A modern yard is not complete without a convenient canopy. A simple structure serves as reliable protection from precipitation, protects your car from the sun and corrosion. Are you planning to make a carport for your car? This design does not require much money or effort. It is quite possible to do it yourself. In this article we will tell you how to build a simple, functional canopy that will reliably protect your car. Let us explain what materials can be used for such construction.

The only thing that a roof and four pillars cannot protect a car from is the cold, but this is not necessary during the warm season.

One of the carport options

Wooden frame with wooden roof

Advantages:

+ It's inexpensive.

Moreover, the price is lower both for the material itself (wood is cheaper than metal) and for independent installation (no special equipment is needed, ordinary tools will do).

+ You can install it yourself.

Even a non-professional can build wooden structures. There is no need to hire workers or craftsmen or buy a welding machine.

+ The material is environmentally friendly.

Treated logs look natural and organic in most areas. The tree exudes a pleasant aroma and creates the impression of comfort and reliability.

+ No solid foundation required.

Even a parking shed for 2-3 cars is so light that it does not require complex site arrangement.

Flaws:

-Requires regular treatment.

Without special impregnation, the wood will deteriorate and rot.

- Fire hazard.

One spark can destroy a structure in half an hour.

- Short service life.

Especially compared to metal canopies. A wooden one will last no more than 10 years without changes.

This is interesting: Metal and wooden shelving for the garage: advantages of choice (24 photos)

Metal frame with polycarbonate roof

Advantages:

+ Reasonable cost.

Polycarbonate cannot be called a cheap material, but it is quite affordable. The average price is 300 rubles per square meter.

+ Reliability.

The metal base is strong and durable, it will withstand hurricane winds and will not tilt due to snow load. Roofing sheets are difficult to tear or break.

+ Quick installation of the canopy.

Owners of their own plots with construction experience can even try to install it themselves. Flexible and lightweight polycarbonate (weighing 16 times less than glass) is quite easy to install. However, before doing this, it is important to study a number of nuances.

+ Does not require special care.

All you need to do is wash the canopy regularly with clean water.

+ Attractive appearance.

The sheets go well with the metal base. From a huge catalog of colors it is easy to choose the appropriate option or order sheets with drawings. Transparent panels create a colored shadow under the canopy and do not create the feeling of an enclosed space.

Flaws:

- The damage is irreversible.

Polycarbonate is stronger than glass, and when a protective layer is applied, it is not afraid of even hail impacts. But it can be damaged. Stones that fall on the roof will cause scratches or cracks. The integrity of the surface can also be damaged during installation if you run a tool across the plastic. On a hot day, the sun will highlight all the defects.

- The color will fade.

After a few years, colored or simply transparent plastic will lose its brightness and become cloudy. Due to exposure to ultraviolet radiation, old polycarbonate no longer looks as attractive as it did after installation.

- You need to be careful during installation.

It is better to turn to professionals who will not make mistakes during installation. The most common of them is the absence of thermal play. As a result, the coating becomes cracked and needs to be replaced.

Polycarbonate carport

One of the common and popular awnings, which are often used by summer residents and owners of country houses. We wrote earlier about various structures for a summer house that you can build with your own hands. Such a material can be a monolith or consist of cells. Their differences are:

- Thanks to its cellular structure, cellular polycarbonate is lightweight and easy to install. The monolithic base can withstand high pressure and loads.

- Cellular material is cheaper, but its service life is significantly shorter.

- The monolith is installed on a strong and reliable frame; for a cellular frame, it is enough to use supports of small thickness.

Once you have chosen the appropriate material, you should begin installing it. The sheet parameters are determined by the dimensions of the structure itself. It should be cut with a power tool specially designed for this purpose.

Important! If cellular polycarbonate is used for the roof, then water should not be allowed to enter the channels. The sheets should be placed perpendicular to the ground. If these measures are not taken in time, the accumulated moisture will mix with dust, thereby ruining the attractiveness of the canopy. Monolithic coating does not have such problems.

Next comes the sheet installation itself:

- After cutting the polycarbonate, holes are made for fasteners. This must be done before the installation process begins.

- The diameter for the holes in the sheets is chosen larger than the hardware itself. This is done because the material itself changes at high or low temperatures, and if the diameters match each other, then cracks or chips will appear at the fastening points.

- The bottom of the sheets is covered with a special perforated tape, the top is solid.

Roofing - Polycarbonate.

So we need 3 standard polycarbonate sheets 2.1 x 6 meters. And accessories for their installation. Good sheets from a trusted manufacturer with high-quality aluminum fittings will cost about $550, I consider sheets 8 mm thick. At this point, unscrupulous companies can once again deceive you, both in order to earn more and in order to lower the overall estimate in order to make a profitable offer for a client whose main question is “what price?”, and not “what quality?”. Unscrupulous companies may offer you cheap polycarbonate of poor quality, as well as material of less than the required thickness, since it is cheaper. There are a lot of polycarbonate manufacturers and, unfortunately, the quality of most of them is either bad or very bad, which means that the cheaper the material, the less it will last; some cheap brands of polycarbonate already change their color after a year or two, or simply crack and collapse. In order not to pay and not change polycarbonate in the next 2 years, we do not advise you to take cheap polycarbonate, and immediately refuse the services of a company that offers cheap roofing for your canopy, since most likely the rest of the structure will also not be of the best quality and this will save you can be costly in the future.

It is better to choose high-quality polycarbonate from well-known European manufacturers, which is guaranteed to last more than 15 years. By choosing high-quality polycarbonate and paying once without saving, you will not spend money on buying new material in the near future, because paying twice for cheap material will cost you more than buying expensive but high-quality material once.

This also applies to fittings, they also come in different price categories and different quality, but the difference in price will not be so significant and here you definitely shouldn’t save, but unscrupulous sellers can save here too in order to make the estimate either cheaper or more profitable for yourself. So pay attention to this.

Using high-quality polycarbonate, you have nothing to worry about, since the material from world-famous manufacturers goes through many levels of inspection and testing, has all the necessary international quality certificates, and first of all, the manufacturers of such polycarbonate monitor the quality and reputation, since it costs them a lot. Not only simple canopies are made from such polycarbonate, but also structures of such scale as stadiums, etc. If you want your canopy to be made from materials of the same class as those used for international stadiums, then use only trusted brands.

So, for a canopy 6.3 x 5.5 meters, a good cellular polycarbonate along with components will cost about $550.

So what should you order?

The choice of material for the canopy depends only on the wishes of the customer. When purchasing a structure, it is important to take into account not only the external attractiveness of the material, but also its durability, strength, and stability. Of the listed options, a metal frame with corrugated sheets or polycarbonate will last the longest – up to half a century.

The period declared by the manufacturers during which the design will not change and retain its properties is 10 years for the frame, the same for steel sheets and 20 years for plastic ones. Of course, the actual service life, subject to all operating rules, is much longer. But there are also nuances. For example, if polycarbonate is easily damaged, then corrugated sheeting is practically invulnerable.

What to choose? You decide!

Own production

We produce fully finished products of high quality.

Decent quality

Neat cleaned welds, uniform coloring without sagging or drips.

Transparent prices

The price is fixed in the contract and cannot be changed.

Skilled Russian workers

All work is performed only by qualified Russian workers.

Technical side of the issue

Support posts for wooden carports are made from timber 150*150, 100*100 mm, or rounded logs with a radius of 150-200 mm. For metal structures, a round steel pipe with a diameter of 100 mm or a profiled one with an edge of 80 * 80 mm is suitable. The distance between supporting structures is 1.5-2.0 m; in some cases, three-meter spans are allowed, but such options require complex engineering calculations.

Carports made of polycarbonate, photo project of parking for 2 cars

For purlins - profiled pipe 40*80 mm, for large carports - 80*80 mm, for mauerlat 100*100 mm or 150*150 mm, for metal sheathing - pipe 40*40 mm, for rafter system made of wood - edged board 100*40 mm.

Carport made of wood, photo of a drawing with parking dimensions for one car

Dimensions

The ergonomic size of the canopy for an average car is 5 * 2.3 m, the dimensions of the building are considered universal - 6.6 * 3.6 m, suitable for minibuses, SUVs, crossovers. To make the carport for 2 cars convenient, but at the same time not take up additional space on the site, it is optimal to choose a size of 6.3 * 5.9 m.

Carports made of polycarbonate, cantilever design in the photo

The height of the canopy directly depends on the height of the car plus the upper trunk with things. Too low will be inconvenient when getting out of the car, so it is advisable to make the height 1.9 - 2.2 m; if you make the building higher, precipitation will fall on the site.

Construction of a carport with your own hands, drawings of a parking lot adjacent to the gate

According to standards, the dimensions of a carport should be 1 m larger than the car in length and 1-2 m in width. The width of a carport for two cars is calculated as follows: the sum of the widths of two cars + 1 m on each outer side + 0.8 m between cars.

How to make a carport with your own hands, photo idea of a simple design under the Polonso farm

For self-construction, ready-made projects with dimensions and recommendations can be downloaded on the Internet. We have offered several practical options on how to make a carport with your own hands. If the finished project does not suit you, you can make the drawings yourself based on the finished one, changing the dimensions.

Main load-bearing elements for a wooden carport

Dimensions of carports

The minimum dimensions of a car are 1.6 by 3.6 m, the maximum are 1.8 by 4.9 m. The height of the canopy is such that a person can easily pass under it - at least two meters, but, depending on the design of the structure, this figure can be increased to 3.5 m. In order for the car to freely move in and out from under the canopy, and its doors to open, without the risk of damage, the distance between the supports is 2.5-3.1 m. A comfortable roof length that allows you to protect the car from rain - 4.2-6.5 m, depending on the size of the car.

To assemble a carport with your own hands, you need to be able to draw up a plan, as well as process materials.

Tip: to simplify calculations, add 40-50 cm to the dimensions of the car on each side.

Design Features

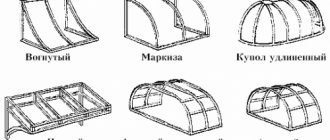

Polycarbonate canopies have different roofs: straight, arched, wavy. But you need to take into account that fallen leaves can accumulate in wavy autumn, and snow in winter. The roof shape can be single-pitched, arched or gable.

A standard canopy consists of several elements:

- Metal supports.

- Ferm.

- Runs.

- Polycarbonate.

Depending on the type of construction, cellular or monolithic polycarbonate is selected. It comes in a variety of shades and thicknesses.

Manufacturing and installation work.

The next point in pricing is the cost of manufacturing the canopy. This may include the cost of a surveyor and consultant, preparation of design documentation, production of a canopy, delivery of all necessary materials, concreting, installation, welding work, painting work, installation of polycarbonate, etc., it all depends again on what kind of canopy and where it is is installed . The cost of such work will be 30-50% of the total cost of the canopy, everything again depends on the type of canopy and the construction company. I would like to note that a good manufacturer works quite a lot of people to produce a high-quality canopy, and high-class specialists should be well paid, so such a company will not have the lowest cost of work.

Cheap welding and high quality welding.

If you look for the lowest cost, there is a high chance that you will encounter workers with no experience and low quality of work. The work of good specialists should be paid accordingly, so it cannot be the lowest. Of course, there are cases when some companies may secretly include in the cost of making a canopy the salary of 2-3 secretaries, the rent of a large office with leather sofas, the salary of 5 accountants and 10 managers, and the quality of the finished canopy will not be the best, so it would be worth paying attention to this too attention. Our position is that everything should be in moderation and fair to the client. In our example, the cost of all work (this is the price of EPlastik, which is the average price for our region) will be approximately $700-800. With a very high quality of work, we can offer such a price thanks to a properly planned budget, well-selected specialists, and many years of experience. With the same high quality of work, most other companies will charge $1,000 or more for the job.

We assume that the cost of work on a 6.3 x 5.5 meter canopy will be $750.

Location of the canopy on the summer cottage

You need to decide where it is best to build a parking lot. You can put the shelter right at the entrance, then you won’t need to taxi between the flower beds. But if it’s raining or snowing outside, you’ll have to run to the dacha in the rain. The location of the canopy at the back of the site can create additional difficulties for parking.

Advice: a good solution would be a canopy located along the fence to the entrance to the house.

Carport in front of garage

If you can’t decide what to build: a garage or a shed, there is a compromise option - a garage with a shed. Of course, it is only suitable if the area of the site allows you to accommodate all this.

Experienced car enthusiasts assure that vehicles feel better under a canopy than in a closed, damp room. However, this design has many advantages:

- You can park your car in the garage overnight.

- A shed and a garage will come in handy if guests come to the dacha and you need to find space for several cars.

- If you install a canopy between the garage and the dacha, you can use it as a gazebo in inclement weather and even install a barbecue.

Sheds attached to the house

The location of the canopy in close proximity to the house is convenient because you do not have to cross the entire yard every time there is a need to warm up the engine before leaving or load crops into the car. In addition, a covered space adjacent directly to the dacha will allow you to store things needed for the household or use a carport instead of a gazebo.

It is important to note that the canopy near the dacha is not only practical, but also beautiful. With the help of a well-placed canopy, you can emphasize the advantages of the facade of the house or delicately hide the shortcomings.

Carports for two cars

The most difficult thing is to find a suitable place for a carport for two cars. This building is quite large, which means it can cover the façade of the house. Not the best option.

Tip: arrange the parking lot for two or more cars so that there is entry from different sides for easy parking and exit.

The minimum size of the area for two cars is 8 by 6. Moreover, if the cars differ in size, then the length and width of the shelter should be commensurate with the largest car.

There is also a nuance: it is better to build a large canopy without a support in the center, because it can interfere with free maneuver when parking.

Designs with a utility room are good, where you can store a variety of spare parts, repair tools and other small items.

Advantages of carports made of polycarbonate

The storage and protection of personal vehicles is trusted to a polycarbonate canopy for several reasons:

- A combination of lightness and high strength.

- The relatively light weight of the structure does not require a special foundation and can be installed directly into the ground.

- High strength and excellent load-bearing capacity, which means that the canopy is not afraid of heavy snowfalls, heavy rains and gusty winds.

- It transmits light and is transparent, so it will fill the space with natural light.

- It has an aesthetic appearance and will highlight the beauty of a country house.

Car owners often build carports on their property that can accommodate several cars at once. This is necessary if the family is large and most have their own vehicles, or when the owner of the house likes to invite guests.

The design is relevant even in good weather. It is able to protect the car from strong heating from direct sunlight. Also, often some part of the carport is equipped for family leisure. You can set up a folding table, chairs and have fun outdoors. It turns out that the canopy is not only for vehicles, but also for its owners.

The practicality and benefits of a carport are quite high, since this building performs a large list of tasks. That is why it is increasingly being chosen as an alternative to a garage.

Types of canopies

All canopies have the same purpose - to protect the car from precipitation, sunlight, and other “surprises” of the environment. However, they also have their own characteristics.

- Accommodation.

- Mobility.

- Material for supports and frame.

- Roof structure.

- Roofing material.

Various coatings are used for roofing work. However, not all are suitable for awnings. The following materials are most often chosen.

- Corrugated sheet - These are corrugated or ribbed sheets of thin steel or aluminum. They have advantages and disadvantages.

Pros:

- simple installation;

- lightweight, non-flammable material;

- the top coating creates protection against rust, temperature changes, and mechanical stress;

- wide color variety.

Minuses:

- if the protective coating is damaged, rust forms;

- loud noise during rain or hail.

- Metal tiles - These are metal blanks that have been stamped, galvanized, and then coated with polymer. They have positive and negative qualities.

Pros:

- high durability;

- low weight facilitates installation work;

- high tightness of joints;

- Fire safety;

- resistance to temperature and humidity fluctuations.

Minuses

- loud noise during rain or hail;

- the protective layer is easily damaged, so installation is carried out in soft shoes;

- with a slight roof slope, snow melts poorly.

- Ondulin is cellulose impregnated with bitumen with polymer additives. Builders note the advantages and disadvantages of this coating.

Pros:

- easy installation due to the wavy shape;

- environmental Safety;

- high durability;

- wide color variety.

Minuses

- in hot weather it heats up, and then the smell of bitumen appears;

- with prolonged use, color loses;

- flammable material.

- Polycarbonate is a polymer material consisting of several panels with stiffeners. Available in transparent or colored versions. It has advantages and disadvantages.

pros

- sheets have different sizes and color shades;

- high strength;

- simple installation;

- Fire safety;

- When destroyed, no fragments are formed.

Minuses:

- Great care is required when clearing the roof of snow, as the material is easily damaged by sharp objects;

- contact with solvents, ammonia, mineral salts is not allowed;

- there are restrictions on fasteners.

How to build a polycarbonate carport with your own hands

We will build a simple metal structure with a pitched roof and a polycarbonate roof.

Project with dimensions and materials for making the structure

We choose a place, fence it around the perimeter with posts according to the drawing, and stretch the rope. We remove the soft layer of soil and dig a pit approximately 300 mm deep. On the sides, every 1.5 - 2 m, we dig holes for support pillars, 700-100 mm deep, depending on the height of the groundwater and the nature of the soil.

We level the bottom, lay sand and crushed stone, a layer of 100 mm, compact it so that there are no traces of a person of average weight. We install the formwork, knit a reinforcing frame for the slab, only corrugated rods 8-12 mm, cell 100*100, 200*200 mm. We reinforce the pillars separately. To do this, pour 200 mm of concrete at the bottom of the pit, and insert reinforcement into it; the frames can be made in advance, tie the rods in the form of pillars and wrap them with roofing felt in 2 layers.

Good to know: You can not pour a columnar foundation separately, but immediately concrete the load-bearing posts into the ground: a metal pipe or beam, but this option is less practical, since the material in the ground will collapse even with a protective layer.

We pour concrete, a thickness of 100 mm is sufficient for a slab, and wait for the concrete to set. Since the base will not be loaded, after a week you can begin the main work.

Using corners and brackets, we attach supporting metal posts with a diameter of 50-100 mm to the columnar foundation, check the plumb line, and install slopes to maintain the geometry. We check the height of the pillars and cut them if necessary to maintain the slope of the roof.

Ways to secure vertical support posts

We make the strapping along the upper heads and weld it to the base with a 40*40 mm metal profile. Next, we attach additional strapping perpendicular to the posts, thus obtaining a right triangle for the truss. Using rolled products of a smaller cross-section, we weld the stiffeners of the rafter system. We lay the rafters from a square metal profile perpendicularly, every 800-1200 mm, the canopy over the edge of the trim is 200-300 mm, and we weld it. We clean all parts with a stiff metal brush and wash with solvent. After drying, prime and paint.

Types of roof configurations and their advantages

The shape of the roof is determined by the roofing material and its placement in relation to the structure. The most common roofing forms for making a canopy:

Photo, drawing and roof diagram

- A pitched sloping roof is a simple way to arrange parking for cars on a summer cottage. It is economical, does not require special skills or professionalism during construction, is quickly erected, and is resistant to strong winds.

- A gable roof (hip) is more rigid and has high windproof characteristics.

- The arched shape has increased rigidity and is very durable. When creating an arched canopy, the slope angle must be made no higher than 10 degrees. When installing arched systems, there is no need to install a gutter.

Material for frame and supporting structure

The “skeleton” of the mini-garage is formed from the following materials:

- tree;

- metal;

- stone;

- brick;

- concrete.

The supporting pillars and frame parts of the roof are made using precise geometric technology with straight, diagonal and rounded elements. In the case of wood, there are at least 4 main options for connecting roof parts. They are connected with ordinary and construction hardware. Metal structures are welded. Working with wood and metal requires the participation of at least several people. With brick, stone and concrete buildings the situation is more complicated. You can still build a brick structure yourself, but not a concrete or stone one. In the last 2 cases, teams of craftsmen work. Metal canopies look good against the backdrop of garden plants, just like wooden ones. They have many absolute advantages, and well-finished wooden ones at least look beautiful. Stone mini-garages are not much inferior to them in terms of aesthetics. In addition, buildings made of stone look more modern. A brick and concrete canopy is decorated with panels or something like that.

Stone, concrete or brick

These are not the best materials for self-construction. The frame and supporting structure made of brick, concrete and stone take much longer to calculate. Heavy equipment is used to install bulky elements. The coverings of the finished canopy are left unchanged or finished with something like lining, siding, or relief panels. As a result, owners receive an aesthetically pleasing structure and save money by eliminating the need for a conventional garage. Combining materials, including topcoat, offers durability benefits. Maintaining stone/brick/concrete supports does not require much effort, but takes more time than maintaining structures on thin posts. A brick structure is primarily about durability and variability in terms of configuration. They try to emphasize good taste and status with stone, and the coatings do not require additional finishing.

Metal

Profiled pipes with a cross section of 80×80 mm are also used. Modifications with protection from dampness are selected, because the metal is subject to corrosion. After pouring the foundation, points for the pillars are marked, after which the recesses are made with a drill. This is a convenient approach with high precision of action. The holes are then filled with concrete. The pillars are connected by cross members and go to the main frame. The metal top of the canopy is mounted using a welding machine. The roof frame is made closed or everything except the top layer with roofing material is left free. That is, in the end they get a monolithic structure or a canopy with a truss. The upper part of the metal canopy is assembled from profiled pipes with a cross-section of 40×20 mm. Under wide canopies you will have to make long curved elements, and the complexity of the work will increase several times.

Tree

Anyone who is more or less versed in carpentry and construction can assemble a homemade structure from wood. Processing and preparing wood yourself leads to a significant loss of time. It includes cutting and preparing elements. Although the preliminary work will take at least a week, the implementation will be relatively simple, especially since there is the largest selection of tools for woodworking. All nodes are connected with plates and hardware. Wood is used mainly in the form of bars. They are inserted into the foundation or screwed in with special metal connections with large anchors. The material for the canopy is processed with double care so that fungus does not appear on the wood near vehicles and automobile accessories. From an aesthetic point of view, the worst that can happen is cracking. Wood is inferior in durability to other materials.

What should be the height of a carport?

The dimensions of the summer cottage canopy depend on the size of the machine. It must fit with the calculation of opening the doors, hood, and trunk. Therefore, we make the width several centimeters larger.

If you decide to make a carport with your own hands, consider the following parameters:

- height - from 2.20 m to 2.5 m. With high structures, precipitation will fall on the car;

- the minimum height must be no lower than 2 m.

When calculating the dimensions for two cars, take the distance between the rear-view mirrors as 0.5 m.

Review of the most popular materials

Polycarbonate, corrugated sheeting and wood are most often used for canopies.

Advantages and disadvantages of polycarbonate

Polycarbonate has become increasingly popular in recent years. Its distribution is associated with a number of advantages:

- impact resistance;

- light weight of the material, which avoids the need to create a bulky frame;

- plasticity, allowing you to create a structure of complex shape;

- UV protection.

The disadvantage of polycarbonate is its strong expansion under the influence of high temperatures and vulnerability to mechanical stress.

Polycarbonate carports are very popular

Features of corrugated sheets

Corrugated sheeting, like polycarbonate, has a low price. But there are several fundamental differences:

- corrugated sheeting heats up quite strongly in the sun, so if there is no shade in your yard, it is better to abandon the idea of making a canopy from corrugated sheeting;

- corrugated sheeting has poor sound insulation;

- metal will not transmit light, so it is advisable to conduct electricity under the canopy;

- corrugated sheeting is more durable, and even a large fallen branch will not damage the canopy.

Corrugated sheeting is a durable material that can withstand even a very thick layer of snow.

Wooden sheds: pros and cons

You can also make a carport out of wood. This design looks as natural as possible against the backdrop of nature, but we must not forget about several disadvantages. The main disadvantage of a wooden canopy is the need to regularly open it with antiseptics and varnishes. If this is not done, within a few years the tree will begin to rot.

A wooden canopy looks very attractive, but do not forget that wood requires careful care

Drawings and diagrams

Before construction begins, a design for a carport is made. A simple design has a budget shelter with a pitched roof. It is usually used if you need to make a carport attached to a building. With this arrangement, the roof is completely adjacent to the wall.

The option with a pitched roof is suitable for a detached building. In the southern regions, where little snow falls in winter, the roof is made flat, without a slope. If the winter is snowy, the roof is covered with a slope of at least 10°. Then the low side of the roof is turned to the south or east to create shade under the shelter. Additionally, a wall is made on the south side or tall plants are planted.

If you need to build a carport made of polycarbonate, choose a vaulted roof shape. This idea is easy to implement due to the flexibility of the material. The convex roof facilitates precipitation in winter.

A gable metal or wooden canopy is more complex in design. It consists of many components. The support pillars are fastened with load-bearing beams and spacers made of boards are installed. Then the rafters are installed and the roofing material is laid.

On a note!

A metal gable roof is easier to manufacture than a wooden carport of a similar design.

Schemes and drawings of canopies

We have collected the best shed designs for building in a country house or in the courtyard of a private house. Please note that dimensions in the drawings may vary and are indicated in millimeters or centimeters.

Arched carport diagram

Scheme of a carport made of metal and polycarbonate

Fabric awnings in the yard

If you don’t want to bother with complex structures of canopies made of metal or wood, we recommend turning your attention to lightweight canopies made of thick fabric. They are sold with a ready-made metal frame that is attached to the wall, so there is no need to build anything additional

A special advantage of this design is the ability to quickly remove the awning by simply folding it - special levers and automation allow this to be done in a second.

Fabric sun canopy

You can make an awning from fabric yourself, but then it will differ little from buildings made of corrugated sheets or polycarbonate, although the appearance of such a canopy will be more picturesque and interesting. This kind of sun canopy can be made by building a metal frame and putting a piece of bright fabric on it.

Country canopies made of fabric

Project preparation

The construction of a canopy begins with the preparation of the project. It includes a drawing with basic dimensions and a description of the parameters of the future design. The project takes into account optimal operating conditions, coating composition, characteristics of the base and coating.

- Choosing the best winter option.

All the benefits of a carport are fully realized in winter.

When developing a project, the climatic features of the area must be taken into account.

It has been proven that it is better to store a car under a canopy in winter.

The structure of support pillars and roof reliably protects from precipitation, and also does not create its own microclimate. Having driven under a canopy in winter, the car gradually cools down, which means it does not become covered with dew. In the garage, due to temperature changes, dew falls, which gradually destroys the metal of the body.

In areas with cold and long winters, a more durable design is chosen that can withstand a thick layer of snow. The frame made of wood or metal is additionally reinforced to withstand a load of up to 150 kg per square meter. m of roof.

Among roofing materials, only polycarbonate does not change its qualities in harsh winter conditions.

- Choice of site coverage.

An inexpensive and simple covering method is backfilling with crushed stone. To avoid descent, the covering must be at ground level. The rigidity of crushed stone is achieved by high-quality compaction.

More expensive methods are laying concrete or paving slabs. In any case, the site is prepared before laying: the soil layer is removed, backfilled with crushed stone and sand, and compacted.

- Selection of design dimensions.

Depending on the number of cars, sizes are chosen.

The standards establish that for one car, the canopy must be one meter longer than the car, and up to two meters wider.

For two cars, the width of the canopy is calculated by the formula: W = W1 + W2 + 2 m + 0.8 m, where:

- Ш1 and Ш2 – machine width;

- 2 m – 1 m margin on the outer sides of the vehicles;

- 0.8 m – distance between cars.

The height is selected taking into account the dimensions of the car with cargo on the trunk. With a very high canopy, slanting precipitation enters the structure. The optimal height is 2.3 meters.

The following sizes are considered universal:

- An average car with a small platform – 6.0 x 3.0 m;

- Minibus, SUV – 6.5 x 3.5 m;

- Two cars – 6.5 x 6.0 m.

- Selection of support materials.

Suitable building materials for racks are: metal, wood, concrete, brick, stone.

Typically, supports are made of metal or wood. They are easy to install, and most importantly, they are cheaper than other building materials.

- Metal stands.

The main requirement for prefabricated metal supports is strength. To withstand the load of a roof with snow cover, 100 mm metal pipes will be required. The diameter depends on the installation pitch. The minimum size of pipes is allowed if there are many racks. But for a pitched roof with four posts, pipes of maximum diameter will be required.

- Wooden stands.

There are special requirements for wooden supports. First of all, this is due to possible rotting due to moisture. Supports made from high-quality wood, treated before installation, will last up to 15 years.

Sufficient reliability is provided by 200 mm rounded logs and 150 mm .

Before purchasing material, you need to calculate the number of racks. Depending on the step, different quantities are required. Each rack must withstand pressure up to 250 kg.

It is estimated that the average car with a small area will require 6 racks. A distance of up to 3 m is selected between the supports. Racks must be placed at the corners of the building.

- Selection of materials for coating.

Corrugated sheeting or ondulin are best suited as a covering for a detached building. They have high reliability and durability, so they last more than 20 years. Only metal tiles last longer, but they are more expensive, and most importantly, they delay snow melting. These coverings do not allow light to pass through, so there is always shadow under them.

Polycarbonate is best suited for canopies. The main attention is paid to the choice of material quality. In hot weather, three-layer polycarbonate with a high rate of absorption of sunlight creates good shade.

For a shed attached to a house, it is logical to have a roofing covering of the same type as the house.

The main parameters of roofs are established by the “Building Codes and Rules”. They are used when designing roofs with any covering. The slope in degrees or percentage is determined by the horizon level. The type of roofing material is of great importance when choosing a slope.

For all roofs on pillars, the optimal slope is considered to be from 15 to 25 degrees.

The amount of materials is determined by the roof area. They are purchased with a reserve: 5% more than the calculated area.

Stages of canopy construction

Preparation work.

First of all, prepare a place for the canopy. It is cleared of plantings and debris, and markings are made. The prepared site is leveled by pouring soil, sand, small pebbles or crushed stone into the depressions, or cutting off the existing hills. Then everything is thoroughly compacted. In the case of attaching a canopy to a residential building, you need to drill or dig holes to a depth of 50-60 centimeters, with a diameter of about 20 centimeters. They are necessary to build a base for a canopy. At the same time, the cable for lighting should be laid. Depending on the size of the canopy being constructed and the materials used for its construction, the pillars are placed from each other at a distance of 1-1.5 meters. The convenience of such a base for a canopy is that there is no need to connect it to the main foundation of the house.

You need to pour a bucket of crushed stone into all the recesses, install vertical pillars and fill them with cement mortar. Each support is leveled. If the canopy is constructed from wood, then the lumber must be dried and sanded. Before installing the boards, it is necessary to soak them with an antiseptic, dry them or paint them. If the canopy is located in a low area, then the ends of the wooden posts need waterproofing. To do this, they are wrapped in roofing felt or film and hot bitumen is used to fill them. When planning the installation of metal supports, it is recommended to take an aluminum or galvanized profile. If ordinary metal is used, it should be treated with a primer containing zinc phosphate.

The covering used as a floor under a canopy can be:

- poured, made of concrete or cement mortar;

- tiled paving or wooden;

- from medium-sized gravel or sand.

Installation work on the construction of a fiberglass canopy. Assembly of the extension begins after the concrete under the supports has completely hardened (about 14 days). The brackets necessary for mounting the load-bearing transverse beam and the attached canopy are attached to the wall.

Lathing. After installation, the top trim is made. Cemented supports are connected from the ends to the beam, and then to each other. If the frame is made of wooden parts, then they are connected with a steel angle, if it is made of metal, they are welded. Welding seams must be cleaned and coated with primer. Rafters are attached to the transverse beams at a distance of 60 centimeters. Place the sheathing across the rafters at a distance of 30 centimeters from each other, attaching it with self-tapping screws.

When using wooden beams, its dimensions should be:

— 12*12 cm for racks; — 10*10 cm – cross beams; - 7*7 cm - rafters; - 5-5 cm - lathing.

When making a frame from a steel profile:

— 4*6 cm – racks; - 3*5 cm - sheathing and rafters.

Roof construction. To install it, you need to cut fiberglass sheets to size. Then, holes are made in them for fasteners and screwed to the sheathing. Make sure that the cells on the sheets are directed downward, which will facilitate the removal of condensate. There should be a rubber thermal washer on the screws that secure the sheets.

It is necessary to leave a small space between the sheets when covering with polycarbonate, as they have the ability to expand when heated (for example, sunlight). When making holes for fasteners, you should also leave a margin of 2 to 3 millimeters. A polycarbonate canopy does not require special care. It is enough to periodically wash it with clean water, and it will serve according to the manufacturers’ warranty for 50 years.

So, a canopy attached to the house is an excellent place for a full-fledged summer holiday on a summer cottage. It’s not difficult to make, all you need is the desire and the necessary tools.

Important nuances when making it yourself

When wondering how to make a carport or how to build a carport, there are several important things to consider.

The general design, and you need to decide on it before you start making a carport for your dacha with your own hands. The canopy can be different:

- attached to the wall on one side and open on the other three or open completely - its reliability, aesthetics, and the need for sound insulation depend on this;

- it can be one-story or two-story - on the second floor you can arrange a gazebo or store the necessary little things, without which not a single summer cottage can do.

The roof structure can be:

- single-pitch or gable canopy - and not only the aesthetic side of the issue depends on this, but also how well moisture will drain from the roof;

- canopy with or without a canopy - under the canopy you can place the necessary things related to the car in one way or another.

General location. The parking shed should be located:

- on a very slight slope - enough for water to drain, but too small for the car to be parked in the yard;

- in the shade - not necessarily full, but sufficient so that the roofing material does not fade (especially important for plastic roofing and slate).

Dimensions. It depends on them how expensive it will be to build a carport with your own hands and how convenient it will be to drive under it:

- the height should be one meter higher than the car along with the top trunk - if you make it larger, precipitation will get inside, if less, the car will not fit properly;

- the length should be one meter longer than the length of the car itself;

- the width should be two meters more.

As a result, a house with a carport will be made according to all standards, and it will not be clear from it that the owner first had to spend a long time figuring out how to make a carport with his own hands. Attention to detail, accuracy and adherence to rules will make this possible.

DIY carport: step-by-step construction

To build this structure for a car without errors, choose a suitable location. This issue has been studied in detail above. It should only be emphasized that the new building should not worsen the functionality of existing objects: house, garage, gazebo. It is created in a single style.

If the canopy is attached to the house, the butt joints are studied separately. It is necessary to exclude the possibility of mutual negative influence during the movement of supports due to high groundwater levels in severe frosts. In the most difficult situations, the structure is installed on a pile-screw foundation.

To find out how to inexpensively make a reliable support, geological research will be useful. To do this, before starting construction, several holes are made in the intended locations for installing the poles for the canopy. Such a check is required if the extension weighs significantly. If the foundation for the pillars turns out to be too expensive, they try to find a suitable place to install the carport in the yard or garden.

Several options for concreting pillars. The metal support can be immersed in the solution, or the corresponding embedded parts can be installed in it when pouring.

At the same time, you need to decide on the materials of the frame and roof. This will help calculate the load from the building and the parameters of the foundation. The following details should be clarified at this stage:

- If there is not enough natural light, you will have to install appropriate devices. They must be designed for outdoor use. Lamps that meet the IP54 standard and higher are well protected from moisture.

- LEDs are used to save energy. Such lamps are able to function uninterruptedly in difficult conditions for several years.

- A country carport near the house is useful for minor repairs, changing oil and other consumable fluids, cleaning the interior and washing. To connect electric tools, you can install a socket here. You should find out how to install it and other devices and wiring in accordance with current safety standards.

- A single-pitched and double-pitched canopy must be supplemented with an appropriate drainage circuit. It is necessary to clarify how to properly connect it to the general sewerage system.

After the answers to the above questions have been received, drawings must be prepared. If you don’t know how to do it yourself in strict accordance with design standards, contact specialized specialists. A lightweight, simple yard plank structure can be built with a large margin of safety without careful calculations. But even in this budget option, it is better to prepare a documentation package:

- sketches with dimensions;

- lists of materials, tools;

- important technological notes.

This description of a typical algorithm of actions will help you figure out how to build a carport in your country house with your own hands:

- To determine the boundaries of the roof, you need to take the appropriate parameters of the machine and increase the boundaries in all directions by 0.8-1.25 m. The supports are installed so that they do not create obstacles when maneuvering and disembarking passengers.

- Based on the design documentation data, the necessary components are purchased.

- The site on the garden plot must be prepared taking into account the weight of the vehicle and the intensity of use of the parking lot. In any case, remove the soil to a depth of 15 cm or more. A cushion is created from crushed stone, gravel, sand, and the appropriate layer is compacted to obtain a homogeneous structure.

- Taking into account the characteristics of the chosen technology, a strip, columnar, or slab foundation is constructed.

- For heavy equipment, a platform is created from reinforced concrete.

- After the construction mixtures have completely hardened, installation operations begin. First, a frame made of metal or wooden elements is installed. The roof, decorative elements, lamps, and other equipment are attached to it.

For your information! The installation of utility networks can be divided into several stages. Some channels, for example, can be created when leveling the site during the process of pouring the foundation.

The following photos provide additional useful tips and tricks.

It is more convenient to weld and paint individual parts in a stationary workshop. Directly on site it will be enough to perform only installation operations

You can make various useful devices from a banner or truck awning. In particular, a carport

The fabric makes a good protectant from the sun and rain.

It should be noted that it is difficult to create a durable, reliable structure from available materials. You should give preference to a carefully designed project, or purchase a ready-made kit for the appropriate purpose.

In this video, the author of the project talks about how you can cheaply create a functional garden shed at your dacha:

Related article:

Sheds attached to the house. Photo examples of designs made from various materials and tips for do-it-yourself installation in a separate publication on our portal.