Sand or “gartzovka” mixture – what to choose

For an individual developer, the budget for landscaping is extremely important. Therefore, when laying paving slabs, the following questions are relevant:

- proportions of sand/cement in the mixture;

- Is it possible to replace the prance with clean sand?

Proponents of the prancing paving technology cite the following arguments:

- when adding cement to a dry mixture with your own hands after heavy rainfall, moisture penetrates through the seams into the grout layer, hydration of the cement stone occurs;

- in the presence of clay under the underlying layer of crushed stone, the concrete crust formed from the grit prevents water from penetrating into this intumescent rock.

On the other side:

- dry prancing without mixing inside the concrete mixer will not be able to turn into either mortar or concrete with any amount of water penetrating the cement;

- When facing surfaces with clinker and ceramics, dry CPS is strictly prohibited, since hydration causes damage to materials that are made from similar raw materials, but using different technologies, so some experts do not recommend laying concrete paving slabs on a paving stone.

You can calculate the consumption of sand or components for sanding (sand + cement) based on the geometric dimensions of the area on which paving slabs need to be correctly laid:

- volume of sand - obtained by multiplying the area of the path (parking lot, recreation area) by the thickness of the standing area (usually 3 - 5 cm);

- the amount of cement is 3–5 times less than sand;

- compaction coefficient – when using an area vibrator (vibrating plate) for compaction is 1.18.

The volume of crushed stone is calculated in a similar way, but the compaction coefficient for this inert material is 1.3.

Advice! It is very difficult to calculate on your own how much grout or sand is needed to fill the joints due to the variety of sizes and configurations of the tiles. Therefore, experts recommend focusing on an average of 4 - 5 kg/m2 with standard 3 mm joints, which are usually obtained when using paving slabs 6 cm thick.

Paving technology

Due to the variety of configurations and sizes of paving slabs, professionals call them FEM (shaped paving elements). In principle, the laying technology is identical, both when using pliers and sand:

- tamping the underlying layer of crushed stone with your own hands to ensure rigidity and stable geometry of the base;

- installation of curb stones on mortar or sand concrete to provide a spatial “trough”;

- installation of storm water inlets and storm drainage trays;

- after which, all that remains is to correctly lay the tiles inside the curbs.

Step-by-step diagram for laying paving slabs.

Paving can be done using a dry mixture of cement and sand in a ratio of 1/3 - 1/6, respectively, or using clean sand. To save the territory improvement budget, the thickness of the dry mixture is taken less (3 - 5 cm) than clean sand (5 - 10 cm).

Marking

Straight sections to be paved can be marked with your own hands using classical technology:

- cast-offs - made of two wooden pegs with horizontal strips nailed to them;

- installation - cast-offs are installed along the edges of a path or parking lot, the cords are pulled with a slope along the length of 2 - 4 degrees for natural drainage.

To reduce the time of laying paving slabs, you should adjust the width of the path depending on the size of the solid slabs. It will not be possible to completely avoid cutting, but the craftsman’s labor costs will be significantly reduced.

Advice! In radius and curved areas, marking is done with paint or lime mortar on the ground after preliminary planning of the territory.

Soil preparation

With the dry paving method, it is necessary to ensure the maximum possible rigidity of the base and carry out some measures to eliminate the swelling of clay soils underneath it. The soil preparation technology is as follows:

- cutting off the fertile layer - sierozem or chernozem is removed, trench depth 0.4 m minimum;

Tile base.

Important! The height of curbs and storm drainage trays is greater than the thickness of the tiles. Therefore, it is necessary to create deeper trenches along the outer perimeter.

In this case, it is necessary to take into account what material will be used when laying the tiles:

- mixture of cement and sand – 3 – 5 cm;

- clean sand – 5 – 10 cm.

Crushed stone should be compacted using a hand tool (tamper with a handle) or a vibrating plate.

Installation of curbs

You can install the curbs with your own hands, like using a mortar. The proportions of cement/sand will be 1/3. The technology for installing curb stones is as follows:

- preparing the mixture - it is preferable to mix the solution inside a concrete mixer; to ensure plasticity, a tablespoon of detergent (for example, Fairy) is added per batch;

- installation of curbs - the mixture is laid at the bottom of the trench, a curb stone is installed, which is pressed down with a rubber mallet along a cord;

- installation of storm drains - trays are mounted close to the curb on the inside;

If paving slabs are laid as a blind area without a concrete base, roof drainage is carried out in several ways:

- a rainwater inlet is installed under the vertical roof drainage pipe;

Stormwater inlet built into the blind area.

Drainage of wastewater through a storm drain tray.

The seams between the curb and the storm drain are filled with mortar, dry mixture or sand.

Laying sand

The technology for applying the mounting layer has several options:

Component ratio

When producing paving slabs, it is recommended to strictly follow GOST standards and manufacturing rules; failure to comply will lead to a deterioration in product quality. If necessary, you can add a little water to the composition. The main thing is that the finished solution is well mixed.

Composition of mixtures for the production of paving slabs - table of proportions

To obtain concrete of normal quality, cement for paving slabs, sand and crushed stone are mixed in a ratio of 1/2/2. Below is a recipe for preparing a concrete mixture based on a bag of cement weighing 50 kg. General proportions, recipe and composition can be found in GOSTs and SNiPs, and clear technical requirements are specified in GOST 17608-91.

- Water 15–20 liters (2 buckets), the exact amount depends on the humidity of the bulk substances used.

- The plasticizers included in the composition, according to the requirements, are diluted in a small amount of warm water and then poured into a concrete mixer with the rest of the water and mixed.

- Add paving slab dye and stir.

- We fill three 12-liter buckets of clean crushed stone and wait until everything is mixed.

- Pour the cement included in the mixture into the resulting mass, divided into 3-4 portions, giving time to mix each portion.

- We fill in another bucket of crushed stone and after mixing, we fill in 4 buckets of sand, just like cement, mixing each bucket.

- Add the last bucket of crushed stone and mix everything thoroughly.

Next comes casting and laying out raw paving slabs for pre-drying. After a few hours or a couple of days, depending on the atmospheric drying conditions and the proportions and recipe, you can remove the molds, and then continue drying the finished product for two weeks.

Basic concepts of prancing and its varieties

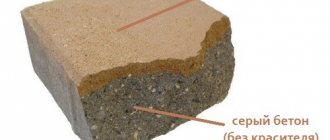

Many people do not know what prancing is. Gartsovka is a dry mixture based on 2 components, which act as the main component and a connecting element. The first component that forms the basis of the mixture is sand, small fractions of expanded clay or calcium. Lime, clay or cement are used for the binding element.

Many people mistakenly confuse grout and cement mortar. Gartsovka is a dry mixture, and the cement mortar is initially based on a proportional volume of water, so the mortar and prawns are two different things.

Depending on the number of components used, simple and complex varieties are distinguished. The first type is based on two components, which is the standard choice for laying paving slabs. The composition of a complex prance can include up to 5 elements, and the use of such a mixture is not limited to one process.

There are degrees of strength that indicate the strength of the mixture. They look like this:

Also, the dry mixture can be light or heavy. A light prance consists of elements whose fraction does not exceed 1.25 mm, and a heavy one consists of components whose fraction is more than 2 mm.

Gartsovka: what is it, where is it used and what problems does it solve?

The assortment of construction stores includes dozens of different bulk materials, which differ from each other in appearance, scope of use and technical characteristics. Not the least place among them is the prancing horse. Of course, it is not as popular as cement or sand. Therefore, not everyone knows about it. At the same time, the scope of use of this material is quite wide. It is quite understandable that newcomers to the construction business often ask the same question: prancing - what is it? To understand what we are talking about, it is worth hearing the opinion of experts.

The concept of prancing

Gartsovka - what is it? This term is usually understood as building bulk material of light gray color. It can be purchased in stores packaged in bags.

The material belongs to the class of lime-cement-sand, since it contains 2 main components:

filler (this role can be sand, expanded clay, dolomite, calcium or marble flour),

binding element (most often cement, gypsum or lime).

Scope of application

This mixture is used in many construction and finishing works:

laying various building materials,

In addition, the building mixture is often used in the construction of roads, as a base for asphalt pavement and when laying paving slabs. In this case, choose a seal with cement in the composition.

Brand of building material

The brand of the garter characterizes the strength of the finished mixture. Therefore, when purchasing building materials, this indicator is paid attention to first. There are 4 mixture options:

Their main difference is the ratio of sand and cement in the mixture. Mark M-1 indicates that sand and cement are present in a 1:1 ratio. M-4 contains 1 part cement and 4 parts sand.

Formulation differences

When buying a ready-made prance, you should pay attention to several more characteristics of the building material:

Simple and complex compositions. In a simple prancing, the composition contains only 2 ingredients (sand and cement). However, manufacturers also offer complex mixtures, which, in addition to these two components, may include lime, gypsum and clay. The characteristics of the finished solution depend on these indicators.

Light and heavy mixtures. The difference in this case lies in the quality of grinding of the components (fine or coarse). Light prances have a fraction of up to 1.25 mm. Heavy options may include particles with a fraction of up to 2.55 mm.

Homemade prancing - what is it?

Now many people prefer to purchase a ready-made mixture, as this eliminates the need to mix ingredients. This means the time required to complete construction or repair work is reduced.

Advantages and disadvantages

These include:

- Low cost;

- Possibility of producing large volumes independently;

- Environmental friendliness of the finished mixture;

- Long service life;

- Possibility to restore the coating to its original condition.

- The mixture requires the correct proportion. For example, if there is not enough cement in the composition, the end result can quickly crack. Therefore, in order to prepare the mixture yourself, you need to have an excellent “eye” or purchase ready-made options;

- It is inconvenient to make a prance in a container. Therefore, a small area with a flat concrete surface is required;

Taking into account all the disadvantages and advantages, plywood has rightfully been used for many years and deserves to be called a high-quality material for laying paving slabs.

Advantages of ready-made mixtures

Making your own dry mixture for laying paving slabs can have its drawbacks. On the one hand, this allows you to select better components, but on the other hand, any deviation from the proportions can negatively affect the installation of the material and its durability.

Factory prancing is sold both in small volumes (50 kg bags) and in bulk. Its advantages include a balanced composition, which is guaranteed not to crack or collapse under the pressure of the tile. Often, to improve technical characteristics, various plasticizers are added to the factory mixture, which make the mixture elastic.

Application area

Due to its excellent characteristics and low cost, garnet is popular in many areas of finishing and construction. Basically, dry mixture is used in the following processes:

- Laying paving slabs;

- Creation of floating floors;

- Plastering walls;

- Finishing of other surfaces.

Plastering walls and ceilings is often done using a plastering machine. Moreover, its production is carried out in domestic conditions by the hands of builders. The dry mixture is excellent for leveling walls and ceilings, and large unevenness will be corrected with minimal investment and effort.

Types of prancing mixture

As mentioned earlier, prancing has several types. The use of each type depends on many factors, so the existence of several varieties is natural.

Depending on the number of elements in the finished mixture, there are two types of prancing - simple and complex. The first option consists of two main components: a base (sand or calcium) and a binder (gypsum or cement). A complex mixture includes the use of more than 3 components in the base (the number sometimes reaches 5 elements). For example, to level walls where a large layer is needed, a complex grout is used, which includes sand, cement and shell rock.

Preparation of mortar for paving slabs

Sand, crushed stone, cement are taken in a ratio of 2:1:2. Additives and additional ingredients are added according to the manufacturer's instructions. When all the components are ready, proceed to the actual mixing of the solution:

- Turn on the concrete mixer and pour in twenty liters of water, which will dissolve all the added additives.

- A plasticizer is added, the ratio of which to the total mass of cement is 0.7%.

- Dye is injected. Its amount varies from 2 to 5%. It all depends on the desired color saturation.

- After about 10 minutes, when the additives have already dissolved, crushed stone is placed.

- Sand is added next, waiting 2-3 minutes after introducing the sealant.

- When the mixture becomes homogeneous, begin pouring concrete.

- Lastly, a thickener is introduced and the solution is poured into molds, which can either be purchased ready-made or made independently.

Water, if necessary, is added after filling the concrete. The main thing is that the solution stays on the trowel without slipping or cracking.

Brand of construction mixture

If we talk about the factory production of prawns, there is the concept of a brand of construction mixture. This concept is denoted by the letter “M” and means the proportion of the binding component to the base. There are 4 brands in total that indicate the composition of the seal for laying paving slabs.

For example, M-2 says that for 1 part of cement in a dry mixture there are 2 parts of sand or other material. M-1 is the most fragile grade and is rarely used, while M-4 is most often purchased for use in various applications.

Factory production is not cheaper, but it is more reliable, because the proportions in the finished dry mixture are strictly maintained. This ensures maximum viscosity during laying of paving slabs and subsequent service life.

Choosing cement for grouting

Prance brand, what is it? It depends entirely on the type of cement chosen. The following types are used:

- M-300 is a universal cement that can be used both for laying paving slabs and for performing work that requires increased strength of the mortar.

- M-200 - cement for laying tiles and other building materials. The strength corresponds to the declared types of work, so this cement is not suitable for other purposes.

- M-400 and M-600 have increased strength characteristics. It is believed that these types are not suitable for laying outdoor tiles, but they provide a 100% guarantee that over time the mortar will not crack or collapse from exposure to precipitation.

The choice depends on the thickness of the tiles used, the climatic characteristics of the region and personal wishes for the strength of the mixture.

Making prancing with your own hands

Experienced specialists know how to make a prance. Before kneading the prawn with your own hands, you need to purchase all the components and prepare the necessary tools (sieve, shovel).

The process of preparing the dry mixture is as follows:

- Filler (sand, calcium or other substances) is poured through a sieve onto a flat concrete surface;

- The base layer is leveled with a shovel;

- Similarly, a binder (clay or cement) is poured through a sieve;

- The entire layer is thoroughly mixed with a shovel to achieve uniform distribution of the components among themselves (it is very important to avoid large elements and lumps).

The concrete surface on which the dry mixture will be prepared must be clean of foreign elements and protected. The larger the surface area, the more prancing can be made with less effort.

Many people may think that they forgot to add water during the process. However, this action will lead to the preparation of cement mortar and the whole main idea will be lost.

Important! When preparing a dry mixture with your own hands, you must remember the correct ratio and reasonable amount of cement or other binding material. Otherwise, the finished layer will have poor characteristics.

Technology for laying paving slabs on a paving slab

Laying paving slabs on a paving slab differs from the standard method. Each tile is placed on a dry mixture. However, the success of the process and the quality of the masonry are not inferior to any traditional method. Also, dry mixture is often used not only on flat surfaces, but also on inclined planes.

The entire process of laying paving slabs on a paving slab can be divided into 3 stages, which should be taken very seriously.

Preparatory

The paving slab compound is poured onto the surface that will be covered with paving stones or paving slabs. The plane must be prepared for this: the humps are knocked down, and the holes are filled with rubble or sand. After finishing the planning, a layer of crushed stone is poured, the thickness of which is from 10 to 15 cm, depending on the finished project and the surface level. It is recommended to plan the surface using a thread that is pre-leveled.

Fencing

The fencing is carried out strictly according to the project, which is agreed with the customers. For this purpose, ready-made borders are used or sides are poured using cement mortar.

Fencing with curbs is safer and faster, because they can always be adjusted in height using a mallet. Cement sides must be poured onto the formwork, which is pre-set in height and size.

A storm drain (drain for rainwater) is installed on the inside of the curbs, if this is provided for by the project.

Laying

The dry mixture is poured onto the prepared and fenced surface. The layer of garter should range from 5 to 7 cm, which provides high-quality support for the future sidewalk. Material consumption depends on the thickness of the pillow and its purpose. The prancing layer is leveled and adjusted to the level using a rule. It is best to tension the thread according to the marks marked with a level.

A very optional, but important step during the preparation of the prance is tamping the pillow using improvised materials or casting it out. This process will provide better grip, but greater dry mixture consumption.

Paving stones or paving slabs are laid on the finished dry mixture cushion. As always, each tile is adjusted to the level using a rubber mallet to avoid damaging the product. All elements of the paving slab puzzle must be correctly joined. This will be facilitated by a long time for correct alignment of the tiles, because the grout does not harden like cement mortar.

Once the paving slabs are laid, the entire surface is hosed down in small quantities to ensure the pavement adheres to the base. Many are waiting for the first rain.

It is not recommended to use the method of laying paving slabs using a dry mixture where the soil moisture exceeds the normal level. Also, the prance is used in pedestrian areas where the load on the sidewalk will be minimal. Roadways regulate the use of cement mortar for paving.

Table of contents:

The building materials market is literally replete with ready-made dry mixtures, which significantly simplify finishing work. These are multicomponent formulations sold in the form of a dry substance with the addition of plasticizing additives and modifiers.

However, just 20-30 years ago , builders used simple compositions prepared from available components for the construction of buildings, landscaping and finishing. One of these materials is prancing. Let's talk about it in more detail.

What is it?

In fact, the composition, as such, is not a secret, because back in Soviet times it was successfully used by the most qualified builders. Light and easy-to-prepare gartzovka (the composition of which is cement, sand, lime) will serve as a good fastening material. Where can it be used ?

Application and composition

In fact, the range of applications for this mixture is quite wide: construction work (external and internal), plastering of stone, wooden and even concrete surfaces. Prancing for screeding is very popular ; with its help you can lay bricks, putty and level walls (and it will also fit perfectly on ceilings). Read more about what kind of putty you can use to level a ceiling here. It is also interesting that paving slabs , both as a layer between the material and the concrete base, and for grouting joints.

Where is the two-component construction mixture used?

Despite the fact that many consider prancing to be a relic of the past, this composition is quite widely used in modern construction. In particular, the mixture is suitable for the following types of work:

floating floor devices;

leveling any bases, including aerated concrete (plaster).

as a stretching putty for wall structures and ceilings.

base embankments for laying paving slabs and paving stones.

Gartsovka is an ideal adhesive with high adhesion and strength. At the same time, preparing the solution is cheap, compared to the prices of ready-made formulations from well-known manufacturers.

Varieties of standard prancing

In addition to classification according to the degree of strength, prancing can vary in composition and even filler fraction. For example, you can divide the mixture into the following types:

Light – grinding of the main components does not exceed 1.25 mm .

Heavy – the fraction of components varies within 2-2.55 mm , but does not go beyond this range.

Another classification can be seen in the table.

A two-component mixture consisting of two ingredients. Proportion according to the recipe.

Up to five components in the composition. Clay, lime, and gypsum can be added to cement and sand.

Many people confuse cement mortar and grout, but these are fundamentally different building mixtures.

To prepare the solution, mixing water is required to increase workability. Gartsovka is always a dry substance.

Advantages and disadvantages

The praises of the prancing horse can be sung endlessly, however, like any building material, this dry mixture has its pros and cons. Details in the table.

Possibility of self-cooking.

If desired, the mixture can be made in any quantity.

Absolute safety in environmental terms: there are no chemically active substances in the composition.

Forms a durable coating that can always be restored to its original level.

To cook in large quantities, you will need a large, flat surface.

Sensitivity to proportions. If the amount of cement is below the recommended standards, the coating will crack.

If you have no experience in preparing such mixtures, it is better not to take risks, but to buy ready-made prawns.

How to make the mixture yourself

From a technological point of view, the process of making a garter does not look complicated. To do this, you will need a shovel, a striker and a sieve for sifting sand. As a striker, you can use a flat concrete surface or a sheet of metal, the dimensions of which allow you to prepare the required amount of the mixture.

For a high-quality composition, it is important to exclude any lumps and stones from the components, so the filler must be carefully sifted.

The process of preparing prancing looks like this.

Sand is poured onto the striker in the amount necessary to produce the required volume of the mixture.

The filler is poured into a bed or small pile, which needs to be slightly leveled.

Add a binder (cement and lime) and begin to prance: mix the components until a homogeneous mass is obtained.

Make a small well in a pile of mixed ingredients and add water in portions. The composition is mixed again until the liquid is completely absorbed by the components.

The procedure is repeated until the solution reaches the desired consistency.

Please note that the amount of grinder should be such that it has time to use up the composition before it sets, otherwise it will be difficult to clean the striker later.

The proportions of materials directly depend on the required strength of the composition. The recipes of some compositions are given in the table.

cement M300 – 1 part;

lime (fluff) – 0.7 parts;

quartz sand – 6 parts.

cement M400 – 1 part;

lime (fluff) – 0.3 parts;

quartz sand – 4 parts.

Let us remind you that you can buy the prawn ready-made: the mixture is included in the assortment of any construction stores.

Gartsovka composition

Home / Construction contracts / Gartsovka machine / Gartsovka composition

Some information about the specification and application of the prance.

Gartsovka is a simple two-component mixture based on a binding ingredient (gypsum, lime or cement) and a filler (dolomite, sand, marble flour, expanded clay or calcium). Intended for the preparation of masonry and plaster mortars for interior and exterior construction work. It is a light gray powder consisting of a mixture of high-quality washed sand (quartz sand) and cement.

The amount of sand depends on the quality of the cement used. Mixture compositions 1:1, 1:2, 1:3, 1:4, 1:5. A mixture with excess cement will subsequently crack. A mixture with excess sand does not crack, but has reduced strength. The strength of the mixture is characterized by the brand. The grade of the cement mixture is the compressive strength (kgf/cm²) of standard 70.7 mm cube samples, which are made from the working mixture and tested after 28 days of hardening.

For example, for the M4 grade of gritsovki, the ratio of cement:sand ingredients is 1:4.

Find out the cost of the work.....

VIDEO OF THE ASSAULT….

Our equipment: PUTSMEISTER S5 EV|TM

Applying a carpentry to the wall by machine:

For decades, a similar mixture was the most common finishing material on construction sites in the USSR. Gartsovka was used by hundreds and thousands of qualified builders, since its cost was several times less than that of other modified ones. And besides, prance is the simplest mixture for finishing work. Therefore, despite all the technological advantages of newer compounds, the prancing machine is not losing its position. A survey conducted in 2002 among construction firms in Kyiv showed that the garter is used in 20% of firms.

Application and characteristics.

Dry lime-sand mixture (gartzovka) TU 5745-008-03987716-98. Gartsovka is used for preparing plaster and masonry mortars for external and internal construction work, plastering stone, concrete, wooden (shredded) and brick surfaces. And also as a mortar (preferably with cement) for laying bricks and as a putty for leveling ceilings and walls.

Gartsovka is a light gray powder, which consists of environmentally friendly and high-quality quartz sand (from the Pavlovsky quarry) and lime, which is used after thorough mixing with water.

The surface for plaster must be cleaned of dirt and dust, and if the surface is smooth, roughness must be created. Dry prawn is mixed with water in an amount of 60 to 80% by weight of the mixture and kept until the lime is completely slaked. After this, the resulting mixture must be thoroughly mixed. The resulting prance is used within 24 hours. When preparing more complex solutions, it is necessary to add cement or gypsum to the mixture. Gartsovka.

If you need to make a solution with your own hands, then the easiest and most convenient way to do this is considered to be a prancing machine. In fact, prancing is a synonym for the word mixing and is a special construction term. What do you need to have for prancing? Of course, the components for the solution should already be prepared. Most often it is cement, sand and possibly lime. All components of the solution must be dry and free of lumps. If for some reason there are lumps, or there are large pebbles in the sand, then before performing prancing, it is necessary to sift the material through a sieve. The sieve is chosen so that it easily passes the sifted material, but at the same time separates a fraction of unnecessary size (lumps, stones, etc.). That is, the sieve should not be too small - it is difficult to work with, nor too large - such a sieve will allow large inclusions that you do not need in the solution to pass through. You will also need a shovel, it is better if for prancing you have a shovel or, as it is also called, a picking shovel. And the third thing that needs to be prepared for convenient prancing is the firing pin.

What is a striker? The striker is a flat area. The following types of strikers for prancing can be distinguished. Concrete firing pin, metal firing pin (iron firing pin), wooden firing pin. A concrete striker is a flat section of a concrete surface. The concrete striker is usually not made on purpose. The head is made of concrete, most often, an area of some kind of concrete pour, possibly a floor, a foundation, a flat concreted area. All this can be used as a concrete striker made of concrete. The main thing is not to forget to immediately clean the mortar from the concrete striker after prancing, before it has time to set. After all, a concrete striker may still be used for its intended purpose. A metal striker (iron striker) for a prancing gun is usually a discarded sheet of metal. An iron striker is also called a sheet striker. The sheet for the striker is made of iron, you can take a very thin one. This can be a striker made of a sheet 1 mm thick or less. It does not matter which sheet is used for the metal striker; you can make a striker from a sheet of ferrous metal and a striker from a galvanized sheet. After prancing, the iron striker is usually also watered with water, cleaned and laid out to dry. So that the metal striker can be used for prancing many times. A wooden striker, for it they take either a shield from several boards, or a wooden striker is made from a sheet of plywood, a wooden striker is made from a sheet of fiberboard and similar sheet materials. Quite often you can find a wooden striker made of wood covered with thin sheet metal - tin. Such a wooden striker is much more convenient and lasts much longer than a simple wooden striker made of wood without metal.

Technically, the prancing on the striker looks like this. First, sand is poured onto the firing pin. Sometimes it is recommended to pour out the sand in the form of a bed, but many builders do not like this method and prefer to pour out the sand in the form of one heap, which is then slightly leveled. Cement and lime are poured onto the sand for prancing. Then the resulting pile (or bed) is mixed with picking (scoop) shovels until a homogeneous dry mixture is obtained. Make a hole in a pile of dry mixture and gradually pour water into this hole. After each portion of water, prancing is continued until the water is completely absorbed. After this, a new hole is made in the middle of the heap, water is poured in and the prancing operation is continued several times until there is a heap of solution on the striker instead of biting the dry mixture. The solution is produced and, if necessary, a new portion of the solution is prepared using the prancing method on the striker. It must be remembered that the solution must be worked out completely, without allowing it to set on the striker. If this happens, then you have to beat the cement off the striker. If in the case of a metal striker made of iron, this is relatively easy to do. For a concrete striker made of concrete, this is much more difficult.

Prancing composition. The composition of the prawn completely corresponds to the recipe for preparing the solution you are going to make. For example, if you need a mortar of grade M150, then the composition of the grout will be as follows: 1 part of cement of grade M400, to which 0.1 parts of fluff lime and 2.5 parts of sand are added. This is the composition of the prancing agent for obtaining the M150 solution. For M100 mortar, the composition of the grout will be as follows: 1 part M400 cement, add 0.3 parts fluff lime and 4 parts sand. For M50 mortar, the composition of the grout is as follows: 1 part M400 cement, plus 0.5 parts lime and 5.5 parts sand. For the M50 solution, the composition of the seal changes. Now M300 grade cement is used. So 1 part of M300 cement, plus 0.7 parts of lime and 6 parts of sand. And more about the M25 brand solution. The composition of the gartzovka is 1 part of M300 cement, 1 part of lime and 11 parts of sand are added to it. Everything is clear with the composition of the prance, we’ve sorted it out

Buy prancing in bags. Nowadays the sale of ready-made building mixtures is quite widespread and you don’t have to prepare the prancing on the striker, but buy the prancing in bags directly in the store in ready-made form. In our city, you can buy bagged garter in any large hardware store or hardware supermarket. When you want to buy a prance in bags, then try to give preference not to the price of the prance, but to trusted brands and brands of prance manufacturers. The price of a prance does not mean at all that the prance is equally well made. The price of the prance should not hypnotize you. It’s better to buy prance in bags a little more expensive, but be sure of the quality of the dry mixture - prance.

Consultation by phone

Laying paving slabs on a paving slab

This installation technology is called the “dry” method and is ideal for paving flat or sloping surfaces. The work is carried out in several stages:

Soil preparation. To lay the tiles on the trellis, you will need the most durable and level base possible. Therefore, any holes and bumps are eliminated, the surface is compacted and lined with a layer of geotextile. After this, a layer of crushed stone is poured, at least 10 cm .

Installation of curbs. Curbs are set in accordance with preliminary markings using cement-sand mortar. The height of the curbs is set with a rubber mallet. If provided for by the design, a storm drain is installed on the inside of the curb.

Laying tiles. The prepared prance is evenly distributed between the curbs and pulled out according to the rule according to the established level. Recommended layer thickness 5-6 cm . Then the tiles are installed, which are leveled with a rubber mallet. After this, the mortar joints are filled with a dry mixture.

After the first rainfall or watering from a hose, the hook reliably grips the paving slabs, which completely eliminates the displacement of the surface.

The dry laying method is used only on soils with a low level of moisture absorption. Otherwise, the solution will wash away due to frequent and heavy precipitation.

The use of a garter is an excellent option for dry installation of paving slabs

The modern market has made the work of builders and road workers much easier - there is an abundance of materials on it. But old technologies are not losing their positions either. Gartsovka (mortar) is still used in laying paving slabs. More details about what prancing is written below.

What is prancing, composition of the material

This term “hides” a dry mixture, and the composition of the prawn usually contains 2 components. The base (or filler) includes quartz sand or expanded clay, calcium, and marble ground into flour. The following binders are used: gypsum, cement, clay, lime.

Gartsovka is sometimes confused with cement mortar, but there is a difference. The powder is used for dry installation, and only then water is used, and in the solution the liquid is one of the components.

Paving slabs on the porch using a paving stone

Area of use of the prance

The light gray mixture is intended for preparing plaster and masonry mortar. The popularity of the two-component powder is due to its low cost and ease of use. The use of a pliers is often practiced for the following work:

Laying tiles using a trimmer

- for plastering surfaces of any type;

- when installing floating floors;

- as a putty on ceilings and wall structures;

- when laying paving stones and paving slabs.

Gartsovka is valued for its high strength and good adhesive properties. Therefore, this composition will be used in technological processes for a long time.

Advantages and disadvantages of the building mixture

In addition to the already mentioned positive properties, the prance has other advantages:

- gives a durable coating that can be easily restored;

- the composition does not contain active chemicals, so the mixture is an environmentally friendly and harmless material;

- Gartsovka is easy to prepare and use yourself;

- the mixture can be prepared in any quantities, which eliminates downtime.

Even if there is no opportunity or desire to tinker with the preparation of this building composition, it can be purchased ready-made.

Scheme for laying paving slabs on sand and dry mix

What types of prancing mixture are there?

Two-component is the standard type of prance. But sometimes you can see a complex composition, when not one binding element is added to the filler, but several. In total, the mixture can contain up to 5 components.

The dry mixture is also classified according to the ingredient fraction. In a light form, the grinding is no higher than 1.25 mm, in a heavy composition – within 2-2.55 mm.

Brand of construction mixture

4 brands of powder are produced, designated by the letter M. The numbers from 1 to 4 indicate the ratio of the binding element to the filler. For example, M-3 says that 3 parts of sand (or other component) are added to 1 part of cement.

The strongest adhesion is provided by an equal ratio of ingredients, but M-1 is considered the most fragile. The most popular brand of prancing car is M-4.

Making prancing with your own hands

It will not be difficult to achieve the desired composition; just purchase the components and prepare the tools (sieve, striker, shovel). In the process, it is necessary to achieve a high-quality homogeneous mixture without lumps and stones. To prepare prancing, follow the following algorithm:

Preparation of the prancing mixture

- sand (or other filler) is sifted onto the striker (a flat metal sheet or concrete surface);

- the resulting pile is slightly leveled;

- the same procedure is repeated with the connecting link;

- now it’s time for prancing, that is, thoroughly mixing the components;

- Making a small well in the mixture, add a small amount of water and stir until it is absorbed into the powder.

Kneading with adding liquid is repeated until the mixture reaches the required consistency.

With the preparation of a two-component powder, everything is extremely simple - the required proportional ratio of filler and binding element is selected. To make a complex mixture of prance, it is recommended to follow the recipe.

M-50:

- quartz sand – 6;

- cement M300 – 1;

- fluffy – 0,7

Compositions of cement-sand mortar

M-150:

- filler – 4;

- fluffy – 0,3;

- M400 – 1

Gartsovka, sold in packages, already contains the required amount of mixture ingredients, so it can immediately be used for its intended purpose. It is important to comply with the standards correctly.

So, when laying paving slabs, you will need at least 5 kg per square meter (provided that the powder is poured 3 mm thick).

When finishing walls, the consumption is much less - up to 1.8 kg per square, but a layer thickness of 1 mm will be sufficient.

Technology for laying paving slabs on a paving slab

Unlike conventional cement mortar, grout is used for laying slabs “dry”. This method is used with equal success on both flat and inclined surfaces. The entire technical process can be divided into 3 stages.

Base for laying paving slabs

Preparatory

The garnet is laid on a perfectly flat surface. All the holes are filled up and the mounds are cut off, the area is carefully compacted. After this, the base is covered with geotextiles, and then a 10-centimeter layer of crushed stone is poured.

Aligning the prancing rule

Fencing

Taking into account the marking of the future sidewalk, curbs are installed using sand-cement mortar. To adjust the height of the curbs, they are pressed down with a rubber mallet. Now a storm drain is installed on the inside, if provided for by the project.

Options for bordering tiles

Laying

The space limited by the curbs is filled with garter and leveled into a layer of 5-6 cm, using the rule and focusing on the level. Lay paving slabs, adjusting the elements to each other with the same rubber mallet. When all the pieces of the “puzzle” are laid, the seams are filled with prancing powder.

Consumption rates

Here a lot depends on the type of work performed. In particular, when plastering walls, material consumption will vary within 1.8 kg/m2 , provided that the layer thickness does not exceed 1 mm .

When laying paving slabs, different standards will apply. The approximate material consumption will be about 5 kg/m2 , with a standard mortar joint thickness of 3 mm .

Also useful for repairs:

- DIY stone shower tray

- Useful repurposes from old things

- Current calculation for a three-phase circuit