In areas with clayey or swampy soil, conventional concreting of supports is undesirable, since due to the excess amount of moisture during freezing and thawing, the soil will constantly deform, and at one point they will simply be pushed out. In such cases, butting of fence posts is used - backfilling with crushed stone. This method is sometimes called dry concreting. Butting fence posts allows you to protect them from deformation and premature destruction.

Installation of a corrugated fence

Requirements for intake pipes

If you don’t want to spend time, effort and money repairing the fence in a year or two, then you should immediately worry about constructing posts that are sufficiently strong and reliable. These should be supports that will be able to cope with the weight of not only the spans of the fence, but also with dynamic loads.

It is very important to correctly calculate the safety margin so that the fence around the summer cottage can withstand the effects of wind, snowdrifts or animals. The selected posts for constructing a fence for a summer residence must be designed in such a way as not to deteriorate the appearance of the fence itself . Therefore, if they look out of place against the background of the main structure, then you need to deal with them in such a way that they are hidden from others.

Hammering the supports

To install high supports, you can use a “grandmother” - a device for driving piles.

Installing fence posts is an easy and inexpensive option that provides a strong foundation for the fence. There are two recommended ways to hammer in supports:

- a sledgehammer, which is used for two-meter structures;

- a special device for driving supports into the ground, used for three-meter posts.

When driving the supports, there will be no need to transport the working material to the site and no time for preparing the concrete mixture. However, before choosing an installation method, it is worth familiarizing yourself with the advantages and disadvantages of each of them.

Advantages

The advantages of driving supports include:

- Ease of execution. The structure is driven into the soil without using a solution or digging a hole.

- No soil heaving when using support driving.

- The low cost of the method is due to the absence of the use of additional material and the cost of transportation and other auxiliary equipment.

Flaws

Hammering supports for fences has the following disadvantages:

- This installation method is not suitable for all types of soil. On soils with a high content of sand and peat, the structure will be unstable.

- It is not possible to use the hammering method for massive structures, since the pillars will sag or fall apart under their weight.

- Difficulties arise when installing supports in soil with high density, since such soils contain many stones that will lead to deformation of the pillars during installation.

Selection of installation technology

When deciding which is the best technology for installing poles to choose, you should first of all take into account such a parameter as the characteristics of the soil. To ensure that the supports do not require attention for a long time after installation, you must first conduct geological studies of the site in order to find out what the depth of freezing is and at what level the groundwater flows.

If the dacha plot is located on heaving soil , then the method of concreting pillars should be abandoned. Otherwise, with the onset of spring, they may be “brought out.” In winter, when the ground becomes frozen, it takes on increased volume due to its water content. This process is usually called soil heaving. When the air temperature rises and reaches positive levels, the soil thaws, as a result, the ice turns into liquid, and this inevitably leads to subsidence of the soil.

It is important to note that the ground thaws differently in different areas. The earth warms up more strongly on the south side, therefore, with the arrival of heat, uneven subsidence of the pillars is observed. Melt water also makes its contribution , which, acting on the concrete base, causes its destruction.

If the dacha plot is located on hard ground, then it is recommended to choose the method of driving in pillars. If the land is located on sandy or sandy-clayey soil, then it is best to use concreting technology. Driving is attractive primarily because this method of installing the base takes a minimum of time. For this reason, this option should be considered in cases where the task is to erect temporary fences.

Necessary tool

To do the concreting of pillars with your own hands, you will need the most common construction tools, namely:

- bayonet and shovel shovels, crowbar;

- wheelbarrow;

- drill or hole drill (hand-held or tractor-mounted);

- tamping;

- concrete mixer (How to prepare concrete yourself, read the article Concrete: how to prepare it yourself)

- measuring devices:

- roulette;

- level;

- theodolite, level;

- a plumb line and a regular nylon cord.

Concreting pillars

concreting should be chosen as the most effective method for installing pillars . This installation method has a number of advantages:

- Long service life. If fences are installed on soils that are resistant to swelling, then they can last up to 50 years;

- Anti-corrosion protection. Concrete is resistant to moisture, and therefore is not afraid of rust;

- High structural stability. Installing fence supports using this method prevents them from wobbling in the ground.

Within the framework of concreting technology, two types of this method of installing pillars can be distinguished:

- complete;

- partial.

Partial concreting

This method of installing supports is based on the following: prepared supports are immersed in the ground, after which they are partially filled with cement mortar. It is better to use concrete using this method, primarily because it can help reduce the cost of installing the fence. It is advisable to consider this option if the fence is planned to be installed on stable ground and under the influence of light loads.

The partial concreting method itself can be implemented in two ways .

In the first case, after placing the supports in the dug holes, the lower part is compacted, which, in principle, is also typical for the technology of installing pillars using rubble stone. If metal supports are used, it is recommended to drive them into the ground and fill the rest with concrete. It is advisable to consider such an option if the installed poles are intended for fencing made of corrugated sheets.

When starting to concrete pillars using this method, it may be necessary to make formwork that will help avoid soil spreading. This method of installing supports is superior to all others in terms of the time it takes to complete the work, which is minimal. But this technology is not recommended for use on heavy soils that are unable to absorb moisture, since with the arrival of spring there is a danger of the pillars skewing.

The second option for installing pillars using the partial concreting method involves filling the lower part of the pit with concrete mortar until the soil freezes , after which a support is placed there, and then the free space is filled with crushed stone and thoroughly compacted. By choosing to concrete the supports in this way, you can minimize the impact of buoyancy forces. However, it is not ideal due to a number of disadvantages:

- When the hole is filled with concrete for the first time, it is difficult to ensure the verticality of the supports;

- It takes about 5 days for the concrete to finally harden.

Full concreting

From an economic point of view, it is advisable to choose this technology for installing poles only if it is assumed that the poles will experience significant loads. Installing pillars on stable ground using the concreting method is technologically simple. They begin to concrete the supports by creating a sand cushion up to 10 cm thick. After this, they begin to install the supports, and formwork is erected along its perimeter. The finished well is filled with concrete mixture.

To avoid bubbles when installing the supports, after pouring the mixture, it is pierced with steel rods . Before the time comes to begin installing the spans, at least 3 weeks must pass - this is how long it takes for the concrete to finally harden.

Among the advantages that full concreting technology provides, it should be highlighted that the supports can withstand temperature fluctuations and precipitation well. This installation method is ideal for the construction of massive fences that are built in areas with sandy soil and groundwater.

About scoring methods

- Use a regular sledgehammer and a wooden spacer if the pillars do not exceed two meters in height. This process is the most labor-intensive;

- Hammering with the help of a headstock. Due to the guide part of this design, the impact forces of the driven pipes are aligned;

- Using a pile driver. A special device that simplifies and speeds up the driving of posts.

Which cases are acceptable for driving and which are not?

Installation is permitted if:

- The site has little stony soil;

- There are marl rocks, that is, with a clay-carbonate composition.

Hammering fence posts by hand

This method cannot be used when:

- The soil is too soft;

- Rocky rocks are present at very great depths.

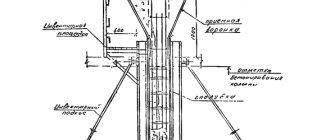

How to hammer supports with a headstock

The headstock, as a special tool, can be driven into poles even three meters long. This tool has several metal parts. It is used when it is necessary to drive in a wide and high post. You can make such a device yourself.

To do this, you will need a meter-long pipe so that its internal diameter is larger than the pole itself and so that it can be put on the pipe. Take a thick metal sheet and cut out a shape similar to the diameter of the pipe, weld the end of the pipe with it.

Drawing of headstock for driving posts

The end of the pipe must be welded with some heavy objects so that the headstock has a weight of up to 30 kg. Make two handles with handles, each one meter long, and wrap them with electrical tape to make it easier to work with them. When you install the post in the right place, put the headstock on it. Using the handles, you need to lift the structure and forcefully lower it down.

A tripod placed above a pole will also help. Weld a block onto the top. Using a rope, this block will make driving the fence base easier. The principle of operation is simple: you lift the block as high as possible and forcefully lower it down. Remember that such a folk device must have a diameter larger than the pole.

Drivers for driving fence bases

The principle used here is that upon impact, the device does not have springs or other mechanisms that would impede the movement of the hammer. This special device is a pile driver, with the help of which a series of blows is made.

This design simplifies and speeds up driving the posts. The pile driver machine helps to lift and install supports at the diving site. You can use either a self-propelled or non-self-propelled, manual pile driver.

Using this technique, the pillars are dragged to the place where they need to be installed, and then, according to the design position, they are immersed in the ground.

Having fixed one pillar, the pile driver is moved to the next working point. A device such as a pile driver can also dismantle pillars that have been concreted. It turns out that in a very short time you can redo the fence using a unit such as a pile driver.

Return to contents

Driving into the ground

In cases where work is planned to be carried out on problematic soil, and it is not expected that the fence will be subjected to significant loads, it is recommended to drive the posts into the ground.

Installation technology

The essence of installing supports using this method is as follows: first you need to create a hole using a hand drill, the diameter of which should be smaller than the posts. After this, the support is taken and driven into the hole with a hammer or sledgehammer. It is desirable that the hole created in the ground be as narrow and deep as possible, since this increases the reliability of the support installation.

Benefits of technology

- Minimum time required to complete installation of supports;

- The ability to perform installation without the use of specialized equipment;

- Protection of supports from soil heaving in places of moderate humidity;

- Low work costs.

Flaws

This technology for installing pillars is suitable only in cases where it is planned to erect lightweight fences that are not prone to demonstrating such a phenomenon as “windage”. When the soil is waterlogged, which can occur in the spring or after heavy rains, there is a danger of the pillars skewing.

Also, the method of driving in supports for a fence is not without other disadvantages:

- When installing pillars on peat, marshy and sandy soil, it is impossible to ensure the stability of the structure;

- If the support is installed on too dense soil or there are quite large stones in it, this will cause deformation of the supports over time.

A similar technology for installing poles is applicable for wooden fences and chain-link fences.

In order to increase the durability of fence posts, it is not recommended to install them without treating the immersed part with an anti-corrosion compound.

This technology is not suitable for fencing made of corrugated sheets, since it cannot ensure the horizontality of the installed supports . If you neglect this advice, then after completion of installation work the fence will not be level. The method of driving posts into the ground makes sense only in cases where the fence made of corrugated sheets is planned to be used as a temporary fence.

In order not to make a mistake with the choice and to understand which option - concreting or driving fence posts into the ground will be the most preferable option, many factors should be taken into account. The key factors are the nature of the soil, the material of the fence, the type of terrain, etc. In some cases, it makes sense to choose a more complex option for installing a fence, which requires greater costs, so as not to have problems with the fence for many years.

About the advantages and disadvantages of installing poles in this way, such as driving

The advantages are that using this method does not entail large financial costs.

The process of hammering a post with a special apparatus

You don't have to use special equipment. Avoid financial costs for transportation of all kinds of building materials and temporary costs for their preparation.

Minuses

If the site has soft soil, expansion of the hole will be inevitable, which will lead to unstable installation of the pillars. When a pole becomes clogged, its upper part becomes deformed. When hammering by hand, the height of the posts is very poorly controlled, because the hole may break or the post itself may become warped.

Pillars that are not installed by concreting will not last long due to moisture penetration. If you know that your fence will stand temporarily, no more than five years, then you can use this method. If more, we advise you to concrete the pillars. But you can use an expensive mechanized method using special equipment, then you can avoid negative aspects.

Erecting a fence around a site or a specific building is a procedure that is essential for suburban construction. The quality, durability and decorative components of the fence are as important as for other buildings. During installation work, the question always arises: “What is better: concrete or hammer in fence posts?”

Let us answer briefly - the choice of method for attaching the posts depends on the type of fence and the requirements for it.

Conclusion

The installation of posts is of great importance when constructing a fence. They perform a supporting function on which the entire structure rests. Therefore, before you begin installing the poles, it is important to decide on the method of their installation. First, you should analyze the construction site, find out the structure of the soil and the water level in the soil. Determine the load-bearing capacity of the selected area and find out the possible environmental influences on the structure.

When choosing a method for installing supports - driving in, you should not rush for a low price and ease of installation, because these factors can contribute to the rebuilding of fences after a short period of operation. It is still better to choose concreting when installing heavy structures. Concrete the pillars in compliance with the technological installation sequence, and they will last for decades, while maintaining their strength and strength.