact that incorrectly calculated overlap of reinforcement leads to non-hardening of concrete in some places, which leads to weakening of the entire structure as a whole. To build a strong and reliable frame, several methods are used, including knitting, for which it is necessary to use an overlap.

Advantages of mechanical joining

This method is the most profitable and, accordingly, the most frequently used. If we compare the process of mechanical joining of reinforcement with overlap joining of reinforcement, the main advantage here is that there is no significant loss of material. Overlapping joints lead to the loss of a certain amount of reinforcement (approximately 27%).

If we compare the mechanical connection of reinforcement with joining by welding, then in this case the speed of work wins, which takes much less time. In addition, welding should be performed only by professional welders to avoid poor-quality work, which can lead to negative consequences in the future. As a result, if you carry out mechanical joining, you can significantly save on wages for qualified craftsmen.

This connection method also results in a fairly strong structure. It is possible to obtain an equally strong connection using this method in various weather conditions and at any time of the year.

Return to contents

The amount of overlap when connecting reinforcement according to SNIP

The Sanitary Standards and Rules of 2003 (abbreviated SNiP) describe all types of fittings connections that currently exist. Overlapping joints are created without the use of welding machines, in this they differ from mechanical (for which couplings and special equipment are used) and welded (for which a welding machine is respectively required). There are three types of overlap joints:

- Rods with hooks and claws (bends) at the ends.

- Rods with a straight end (with welding or installation at the intersection of reinforcement).

- Rods with straight ends (profile).

The Sanitary Standards and Rules of 2003 recommend overlapping reinforcement with a cross-section of up to 40 mm. In turn, the world analogue of building codes, namely ACI 318-05, states the maximum permissible value of the cross-section of the rods is 36 mm. This is due to the lack of evidence base for the reliability of connections of larger diameter, since no tests have been carried out. Also during knitting, it is worth leaving a certain free space around the overlap.

It must be taken into account that the minimum distance that must be left for reserve, both horizontally and vertically, is 25 mm. However, if the cross-section of the reinforcement itself is more than 25 mm, then the margin must be calculated according to the diameter step. The largest distance between elements is 8 sections of the rod. But when using wire in knitting, the distance is reduced to 4 sections.

It is not recommended to use tying in areas of greatest pressure, since the joint is not designed for such loads, but only for fastening the reinforcement and maintaining them as a single structure.

Technical features of weldless joint

It is necessary to space adjacent connections apart. Moreover, in such a way as to achieve simultaneous connection in one section of up to 50% (no more) of the reinforcing elements. The design section, which we will determine in order to determine the value of the joining reinforcements, is understood as the area of 130% of the total overlap parameter (measured along the bars).

Here it is necessary to understand that when designing, the joints of the rods are considered as lying in the same section, provided that the centers are located exactly in the specified zone. The shortest distance between joints according to SNiP is 610 mm. According to ACI 318–05 and sanitary standards, it is recommended that untied (free) connections of rods be made in structures without prestressing.

This advice is quite logical, because the concrete mixture with such a connection will flood the rods from all sides. And this is a guarantee of ultra-reliable fixation of each rod, which cannot be achieved when pouring an incomplete circle of reinforcement and an adjacent rod tied with binding wire. In addition, the overlap in length cannot be less than 25 cm.

Another important provision of the Sannorm is that in the 1st design section the connection can have no more than 50% of steel rods in the foundation strip. In addition, it is possible to join welded mesh and individual reinforcing elements using the described option without the necessary separation. However, such an assumption will only be valid when using reinforcement for structural reinforcement.

An overlap of 30 cm or more is possible provided that the reinforcement is functioning in compression. In many foreign countries, in construction documentation, the overlap was set at a level of 40 diameters of the connecting reinforcing elements. In the CIS countries, this value is equal to 50 diameters (A400 fittings).

Also, the value of the recommended overlap depends on the grade of concrete for pouring the foundation. For example, for the M300 mixture it has 35 diameters, M250 - 40, M200 - 50. But for reinforcing bars A-II and A-I, the overlap is always selected based on 40 diameters. But it should be borne in mind that all this will be true for the indicators in the calculation. In practice, real (not minimum) overlap values are usually several times larger.

Reinforcement overlap under different conditions

The joint locations of the reinforcement and the location of the lattice should be determined by the designer, not the builders. Since the overall picture of the project, as well as knowledge of the load in different places, is known only to him. Otherwise, the design may be damaged.

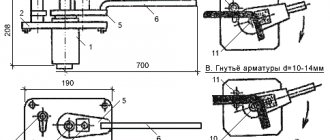

For example, when reinforcing a column, several fundamentally important steps should be followed:

- The outlet must be bent to a slightly longer length than the cross-section of the reinforcement (for a diameter of 16mm it is 20mm).

- It is necessary to bend the reinforcement without heating, but with the help of special means that can provide the required bending radius.

- The bend radius must be indicated in the project and emphasis should be placed on it, since builders are unlikely to do this without instructions.

Consumption rates for reinforcement for overlap

The required length of reinforcement bars varies according to several criteria:

- For compression reinforcement, the required length will be as follows. So, for fittings with a diameter of 6 mm - length 20-22cm; 8mm - length 20-29cm; 10mm - length 25-36cm; 12mm - length 30-43cm; 14mm - length 35-50cm.

- For tensile reinforcement, the required overlap length of the bars must be greater. For example, for a diameter of 6 mm - length 20-29cm; 8mm - length 27-38cm; 10mm - length 33-48cm; 12mm - length 40-57cm; 14mm - length 46-67cm.

The higher the strength class of concrete, the shorter the length of the overlap rods should be. The only exceptions are 20, 28 and 32 mm fittings. With concrete strength class B35, the length of the rods should be 655, 920 and 1050 mm, respectively.

Important nuances and requirements for viscous connections

The process of connecting reinforcement using wire seems much easier than the welding option or the use of pressed couplings and special devices. However, it also has its own subtleties and nuances. It must be taken into account that you should not connect reinforcement in places with increased load (for example, corners of buildings). Moreover, it is desirable that there is no load at all at the knitting site. If it is technically impossible to meet this requirement, then you should use a simple formula: Connection size = 90 * Cross-section of the rods used.

You also need to pay attention to the main parameters:

- rod cover length;

- location of the connection and features of this place;

- the location of the overlaps in relation to each other.

There must be a distance between adjacent points of connection of the reinforcement bars, which can be calculated using the formula: Distance = 1.5 * Length of the overlap, however, the resulting value must be no less than 61 cm.

Also, do not forget that the dimensions of such connections are regulated by technical standards and the overlap depends not so much on the cross-section of the reinforcement, but on:

- brand of concrete used for pouring;

- purposes for using connections;

- class of operated fittings;

- load exerted on the base.

Types of connections

There are two main methods of fastening reinforcement, according to building codes and regulations (SNiP), namely clause 8.3.26 SP 52-101-2003. It states that the connection of rods can be performed using the following types of joining:

- Joining of reinforcement bars without welding, overlapping.

- overlapping using parts with bends at the ends (loops, legs, hooks); for smooth rods, only loops and hooks are used;

- overlap with straight ends of reinforcing bars of periodic profile;

- overlapped with straight ends of reinforcing bars with transverse type fixation.

- Mechanical and welded connection.

- when using a welding machine;

- using a professional mechanical unit.

SNiP requirements indicate that a concrete foundation requires the installation of at least two continuous reinforcement frames. They are made by fixing the rods overlapping. For private housing construction, this method is used most often. This is due to the fact that it is available and cheap. Even a beginner can start creating a frame, since you need the rods themselves and soft knitting wire. You don't need to be a welder or have expensive equipment. And in industrial production, the welding method is most often used.

Note! Clause 8.3.27 states that overlapping reinforcement connections without welding are used for rods whose working cross-section does not exceed 40 mm. Places with maximum load should not be overlapped by bonding or welding.

Real values of reinforcement overlap

The length of the overlap of the rods during anchoring is set based on the force acting in the reinforcement structure and the perception of the resistance forces of the steel elements, as well as the adhesion forces of concrete and reinforcing rods along the entire length of the connection. Sanitary standards for overlap of reinforcement when knitting recommend the following overlap lengths (all parameters in mm) overlap/section:

- 1090 / 36;

- 960 / 32;

- 860 / 28;

- 760 / 25;

- 680 / 22;

- 580 / 18;

- 480 / 16;

- 380 / 12;

- 300 / 10.

The SNiP tables also contain the anchorage overlap length for various grades of concrete mix for compression/tension reinforcing bars.

There are some other important points of SNiP that were discussed in this publication:

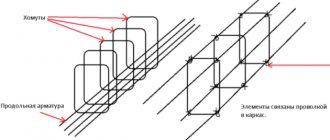

- installation of transverse additional reinforcement is mandatory in the overlap anchoring area;

- preventing the anchoring of adjacent rods from being separated by at least 61 cm;

- cross-shaped overlaps must be connected using plastic clamps or clamps or annealed viscous wire.

According to these tables, the shortest overlap length for concrete mix M450 with a cross-section of A400 rod of 6 mm = 20 cm. But for concrete M250 and reinforcement with a cross-section of 40 mm, the length will be already 158 cm.

Reinforcement is an important part of the design of all monolithic structures, on which the long-lasting and reliable future of the structure depends. The process involves creating a frame from metal rods. It is placed in formwork and filled with concrete. To create this frame, they resort to knitting or welding. In this case, a correctly calculated overlap for the reinforcement plays an important role in knitting. If it is insufficient, the connection will not be strong enough, and this will affect performance. Therefore, it is important to figure out what kind of overlap to make when knitting.

There are two main methods of fastening reinforcement, according to building codes and regulations (SNiP), namely clause 8.3.26 SP 52-101-2003. It states that the connection of rods can be performed using the following types of joining:

- Joining of reinforcement bars without welding, overlapping.

- overlapping using parts with bends at the ends (loops, legs, hooks); for smooth rods, only loops and hooks are used;

- overlap with straight ends of reinforcing bars of periodic profile;

- overlapped with straight ends of reinforcing bars with transverse type fixation.

- Mechanical and welded connection.

- when using a welding machine;

- using a professional mechanical unit.

SNiP requirements indicate that a concrete foundation requires the installation of at least two continuous reinforcement frames. They are made by fixing the rods overlapping. For private housing construction, this method is used most often. This is due to the fact that it is available and cheap. Even a beginner can start creating a frame, since you need the rods themselves and soft knitting wire. You don't need to be a welder or have expensive equipment. And in industrial production, the welding method is most often used.

Note! Clause 8.3.27 states that overlapping reinforcement connections without welding are used for rods whose working cross-section does not exceed 40 mm. Places with maximum load should not be overlapped by bonding or welding.

Overlapping of rods by welding is used exclusively with reinforcement grades A400C and. Only these grades are considered weldable. This also affects the cost of products, which is higher than usual. One common class is the . But merging products with them is unacceptable. As the material heats up, it becomes less durable and loses its resistance to corrosion.

In places where there is overlap of reinforcement, welding is prohibited, regardless of the class of the rods. Why? If you believe foreign sources, there is a high probability of the connection breaking if it is subjected to heavy loads. As for Russian rules, the opinion is as follows: using electric arc welding for joining is allowed if the diameter size does not exceed 25 mm.

Important! The length of the weld directly depends on the class of the reinforcing rod and its diameter. For work, electrodes with a cross section of 4 to 5 mm are used. The requirements regulated in GOSTs 14098 and 10922 state that overlaps can be made by welding with a length less than 10 diameters of the reinforcing bars used for the work.

Connecting rods by welding

Overlapping of rods by welding is used exclusively with reinforcement grades A400C and A500C. Only these grades are considered weldable. This also affects the cost of products, which is higher than usual. One of the common classes is class A400. But merging products with them is unacceptable. As the material heats up, it becomes less durable and loses its resistance to corrosion.

In places where there is overlap of reinforcement, welding is prohibited, regardless of the class of the rods. Why? If you believe foreign sources, there is a high probability of the connection breaking if it is subjected to heavy loads. As for Russian rules, the opinion is as follows: using electric arc welding for joining is allowed if the diameter size does not exceed 25 mm.

Important! The length of the weld directly depends on the class of the reinforcing rod and its diameter. For work, electrodes with a cross section of 4 to 5 mm are used. The requirements regulated in GOSTs 14098 and 10922 state that overlaps can be made by welding with a length less than 10 diameters of the reinforcing bars used for the work.

Welding with multilayer seams

When highly qualified welders are available or when the volume of work is small, welding with multilayer seams without the use of forming elements is often used to join reinforcement. This method is most suitable for connecting reinforcement located in a vertical form. Bevel angles, their direction, bluntness and dimensions, cutting shapes, gaps between rods are standard.

Welding of reinforcement with multilayer seams is performed using a single electrode. The welding seam is first applied on one side of the groove, and then across the entire width on the other. During welding of the groove, it is necessary to periodically clean the deposited metal from slag.

The mode for this type of welding is set to the one indicated in the passport data of the electrodes. In this case, they are usually used with a calcium fluoride coating.

Anchoring reinforcement is an essential element in the manufacture of critical reinforced concrete structures. Neglect of this seemingly insignificant detail often ends in failure even for experienced builders.

In this article we will look at the key methods of anchoring and connecting reinforcement to stiffen the product (whether it is, or), as well as the rules governing the standards for anchoring reinforcement products.

Anchoring reinforcement

- this is the process of securing the ends of reinforcing bars in the mass of concrete, which is achieved by setting the cross-section of the rod to such a length that would be sufficient to transfer forces from the reinforcement to the concrete.

In the anchoring zone, a rod working in tension will function to pull out the reinforcement from the concrete through the adhesion surface, and a rod working in compression, on the contrary, will transmit forces into the concrete.

Docking reinforcement using the knitting method

This is the easiest way to ensure a reliable rebar structure. For this work, the most popular class of rods is used, namely A400 AIII. The overlapping reinforcement connection without welding is performed using a binding wire. To do this, two rods are placed next to each other and tied in several places with wire. As mentioned above, according to SNiP, there are 3 options for fixing reinforcing bars with viscous. Fixation with straight ends of a periodic profile, fixation with straight ends of the transverse type, and also using parts with bends at the ends.

It is absolutely impossible to connect reinforcement bars with an overlap. There are a number of requirements for these connections so that they do not become the weak point of the entire structure. And it’s not just about the length of the overlap, but also other points.

Important nuances and requirements for viscous connections

Although the process of connecting rods using wire is simpler than connecting them with a welding machine, it cannot be called simple. Like any work, the process requires strict adherence to rules and recommendations. Only then can we say that the reinforcement of the monolithic structure is done correctly. When connecting reinforcement with an overlap using the knitting method, you should pay attention to the following parameters:

- rod cover length;

- location of the connection point in the structure and its features;

- how the overlaps are located one to the other.

We mentioned that it is impossible to place an overlapping reinforcement joint in an area with the highest degree of load and stress. These areas also include the corners of the building. It turns out that you need to correctly calculate the joints. Their location should be in areas of the reinforced concrete structure where there is no load, or where it is minimal. What to do if it is technically impossible to comply with this requirement? In this case, the size of the overlap of the rods depends on how many diameters the reinforcement has. The formula is as follows: the size of the connection is equal to 90 diameters of the rods used. For example, if Ø20 mm reinforcement is used, then the overlap size in the area with high load is 1800 mm.

FITTING LENGTH 11700

18.03.2019

|In Armature

|By SEO

Long products

- Rebar, wire rod

- Beam, channel

- Corner

- Circle

- Stripe, square

Sheet metal

- Hot-smoked sheet

- Cotton sheet

- Galvanized sheet

- Corrugated sheet

- Expanded metal sheet (PVL)

- Stainless steel sheet

Pipes

- Pipes h/d

- Cold pipes

- VGP, electric welded pipes

- Stainless steel pipes

- Pipeline accessories

Stainless steel

- Circle, square, hexagon

- Strip, corner

- Stainless steel pipes

- Stainless steel sheet

- Stainless steel hardware

- Accessories for stair railings

- Pipeline details

Hardware and metal raw materials

- Calibration, silver

- Wire, ropes

- Mesh, tape

- Radiators, electrodes

Non-ferrous metals

- Aluminium, duralumin

- Copper, bronze, brass

- Tin

- Lead

- Zinc

Reinforcing bars with a diameter of 8 mm are considered thin. In a ton, the amount of material will be 2,534.2 m. Calculation of the weight of reinforcing wire per square meter. Article on the topic: Product design features. 10 mm reinforcement is used to create lightweight buildings: private houses, garages, where strip foundation pouring is used. Having this data available, it is easy to calculate the total amount of materials that will be required to construct a specific structure - be it a foundation or a monolithic building.

It’s quite easy to make an independent calculation using the already established formula; it will look like this: 1m*(3.14*0.01m*0.01m/4)*7850 kg/m³=0.617 kg. The linear meter of wire in the structure is calculated as follows: kg/m². All domestic fittings go through quality control stages before reaching metal warehouses, which guarantees their compliance with GOST. This is the value of the weight of reinforcement 8 that is given in the table of correspondence between weight and length of reinforcement. Reference! The volume of a steel rod is calculated by multiplying the footage by the geometric area of the circle - 3.14*D*D/4.

In general, the calculation algorithm is similar. The formula for calculating the weight of reinforcement is very simple - the length of the reinforcement multiplied by the weight of a linear meter of reinforcement. Calculating the weight of the reinforcement will help in estimating the cost of construction, as well as the price of the finished object. The higher the diameter of the reinforcement, the greater the weight of a meter of material. This figure in all cases was 887.8 g. Among the main advantages inherent in reinforcement 16 are: strength, reliability and corrosion resistance. The diameter of the reinforcing bars is taken from the construction plans and calculations. Therefore, the choice of material is individual.

Reinforcement is a building material that is a combination of certain metal elements intended for the construction of a monolithic structure with cement mortar. The weight of 1 linear meter depends on the external structure of the profile, which can be corrugated or smooth. Approximately 1% should be added to account for welding errors. Serves as a support to retain tensile stress and to strengthen the concrete structure in the compression zone. Thus, a total of 18 m of reinforcement 6 is obtained, the weight of which is 0.222 kg/m. Calculating the total weight of reinforcement 10 is quite simple: just sum up the total length and multiply it by the mass of a linear meter of material.

Reinforcement length 11700

The weight of the reinforcement must be known at the design stage of a construction project. Calculation of the volume of a meter of rods: 0.00011304*1=0.00011304 m³. Helpful advice! The diameter size must be obtained from the manufacturer. If it is necessary to calculate the mass of a specific reinforcement bar, then the area of the circle is multiplied by its length. Reinforcement weight table: GOST, regulating the quality of the product.

The presence of ribs and corrugations on the outside provides more reliable adhesion of the rods to the concrete solution. 16-mm rods are widely used in the arrangement of welded metal structures, reinforcement of concrete structures, construction of roads, bridges, and spans. Reinforcement 20, for example, is more vulnerable to corrosion, but is ideal for welding. It is reinforcement 12 that is recommended by construction standards for the construction of strip foundations for cottages and private houses. The fittings produced in accordance with GOST 5781-82 are bars with a smooth surface of class A, as well as profiles made of periodic steel of classes from A-II to A-VI. In order to determine the mass of one hundred meters of reinforcing wire with a diameter of 4 mm, it is necessary to multiply the specific gravity by the footage. This is the most complex and time-consuming option for calculating weight.

Formulas for calculating I-beams. The following methods are used to calculate the weight of the reinforcing mesh. Features of the technological process for manufacturing reinforcing steel determine the entire range of reinforcement. The assortment has two classes: BI - with a smooth surface and VR-1 - material from a periodic profile. These are metal rods of medium thickness with a high degree of strength. It is better not to measure it yourself to avoid errors.

To do this, enter into certain cells the given weight of the reinforcement in tons, the number of the corresponding profile and the length of the rod in millimeters. The weight of the entire mesh can be calculated by multiplying the value obtained for 1 m² by the required number of square meters in the reinforced frame. At the same time, it has a high degree of adhesion to concrete. The main technical characteristics of the material are as follows: for production they use steel marked 25G2S and 35GS. Reinforcing bars with a diameter of 8 mm are considered the thinnest and resemble ordinary wire. ribbed pitch - A400 and A500, reinforcement class A3. The technological process of their production is regulated by GOST 5781. Such fittings, like rods of other thicknesses, are produced by hot-rolled or cold-rolled methods.

Universal features and ideal weight of reinforcement 12. If the obtained result is checked with the table, we will find that the data corresponds to state standards. They are practically indestructible. The calculation will look like this: 92*100 = g (or 9 kg 200 g). The surface of the reinforcement 8 can be corrugated or smooth. For example, a coil of wire with a diameter of 4 mm weighs 10 kg.

Reinforcement frames and structures using it last for a very long time. If it is necessary to calculate the mass of a particular rod, then the area of the circle is multiplied by its length. The calculation looks like this: 10/0.092 = 108.69 meters. The amount of material consumption is calculated per cubic meter of concrete. For example, let’s calculate the weight of reinforcement 14. If you multiply it by volume, you will get a general indicator of the specific gravity of one meter of reinforcement.

A rod weight of 8 mm per meter is most appropriate in places where excess weight is unacceptable, but additional strength is required. Thus, the concrete structure itself in this case has higher quality characteristics. Reinforcing steel produced on the domestic market is widely used in construction, has high-quality characteristics, and meets all GOST requirements for rolled metal. Here you cannot do without knowledge of the weight of the reinforcement in a meter. The general characteristics of reinforcement 10 are as follows: rod diameter – 10 mm, one ton contains 1622 m of rolled steel, weight of 1 meter of reinforcement 10 mm – 616.5 g, permissible error when calculating weight is +6%, steel classes used in the production of this type rolled metal: With the given parameters, you can easily find out the required quantity and weight of the building material.

The reinforcement 16 is capable of absorbing significant tensile and bending loads, redistributing them evenly over the entire surface. Important! Each type of reinforcement has its own characteristics, and a large diameter does not necessarily guarantee good strength. The higher the diameter of the reinforcement, the greater the weight of a meter of material. Reinforcing components are mainly used in the construction of foundations and the construction of walls of concrete monolithic buildings. The procedure for calculating the weight of reinforcement is 12 mm per meter, the length of the entire rod. Radius is, as you know, half the diameter.

It withstands high loads of flexibility and stretching, distributing it evenly over the entire surface. Most often, reinforcement 16 is used for high-quality reinforcement of concrete structures. The weight and quality of the material ensure its reliability, so builders characterize it as durable, reliable, wear-resistant and environmentally friendly. Tolerance is possible only in a larger direction and no more than 10 cm, and the curvature should not exceed 0.6%. The weight of a mesh made of reinforcing wire for plaster, a reinforced frame for a reinforced concrete foundation, a reinforced mesh for brickwork depends on the dimensions of the fabric, the area of the cells and the diameter of the rods in millimeters. In the capital construction of monolithic country houses one cannot do without reinforced structures. These calculations can be clearly seen using the example of determining the weight of 1 meter of 12 mm reinforcement.

We determine how much one meter of 12 mm reinforcement weighs. Price per linear meter of I-beam profile. The volume is determined independently, taking into account the fact that the reinforcement bar has a cylindrical shape. To determine the footage, you need to divide the total mass by the specific gravity. All the necessary data, taking into account the class of steel and the diameter of the rods, is given in the calculation tables.

Helpful advice! In any calculations and calculations of the mass of reinforcement, one should not forget about the permissible error readings. If you measure it yourself, this will entail errors in the calculations, since the surface of the reinforcing bars has a ribbed structure. In addition, it is affordable and easy to install, and is also used in other areas of production. The method of calculating specific gravity requires special skills and knowledge. The calculations carried out coincided with the data in the table for the weight of reinforcement per meter of 12 mm. At the same time, the weight of a meter of hot-rolled steel reinforcement does not depend on them.

Its area is calculated using another formula, where the constant number Pi with a value of 3.14 is multiplied by the radius squared. One of the most popular in construction is a rod with a diameter of 10 millimeters. Calculation of the weight of reinforcement 12 in 1 meter: 0.00011304 m³*7850 kg/m³=0.887 kg. Low carbon steel is used to produce reinforcing wire. The weight of 1 meter of reinforcement 8 is 394.6 grams. The diameter of the reinforcing bar in the range from 8 to 25 mm is considered the most popular profile size in the construction market.

We'll get a full 4 kilograms. To calculate the weight of the reinforcement, you need to add up the total length of all the rods and multiply it by the mass of one meter. For example, the grid dimensions are 50x50x4. First, you need to remember the formula for calculating weight from the physics course, according to which mass is equal to the volume of an object multiplied by its density, that is, specific gravity. The diametral values of ordinary wire are 3, 4 and 5 mm. The main condition for carrying out such calculations is the presence of an appropriate table. According to these indicators, steel can be hot-rolled rod or cold-drawn wire.

Scope of application and calculation of the weight of reinforcement 10 mm per meter. Rebar with a diameter of 12 mm is considered the most popular and in demand in the construction industry. Specific gravity of reinforcement: correspondence tables taking into account linear footage. The weight of the material, calculated accurately and correctly, will help to realistically estimate not only the costs of organizing construction work, but also an important part of the cost of the entire project. This is the simplest calculation option. How much a meter of reinforcement weighs is something both designers and builders of buildings and structures made of reinforced concrete need to know.

Its dimensions are the most optimal for various types of construction work. A table of weight and length ratios for different types of structures will help you make the correct calculations. Having studied the table, you can notice one pattern. The third column displays the total length of the reinforcement elements in one ton. Calculations are performed using the given reinforcement table.

In this case, knowledge of geometry will come in handy. Helpful advice! The easiest way to calculate is to use special programs (or an online calculator). The formula says: the volume of a cylinder is calculated by multiplying the cross-sectional area by the height of the figure. The letter A is used to mark hot-rolled and heat-strengthened reinforcement, the letter B is for cold-deformed material, and the letter C is for welded rolled products.

The weight standard for reinforcement of the corresponding diameter is regulated by developed standards - GOST 5781-82 and GOST R 52544-2006. Reinforcing material is divided into assortment classes with special designations from AI to A-VI. It is applicable only in cases where there is no table with standards available and the possibility of using an online calculator is excluded. The sequence of independent calculations using the formula is as follows: Determination of the area of the circle: 3.14*0.006²=0.00011304 m². A linear meter of a profile rod is a piece of material one meter long.

The mass of the rods, accordingly, regulates their diameter. D is the diameter. During construction work, an accurate calculation of the mass of reinforced structures is necessary. The brand of material from which the reinforcement is made is also taken into account. Characteristics of reinforcement 12: rod diameter – 12 mm, one ton contains 1126 m of rolled stock, rod ovality – no more than 1.2 mm, pitch of transverse protrusions – from 0.55 to 0.75* dH, weight of 1 meter is 887.8 g, rolled length – from 6 to 12 m.

The total length in one ton, on the contrary, is inversely proportional to the thickness of the rods. The calculation process itself (when drawing up a construction plan, taking into account the construction of the reinforcing mesh) includes the following steps: select the appropriate diameter of the rods, calculate the footage of the required reinforcement, multiply the weight of one meter of reinforcement of the corresponding diameter by the number of required rods. The main characteristics are as follows: smooth and corrugated type of profile, steel grades used in production: 35GS, 25G2S, 32G2Rps, A400, weight of 1 meter of reinforcement 16 mm - 1580 g, diameter area - 2.010 cm², rod length - from 2 to 12 m. GOST indicators are set from 6 to 80 millimeters. Thus, knowing the weight of the reinforcement according to GOST 5781-82, it is easy to calculate the coefficient of the overall reinforced structure; you can determine the weight of the reinforcement in relation to the required volumes of concrete. The result is identical to the previous one. The complete procedure for calculating the weight of 1 meter of reinforcement 12, represented by a mathematical expression, will look like this: To independently calculate the weight of reinforcement 12 mm per meter, you need to use a certain formula. The weight of the wire is calculated in accordance with special standards and data given in the table: The weight for a specific case can be calculated using the following algorithm.

It was on reinforcement 12 that an example of calculating the weight of a linear meter of a product was considered. For example, for construction it is expected to use 2300 meters of reinforcement 14. The standard length of the rods is 6000 or 12000 mm. A significant part of the time, effort and material costs during the construction of a building made of concrete falls on the creation of a reinforced frame, which is made from reinforced rods and meshes. The mass of the reinforcement in this case is equal to the weight of the entire steel frame, including the foundation, walls and concrete floors, as well as the mass of welded mesh poured with concrete.

The correspondence of class, diameter and grade is clearly demonstrated in the table: If we take, for example, class A-III reinforcement, then it is used to strengthen the foundation of concrete buildings erected in a short time. At first glance, they resemble simple wire. 10 mm reinforcement is classified as an easily processed material, since the rod is easily bent or subjected to any other necessary deformation. For steel, this figure corresponds to 7850 kg/m³. A similar indicator of the weight of 1 meter of reinforcement 10 is contained in the table of the ratio of diameter and weight of one meter. The weight of reinforcement is calculated in different ways: according to standard weight data, taking specific gravity as a basis, using an online calculator.

Thus, to complete this volume of work, 2 tons 783 kilograms of steel rods will be required. To avoid unnecessary costs, you should calculate the required amount of material as accurately as possible. The cross section of a cylinder is a circle. Reinforcement: weight and length, ratio and calculations in construction work. Characteristics, dimensions and calculation of the weight of reinforcement 8 mm per meter. It can have both a smooth and embossed surface.

Reinforcement: weight and various options for calculating it. Reinforcement with a diameter of 12 mm is rightfully considered the most popular in the metal rolling industry and the most in demand. The square meter area includes 18 rods of 1 m each. This reinforcement amazingly combines such qualities as strength, flexibility and fairly low weight. Reinforcement weight 16 mm per meter: features and technical specifications. The need to calculate the weight of reinforcement: weight and length correspondence tables. High quality steel is used in production in accordance with GOST 5781-82. Calculations based on specific gravity using the example of calculating the weight of a meter of reinforcement 12.

A table of the weight of a linear meter of reinforcement, the length and diameter of the rod will help you make the correct calculations: Using this table is quite simple. The weight of 1 meter of rods is 1.21 kg. The first column contains data on the diameter of the bar, the second column contains the weight of a linear meter of a specific type of reinforcing bar. At the same time, the majority of costs in the process of purchasing materials mainly fall on fittings. Reinforcement 16 belongs to the category of rolled metal products. Low-carbon steel is used for its production. According to the calculations, by analogy with previous brands of reinforcement and in accordance with the table of the ratio of diameter and weight of one meter, the weight of reinforcement 16 in 1 meter is 1.580 kg.

The fittings are widely used in construction, have high-quality characteristics, and meet all GOST requirements. The specific gravity of the reinforcement is 7850 kg/m³. The number of rods of the corresponding diameter in one ton is calculated similarly. We carry out the calculation: 2300 * 1.21 = 2783 kilograms. Marking of material, weight of 1 meter: assortment table. GOST R 52544-2006 are profiles of classes A500C and B500C made of periodic steel, intended for welding. The same applies to weight.

The reverse calculation can also be done. The reinforcing wire meets the requirements of GOST 6727-80. Thus, by accurately calculating the mass and footage of reinforcing bars, you can save significantly during the construction process and, conversely, avoid a shortage of rods already at the stage of constructing a reinforced structure. They range from 1 to 6%. The weight of 1 meter of 8 mm reinforcement is calculated using the above formula using the specific gravity of the corresponding steel: 1m*(3.14*0.008m*0.008m/4)*7850kg/m3=0.394 kg. It is based on a formula for determining mass using quantities such as the volume of an object and its specific gravity. This is especially important to consider when large volumes of welding work are expected.

Correct calculations will help in drawing up estimates and will avoid unnecessary costs for materials. When independently calculating the volume of reinforcement, you need to take into account the fact that the rod has a cylindrical shape. If we take the mechanical characteristics of reinforcing steel as a basis, such as strength and weight, then the material is divided into separate assortment classes with corresponding special designations from AI to A-VI. The necessary data can be found in the general table. The required number of rods according to the standard weight is determined using the above weight table in relation to the linear meter.

The material is based on periodic steel. The data is taken from the table. Thus, we find that the radius is 6 mm or 0.006 m. Depending on the length of the reinforcement, the corresponding value is substituted into the formula and the weight is calculated from it.

see also

- FITTINGS LENGTH AND WEIGHT

Private trade unitary enterprise "Metallobaza Aksvil". UNP st. Selitskogo, 17, 214a, city. Reinforcement weight, theoretical weight of 1 linear meter of reinforcement,…

- FITTINGS TABLE WEIGHT LENGTH

It is noteworthy that the mass of a linear meter of hot-rolled steel does not depend on the basic mechanical characteristics it possesses. Reinforcement…

- ONLINE REINFORCEMENT CALCULATOR LENGTH WEIGHT

To calculate the weight of the reinforcement, you can resort to two methods. Finally, once you have the values compliant with the regulations, read on and...

- LENGTH AND WEIGHT OF FITTINGS TABLE

The nominal diameter of a grooved rod is equal to the nominal diameter of a rod with a smooth surface of the same profile number. To calculate the mass of the batch...

- REINFORCEMENT RODS LENGTH 11700

Calculating the total weight of reinforcement 10 is quite simple: just sum up the total length and multiply it by the mass of a linear meter of material. Especially…

Overlapping under different conditions

So what is the overlap of the reinforcement when knitting? What is the exact data? Let's start by looking at examples. The first factor on which the overlap depends is the diameter of the rods. The following pattern is observed: the larger the diameter of the reinforcement used, the greater the overlap becomes. For example, if reinforcement with a diameter of 6 mm is used, then the recommended overlap is 250 mm. This does not mean that for rods with a cross section of 10 mm it will be the same. Typically, 30-40 times the reinforcement cross-section is used.

So, to simplify the task, we use a special table that shows what overlap is used for rods of different diameters.

| Diameter of used fittings A400 (mm) | Number of diameters | Estimated overlap (mm) |

| 10 | 30 | 300 |

| 12 | 31,6 | 380 |

| 16 | 30 | 480 |

| 18 | 32,2 | 580 |

| 22 | 30,9 | 680 |

| 25 | 30,4 | 760 |

| 28 | 30,7 | 860 |

| 32 | 30 | 960 |

| 36 | 30,3 | 1090 |

| 40 | 38 | 1580 |

With this data, everyone can do the job correctly. But there is another table that indicates overlap when using compressed concrete. It depends on the class of concrete used. Moreover, the higher the class, the smaller the spacing of reinforcement joints.

| Section of A400 reinforcement used for work (mm) | Length of overlap, depending on concrete grade (mm) | |||

| B20 (M250) | B25 (M350) | B30 (M400) | B35 (M450) | |

| 10 | 355 | 305 | 280 | 250 |

| 12 | 430 | 365 | 355 | 295 |

| 16 | 570 | 490 | 455 | 395 |

| 18 | 640 | 550 | 500 | 445 |

| 22 | 785 | 670 | 560 | 545 |

| 25 | 890 | 765 | 695 | 615 |

| 28 | 995 | 855 | 780 | 690 |

| 32 | 1140 | 975 | 890 | 790 |

| 36 | 1420 | 1220 | 1155 | 985 |

As for the stretched concrete zone, in contrast to the compressed zone, the overlap will be even greater. As in the previous case, as the brand of solution increases, the length decreases.

| Section of A400 reinforcement used for work (mm) | Length of overlap, depending on concrete grade (mm) | |||

| B20 (M250) | B25 (M350) | B30 (M400) | B35 (M450) | |

| 10 | 475 | 410 | 370 | 330 |

| 12 | 570 | 490 | 445 | 395 |

| 16 | 760 | 650 | 595 | 525 |

| 18 | 855 | 730 | 745 | 590 |

| 22 | 1045 | 895 | 895 | 775 |

| 25 | 1185 | 1015 | 930 | 820 |

| 28 | 1325 | 1140 | 1140 | 920 |

| 32 | 1515 | 1300 | 1185 | 1050 |

| 36 | 1895 | 1625 | 1485 | 1315 |

If the overlap is correctly positioned relative to each other and made to the required length, then the base skeleton will receive a significant increase in strength. The connections are evenly distributed throughout the structure.

According to the norms and regulations (SNiP), the minimum distance between connections should be 61 cm. More is better. If you do not maintain this distance, the risk that the structure will deform under heavy loads and during operation increases. It remains to follow the recommendations to create high-quality reinforcement.

When carrying out activities related to the reinforcement of concrete structures, it becomes necessary to connect reinforcing bars to each other. When performing work, it is necessary to know what overlap of reinforcement is, how many diameters according to SNiP the amount of overlap of rods is. The strength of the foundation, or reinforced belt, depends on the correctly selected overlap length, which takes into account the cross-sectional area of the reinforcement. Correctly performed calculation of reinforced concrete elements, taking into account the type of connection, ensures the durability and strength of construction projects.

Types of connections between reinforcing elements

Wanting to understand the possible options for joining reinforcing bars, many craftsmen turn to the requirements of current regulatory documents. After all, a successfully executed connection provides the required margin of compressive and tensile strength. Some developers are trying to find an answer in accordance with SNiP 2 01. Others are studying building codes and regulations numbered 52-101-2003, which contain recommendations for the design of structures made of reinforced concrete reinforced with non-stressed steel reinforcement.

In accordance with the requirements of current regulatory documents, steel reinforcement is used to strengthen non-stressed elements, in contrast to stressed structures, where reinforcing ropes of classes K7 and higher are used for reinforcement. Let us dwell on the methods used for fixing reinforcing bars.

The current building codes and regulations (SNiP) describe in detail the fastening of reinforcement using all currently existing methods.

The following options are possible:

- overlapping connection of knitted rods without welding. Fixation is carried out using additional curved steel rods that repeat the configuration of the reinforcement connection. According to SNiP, it is allowed to overlap straight rods with transverse fastening of elements using tying wire or special clamps.

The overlap of the reinforcement when knitting depends on the diameter of the rods. Concrete-filled structures made of knitted rods are widely used in private housing construction. The developer is attracted by the simplicity of the technology, ease of connection and reasonable cost of building materials;

- fixing reinforcing bars using household electric welding equipment and professional units. The technology for connecting reinforcement using welding installations has certain limitations. After all, significant internal stresses arise in the welding zone, which negatively affect the strength characteristics of the reinforcement cages.

The process of mechanical connection of reinforcement

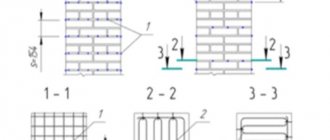

Scheme of foundation reinforcement with stiffeners: 1 – Mesh of working reinforcement, 2 – Vertical reinforcement.

To join the reinforcement mechanically, you will need an appropriate tool - a hydraulic press.

Materials you will need:

- pressed and threaded coupling;

- reinforcement bars.

The mechanical connection technology is quite simple and is as follows:

- a steel coupling is placed on the reinforcing bar;

- it is crimped with a hydraulic press;

- for the second rod the process is repeated again.

As a result, it takes very little time to create a mechanical connection. Instead of couplings, it is allowed to use thick-walled steel pipes or couplings that have a partition in the center, which greatly simplifies installation.

Strong mechanical joining is possible for reinforcing bars of different diameters. This is done thanks to the presence of replaceable dies in the hydraulic press.

To perform this type of docking, you do not need the help of professionals; almost anyone can cope with the task. But there is one important condition: the work must be performed by two people at once.

Return to contents

Fixation of reinforcing bars by electric welding

Joining of reinforcement using electric welding is used in the areas of industrial and special construction. When connecting using electric welding, it is important to achieve a minimum distance between the rods and fix the elements without a gap. Increased load capacity of the connection zone, stretched from action, is achieved when using reinforcing bars marked A400C or A500C.

Professional builders pay attention to the following points:

- It is inadmissible to use common reinforcement marked A400 for welded joints. As a result of heating, strength is significantly reduced and susceptibility to corrosion increases;

- increased likelihood of damage to the integrity of the rods under the influence of significant loads. Current rules allow the use of electric arc welding for fixing reinforcement with a diameter of up to 25 mm;

- the length of the weld and the class of rods used are interrelated. The table of the regulatory document contains all the necessary information about fixing rods using electric arc welding.

The regulatory document allows the use of electrodes with a diameter of 0.4-0.5 cm when performing welding activities and regulates the amount of overlap exceeding ten diameters of the rods used.

Overlapping reinforcement connection without welding when installing an armored belt

Using rods marked A400 AIII, which are popular in construction, it is easy to overlap the reinforcement using annealed knitting wire.

SNiP contain recommendations for tying reinforcement and provide various options for connecting rods:

- connection with overlap of straight ends of reinforcing bars;

- fixation of overlapping rods using additional reinforcement elements;

- tying rods with ends curved in the shape of peculiar loops or hooks.

Using knitting wire, it is possible to connect reinforcement with a profile section with a diameter of up to 4 cm. The amount of overlap increases in proportion to the change in the diameter of the rods. The amount of overlap of rods increases from 25 cm (for rods with a diameter of 0.6 cm) to 158 cm (for rods with a diameter of 4 cm). The amount of overlap, according to the standard, should exceed the diameter of the rods by 35-50 times. SNiP allows the use of screw couplings along with knitting wire.

The distance between the reinforcing bars that are overlapped in the horizontal and vertical direction must be 25 mm and above