What is liquid glass

Liquid glass is a silicate-based adhesive. Recently, you can often find that treating a body with polish is called liquid glass. The remedies actually vary.

When the material dries, a layer is created that does not allow liquids and air to pass through. In liquid form, it penetrates well into the surface to close all pores.

When the material dries, a layer is created that does not allow liquids and air to pass through.

Foundry

Of the inorganic binders used in foundry production, the leading role belongs to liquid glass.

.

Widespread use of liquid glass

in foundry production is associated with the ability to achieve the required technical properties of molds and cores when using it, as well as the non-scarcity of this binder.

The main area of use of liquid glass in foundry production is its use as a binder in the composition of molds and cores for the leading technological process - casting into one-time molds. In the foundry industry, liquid glass is also used for the preparation of non-stick paints and for lost wax casting.

For various molding mixtures in the foundry industry, sodium liquid glass with the following characteristics:

1. High-modulus liquid glass with a silicate module of 3.0+3.5 and higher for LSS mixtures, glass density - 1400+1420 kg/m3.

2. Medium-modulus liquid glass with silicate modulus 2.8+3.0, glass density—1480+1520 kg/m3 for core mixtures according to the “COG-process”.

3. Low-modulus liquid glass with silicate module 2.3 + 2.7, density - 1480 + 1520 kg/m3 for FBS type molding sands.

The use of liquid glass as a binder for foundry molds and cores is based on the processes of liquid glass , accompanied by the manifestation of adhesive properties to the refractory filler (quartz sand or other refractory sands).

Such hardening of liquid glass can be carried out by natural (in air) or artificial (heating, blowing with warm air) drying of the mixture or by introducing special chemical additives - liquid glass .

Production of adhesives

Silicate glue is used in many sectors of the national economy. But one of the simplest and most common uses for a long time has been to use it as a paper connector. Since childhood, the familiar liquid transparent glue in plastic bottles is nothing more than a stationery version of silicate glue. The correct consistency and careful application of liquid glass made it possible to glue different types of paper and cardboard. However, it has been found that over time the glue line turns yellow and the joint itself becomes brittle. Therefore, although silicate glue is now used in office work, its use is more limited than before.

Production of detergents and cleaning products

Liquid glasses are used as water softeners (reducing water hardness by binding magnesium and calcium ions), thereby increasing the cleaning ability of detergent compositions, and also increasing their alkalinity. Potassium and sodium liquid glasses are used, on the basis of which cleaning and detergents are produced for household use.

Silicate paints

Liquid glass paints, also known as silicate paints, are aqueous solutions of liquid glass (with sodium or potassium silicates) with colored pigments. There are two types of such paints:

· Actually silicate coatings, also called two-component: they contain, in addition to glass , fillers and pigments. These paints contain no organic compounds.

· Dispersion silicate coatings differ from the first group in that, in addition to the main elements, they also contain a synthetic dispersion and a water repellent. The share of organic components here accounts for no more than 5%.

, liquid glass is most often used , as it provides a more durable and reliable coating.

Note that paints from the first group are usually used to coat mineral substrates. Since they contain, in addition to potassium liquid glass , pigments and fillers that are resistant to alkalis, such coatings are characterized by good vapor permeability.

The second group of paints is easy to use and is used in various fields. Dispersion silicate paints contain special additives that have water-repellent properties. It is this feature that makes them popular in construction work. Coating walls with this paint significantly increases their service life.

What is liquid glass paint used for?

Paints that are made on the basis of liquid glass can be used to paint brick walls. They are also used for decorating rooms after plastering. Such paints are good to use on surfaces that were once painted with lime, cement or silicate paint. Let us immediately note that it is not recommended to paint surfaces that previously had acrylic or alkyd paint applied with silicate coatings.

Paints based on liquid glass are perfect for both interior and exterior decoration. Today, a separate subtype is presented on the market - facade silicate paints. These decorative coatings are intended for finishing building facades. Due to their characteristics of strength and vapor permeability, these paints will help preserve and protect the facade from external influences for many years.

It should also be noted that coatings based on liquid glass are often used in the automotive industry. For example, since 2008, Japanese manufacturers began producing aerosol paints based on liquid glass for cars.

Advantages and disadvantages of paints based on liquid glass

We have already mentioned above the characteristics of such paints. In this section we will focus on their main advantages and disadvantages.

Among the main advantages of these paints:

· high vapor permeability;

· fire resistance;

· durability;

· low pollution;

· water-repellent properties (especially for dispersion silicate paints);

· complete environmental safety.

But there are several disadvantages to such coatings:

· small range of colors, which is due to the high alkalinity of the paints themselves;

· high diffusion of carbon dioxide, which is why it is not recommended to paint concrete surfaces with it.

Manufacturing of fire retardant coatings

Fire resistance of silicate paints

liquid glass- based paints is their fire resistance. Such decorative coatings belong to the class of non-flammable paints.

Their peculiarity is that when dry, these paints form a film that has fire-retardant functions. Paints made from potassium liquid glass are considered to be of the highest quality and resistant to fire.

Typically, non-flammable paints, in addition to glass , also contain special fillers that are highly fire-resistant. It can be ground fluffed or not vermiculite, talc, perlite, kaolin wool fibers, asbestos (fluffed).

Such paints are often supplied in double packaging: a separate mixture of fillers, pigments, additives, etc., and the actual packaging with liquid glass. The paint must be mixed before use. After this, it can only be used for 12 hours.

The characteristics of strength, fire resistance and vapor permeability possessed by paints based on liquid glass have made them indispensable for fire-resistant painting of walls of any premises, creating curtains with fire-retardant properties for cinemas and theaters. These paints will increase the fire safety of any wooden building. In short, when using these paints you will get not only a stylish, but also a safe building.

Production of various types of concrete and cement with unique characteristics

The most common use of liquid glass in construction is adding it to concrete or cement to give them hydro or thermal insulation properties.

Waterproofing

Silicate glue

used for waterproofing walls and ceilings, wells, foundations and plinths of buildings, which are often exposed to the negative effects of wastewater, temperature changes, and high humidity.

The use of liquid glass

several times increases the resistance of the listed structures to atmospheric influences.

A solution for waterproofing wells is prepared as follows: add 5% liquid glass and mix thoroughly. The walls of the well are first coated with diluted liquid glass and water.

, and then covered with a layer of the resulting waterproofing solution.

Making fireproof mortar

Liquid glass solution

can be used when laying fireplaces and stoves.

Initially, prepare a regular cement-sand mortar (1 part cement to 3 parts sand), after which silicate glue

in the amount of 1.5-5% by weight of cement. It is better not to dilute the solution in large quantities, as it quickly loses its mobility.

Soil strengthening

Primer of the screed surface

Liquid glass

is an ideal material for protecting basement and attic floor coverings from water and fire.

to prime the floors with pure silicate glue

; it is necessary to prepare a special kind of primer.

In addition to silicate glue,

it contains cement and water.

Preparation proportions: for 12 kg of cement you need 1-5% liquid drain to the solution. First of all, cement is mixed with water, which in its quantitative ratio should not exceed 3-5% of the weight of liquid glass

, using a drill with a mixer attachment.

After mixing, the mass is poured into liquid glass

and mixed thoroughly again. If the primer dries too quickly, you can add a little more water and stir the solution.

Features, characteristics and composition of liquid glass

Sodium or potassium silicate is introduced into the base; microcrystals, which are responsible for closing the structure of the material, and quartz sand are also added. Coloring is not used, because coloring leads to deterioration of properties, and the seam will not be beautiful. A good waterproofing result is obtained due to the technical characteristics of the product:

- Moisture-repellent property;

- Antiseptic protection;

- Antistatic effect;

- High level of curing;

- Protective property against the harmful effects of alkaline acid substances;

- Fire resistance.

Coloring is not used, because coloring leads to deterioration of properties, and the seam will not be beautiful.

The main pros and cons of liquid glass

The choice of whether to treat a surface with liquid glass is easier when the positive and negative aspects of the process are known. The following advantages of the material can be noted:

- Creating a film that does not allow moisture to pass through;

- High level of adhesion, penetration into any surface cracks;

- Economical consumption, can be added to cement mortar;

- Reasonable cost;

- Long service life;

- Resistant to a variety of substances.

The presence of a large number of advantages does not exclude the disadvantages:

- Incompatible with all materials, can only be applied to concrete and wood;

- The layer is brittle, additional product should be applied on top;

- It is not possible to apply over another finishing material; paints and varnishes do not adhere to it;

- Carrying out the application requires special skills; it is almost impossible for a beginner to do the job with his own hands;

- The product cannot be tinted.

The product dries very quickly, so the work requires a fast pace from the master.

The surface is rarely covered with liquid glass separately; it is usually combined with another waterproofing material, but the product helps to obtain high-quality protection on concrete and wooden bases.

The surface is rarely covered with liquid glass separately; it is usually combined with another waterproofing material.

Construction of a house from start to finish

Liquid glass is often used in construction and renovation work. It is based on potassium or sodium, as well as their mixtures. The advantages of using liquid glass in a solution in certain proportions are a significant improvement in the quality and service life of impregnated materials at a low cost of the mixtures used. In addition, glue is added to various silicate masses, which increases their fire-resistant properties.

Liquid glass in concrete helps improve its moisture-resistant properties; prevents the growth of fungal formations, increases its heat resistance.

Areas of application

Due to its unique properties, liquid glass is used in various sectors of the national economy, including textile and foundry production, as well as other types of activities. In construction, the addition of liquid glass to concrete and cement mortars occurs at various work sites.

So, to make a primer, glue is mixed with cement mortar 50/50. The proportions of liquid glass in the concrete solution can reach 25% of the total mass of the mixture. For example, to create moisture-resistant compositions, the percentage of liquid glass should not exceed 5-15, and to obtain fire-resistant compositions - no more than 15-25. In addition, to give wood and fabric surfaces additional fire resistance and water-repellent properties, they are also impregnated with liquid glass.

Glue is added to solutions when laying the foundations of buildings where there is a high groundwater level or excessive dampness. Such foundations contribute to the waterproofing of the object and do not require additional treatment against mold, since liquid glass works as an antiseptic.

Also, during the construction of hydraulic structures, laying stoves or fireplaces, liquid glass is added.

Cooking method

Since the production of siliceous and aluminosilicate concretes is carried out in industrial conditions and on a large scale, it is quite difficult to make compositions with precise dosage at home.

However, by adhering to the proportions of additives, knowing the properties of the ingredients and following the technology, you can obtain a mixture of fairly high quality. Thus, 72 liters of liquid glass are added to one cube of M400 concrete, which creates the maximum tension of the solution, but the proportion of 1:10 is more often used in private and small construction.

Since a thick mixture of concrete and liquid glass hardens quite quickly, such a mass should be prepared in small volumes and used immediately.

Areas of application of liquid glass

There are three main areas of use of liquid glass. The following areas can be identified for use:

- To treat the base to create a barrier from liquids and other environmental influences;

- Used together with a concrete mixture to improve waterproofing properties, the drying process will be shortened;

- For the production of various types of concrete.

It is used together with a concrete mixture to improve waterproofing properties and the drying process will be shortened.

Tile solutions

To make a concrete mixture manually, you need to make a small batch. It would be correct if the concrete dry mixture is added portionwise to the aqueous glue solution, and not vice versa.

The solution must be well mixed. It should be noted that liquid glass is used as waterproofing for concrete, as well as a fire-retardant and antiseptic coating. This adhesive, when added to various building materials, produces excellent insulating mixtures and impregnations. Here are some examples. If you add cement and water to the glue, you get an excellent primer.

Purpose of application

The recipe is as follows: 1 volume of cement to 1 volume of liquid glass. First, cement and water are mixed, then silicate glue is added. So paving slabs using liquid glass definitely require attention. It usually costs more than similar ones, but without ZhS in the composition. As for how much liquid glass needs to be added to the solution, there is no clear answer.

The main reason for the destruction of paving slabs during operation is the penetration of moisture into the coating through the surface and seams between the elements. Water inside the tiles creates voids and makes the coating porous, which allows dirt to penetrate and cracks to appear.

Here, depending on what goals you are pursuing, if you simply want to increase the waterproofing properties, then you can simply follow the advice on the packaging of the substance. Your email will not be published.

The question of where liquid glass is used is a common one. Not everyone knows that this building material is nothing more than ordinary silicate glue, which can be based on potassium, sodium or lithium. Manufacturers often take all elements as a basis at once.

Performing cladding with a seam makes it possible to make wider use of various devices, devices and templates for installing tiles. Paving stones and paving slabs Production and laying of paving stones and paving slabs.

Site search.

The effect of soluble glass additives on strength in % of the non-additive

About paving slabs Tiles on the roof Drainage and tiles Printed paths Drainage Walls and tiles Cladding and tiles Steps and tiles Wall cladding Types of cladding Staggered cladding Type and quality of tiles Glass tiles Tiling tools Spatulas and joints Surface preparation Cement mortars Cladding along beacons Appliances Installing a template Racks and plumbs Batch cladding Leveling the mortar Ceramic tiles Mastics for tiles Fastening tiles Using glass Seams and their meaning Mortars for tiles Polystyrene tiles Mastics Features of cladding Quality of cladding Elimination of defects.

About paving stones Clinker paving stones Clinker coating Seam material Coating thickness Ceramic paving stones Dimensions and dimensions Shaped paving stones Laying paving stones Formation of borders Bed of paving stones Moisture transmission Coating systems Paved surfaces Types of laying Edges and drainage Types of dressings Paving stone design Walls and parapets Paving with paving stones.

The main reason for the destruction of paving slabs during operation is the penetration of moisture into the coating through the surface and seams between the elements. Water inside the tiles creates voids and makes the coating porous, which allows dirt to penetrate and cracks to appear.

LLC "Arena" Izhevsk, st. The water-based product quickly wears off and becomes deformed, because its structure does not allow it to penetrate into the deep pores of the tile material. Silicone and acrylic impregnation, on the contrary, will provide reliable protection for the pavement surface. Varnish with the Wet Stone effect can be used at any temperature, even below freezing, which makes it possible to use the product in any climatic conditions. Thanks to the transparent consistency of the varnish, after its application, the tiles retain their original color and the surface is easy to clean.

To treat tiles with impregnating varnish, you do not need to carry out special preparatory measures.

Types of liquid glass

The constituent elements are potassium or sodium silicate. It is impossible to create a rating based on the type of this element that is selected for production and the funds are divided, because they differ in a number of properties:

- The first element has a protective property against alkalis, has a high degree of adhesion, and does not form a glass sheen on the surface;

- The second creates the same protection, but shines.

There is a granular type; water is added to the composition before use.

The constituent elements are potassium or sodium silicate.

Water repellent for paving slabs

When arranging a garden area, it is important not only to lay paving slabs correctly and beautifully, but also to protect them from the possible destructive effects of precipitation. This task can be easily dealt with using a water repellent for paving slabs.

It is enough to simply apply it to the surface, and the tiles will be protected from rain, snow and frost. In winter there will be no ice on it - the path will be absolutely safe. In summer, the color shades will look brighter, and the coating itself will dry at the first rays of the sun after rain.

Negative effects of water on concrete paving slabs

Atmospheric moisture entering the surface of a paved surface can cause serious damage to it. Rain and melt water are never sterile, especially in urban areas.

They are saturated with car exhaust gases, industrial emissions, weak acid and alkaline solutions. Such waters may contain light hydrocarbons and various microorganisms. All this, penetrating into the pores of the paving material, contributes to its contamination, the appearance of stains and changes in color shades. Besides:

- a damp surface is a good environment for the emergence and further growth of various fungal formations and mold;

- penetrating inside the concrete, water washes away the salts present in its composition, which appear on the surface in the form of unsightly white efflorescence;

- Wet paving slabs experience a sharp decrease in frost resistance, which can lead to their destruction after just a few seasons.

Therefore, the issue of protecting the paving surface from the negative effects of moisture is very relevant and should be resolved immediately after the completion of the masonry. This will save you time and money in the future.

High-quality water-repellent impregnation

The problem with colored paving stones made from concrete is the possible penetration of moisture between the tile joints and into the tile itself through pores in the material. And if water that gets through the seams goes through the base into the ground, then the moisture in the pores can freeze and destroy the material.

How to choose liquid glass for waterproofing

There are several types of liquid glass on sale. They are selected for different needs. The presence of sodium silicate in the composition is better suited for creating a barrier against water. Potassium silicate is better suited to create fire protection against fire on wooden material, it also has antiseptic and vapor permeable properties.

Potassium silicate is better suited to create fire protection on wood material.

How to work with liquid glass for waterproofing: general application recommendations

To treat the surface with this product, you need to prepare the surface first. It must be clean and grease-free. The product is used after the walls are painted. The tool used is a roller or a brush.

For the cement mixture, use a wide spatula.

All layers must dry well. How long liquid glass dries will depend on the environment. It takes a little time, but to get the best result, it is advised to wait a day for active use, especially when it comes to the field.

All layers must dry well.

Other base preparation technologies

Each layer of the base must be compacted well.

There is another technology for preparing the base, without the use of geotextile film. After leveling the soil (digging and subsequent compacting), we perform backfilling. First we pour sand, with the help of which we level out small unevenness. Then we make drainage using crushed stone of a fraction of 20-40 mm, which will drain melt and rainwater. The drainage layer is 10-20 cm. We pour finer (10-20 mm) crushed stone on top - it serves as a separation of the drainage layer and the upper sand-cement layer. This is a thin layer, reaching up to 5 cm. We compact each layer well.

For problem soils, it is recommended to make a concrete screed. After the base is dug and leveled, we install formwork into it and pour concrete. Then we wait for the screed to stand and apply a layer of 3-7 cm in height to it. This is a screed made from a mixture of cement and dry sand. After this, we proceed directly to laying granite paving stones.

How to prepare a solution with liquid glass

The ratio of solvent to glass can be varied. Here you should study the instructions on the packaging. Because an individual brand may have different requirements. It is better to dissolve the material using a construction mixer, then it will be easier to obtain a homogeneous solution.

It is better to dissolve the material using a construction mixer, then it will be easier to obtain a homogeneous solution.

Methods of using liquid glass

ZhS can be used in different ways. They are suitable for different tasks, knowing them will help you choose the right option:

- Coating method, pure liquid iron is used, most often sodium. It is used for surfaces that attract dirt and are porous. Drying takes half an hour or an hour;

- The penetrating method involves the same process as the previous one, but water is added to the composition. It is used to cover hard-to-reach areas and requires prompt work;

- Application in concrete mortar.

It is used for surfaces that attract dirt and are porous.

Liquid glass for concrete waterproofing

In construction, they often resort to diluting liquid glass in a concrete mixture to improve its quality. To obtain the desired high-quality effect, the features of the process should be taken into account:

- It is unacceptable to add liquid glass to the finished mixture; they start by preparing the mixture, and add glass to the water, mix them, then pour them into the dry mixture;

- The ratio of materials can be varied in order to obtain various properties, so the recipe is selected according to the situation, and then strictly adhered to;

- Adding liquid glass helps improve the solution, but the curing process will be shortened, so it is recommended to prepare a small amount at a time.

The ratio of materials can be varied to obtain different properties.

Inlaying ceramics with glass

Once upon a time, in my childhood, in order to get money for ice cream, there was a simple way - to hand over bottles of kefir, beer, and wine to a glass collection point; white, green, brown... in short, whatever you come across. Many years have passed since then and I don’t know if such drop-off points exist now, but I just throw away the bottles. Or rather, she threw it away. It turned out that empty bottles can be an excellent material for decorating ceramics. This technique does not have a specific name, but this does not diminish its advantages: it is very simple and extremely effective. Let's call this technique “Glass Inlay”. Even a novice ceramist can easily master this technique.

I would like to invite everyone to join me in making just such a stand for incense sticks. What gives this product a special charm is the crackle (a network of small cracks) on the surface of the glass.

So let's get started.

IMPORTANT! We work with broken glass. Be very careful not to get hurt!

To create our next masterpiece we will need:

The first is the surface on which we will work - a gypsum board, or a piece of plywood, or a piece of thick fabric. A table with a plastic cover is not very suitable, because... the clay will most likely stick to it.

The second is a piece of fireclay. This is a very common and very patient clay mass. She patiently allows herself to be bullied by any newcomer to ceramics. For example, I used regular cream chamotte. Porcelain and earthenware are not suitable for this technique because of their fragility.

Third - several bottle fragments. The main colors used for this technique are transparent, green, brown-green, brown and blue. I use red very rarely, because... red glass is rare. Most often it is simple glass covered with film or paint. This means that the desired effect will not be achieved during firing.

The fourth is a simple brush.

Fifth - slip (liquid clay). The slip is made very simply: in a small container in water we dissolve a piece of clay from which we are going to sculpt.

Sixth, a muffle furnace in which our product will need to be fired. Firing temperature 1200 degrees.

The sculpting technique in which we will work is called “plait sculpting.”

Take a piece of cream chamotte. You say: “How creamy is it?!! He’s almost black!” Don’t worry, after firing the fireclay will become light, almost white. Many clays like to fool beginners by unexpectedly changing color when fired.

So, take a piece of fireclay and roll it out with both hands on the work surface. It turns out to be a long sausage or rope.

Before it starts to dry out and, consequently, break, we twist it into a spiral. This is how we get the bottom for our stand.

Roll out another sausage. From it we mold the side walls of the product.

Dip the brush into the slip and apply it to the junction of the two sausages. Use your finger to smooth out the joint. Ideally, when parts made of clay are connected to each other, notches are applied to the joint with a sharp object, then lubricated with slip and the parts of the product are pressed against each other.

We give the product the shape of a small plate and do not forget to provide a hole where the incense stick will eventually be inserted.

It turns out to be such a stand.

At the final stage, we will need to fire our product, which means that we need to caulk all the cracks in it, otherwise molten glass may leak through them and ruin the stove.

I decided to do this on the outside of the product. We turn the stand upside down, roll out a thin flagellum from clay and begin to caulk all the recesses and crevices on the surface with it. You can do this with your finger or a stick - whichever is more convenient for you. If the product dries out quickly, you can lightly lubricate it with slip.

So, the bottom was caulked.

While the product is still damp, press pieces of broken glass into the bottom. Carefully! Do not pierce the product and do not get injured!

I decided to use only green shards. For a greater decorative effect, you can apply high-temperature glaze to the edge of the stand (we will fire the product at a very high temperature!) of your favorite color. If the glaze accidentally flows onto the bottom of the product, it must be wiped off with a damp cloth. Otherwise, during firing, the product will stick tightly to the stove.

If we are satisfied with the design of the product, we leave it to dry for a couple of days. Preferably on a surface that absorbs moisture: wood or cardboard. You need to know that drying clay does not like radiators and drafts. It is good to dry clay products in a cardboard box.

Dried cream chamotte becomes light gray.

The completely dried product is fired in a muffle furnace at a temperature of 1200 degrees. During firing, the fireclay product becomes very durable, and the glass turns into a liquid state and, like water, spreads along the bottom, forming a smooth surface. After cooling, crackle forms on the surface of the glass.

If you didn’t manage to put the required amount of glass the first time, and bald spots formed on the bottom of the stand, it doesn’t matter. Add another piece of glass and repeat the firing.

And here is what happened after firing.

You can mix and match pieces of multi-colored glass in various ways, getting more and more new effects. As an option, at the modeling stage, make low partitions out of clay in the product - you will get cells. Place glass of a certain color in each of them. Thus, you will get a clear pattern, reminiscent of a mosaic or inlay.

Create boldly and with pleasure!

Application of liquid glass by coating method

The coating method is considered the simplest. It can be done using a roller, brushes or spray gun. Proceed as follows:

- Clean the surface and degrease. Concrete must be brushed to obtain an even coating.

- For a concrete surface, usually 1 layer of the product is sufficient; if a deeper finish is necessary, more layers are made, each one must stand and dry until the next half hour to forty minutes.

For a concrete surface, 1 layer of the product is usually sufficient.

The feasibility of waterproofing with liquid glass at various sites

It is popular to create waterproofing from this material, and the result is effective. It can also be selected in the following cases:

- Treatment of a concrete product located outdoors helps to obtain moisture protection, after which the item can be used under water;

- Waterproofing pools is easier with this substance;

- Treatment of basement structures helps to obtain antiseptic and moisture protection;

- Treatment of the foundation forms a film-like coating against water to protect the rest of the structure.

Waterproofing pools is easier with this substance.

Foundation waterproofing with liquid glass

The foundation is usually treated with the coating method described above. Seams can be processed using a penetrating technique. Work stages include:

- The seam and joining parts are embroidered, U-shaped grooves are made in the area of the cracks, and all debris is removed from them.

- A 5% concentrated solution of glass and water is prepared and poured into the cement.

- The prepared solution is used to close the recesses.

The foundation is usually treated with the coating method.

Waterproofing a well with liquid glass

The well must be protected from the inside. The main thing is that its rings are well secured. To improve fixation, you can cover the seam areas with ropes made of flax or jute, coated with liquid glass. They proceed to applying LC, the first layer consists only of glass, the second of cement mixed with sand and glass.

The well must be protected from the inside.

The silicate industry includes the production of glass, ceramics and cement.

⇐ PreviousPage 3 of 3Glass is a hard, amorphous, transparent alloy usually produced by heating mixtures of silicates or metal oxides with silicon oxide. Heating is carried out in special melting furnaces. The properties of glasses depend on the composition of the charge (a mixture of starting substances) and the method of their manufacture . The mixture is melted in special furnaces, and then products are formed from it.

Ordinary glass (window glass, tableware) has the composition Na2O∙CaO∙6SiO2. Raw materials - soda, chalk, quartz sand. Refractory glass is obtained by replacing soda with potash (i.e. Na2O with K2O). And if we replace CaO with PbO, we get crystal. Chemical glass, resistant not only to temperature changes, but also to aggressive environments, is obtained by replacing part of the SiO2 with B2O3. The color of glass is given by metal oxides (Fe2O3 - brown, FeO - green, CoO - blue) or the metals themselves (Au).

Fibers can be obtained from glass (optical fibers, glass wool, fiberglass), and in combination with polymers - the so-called. fiberglass. An optical fiber is a strand of glass used to carry light within itself through total internal reflection. Optical fiber cables are used in fiber optic communications, which allow information to be transmitted over longer distances at higher data rates than electronic communications.

By introducing special additives during the glass melting process, it is possible to obtain glass-crystalline materials - glass ceramics. Sitalls are glass-crystalline materials obtained by volumetric crystallization of glasses and consisting of one or more crystalline phases uniformly distributed in the glassy phase. Sitalls have low density, high mechanical strength, especially compressive strength, hardness, heat resistance, thermal resistance, chemical resistance and other valuable properties. Citales are used for the manufacture of parts that require strength and heat resistance (chip substrates, device housings, chemically resistant equipment...

Ceramics are materials made from refractory substances: clay with the addition of various mineral impurities: sand, carbides and metal oxides. Depending on the application, a distinction is made between construction, fire-resistant, chemical-resistant, household and technical ceramics . Construction is the production of bricks, tiles, pipes, and tiles. Refractory is the production of linings (bricks, tiles) for blast furnaces, steel-smelting and glass-melting furnaces. Chemically resistant ceramics are used for chemical reactors. Household items include porcelain and earthenware products. Technical is used for the manufacture of substrates in microelectronics, insulators and capacitors in electrical engineering, spark plugs, thermocouples, etc. The process of making ceramics includes preparing the ceramic mass, molding, drying and firing according to a strictly specified regime . Sometimes ceramic products are coated with glaze - a thin layer of glassy material. To do this, the product is coated with a layer of quartz powder and special additives and subjected to re-firing. The glaze makes the ceramic waterproof and prevents contamination.

Cement production . Ordinary cement (silicate) is produced by firing a mixture of clay and limestone. Those. cement is a mixture of calcium aluminates and silicates . These mixtures are usually prepared, but sometimes calcareous-clayey rock - marl - is found in nature. When cement is used as a binding material, it is usually mixed with sand or other filler and (immediately before use) water is added. This mixture is called cement mortar. If you add crushed stone or gravel you will get concrete. If you use iron reinforcement during construction, you will get reinforced concrete.

Exercises

№1. Write down the structure diagram, electronic and graphic formula of carbon (Carbon). Is it true that carbon is a typical non-metal? Why? What is the possible valence of carbon in its compounds? Why? Give examples of such connections. What is the minimum and maximum oxidation state of carbon? Why? Give examples of such connections.

№2. What is allotropy? What are the most important allotropic modifications of Carboniferous carbon you know? Draw a conclusion: what do the properties of substances depend on?

№3. What is activated carbon? How is it different from regular charcoal and what is it used for?

№4. Write the equations for the interaction of carbon dioxide with the following substances: lithium oxide, potassium hydroxide, calcium. Which of these reactions relates to ODD? Identify the oxidizing agent and reducing agent in it.

№5. Name these substances. What reactions can be used to carry out the following transformations? Write down the equations for these reactions.

A) C → CO → CO2 → Na2CO3 → Mg(CO3)2

B) C → CH4 → CO2 → K2CO3 → CO2

B) C3H8 → CO2 → H2CO3 → CaCO3 → Ca(HCO3)2

№6. Write equations for possible reactions of silicic acid with the following substances: aluminum oxide, sodium hydroxide, magnesium. Explain why not all reactions are possible.

№7. Name these substances. What reactions can be used to carry out the following transformations? Write down the equations for these reactions.

A) Si → SiO2 → K2SiO3 → H2SiO3 → CaSiO3

B) H2SiO3 → SiO2 → Si → Mg2Si → SiO2

№8. How to determine carbonic acid salts in solutions? Write down the corresponding equations. What are carbonic acid salts mainly used for?

№9What is glass? What determine the properties of glass? What unique properties does quartz glass have?

№10Give a comparative description of the composition and properties of oxides formed by carbon. Draw a conclusion: what is the reason for the similarities and differences between these substances?

№11. Write down the reaction equations between soot and the following substances:

a) oxygen; b) iron; c) phosphorus.

What changes in the equations if you take graphite instead of soot? Indicate the oxidation states of elements in the equations, determine the oxidizing agent and the reducing agent. Draw conclusions about the chemical properties of carbon.

№12. How to determine carbonic acid salts in solutions? Write down the corresponding equations. What are carbonic acid salts mainly used for?

⇐ Previous3

Do-it-yourself waterproofing with liquid glass: general recommendations

Carrying out waterproofing work yourself begins with cleansing and removing fat. The mixture is prepared and the product is applied to the material using a roller, brush or spray. There can be several layers, then each should dry for about 30-40 minutes before moving on to the next one.

There can be several layers, then each should dry for about 30-40 minutes before moving on to the next one.

Liquid glass for waterproofing: useful tips and safety rules

Recommendations from specialists will be useful to obtain good properties from the coating. And the application will be carried out at the proper level. They advise:

- The material cannot be used for bricks, it will lead to destruction of its structure, and the answer to the question whether liquid glass can be applied to glass will be no;

- Prepare the solution in small portions, the hardener acts quickly;

- The proportions must be strictly observed.

The technician must wear protective gloves and clothing to avoid contact with the skin.

Prepare the solution in small portions; the hardener acts quickly.

Liquid glass is the best option for waterproofing various surfaces. Suitable only for concrete and wood, but on them the coating will serve as a reliable layer against water that lasts for a long time. The process must be carried out in compliance with all the rules, otherwise the result will not be of high quality.

Liquid glass for concrete paving slabs

Home / About Concrete / Liquid glass for concrete paving slabs

There are a huge number of options for creating cement mortars. The use of sodium silicate (liquid glass) in concrete is a progressive method of obtaining a good, high-quality and durable cement base. In this article we will look at the purpose for which liquid glass is used for concrete and how to properly introduce it into the cement mass in order to ultimately obtain a high-quality foundation.

So, why is liquid glass added to concrete? For domestic needs, concrete with liquid glass (chemical name - sodium silicate) is used to impart moisture-proof properties to the hardening mass and to improve its strength characteristics. ZhS is used during repairs in swimming pools, when carrying out work on sewer networks, etc. In addition, it is possible to add liquid glass to concrete to accelerate the hardening of the cement mass.

Add liquid glass to the cement base carefully, observing certain proportions. The use of liquid glass in an amount exceeding 5% of the cement mixture may not have the best effect on the performance characteristics of the foundation or product for which sodium silicate is used. Here we are talking more about strength characteristics.

Concrete with liquid glass additives - cut

The use of liquid glass in concrete in increased quantities promotes accelerated hardening of the base, which in turn complicates the process of laying the cement mass.

When preparing the mix and adding additives, it is necessary to adhere to the proportions of introducing this substance into the concrete base.

Now let's look at the pros and cons of using this additive to improve the waterproofing properties of a cement base.

Experts include the main positive characteristics of sodium silicate:

- high level of adhesion - when liquid glass is added to concrete, the mixture turns out to be rather thin, due to which the pores of the treated surface are completely and deeply filled;

- high levels of water resistance;

- profitability - when waterproofing, the consumption of liquid steel is very small;

- prevention of mold;

- low cost;

- durability.

- fast hardening;

- narrow focus - LC is used only for the purpose of protection from moisture;

- the need for precise control of the administered substance.

Scheme of application of liquid glass

In order to objectively evaluate all the pros and cons of using such a mixing additive, you need to understand that it is needed solely to protect the finished structure from moisture. This applies not only to the concrete itself, but also to the reinforcing metal elements.

The procedure for preparing a concrete base with the addition of liquid glass is not inherently complicated, but obtaining a high-quality product is possible only if several important rules are followed:

- The hardening characteristics of the mixture should be reduced. To do this, sodium silicate is first dissolved in water and only after that is introduced into the finished cement or concrete mortar in a thin stream.

- During the introduction of the liquid mixture, the entire mass is constantly stirred, due to which a uniform distribution of the waterproofing substance is achieved throughout the entire volume.

- As soon as the entire amount of liquid crystals has been added to the cement, everything should be thoroughly mixed again, using a construction mixer or a drill with a special attachment.

Considering that such mixtures harden quickly, blanks are made in small quantities. Obviously, it is irrational to prepare the mixture in a concrete mixer - it will set long before the mixing process is completed.

Always mix concrete with liquid glass in small portions so that it does not have time to harden before it is used up

When preparing concrete with liquid glass, only drinking purified water is used, which is free of salt impurities and other inclusions. The latter reduce the performance characteristics of the active substances of the liquid solution.

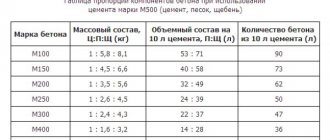

The level of moisture resistance depends on the volume of LC that will be added to the concrete mass. The rate of hardening also depends on the amount of liquid crystal. When preparing the solution, it is necessary to take into account the data given in the table.

Volume of sodium silicate,%

Initial setting, min

Complete hardening, hour

The proportions of sodium silicate introduction largely depend on the task that needs to be accomplished using a solution based on it. Data on dilution and quantitative shares are indicated on the packaging container of the product itself. For example, to waterproof a swimming pool, a concrete solution with 3% JS is used.

You cannot independently increase the volume of fatty acids in the mixture. In practice, this does not lead to anything good: the surface begins to collapse literally 7-10 days after complete hardening.

VIDEO: Liquid glass for waterproofing

Before using liquid glass, it is necessary to understand all the features of its use. First of all, you need to decide what tools are needed for this event.

The addition of liquid glass to concrete in order to increase its waterproofing properties is characterized by the use of the following special tools:

- containers of different volumes - if you add a solution, there is no need to pour it into a larger container;

- a construction mixer or, in the absence of one, as a rule, a drill with a special attachment is used;

- roller;

- brush or brush – facilitates the process of applying liquid gel;

- spray gun – simplifies the process of spraying the mixture;

- mittens;

- special suit (in the absence of one, thick clothing with long sleeves is used).

Before using liquid glass to prepare a concrete base, you must carefully prepare the surface, clearing it of dust and dirt. This will ensure better bonding of the concrete to the plane.

After carrying out cleaning activities, it is possible that defects will be revealed on the surface being treated: for example, these could be cracks, loose seams at the joints of surfaces, etc. They must be sealed to avoid further cracking of the concrete base. And besides, this will not only provide additional protection of the surface from moisture, but also reduce heat loss in the room.

Before proceeding with waterproofing, seal cracks and voids on the surface to prevent cracking of the cement screed

Advice! If you first thoroughly clean the surface treated with a cement base, this will ensure deeper penetration of the LC and, accordingly, will make the foundation or plane strong and durable.

Is it possible to organize waterproofing on your own? It's easy if you follow a few recommendations:

- Using a roller, paint brush or other tool with identical functionality, apply a thin layer of cement mortar to the prepared surface. There is no need to immediately make a layer that is too thick; this may negatively affect the strength characteristics of the surface in the future.

- If there is a need to build a high foundation, then the layers are applied alternately, with a break of 30 minutes. To obtain a level surface, be sure to use a level.

Advice! If work is carried out on a smooth base, such as reinforced concrete tiles, then in order to improve adhesion, it is recommended to first “roughen” such a surface. To do this, you can use a wire brush or coarse sandpaper.

Sodium silicate is not a highly toxic substance, but if it enters the upper respiratory tract it causes irritation of the mucous membrane. Therefore, in order to prevent unpleasant consequences of working with this material, it is recommended to follow the following safety measures:

- a protective suit is a guarantee that the liquid substances will not get on the skin, so do not neglect its presence;

- To prevent liquids from getting into your eyes, wear safety glasses;

If JS or a substance based on it gets into your eyes, you should immediately rinse the mucous membrane with plenty of warm running water. If necessary, you should definitely seek medical help.

Knowing how to use liquid glass to prepare concrete, you can organize the process of building a foundation and waterproofing the surface in the best possible way. We hope the tips and recommendations described above will help you in achieving your goal.

VIDEO: Universal waterproofing - aqua blocker (stop water)

source

Concrete is characterized by a porous structure, and the penetration of moisture reduces the operational properties of concrete building structures - the cement binder is washed out, causing the monolithic body to collapse, and the steel reinforcement to corrode

Liquid glass for concrete waterproofing protects the material from the effects of contact with water.

Liquid glass is an aqueous solution of potassium, sodium or lithium silicate with the addition of modifiers. The scope of application of the product depends on its main substance:

- sodium is used for the production of construction adhesives and waterproofing solutions;

- potassium is used for the preparation of acid-resistant concrete and cement mortars;

- lithium is suitable for strengthening treatment of concrete floor bases followed by polishing.

The silicate compound looks like a thick yellow or gray liquid, it is odorless and does not emit toxic substances. The solvent is water. Treating concrete with liquid glass makes it possible to improve its resistance to external influences.

There are two ways to protect structures made of concrete and reinforced concrete from moisture using silicate solutions - coating the concrete with liquid glass or introducing it into the concrete solution at the stage of manufacturing a monolithic structure. Let's look at how a protective barrier is formed when the composition is applied to the surface, and what liquid glass does in concrete.

When concrete is poured with liquid glass, silicates dissolved in water penetrate into the upper layers of the structure through pores and move through capillaries. Upon contact with the cement binder, silicates crystallize. The substance resulting from the chemical reaction is water-insoluble and resistant to acids.

Surface treatment is carried out to protect against moisture:

- foundations;

- walls and floors in wet rooms, basements, basements;

- balconies and ceilings;

- the inner surface of concrete tanks, wells, monolithic swimming pool bowls, etc.

Why is liquid glass added to concrete? The introduction of potassium and sodium silicates into concrete makes it possible to obtain a material that, after drying, is characterized by a reduced diameter of capillaries and pores. Monolithic structures made from such material are characterized by a low coefficient of water absorption, increased strength and resistance to moisture, and heat resistance.

When adding liquid glass to concrete, it is important to observe the proportions: the silicate solution should be no more than 2-5% of the total mass. Exceeding this norm leads to a deterioration in the mechanical properties of concrete - it becomes excessively brittle.