How to cover a house with facing bricks

Facing a house with decorative bricks performs not only an aesthetic, but also a practical function.

After all, it protects the masonry from aggressive environmental factors and thereby prolongs its durability. Moreover, brick cladding enhances the external thermal insulation of the house - there is always a little empty space between the bricks, which serves as a kind of air cushion. This must be taken into account before covering the house with facing bricks, or using special plaster. As for the price, it would be much cheaper to use mineral plaster, which will last you twenty years. While brick cladding can be called timeless, its lifespan is unlimited. At the same time, the use of brick is also justified by the fact that it does not need to be renewed every year, like plaster. Thus, the initial costs will pay off in full over time.

What are the methods for facing aerated concrete blocks with bricks?

A gas block wall can be covered in several ways. This refers to the distance between the brick and the aerated concrete block, as well as the presence of insulation, if there is a gap between the wall and the cladding. Let's look at each of them in detail.

Dense masonry without gaps and ventilation

The danger of rapid destruction appears when it is planned to use a heated room. That is, the difference in temperatures inside and outside the house will significantly reduce the service life of such a building. When the room is heated from the inside, water vapor will begin to move out through the porous aerated concrete. If there is no gap or insulation, they will accumulate between the gas block and the brick, destroying both materials. In this case, condensate accumulates unevenly, which accelerates the process of decay and deformation of the structure of the gas block. The most cost-effective option would be to use external insulation in the form of mineral wool or wet plaster finishing. A similar finishing of aerated concrete with bricks (without a gap) is applied only to unheated buildings.

Bricklaying at a distance from aerated blocks without ventilation

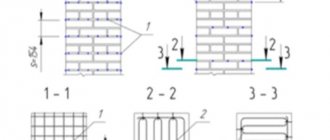

The rules SP 23-101-2004 (Design of thermal protection of buildings) contain a regulation on the principle of the arrangement of layers between the wall and the cladding surface, which states that the closer to the outer layer of the wall, the lower the vapor permeability of the material should be. In accordance with paragraph 8.8, layers with greater thermal conductivity and vapor permeability should be located closer to the outer surface of the wall. British experts, after conducting a series of studies, explained that it is necessary to arrange the layers so that the vapor conductivity to the outer layer increases with a difference of at least 5 times from the inner wall. If this cladding method is chosen, then according to the rules of paragraph 8.13, the thickness of the non-ventilated gap must be at least 4 cm, while the layers are recommended to be separated by blind diaphragms made of non-combustible material into zones of 3 m.

Finishing aerated concrete with bricks with ventilated space

This cladding method is the most rational in terms of the technical characteristics of materials and the durability of the structure. However, the construction of such a structure must be carried out according to certain rules (SP 23-101-2004 clause 8.14).

Let's consider how to line a house made of aerated concrete with bricks with a ventilated gap between the masonry according to all the rules. The air space must have a thickness of at least 6cm, but not exceed 15cm. In this case, the aerated concrete wall itself serves as thermal insulation . If the building has more than three floors, then perforated partitions are placed in the gaps (once per 3 floors) to cut off the air flow. The brickwork must have through ventilation holes, the total area of which is determined according to the principle: for 20 sq.m of area there are 75 sq.cm of holes . In this case, the holes located at the bottom are made with a slight slope outward to drain condensate from the wall cavity.

In the event that it is planned to insulate an aerated concrete wall in addition to the air gap, then thermal insulation materials with a density of at least 80-90 kg/m 3 are used for this purpose. The side of the insulation in contact with the air layer must have an air-protective film on the surface (Izospan A, AS, Megaizol SD and others) or another air-protective shell (fiberglass, fiberglass mesh, basalt wool). It is not recommended to use ecowool and glass wool as insulation, as these materials are too soft and not dense enough. It is also not allowed to use polystyrene foam and EPS due to their flammability and vapor barrier characteristics. When walls made of aerated concrete are faced with bricks with additional insulation on aerated blocks, soft, loose, flammable materials are not used. The vapor conductivity of these materials must be quite high to avoid the formation of condensation.

Let's sum it up

So, what conclusions can be drawn about the methods of facing aerated concrete walls with bricks? For convenience, we summarize the features of each cladding method in a table:

| Characteristics | Cladding without gap | Cladding with gap without ventilation | Cladding with ventilated gap |

| Brickwork | + | + | + |

| Protection of aerated concrete walls from external influences | + | + | + |

| Thermal insulation | Insignificant increase | Increase (resistance of brickwork), decrease (moisture content of aerated concrete wall increases) | No increase (ventilation of space between walls) |

| Service life, building destruction | The service life is reduced by 60%. | Reduction due to humidity and condensation. | No reduction or increase due to the absence of condensation and controlled air circulation. |

| Construction costs | Costs for foundations, expansion (up to 15 cm), bricks, mortar, and flexible connections increase. | Costs for foundations, expansion (up to 19 cm), bricks, mortar, and flexible connections increase. | Costs for foundations, expansion (up to 21 cm), bricks, mortar, and flexible connections increase. |

| Cost-effectiveness and feasibility | Economically unprofitable due to reduced thermal insulation and service life. | No particular benefit in most cases. It is advisable only in an even, temperate climate that does not require heating the building from the inside. | It is not economically profitable, but it is advisable if brick cladding is required on the outside of heated buildings. |

Brick for facing a house, its types

For external cladding and decoration of buildings, mainly three types of bricks are used:

- Hyper pressed,

- Clinker,

- Ceramic.

In the production of hyper-pressed bricks, cement, crushed limestone and various types of pigments are used.

All components are mixed and processed under very high pressure. However, such bricks cannot be fired. Thanks to its texture and special uneven chipping, the brick looks like natural stone. If you line a house with hyper-pressed facing bricks, you will get the following advantages:

- The facade of the building will acquire a well-groomed decorative appearance,

- Due to the wide selection of colors, you can play with the design and create your own unique style.

The only disadvantage is that the structure of this type of brick is so dense that it does not leave any air gap, which means the building will require additional insulation for the winter.

Another type of brick is clinker, made from a special type of clay processed at very high temperatures.

Thanks to this processing method, the brick is quite moisture resistant and is not afraid of low temperatures. Increased strength characteristics make it possible to use it in the finishing of window and door openings, basement floors, and also as a road surface. For example, you can use it to pave the driveway to your house.

If you decide to prefer ceramic bricks for cladding, then it is best to choose hollow ones.

It will not create excessive pressure and load the foundation of the house. The disadvantage of this type of brick is the increased consumption of cement mortar for masonry, since the mortar will disappear in the cavities of the brick. In order to minimize loss, it is recommended to purchase bricks with the smallest holes on the surface for laying.

Types of cladding

There are 4 options for brick cladding:

- No gap.

- With an air gap without a thermal insulation layer.

- Cladding with insulation and ventilation.

- Cladding with thermal insulation, but without ventilation ducts.

There is another method that provides for an air gap, but without ventilation. However, due to the intense accumulation of vapors, gas silicate undergoes deformation and begins to collapse, so this finishing option is not in great demand.

No gap

Such a project does not improve the thermal insulation and durability of the room, and sometimes even accelerates the process of wall deformation. But if there is a need to decorate an unheated building, then finishing with bricks without a gap is an excellent solution. The advantage of this method is the reduction in costs for facing and insulating materials, as well as the ease of installation work.

With a ventilated gap without insulation

Cladding with an air gap and ventilated mesh is considered the most optimal option for most homes. In this case, a small gap is formed between the wall made of gas silicate blocks and the brickwork, and moisture removal is ensured through special holes. The main advantage of the method is the reduction of heat loss, since air is the best heat insulator.

But the solution also has visible disadvantages:

- To protect your home from the cold, you will need to correctly determine the thickness of the layer and the placement of ventilation holes. If the air circulation is excessively strong, the penetration of cold air masses into the building will worsen the thermal insulation capabilities.

- A wall with such insulation is thicker, which increases the cost of material for finishing the basement.

- The resulting voids attract small rodents and insects, which begin to destroy the structure. To prevent this, it is enough to secure special fine-mesh meshes in advance.

With ventilation and gap filling with thermal insulation material

Attaching facing bricks to aerated concrete with a ventilation gap and insulation is a good way to ensure comprehensive insulation of a building from the penetration of cold without sacrificing ventilation capabilities.

This solution is effective when using the following types of insulation:

- Glass wool.

- Mineral wool.

- Other vapor-permeable materials.

Insulated walls have a relatively small thickness, and the amount of insulation and installation costs are added to the basic costs.

Non-ventilated gap with insulation

The latter option involves insulation with sheets of expanded polystyrene without air holes. The solution is suitable for aerated concrete buildings with an existing opaque vapor barrier, which can be used as polystyrene foam.

One of the disadvantages of the design is the flammability of foamed polystyrene, but in practice this is not true. During the production process, the material is treated with special heat-resistant additives, which provide an increased degree of fire safety.

Two powerful insulators made of non-combustible materials are also applied to the surface.

General recommendations for laying cladding

Before purchasing a brick, think about its size and quantity. It is better to import all the bricks at once, this way you can control the color of the product. When choosing hyperpressed brick, make sure that it was made at least three weeks ago. Only after this period has expired does the brick acquire its strength qualities, and accordingly will not crumble during laying.

Brick cladding is used not only for concrete and brick buildings, but also for wooden buildings. The wood of a wooden structure must be treated with an antiseptic and air chambers must be left so that it can “breathe.” This will prevent the wood from rotting.

When laying a layer of brick, make sure that it lags behind the main masonry by a couple of centimeters. This approach will provide the house with better thermal insulation and ventilation.

Features of cladding

Building a house from gas block with brick cladding is not as simple as it seems - this requires experience in working with the material, knowledge of its features, laying rules and a host of other nuances. The technology is complex, so construction can only be entrusted to professionals.

Thus, the main condition is the installation of a ventilated facade - without this, waterlogging of the walls due to vapor condensation cannot be avoided. And if the walls of the cottage need to be insulated, then a ventilated façade is even more necessary. This is a responsible job, only experienced masons can handle it. And these are the specialists who work in our company. Therefore, when ordering the construction of a turnkey country house from us, you can be sure of its impeccable characteristics.

Stages of work

Let's take a closer look at the stages of facing a house. So, in order to cover your house correctly with facing bricks, you need to:

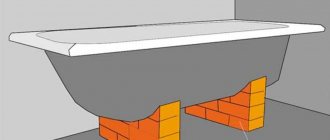

- Start laying from the top level of the plinth, having first leveled the surface using a level. Before applying cement mortar, be sure to position the bricks the way they will be laid in the masonry. Some things may need to be trimmed.

- It is best to start work from the corners of the house, namely by laying several bricks. Pull the cord periodically to check that you are laying the bricks evenly. Use a plumb bob to control the rows vertically.

- To ensure that the spaces between the rows are the same, a metal rod can be used as a template. The mortar is placed on top of the template, then the brick is laid, the layer is leveled with a trowel. Excess mortar from the front surface of the bricks is cleaned with a rag before it dries. After the template rods are removed, the final cleaning of the surfaces from the solution is carried out.

- The last row, located under the eaves, is not overlapped in order to ensure good ventilation.

- Door and window openings are laid out in a layer of one brick.

Tips for getting better results

- For brick cladding, it is best to use cement without additives of the PTs 400 or PTs 500 grades.

- The solution must be diluted in small portions, stirring occasionally, so it does not harden prematurely.

- You should not add additives containing salt to the solution to avoid the appearance of white streaks on the wall.

- Be sure to periodically check how smooth your masonry is. To do this, use levels and plumb lines that will help you identify deviations in time and correct errors.

As you can see, there is nothing difficult about covering your house with facing bricks yourself.

Video

This video provides tips for brick cladding:

Previously, house construction technology did not provide for the use of insulation, nor the use of finishing materials. Many owners of old houses understand that the time comes when it is necessary to cover not only the outer parts of the wall with insulation, but also the surface of the old foundation. To protect the insulation, high-strength brick is used. Finishing brick is popular, despite the large selection of other materials offered in stores. The answer to the question of how to clad a house with brick is of interest not only to the owners of old houses, but also to modern developers.

Cladding the facade of a house with bricks - price, cost of services, scope of work, what to look for

Cladding the facade of a private house begins with the choice of finishing material and ends with the cost of the work carried out. This article contains information that can clarify issues such as types of facing bricks, installation stages, as well as the cost of certain types of work.

When facing a house with brick, the price of turnkey work often depends on the volume of work; the larger the area of the facing surface, the lower the cost of finishing services. For example, with a facing surface area of up to 50 sq. m. the cost of the work is 1,500 rubles/sq.m., at the same time, if the façade area is more than 300 sq.m., the price for cladding a square meter drops to 1,100 rubles.

The cost of cladding a façade with bricks varies depending on the area of the facing surface Source domszytynamiare.pl

Facade finishing. The choice is brick and mortar

When choosing finishing materials, the owner of a country house wants to give the appearance of the cottage originality and uniqueness. Using materials such as siding, block house or plastering, it is difficult to achieve such an effect, since the appearance will remain uniform and repeatable. While, using facing bricks of various textures and shades as finishing, you can easily achieve the required individuality and uniqueness.

Facade cladding with clinker bricks Source brikdorff.ru

Main stages of work and their cost

When ordering the finishing of the facade of a private house with brick, the price of turnkey work is formed from the cost of individual works, an introductory list of prices for which is indicated below. Depending on the area of the facade, the presence or absence of dismantling work, an estimate is formed, which reflects the entire list of work performed, as well as a separate article containing a list of necessary materials.

Preparatory work

The stage includes the installation of metal scaffolding, installation of wooden scaffolding and flooring, protection of the roof, windows and doors from plaster, paint and other products used, preparation of facing surfaces, dismantling of existing finishing. Prices for these works are indicated in Table 1.

Table 1. Preparatory work

| No. | Name of works | Unit | Cost, rub |

| 1 | Installation of metal scaffolding | m² | 90 |

| 2 | Installation of wooden scaffolding | m² | 180 – 230 |

| 3 | Installation of wooden flooring | m² | 250 |

| 4 | Protection of roofs, windows, doors (film covering) | m² | 50 – 80 |

| 5 | Cleaning the plinth | m² | 70 – 100 |

| 6 | Facade cleaning | m² | 180 |

| 7 | Dismantling of the curtain façade | m² | 200 – 220 |

| 8 | Removing tiles and adhesive | m² | 250 – 350 |

Some houses have individual features of finishing with facing bricks Source domodomo.ru On our website you can get acquainted with the most popular projects of stone houses from the best construction companies with an impeccable reputation in the market. You can choose a house without facade finishing, with stone finishing, brickwork, clinker thermal panels, with a warm contour, rough finishing or turnkey. You can communicate directly with representatives by visiting the “Low-Rise Country” exhibition of houses.

Types of finishing brickwork

When finishing masonry, it is important to take a serious approach to choosing the optimal method of tying elements.

Uses various methods:

- straight. When laying bricks using this method, a regular pattern is formed from parallel lines of horizontal and vertical seams;

- decorative. It allows you to create original patterns not only due to the combination of seams, but also due to the combination of bricks of different colors;

- art. Using this method, a relief-volumetric masonry is created, the peculiarity of which is a combination of height differences, patterns, texture and color of the brick.

The development of the technology and the choice of dressing are determined during the test laying of bricks. The most common type of dressing is direct. It allows you to fully use the texture of the brick, combine colors, and also change the size and configuration of the seams. When creating ventilated brick facades, remember that the part of the sheet insulation located between the wall and the brick should not stick out above the brickwork.

You can cover a house with bricks yourself using silicate products

Professional finishers use the following popular masonry methods:

The choice of the optimal option is carried out individually, depending on the artistic taste of the owners of the building and the architect’s plans.

Finishing work

Foam block with cladding both looks aesthetically pleasing and demonstrates greater durability. For a building made of foam blocks, it is necessary to select such external finishing of the facades that, if present, ensures the diffusion of water vapor from inside the house to the outside (find out here how to lay foam blocks).

Note! Violation of the finishing process can lead to negative consequences: steam, not finding a way out, will settle inside the material itself, increasing its humidity.

It is necessary to take a responsible approach to choosing high-quality cladding material for buildings made of foam concrete.

To do the exterior finishing of foam concrete walls with your own hands, the following finishing will not be appropriate:

- ceramic tiles;

- foamed polymer slabs;

- as well as many other materials.

Facade cladding with brick: advantages and disadvantages

Facade decoration of building walls with brick has a number of advantages:

- increased safety margin;

- resistance to mechanical stress;

- resistance to ultraviolet rays;

- variety of shapes, colors and textures;

- reduced water absorption;

- ability to pass steam;

- maintainability;

- long period of operation;

- soundproofing properties.

Along with its advantages, brick cladding also has its weaknesses:

- creates additional load on the foundation;

- needs to protect the surface with water repellents.

If you take into account the characteristics of the products, it is better to clad the house with clinker bricks

Despite the existing shortcomings, brick cladding, performed in conjunction with the laying of thermal insulation material, not only radically changes the appearance of buildings, but also allows them to maintain a comfortable temperature regime.

Materials for cladding houses made of aerated concrete

Despite the fact that aerated concrete has high thermal insulation, the walls still need to be insulated with additional materials.

To begin with, it should be noted that when lining gas silicate or aerated concrete houses, the finishing must necessarily allow the vapors formed inside the house to pass through, therefore, for finishing such houses, cladding options such as plastering with cement-sand mortars, painting with film-forming paints, and finishing with expanded polystyrene, because these materials do not allow moisture and air to pass through. It is worth remembering that cladding a house from an aerated block should be done only after all wet finishing work in the house itself has been completed, because if you first do the exterior cladding of the house, and then begin interior work associated with high humidity, then the porous structure aerated concrete will allow moisture to pass through the walls, which will damage the exterior finish.

The following can be used as cladding in an aerated concrete house:

- painting with vapor-permeable textured paints or putties;

- cladding with various decorative panels, in particular, siding, lining;

- special lightweight thin-layer plaster for aerated concrete;

- brick cladding.

All these methods of lining gas silicate or aerated concrete houses allow vapor to pass freely, do not retain moisture and have excellent aesthetic qualities, which is also important when building a house. Therefore, you can choose any of the above methods, based only on your own preferences.

What type of brick is best to cover wooden walls?

When answering the question about choosing a specific type of finishing brick for laying around the walls of a wooden building, experts do not give a definite answer. Indeed, provided that the masonry is carried out correctly, various types of bricks can be used.

However, there are nuances:

- it is important to make a reliable connection. This is complicated by the fact that timber and brick have different characteristics;

- a ventilation gap should be maintained and a windproof membrane should be provided;

- use vapor-permeable materials that allow you to maintain normal humidity indoors.

How to line a house with facing bricks: features of the technology

Let's look at how to properly brick a house. The complex of finishing measures includes the following work:

- Treating the wooden walls of the building with a protective compound.

- Assembly and installation of a lattice frame made of wood.

- Laying thermal insulation material inside the sheathing.

- Fixing a windproof membrane with one-sided vapor permeability.

After completing these operations, a 60 mm gap should be left to ensure air exchange and a wall of finishing bricks should be erected.

How to brick a house: recommendations from professionals

Professional finishers advise paying attention to the following points:

- quality of the building materials used;

- use of material from one supply;

- providing a ventilation gap;

- correct implementation of reinforcement;

- control of horizontality of brick rows;

- ensuring verticality of brick walls;

- the need for antiseptic wood treatment;

- strengthening the foundation.

Compliance with the technology of laying finishing bricks is a prerequisite for the reliability of the masonry. High-quality cladding will improve the appearance of the building and extend its service life.

Methods for facing a house with facing bricks

After completing the frame of the house, the question arises of how to decorate the facade so that the building gains expressiveness and becomes warmer. Along with plaster and siding, cladding a house with brick is often used. The facing brick itself is distinguished by its beautiful surface, correct dimensions, and a wide variety of colors and textures, so that a house lined with brick takes on an elegant and neat appearance without additional decorative details and decorations. In addition, facing a house with brick is also beneficial for functional reasons, because it protects the facade from the negative effects of weather factors and increases the sound and heat insulation of the building.

Brief description of methods for cladding aerated concrete houses

Plastering walls made of aerated concrete is no different from ordinary plaster. Here it is also necessary to install a plaster mesh, observe the temperature regime and rub down the necessary places.

If the choice of cladding a house made of aerated silicate or aerated concrete blocks has fallen on plaster, then you should pay attention exclusively to special plaster mixtures that are made for aerated concrete. This mixture will allow steam to pass through and will not allow the aerated concrete block to get wet.

The procedure for working with such plaster is no fundamentally different from ordinary plaster. Here there is a need to install a plaster mesh, maintain temperature conditions, and rub down the necessary places.

When facing a wall made of aerated concrete with decorative panels, you first need to secure the structure on which the panels will be attached.

When cladding a house with decorative panels on gas silicate or aerated concrete walls of the house, you must first secure the structure onto which the panels will be directly attached. This structure must be carefully secured. Now on the construction market you can find ready-made facade structures with fasteners that are attached to aerated concrete, and then any decorative panels can be attached to them.

If you decide to paint an aerated concrete house, then the paint or putty must be vapor-permeable so that the aerated concrete can “breathe.” For such work, you can choose any special facade paint or putty that allows steam to pass through, and when performing work, follow the instructions that come with the paint.

Features and types of facing bricks

The basis for the production of facing bricks is the same material that is used for the production of ordinary bricks. However, regardless of the material from which the facing product is made, it must meet the following requirements:

- correct geometric shape (the error in length cannot exceed 4.4 mm, in width – 3.3 mm, and in height – 2.3 mm);

- clear and smooth edges;

- rich, uniform color;

- the product should not have any defects in the form of chips, cracks and delaminations (the surface can be smooth, glazed or textured);

- facing bricks can have frost resistance within F 25 - F The marking value indicates the number of freezing and thawing cycles that the material can withstand without visible damage and a decrease in compressive strength of no more than 20 percent;

- water absorption should be below 6%.

Important: if you are laying facing bricks with your own hands, then you should know the following concepts: the long side of the product is called the spoon, the end part is called the butt, the supporting plane (the largest surface) is the bed.

The following products can be used as facing bricks:

- Ceramic masonry bricks in which clay is used as a filler. Compared to silicate products, the production technology of ceramic elements is more complex, which affects their price (they are more expensive). Among the positive qualities of these products it is worth listing the following:

- water absorption is 6-14% (this figure may be higher according to GOST, depending on the type of clay used);

- frost resistance - from 25 to 50 cycles;

- thermal conductivity is 0.3-0.5;

- a large assortment of colors, textures and sizes (thanks to this, decorative parts of facades can be made from brick, arches and columns can be lined with it);

- The density of the product is in the range of 1300-1460 kg/m³.

- Clinker brick has a dense structure, so it practically does not absorb moisture. However, solid clinker has greater thermal conductivity. In addition, the price of the product is higher than that of conventional ceramic bricks. Its characteristics:

- can withstand up to 100 cycles of thawing and freezing, which makes a house lined with such bricks more durable;

- With clinker you can not only cover the facade, but also use it to lay out columns, decorative belts, facade details, make a beautiful fence and use it in the interior;

- there is a large selection of shapes, colors and textures of this product on sale;

- The density of clinker brick reaches 2100 kg/m³, so it can be used for laying load-bearing elements of a building.

- You can cover your house with bricks yourself using silicate products. They use quartz sand as a filler. When decorating your home with such elements, it is worth considering their characteristics:

- water absorption of the material is 6-8 percent;

- the frost resistance of the elements is low and amounts to 15-50 successive cycles;

- thermal conductivity – 0.39-0.7;

- element density – 1500-1950 kg/m³.

- Cladding a house with products that are produced using hyperpressing technology (semi-dry method) is very similar in characteristics to ceramic bricks, but its price is slightly higher. A striking example of such facing elements is the Bassoon brick, in which shell rock is used as a filler. Characteristics:

- water absorption – 3-7%;

- frost resistance from F 30 to F300;

- strength from 1000 to 4000 kg/m³;

- thermal conductivity 0.43-0.9.

Advice: if you take into account the characteristics of the products, it is better to clad the house with clinker bricks. Although its cost is higher, such investments will quickly pay off with durability and ease of use.

Insulation of the walls of an aerated concrete house when facing with brick

Among the insulation materials used are materials such as: mineral wool, polystyrene foam, expanded clay, penofol.

The following materials can be used as insulation:

- mineral wool;

- expanded polystyrene;

- expanded clay;

- penofol.

- Mineral wool is a completely non-flammable building insulation material, which is made from mineral raw materials and impregnated with special binders, which transform mineral wool into slabs. Such slabs are very easy to use and have excellent thermal insulation and sound insulation properties.

- Expanded polystyrene is a material that has been used in construction for quite a long time and has proven itself well. It is very resistant to moisture, has good thermal insulation characteristics, and is easy to use. The only negative that can be noticed about polystyrene foam is its instability to heat.

- Expanded clay is a round granule with air bubbles inside, which is made from baked clay. Expanded clay absorbs water very well.

- Penofol, or polyethylene foam, is one of the most modern insulation materials at the moment. It is covered on two or one side with foil, which is currently the most effective heat insulator. Penofol material is very thin, so it can be used even when the cladding is adjacent to an aerated concrete wall.

When insulating walls made of aerated concrete, do not forget about the vapor barrier, which will prevent moisture from entering the insulating material.

The choice of material for insulation depends only on the financial capabilities and wishes of the owner of the house.

It is important not to forget about laying a vapor barrier between the insulation layers and aerated concrete walls. If this is not done, the insulation may become wet from the fumes escaping from the house.

Various materials can be used as vapor barriers, for example:

- polyethylene film;

- vapor barrier membranes;

- glassine

Film as a vapor barrier is not the best choice; it does not allow air or water to pass through at all, but it is very easy to work with and inexpensive.

Glassine is a special construction paper that is completely impermeable to water. However, this is a completely outdated building material.

Vapor barrier membranes are currently the best material with vapor barrier properties; moisture vapor penetrates through it only in one direction. The main thing when working with it is to strictly follow the instructions and under no circumstances confuse the outer and inner layers.

Types of facing masonry

Laying facing bricks can be done in different ways. There are quite a lot of them. If you don’t know how to cover a house with bricks, you can choose one of the installation options below. We will not list all methods, but only the most popular:

- Brick laying with a path (spoon). In this case, the whole brick is laid with the long (spoon) side. In each subsequent row, the elements are shifted relative to the bottom row by half or a quarter of the product to ensure that the vertical seam overlaps.

- You can line the house with facing bricks laid in block masonry. In this case, rows with spoon and bonded masonry alternate, that is, one row is laid with the long side, and in the next all elements are laid with their ends.

- Cross masonry is very similar to block masonry - alternating spoon and end rows. In this case, it is necessary to observe the shift of the joints by half the brick. Thus, we will get a pattern that resembles a cross - exactly above the end part of the brick there will be a spoon part, and above it again the end part.

- You can lay out the walls with Gothic masonry, when elements with spoon and butt laying alternate in one row. At the same time, in adjacent rows the spoon is shifted by a third of the length of the brick, and the poke by half of the product.

- Brandenburg or chain laying is done in such a way that a poke is laid in one row every two spoons. In the next row, the end parts of the bricks should be above the junction of the two spoons of the bottom row.

- Chaotic masonry is the most extraordinary method of cladding, when no order is observed and alternation of long and short sides. If this is your first time laying facing bricks yourself, laying them in this way will greatly simplify and facilitate the task for a beginner.

Attention: when laying stone with the end part, the element is first cut in half. Thus, whole products and halves alternate.

Important Tips

If you want to know how to properly line a wooden house with bricks or a building made of other wall materials, then you should adhere to the following recommendations:

- Since facing bricks must be purchased from one batch in order to avoid discrepancies in color or tone, before purchasing it you need to accurately calculate the total amount of material. This is not difficult to do if you find the total area of the facades minus all the openings, and then multiply the resulting value by 51 - the number of bricks in the masonry per 1 m² of wall.

- Before covering a structure made of timber or a wooden house, it is necessary to carry out an antiseptic treatment of all wooden elements. It is better to treat the tree twice, repeating the procedure every other day.

- Also, before performing this work, it is necessary to strengthen the foundation or pour a new tape next to it. To do this, do the following:

- In an old concrete foundation, holes are drilled to a depth of 10 cm, with a cross-section of 1.2 cm. In a brick foundation, the depth of the holes should be greater - 20 cm. These holes should be located 10 cm below the top of the base, their pitch is 50 cm, and the angle of inclination is 15-20°.

- Reinforcing pins made of a rod with a diameter of 1.2 cm are driven into the resulting holes. In this case, the end of the reinforcement 15 cm long should stick out from the foundation.

- Next, a new 30 cm wide strip of monolithic reinforced concrete is poured next to the existing foundation. The reinforcement releases are bound to the frame of the new foundation and remain in the concrete forever.

- Horizontal and vertical waterproofing of the new foundation is carried out from two layers of rolled material - roofing felt.

- Before covering a wooden house with brick, you need to install a ventilation system to prevent the wood from rotting under the cladding. To do this, there must be an air gap 3-4 cm wide between the brickwork and the wooden surface. Also, ventilation ducts are additionally installed on the facade, the area of which should be 0.75 m² for every 20 m² of the facade area. To prevent rodents from getting into the vents, they are closed with special nets.

Technology for laying facing bricks

Typically, facing bricks are laid using jointing. The following technology is used:

- Brick laying is carried out on a fine day at a temperature not lower than +5°C. You cannot perform work at temperatures below zero, as the cement mortar will change its properties.

- Before proceeding with installation on the mortar, the stone is laid “dry”. This will allow you to determine the amount of stone that needs to be adjusted to size and select products for decorating door and window openings.

- Before laying the first row, the base must be leveled.

- To cut stones, a grinder with a stone disc is used. It is prohibited to chip elements with a hammer.

- For laying, a cement mortar is used, which is prepared from 1 hour of Portland cement, 3 hours of sifted river sand and 1 hour of water. The mortar mixture must be rigid enough so that the element does not “float” during installation.

- The mortar is applied to the flat part of the brick in a thin layer. However, it should not reach the front edge by 1 cm.

- When making masonry, first, corner rows are made to a height of 4-6 bricks. To make the dressing more reliable, it is not recommended to use halves of a stone. It is better to take elements ¾ long.

- A cord or fishing line is pulled between the two corners, along which the intermediate bricks are laid and leveled.

- To prevent the facing brick from absorbing moisture from the cement mortar, the product is moistened with water before installation.

- The height of the horizontal seam is 1.2 cm, the vertical seam is 1 cm.

- To ventilate the brickwork in the bottom row, every three vertical seams, a seam is made without mortar and filled with insulating material; in the upper part of the facade, ventilation is carried out due to the fact that the masonry on 1 row does not reach the cornice.

- Every 5 rows, it is recommended to remove cement that has fallen on the front surface using a wet rag.

- The facing layer must be attached to the walls of the building. To do this, during masonry, anchors with a diameter of 0.4-0.6 cm are hammered into the walls. In this case, for each square meter of the facade plane there should be at least 45 anchors, and 8-12 attachment points are made above the window openings.

- If it was not possible to lay dowels in the masonry of the walls of the house in advance, then dowels are driven into the walls, to which the wire is tied. It should reach the middle of the facing layer and go 20 cm in each direction. Thus, the wire is hidden inside the masonry. The installation step of such dowels is 50 cm. In frame and wooden houses, nails 120 mm long are used to arrange the dressing. In a block structure, clasps are suitable for these purposes.

- When the cement has set a little, the seams are opened using a wooden rod. The solution is simply pressed in.

- Window and door openings are always lined with bonded masonry. For greater attractiveness, you can use elements of a different shade.

Video guide for laying facing bricks:

The process of insulating aerated concrete houses when facing with bricks

Even before the process of lining the walls of a gas silicate house with bricks begins, it is necessary to attach a vapor barrier to the walls.

The insulation between the facing brick and the main wall is laid as the lining of the house proceeds. In this case, slabs of expanded polystyrene and mineral wool are secured with nails with wide heads, and expanded clay is simply filled in as the masonry increases.

When insulating the external walls of an aerated concrete or gas silicate house, you should not use mineral wool in rolls - after some time it will shrink strongly, resulting in large spaces not protected by insulation.

It is worth noting that it is necessary to lay the insulation in such a way that there are no joints; if they occur, polyurethane foam should be used.

Particular difficulties may arise when cladding and insulating areas around windows. Polyurethane foam cannot be used here, as it expands greatly when drying, and as a result can squeeze out the facing brick. In this case, it is best to use a special polyurethane sealant, which has a fairly elastic structure, as a result of which no seasonal fluctuations in the walls of the house will affect the quality of the sealing.