22615 0 6

mark_kr October 26, 2016Specialization: professional in the field of construction and repair (full cycle of finishing work, both internal and external, from sewerage to electrical and finishing work), installation of window structures. Hobbies: see the column “SPECIALIZATION AND SKILLS”

The window sill needs to be chosen correctly and placed correctly - then the window will look much better!

It is advisable to think about which window sill to choose for plastic windows in advance - not only before installing the structures themselves, but also before repairs in general. This approach will allow us to choose the optimal size of the product that meets all our requirements, and to find an option that fits perfectly into the overall style of the room.

Fortunately, there is definitely plenty to choose from here - and below I will give brief characteristics of the most popular parts.

The window sill can be quite wide!

In addition, it is not enough to choose the right window sill for a PVC window - it needs to be installed correctly. I will devote a separate section of the article to the nuances of installing window sill boards.

Window sills made of natural or artificial stone.

Stone window sills have the highest strength and durability.

Of course, they have a price, because they guarantee durability and beauty for many years.

Pros:

- Strong, durable;

- Heat resistant and water resistant;

- Do not fade;

- Artificial stone (especially acrylic) is easy to restore if damaged;

- Look cool and solid;

- Wide selection of colors and types of window sills on sale.

Minuses:

- Heavy weight. Window sills made of natural stone are very heavy, unlike artificial ones;

- Low maintainability (for natural stone);

- Susceptible to

- Very expensive (in the cost of materials, installation, repairs).

It is worth noting that artificial stone is a little easier and more practical to use than natural stone. It also has a wide variety of textures, shapes and colors. Such window sills are environmentally friendly, which cannot be said about natural stone, which must undergo a radiological examination.

Therefore, it is worth thinking carefully about which of these materials is better to choose.

Made from artificial stone

Very durable, resistant to all types of influences (mechanical, chemical, biological), have absolute moisture resistance and fire resistance. They are based on mineral fillers and polymer resins.

Dyes create a rich range of colors; the product can be given any shape, which opens up scope for design solutions. Any device (fan, vice) can be securely fastened/installed on such a hard surface. And any scratches that appear can be easily removed by sanding.

It also has its drawbacks. Only specialists can install the products. To securely fasten such models, brackets that can withstand heavy loads are required. And the high price (3,500–8,000 rubles/sq. m) does not allow the products to be classified as the budget segment of products.

There are 2 options for window sills made of artificial stone:

- Made from acrylic composite. A fine filler of marble, granite or quartz chips is compacted and bonded with an acrylic mixture. During manufacturing, hardeners, pigments and other substances are added to the bulk. Additives increase the hardness and viscosity of the material. New properties reduce the likelihood of chipping.

- Made from quartz stone. Quartz chips, making up 90–95% of the product’s mass, are bonded with polyester resins. The technological process involves the addition of mineral coloring pigments (iron compounds, red lead, ocher). This window sill is heavier and denser, but the risk of chipping increases.

No. 4. Wooden window sill: pros and cons

A wooden window sill is an integral addition to a wooden window. Previously, only such products were used in residential buildings, but today they are being replaced by cheaper plastic. Nevertheless, there are still many fans of wooden window sills, since they have many advantages:

- highest strength, especially when it comes to oak, beech or larch wood;

- naturalness and environmental friendliness;

- beautiful appearance, pleasant to the touch surface;

- excellent thermal insulation qualities.

There are many disadvantages to a wooden window sill: price, sensitivity to temperature changes, high humidity, low resistance to ultraviolet radiation, fire, microorganisms and insects. It is better not to spill water on it or place hot dishes.

Manufacturers are trying in every possible way to improve the performance of wooden window sills and extend their service life. The wood must be well dried and treated with antiseptics, then covered with paints, varnishes or enamels, which protect the material from moisture, pests and temperature changes, and at the same time help to emphasize the unique structure of the tree. No matter how hard modern industry tries, wood still remains quite demanding to maintain, and every few years such a window sill will have to be coated with special wax or parquet varnish.

The most commonly used window sills are from the following species:

- coniferous species, with larch having excellent strength characteristics, and pine, spruce and cedar are very beautiful, but soft wood, especially susceptible to changes in humidity and temperature, so you should be extremely careful with such products;

- deciduous species, including oak, hornbeam, cherry, beech, ash, are more expensive, but in terms of strength they are much better than most coniferous species;

- mahogany and ebony are exclusive, which cost a lot of money and will complement a luxurious interior in a classic style.

Window sills are rarely made from solid wood - glued panels are more often used. Those who are ready to choose a window sill from an array should prepare for big expenses. Thin layers of wood are glued together under the influence of high pressure and temperature, and the result is a product that is almost as strong as solid wood, but at the same time acquires additional useful qualities, for example, less susceptibility to deformation. The thickness of the wooden window sill in any case should not be less than 28 mm.

Wooden window sills

Wood is a material that reacts to changes in temperature and humidity. As a result, it can become deformed and crack (which is facilitated by heaters placed under window sills). To prevent this, window sills should be made of laminated, tongue-and-groove or milled wood with a moisture content below 10%. Most often, users prefer local types of wood: pine, oak and beech, less often exotic ones - merbau, jatoba, teak, iroko. Wood is easy to manipulate during processing, so it is not difficult to give the window sill an unusual shape. The surface of the structure should be coated with varnish, wax or oil.

A window sill made of multilayer wood is up to 2.5 m long, 16 cm wide and 3-4 cm thick. Sometimes, for reasons of economy, only the end wall is thickened. However, a thinner window sill - although it gives the impression of being solid and massive - can become deformed. A wooden window sill can be made to order, or if the windows are of a standard size, then buy a ready-made one.

WINDOWS MEDIA recommends reading: How to make wooden windows different from others

Wooden window sills.

As you know, wood has been used since ancient times to decorate window openings. Today it is valued primarily for its environmental friendliness, ease of processing and for giving complex shapes to final products.

Modern wooden window sills are made in two variations: glued, consisting of several layers of wood and solid wood. Before putting it directly into production, wood is necessarily dried and subjected to antiseptic treatment, so that finished products over time would have significantly less chance of undergoing deformation processes.

Important! Gluing several layers of wood to obtain a window sill blank is carried out under high pressure. If the gluing technology has not been violated, then the strength of such products is the same as that of products made from solid wood. Following this, the resulting window sill blank is coated with chemical compounds that give the product an attractive appearance - paint, varnish, enamel. More valuable types of wood are additionally coated with special types of oils and wax for protection, as well as to give their structure a characteristic clear pattern.

Following this, the resulting window sill blank is coated with chemical compounds that give the product an attractive appearance - paint, varnish, enamel. More valuable types of wood are additionally coated with special types of oils and wax for protection, as well as to give their structure a characteristic clear pattern.

Today, window sills made of coniferous wood, for example: cedar, pine, spruce, larch, are widespread. This became possible thanks to their cost, which is very low and ranges from 1000 to 4000 rubles per linear meter of product. However, these rocks have one significant drawback - with a strong difference in humidity and temperature, they are prone to deformation.

In second place in popularity are hardwoods. There is plenty to choose from: oak, ash, beech, cherry, hornbeam, chestnut, maple, etc. The cost of window sills made from these types of wood ranges from 2000-8000 rubles per meter.

The least common are mahogany window sills. This is due to the exclusivity of the material (read the article about mahogany windows) and the high price, which is constantly changing due to the instability of the Russian national currency.

Sizes of window sills for plastic windows

Plastic windows for residential buildings, office premises, and glazing of balconies are always produced according to individual measurements. Before their manufacture, measurements of the window sill surface are carried out, since even with individual construction, openings have deviations of up to 80-100 mm in length and width.

The size of window sills for plastic windows is influenced by the size of the radiator and the placement of curtains in the window structure. When determining the length, take into account the following rule: the curtain should be several centimeters higher than the parapet. Then the window will not fog up, since all the heat from the radiator will be directed to the glass.

The size of the standard protrusion from the wall is from 3 to 5 cm. For larger values, additional corners are installed to strengthen the structure.

To make a parapet, use a standard PVC board with the following dimensions:

- Width: 10 – 60 cm, step size 5 cm.

- Length: 45 – 60 cm.

- Thickness: 1.8 – 2.2 cm.

Construction stores sell six-meter slabs that are cut to the required sizes.

The window sill can be ordered in a traditional size or non-standard size

The indicator of how wide the window sill should be is determined by a number of indicators. This:

- terms of Use;

- permissible load;

- the type of room where the stove will be installed;

- decorative and aesthetic purposes.

The standard width (10-60 cm) makes it possible to install a parapet with different thicknesses of load-bearing walls. This allows you to change the depth of its installation while maintaining the basic operational characteristics.

The width of the board is directly affected by the installation depth of the window profile itself, the value of which changes for each window. To determine the width, measure the distance from the stand profile to the edge of the wall. Add 5 to 10 cm to this indicator so that the edge of the window sill extends beyond the edge of the wall and hangs over the radiator. This affects its operational and decorative parameters. The value is rounded up and an order is placed.

Selecting the maximum width

To install a wider version of the internal parapet, take a slab with dimensions of 60 - 100 cm, in increments of 10 cm. These are the maximum permissible dimensions.

A wide window sill has its functional advantages. It serves as a flower stand, a shelf for storing souvenirs, and a place to place seat cushions. To withstand these loads, it must be firmly fixed.

There are several options for installing a wide slab.

This:

- with jammed window profile;

- with installation on support dies and a ventilation gap;

- using metal brackets.

The latter method is used when installing window sills in glazed loggias, where the windows are mounted on a thin parapet. The brackets are attached to the wall with screws and dowels. Suitable for lightweight plastic boards.

If the balcony area allows, install a wide parapet model. The board acts as a tabletop or as a shelf for placing plants. To ensure the stability of the elements, a pedestal is made from below on which the parapet will rest.

How to trim a PVC window sill - The Window Guru's Guide

The window sill in the interior of the room plays not only an aesthetic role. Its functionality is an important addition. For example, it could be a shelf; this is most often how it is used.

There may be a seat if the window is low. Someone makes a desk from this element, moving a chair to it. There are many options for what you can make from a window sill with your own hands.

In the process of renovating an apartment or house, when replacing old wooden windows with new plastic ones, the owner of the house is faced with the question of whether to install the window sill himself or transfer this process to PVC window installers. Let's just say that there is nothing complicated in this process, so you can easily do it yourself.

Types of window sills

It would seem that only PVC window sills can be combined with plastic windows. But this is not so, because PVC windows themselves today have different colors, imitation of different natural materials, especially wood. So you can choose the window sill based on these considerations. Hence the manufacturers' proposals:

PVC. There is no specific requirement for matching the window with this element in color. For example, a PVC window can be dark in color, and the window sill can be white

Here it is important to follow the interior design concept of the room as a whole.

Wooden. But here you will have to strictly observe the alignment positions

The PVC window must imitate wood, and the color match must be one hundred percent. Stone. In this case, as with plastic, everything should be in the design concept.

How to install

Let's start with the fact that of all the offered options, PVC window sills are the cheapest and most popular. Manufacturers offer these elements in different sizes, but most often installation is carried out on window sills with a width of 60 cm. The thing is that this size allows installation in any modern buildings, even in houses with a wall thickness of 68 cm.

Marking the installation site

First of all, you need to measure the width of the installation site - this is the distance from the window frame to the edge of the wall. Add 2-4 cm to this indicator, which will allow the window sill to fit under the frame. The overhang of the window sill, that is, the distance from the wall to its edge, is also chosen arbitrarily. Here, as they say, it comes down to taste and color...

Advice! The only point that is recommended to be taken into account. If the overhang of the window sill is very large, and a heating radiator is installed under the window, then the protruding part will become an obstacle to uniform heat distribution. Experts say that this reduces the heat transfer efficiency of the heating device by 10-15%.

The length of the window sill is the width of the window opening, plus 20-30 cm, that is, 10-15 cm on each side.

Pruning

Now the obtained dimensions must be transferred to the PVC window sill itself. Since polyvinyl chloride is a material that can be easily processed, it can be cut with a jigsaw or a hacksaw for metal with fine teeth. It won't be difficult to do this yourself.

There is one very important nuance in this matter. Trimming the window sill will depend on the method of installation. There are two options:

- Trim the window sill exactly to the configuration of its installation location. That is, provide two protrusions beyond the slope of 10-15 cm in length. In this case, you will have to trim the element, taking into account not only the shape, but also additional dimensions. But in any case, it will be necessary to groove the slopes and part of the front surface of the wall. The grooves will be shallow, so you can make them yourself using a hammer and chisel.

- Make the cut obliquely, but you will need to dig deeply into the installation sites. This will take a lot of time; you will have to use a hammer drill.

Many masters give their preference to the second option. Why? Because installing a window sill deep into the wall means the reliability of its fastening. Of course, you will have to spend some time, but all this will pay off handsomely. Therefore they do this:

- Markings are made on the wall for the window sill.

- They hammer the slope and wall with a hammer drill to a depth of 5 cm and a width of 2 cm.

Advice! In order not to deal with all this, it is necessary to make grooves of the required sizes even at the stage of repairing walls and slopes. After that, the surfaces are leveled and finished with your own hands.

What tasks does the window sill perform?

The window sill in the house creates additional protection during the cold season, is used as a place for arranging flowers and other decorative elements, and can serve as a relaxation area not only for children and adults, but also for pets.

Thus, the window sill in the apartment performs several important functions.

- Decoration

With the help of some new materials, a window sill can become a wonderful decoration for any room in your apartment. In addition, when using it, you can organically connect the window, slopes, walls and heating devices located under the window. The window sill also serves as a suitable place to place flowers, accessories or books. It is better to avoid a large number of small things near the window, so as not to create a feeling of clutter and not to cut off the path of sunlight. In small kitchens and rooms, a window sill can become a dining place for residents or replace a work desk.

- Preservation of heat in the apartment

Correct installation of the panel prevents the entry of cold air from the street and prevents heat loss.

- Uniform distribution of heat in the room

Thanks to the protrusion of the window sill surface beyond the walls, the flow of warm air from the battery does not rise immediately to the ceiling, but moves around the room. However, you should also not install a very wide window sill, otherwise the window will be insulated from heat, which will lead to the appearance of condensation on the adjacent walls and slopes.

Take the test

To ensure normal air circulation and free movement near the window, the window sill board should not protrude further than 5-6 cm from the wall - when calculating, it is necessary to take into account the finish that will appear during the renovation. The surface should not cover more than half of the battery, otherwise slits should be made to move air. The length of the slab should not extend beyond the edges of the slopes by more than 8 cm.

When choosing a window sill surface, it is necessary to take into account all the requirements, due to which the service life will increase and all intended loads will be withstood. As a result, the window sill must have the following parameters for operation:

- Strength. It should be able to withstand large flower pots and even people. For serious loads, stone or wood products with a thickness of more than 2 cm are usually installed.

- Persistence. It is necessary to preserve the original appearance when exposed to sunlight and detergents.

- Resistant to moisture if the product is installed in the bathroom, kitchen or swimming pool, as well as in other rooms with high humidity levels.

Window sills are usually divided into 2 types: monomaterial (made from one material) and composite. The first type includes products made of granite, wood and marble, that is, consisting of natural materials.

The second type includes laminated products made from wood chips (chipboard/MDF) or polyvinyl chloride (PVC). All these materials differ from each other, so when choosing, you need to take into account their features and properties.

The service life of the product also depends on the raw materials, which determine the quality of the future product. Before making a purchase, find out all the characteristics of the material you choose.

TO DIVE OR NOT?

Yes, definitely, but only tomatoes. Look at the trunk of the tomato, it is all covered with thin “hairs” - these are potential roots. As soon as these “hairs” come into contact with moist soil, they begin to grow and provide additional nutrition to the plants. Many people plant in cups, and then add soil, and when diving, I make a depression with the body of a fountain pen (which is thicker) and lower the sprout into this depression. I twist the trunk in a spiral, it does not break, since the plant is very flexible, and it turns out that the trunk is buried in the ground up to 10 cm. I plant it on the ridge from May 20 to June 3-5, and not perpendicularly, but with an inclination, and again part of the stem I cover it with earth. I water, then mulch, and I get the following picture (Fig. 3):

1 – trunk with roots,

2 – the trunk is still without roots,

3 – upper part of the plant with leaves,

4 – layer of mulch. The plant does not grow upward for four or five days, it grows roots on the trunk, and then begins to grow rapidly. In the future, you can further hill it, which will give additional roots. In the fall, when you pull out tomato bushes, you will see that their stems are completely covered with roots. So I’ll say it again: you can only pick tomatoes; eggplants and peppers don’t have “hairs” on their trunks, so it’s useless to cover them.

GROWING SEEDLINGS – PART 1 AND PART 2

Timeless classic

Wood has always been considered the most popular material, including for the manufacture of window sill boards. And today it has not lost its relevance and attractiveness. But most often wooden window sills can be found in houses built from the same material.

Expensive species such as oak, walnut or beech are used for production. But coniferous wood also remains in demand, although not in the same quantity as before. Perfectly processed and coated with several layers of varnish, these window sill boards can solve the problem of decorating the lower part of the window opening for a long time.

But using natural wood has its limitations. The fact is that this material is quite sensitive to moisture. Water can cause wood to warp, and the drying process contributes to its cracking.

Composite window sills

Composites are a new generation of artificial materials, known by several names (including Marlan, polygranite, Corian, Staron). They are made from a mixture of aluminum hydroxide, acrylic resin and pigment that coats chipboard or MDF boards. Composite window sills have a smooth, non-porous surface, so dust does not accumulate on it.

Composites are warm to the touch and are resistant to abrasion, but not to scratches, which are more noticeable on glossy and dark window sills. To care for them, you should use mild detergents, as well as special milk.

Composite window sills can have one of almost 90 colors, including imitating granite. Composites are the only materials from which large surfaces of any shape can be easily created.

The thickness of a composite window sill reaches 4-5 cm, width - 10-80 cm, and length - a maximum of 3.6 meters.

About options made of chipboard, MDF or PVC

Is it important for you that the material can withstand high temperatures and not lose its basic qualities? Then you can choose chipboard and MDF - window sills made of chipboard and medium-density fibreboard. These products are made from water-resistant materials

In addition, they do not require special care. By the way, many people order such window sills for themselves, choosing a tone “like stone” or “like natural wood.”

And for special “gourmets” you can choose different color options. Such a purchase will have less impact on your wallet than window sills made of natural material. As practice shows, such products can be washed safely

True, you need to start cleaning very carefully, otherwise you risk damaging the protective coating, and your product will swell and become deformed. Experts also advise that when installing window sill boards, treat the edges of the product with silicone sealant (to prevent delamination)

What should those who prefer “standard windows” do? The fact is that most of our citizens prefer to install PVC profiles. And they have their own good reasons for this: such window sills are not afraid of sunlight, temperature changes (they are not afraid of fluctuations from minus 30 degrees to plus 60), they hold moisture well, are fire-resistant and durable. At the same time, the prices for such material are low, plus the colors allow you to choose exactly what you like.

Well, don’t forget that these products are durable (manufacturers provide up to 10 years of warranty), fire-resistant and have a durable construction, which is important if you plan to stand on them yourself or place plants in large flower pots on the windowsill. This window sill is also friendly with ultraviolet radiation

It has protection in the form of a layer of glossy or varnish coating applied over the material.

Anyone who needs to experiment with sizes can safely stop at just such products. After all, they can be ordered in lengths up to 6000 mm and widths up to 600 mm (thickness is usually 18-22 mm). In addition, the specifics of installation are such that the window sill can be cut to order directly at your home. Another advantage of such window sills is that they are easy to install (in just an hour or two when using polyurethane foam). They are easy to clean (just keep in mind that this cannot be done with abrasive products).

What material to choose for the window sill?

To select a material for a window sill, you need to take into account the strength of the material, its reliability, durability, resistance to damage and compatibility with the overall interior.

Today, there are several popular materials for making window sills: durable plastic (PVC), natural wood, particle board (chipboard), medium density fiberboard (MDF), natural and artificial stone.

To make your choice, you need to study some of the features of various materials.

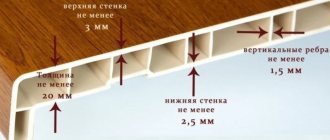

PVC window sills are simple and reliable. The performance characteristics of such a window sill directly depend on the quality of the PVC profile used. The thicker and stronger the chamber walls and internal stiffeners, the greater the resistance to deformation. In addition, modern PVC window sills are made from environmentally friendly materials, which allows the use of plastic window sills even in children's and medical institutions. PVC window sills are easy to clean, are not afraid of moisture, are not susceptible to scratches, do not fade and last a long time. Plastic window sills can be laminated and thus given different looks and colors. But you need to be especially careful when choosing material if you need to make a wide window sill. Not every plastic is suitable for making large surfaces or for increased loads. In such cases, the plastic may sag and deform. Wood or stone are better suited for making wide window sills.

The main advantages and disadvantages of plastic window sills

The high demand for the material is determined not only by its low cost, but also by a large number of other advantages:

The main advantages of plastic products are low cost and variety of colors.

- Moisture resistance. For these reasons, the products are not subject to rotting or corrosion, even if they are used in rooms with high humidity.

- Sustainability. Due to its composition, plastic is chemically resistant to hydrogen peroxide and acetone.

- Strength. The space inside the profile is divided into several chambers, reminiscent of a honeycomb in appearance. There are also diagonal and vertical stiffening ribs inside, allowing even a long product not to sag or break.

- Easy installation. Even a person with no experience in construction work can handle the installation of a plastic window sill.

- Additional space insulation. The presence of internal chambers gives the product heat-saving properties.

- No shrinkage. Unlike natural wood, which can deform depending on changes in humidity or temperature parameters, plastic can withstand such changes.

- Big choice. Due to the fact that a plastic window sill can be presented in any color, the window is given an interesting and individual design. You can also choose stone or wood options.

- Heat resistance. Most manufacturers use the application of additional compounds to the surface, which significantly improves and increases the consumer quality of products.

Plastic window sills are characterized by moisture resistance, heat resistance and durability

It is important to understand that plastic, like any building material, also has its disadvantages:

- Relatively short lifespan. In most cases, especially if the window sill is constantly exposed to the sun, it may lose color.

- Inability to withstand high temperatures. If you place an object that is too hot on the surface, it will most likely leave either a stain or a deformed area.

- Susceptibility to mechanical stress. If a heavy object falls on the material, there is a high probability of a crack or chip, which will require a complete replacement of the window sill, because local repairs cannot be performed.

Some believe that there is no need to purchase and install a window sill, but most experts will not agree with this opinion, because the product performs many useful functions:

- It plays the role of a barrier that does not let cold air into the room and does not let warm air out.

- Forms a microclimate in the room. Thanks to the installed window sill, the movement of heat flows is regulated, because warm air is repelled from the surface and falls directly on the glass, which prevents the appearance of condensation on the windows.

Plastic window sills are made in any shades, as well as with imitation textures

Types of window sills, their advantages and disadvantages

Ecology of consumption. Estate: The window sill is an important element of the interior - it makes the window opening complete and can serve as a shelf for flowers. In this material we will look at what types of window sills there are, their advantages and disadvantages.

The window sill is an important element of the interior - it makes the window opening complete and can serve as a shelf for flowers. In this material we will look at what types of window sills there are, their advantages and disadvantages.

- PVC window sills

- Wooden window sills

- Window sills made of chipboard or MDF

- Window sill made of artificial stone

- Glass window sill

- Window sills made of natural stone

PVC window sills

Plastic window sills are the most common option in city apartments. They are made from the same material as the window profile and have stiffening ribs to provide strength. There are air chambers inside the PVC profile, which makes the structure lighter but maintains strength.

Advantages of PVC window sills:

- resistance to moisture and sunlight;

- high rates of heat and waterproofing;

- long service life - from 30 to 50 years;

- ease of care;

- low cost,

- strength and durability.

In addition to the advantages, this type also has a number of disadvantages. Thus, cheap materials may contain formaldehyde, fumes that have a bad effect on human health. There is also a load limitation - you cannot place heavy objects on window sills with a small number of stiffening ribs, or sit or stand on them.

Manufacturers of PVC profiles produce window sills in a wide range of sizes and colors, so it will not be difficult for the buyer to choose the right size and color for any window opening. In addition to the usual white, they can be painted in any color, as well as imitate natural materials with a glossy or matte surface.

Wooden window sills

This type of window sill was popular before the advent of polyvinyl chloride. However, the fashion for everything natural is returning again and window sills made of natural wood are again in demand in the construction market.

When choosing this option for arranging a window space, you first need to pay attention to the type of wood from which the window sill will be made. The most reliable solids are oak, maple, chestnut, ash and mahogany. There are simpler and cheaper options made from Siberian larch or pine.

Before becoming a full-fledged window sill, wood goes through a number of production processes - it is dried, polished and the surface is treated with oils and wax. To reduce the cost, some manufacturers do not use a whole array, but produce multilayer glued products. If the processing technology is followed correctly, then such a window sill will be only slightly inferior in performance properties to solid wood, and will cost much less.

The main advantage of such products is their appearance and environmental friendliness. In terms of physical properties, wood is much inferior to plastic - it is afraid of moisture and requires special care. In addition, the topcoat will have to be reapplied every few years.

Window sills made of chipboard or MDF

Window sills made of chipboard or MDF are made by pressing and gluing sawdust left over from woodworking production. For decoration, a polymer film or wood veneer is applied to the compressed and glued material. Such panels have a large number of colors and can imitate the surfaces of natural materials. The panels can be cut to the required size, and the ends of such a window sill can be closed with special plugs

Both of these materials are considered suitable for making window sills, but there are certain nuances:

- A chipboard window sill will not withstand direct contact with moisture on the surface - with prolonged contact it will begin to swell and deform.

- A product made from MDF is a little stronger and more resistant to moisture, but direct contact should also be avoided.

These materials also have advantages:

- low price,

- durability with proper care and protection from water,

- ease of installation,

- abundance of shapes and colors.

Window sill made of artificial stone

Artificial stone is an excellent and not so expensive alternative to natural stone. In appearance it is practically no different from natural, and its physical and aesthetic properties are sometimes much higher.

It is made from mineral filler and binding polymer resins, and various dyes are used to add color. As a result of this technology, a monolith is obtained that is not inferior in characteristics and appearance to natural stone. The high viscosity of the material completely eliminates the risk of cracks and chips. In addition, the process of installing a window sill made of artificial stone is much simpler - working with it is not so labor-intensive, and its weight is much less.

Unlike natural stone, artificial stone is not afraid of spilled liquids, dyes, mechanical stress and ultraviolet rays. This window sill does not require special care; it is important to remember only one thing - it cannot be washed with powdered detergents, as the surface can be scratched.

Glass window sill

A glass window sill is a bold design idea that found its audience relatively recently and now more and more people are paying attention to this material. Using glass, you can create a unique window sill in a short time and without spending a lot of money.

Many people mistakenly believe that glass is an unreliable material that will shatter into fragments at the first impact. But this is absolutely not true; modern technologies make it possible to produce especially strong glass that is resistant to impacts, mechanical damage and scratches.

For the production of window sills, tempered glass with a thickness of 10–15 mm is used. Its front line is often made rounded, and the side parts are increased to 30 mm to maximize the massiveness of the structure and create a beautiful relief.

The advantages of this option include ease of installation, low cost, attractive and unusual appearance. The color palette is also rich - there are about 10 shades of glass on the market. In addition to plain glass, there are also colored glasses with unusual patterns and decorative elements and inserts.

Window sills made of natural stone

A window sill made of natural stone is synonymous with luxury and prosperity. Not everyone can afford such a design solution - stone is a very expensive and capricious material, but recently this type of arrangement of window space has become popular.

The main types used in production are marble, onyx or granite. They are supplied to production in the form of large blocks - slabs, from which window sills will be carved in the future.

The most durable stone is granite, but this rock has one unpleasant property - the ability to accumulate radiation, so when purchasing, you must carefully check the documents and certificates.

Marble is slightly inferior in strength, but has a richer palette of colors - from white pearlescent to deep dark. Indian marble is considered the most beautiful - its colors include up to 4 different shades.

Onyx differs from previous options in its ability to transmit light, which, in combination with well-organized lighting, will create a stunning effect. Externally, this stone is similar to marble, but its cost is much more expensive.

When choosing this material, it is worth considering some features:

- Scratches and cracks may appear on the stone over time;

- Colored and acidic liquids must not be spilled on a marble window sill;

- products carved from the same rock may differ in color;

- Do not expose the material to prolonged contact with water.

Working with natural stone is very difficult, so in order not to spoil this expensive material, it is better to entrust the transportation and installation of the window sill to professionals.

published

Subscribe to our Yandex Zen channel!

If you have any questions on this topic, ask them to the experts and readers of our project here.

PS And remember, just by changing your consumption, we are changing the world together! © econet

PVC window sills: manufacturing process

As the name implies, such window sills are made from plastic - polyvinyl chloride (PVC). When manufacturing products, an extrusion method is used: molten plastic is gradually squeezed into special molds and hardens, taking on the shapes we are familiar with.

Many have noticed that inside plastic window sills there are diagonal and vertical thin sections. It is thanks to them that a plastic window sill can withstand significant mechanical loads.

The low weight and durability of PVC window sills are ensured by special substances - softeners, stabilizers and fillers added to the solution during the manufacturing process.

In addition to white, standard plastic window sills, brown window sills in dark and light shades are available for sale. In this case, coloring pigments are added to the solution.

At the end of production, these products undergo strict control to ensure compliance with the stated standards.

Types of plastic window sills

offers its customers, in combination with the installation of plastic windows, the installation of window sills of the brands “Vitrage”, “Danke” and “Moller”. Each of these options has its own characteristics and advantages.

Plastic window sills Vitrage (Russia)

Vitrage window sills are manufactured in full compliance with Russian quality and environmental safety standards; lead and formaldehyde are not used in production. A special protective coating gives the surface a pleasant texture and prevents mechanical and thermal damage. When laminating PVC Stained Glass window sills, films of various colors and shades are used, including wood-look ones.

Window sill made of natural stone

Window sill made of natural stone

This is synonymous with luxury and prosperity. No one will remain indifferent to this material. Also captivating is the fact that the window sill is carved from a single block, which creates a genuine feeling of solidity.

Stone window sills are made from three types of stone, such as:

- Granite

- Marble

- Onyx

Granite window sill

The most durable of this trinity is, of course, granite. But it has one very unpleasant feature: it accumulates radiation. When purchasing this material, you should carefully check all documents and certificates for the stone.

Marble window sill

Marble is inferior to granite in strength, but it has a much wider range of colors. Indian marble is considered the most exquisite; there are about four colors in its arsenal.

Onyx window sill

Onyx is interesting because it can transmit light. This is actually a very big plus, since with the right lighting, you can get indescribable beauty.

Let's look together at all the pros and cons of these materials.

Pros:

- Luxury you can't argue with

- Solidity

- Opportunity to play with backlighting (applies to materials such as Onyx)

Minuses:

- Over time, chips and cracks may appear on the surface

- Marble should not be watered with colored water or acidic liquids.

- Do not expose to prolonged contact with water

- Installation and delivery are complicated due to the fact that the weight of the material is very large

The average person is unlikely to buy such window sills for himself; it probably wouldn’t even be advisable. But the choice is always yours.

Glass window sill

A glass window sill is a bold design idea that found its audience relatively recently and now more and more people are paying attention to this material. Using glass, you can create a unique window sill in a short time and without spending a lot of money.

Many people mistakenly believe that glass is an unreliable material that will shatter into fragments at the first impact. But this is absolutely not true; modern technologies make it possible to produce especially strong glass that is resistant to impacts, mechanical damage and scratches.

For the production of window sills, tempered glass with a thickness of 10–15 mm is used. Its front line is often made rounded, and the side parts are increased to 30 mm to maximize the massiveness of the structure and create a beautiful relief.

The advantages of this option include ease of installation, low cost, attractive and unusual appearance. The color palette is also rich - there are about 10 shades of glass on the market. In addition to plain glass, there are also colored glasses with unusual patterns and decorative elements and inserts.

Design options for glass window sills

Peculiarities

Despite their relatively low cost, plastic window sills are not inferior in quality to their wooden, metal and marble counterparts and have their own advantages:

- plastic is moisture resistant, and therefore is not susceptible to rotting and corrosion in rooms with high humidity;

- plastic is chemically resistant to solutions such as acetone and hydrogen peroxide;

- the cost of a plastic window sill is much lower than wooden, marble and metal products;

- installation work does not require specific construction knowledge or skills;

- due to the fact that the PVC window sill has an internal division into chambers, the product can be considered heat-saving;

- the plastic profile does not need to shrink and warp, as is the case with wood;

- the surface of the plastic window sill is presented in different color shades, and can also imitate marble or wood textures;

- the strength and heat-resistant characteristics of a PVC window sill can be increased by applying a specialized composition.

This product also has its disadvantages:

- relatively short service life;

- low thermal stability (it is not recommended to place hot objects on PVC window sills, as this can lead to staining and deformation);

- plastic products are subject to mechanical stress (if cracks or chips appear on the surface of the window sill for any reason, the only option would be to completely replace the product - local repair of a PVC window sill is impossible).

There is an opinion that a reinforced window sill is a useless thing, devoid of any functionality. In reality, the window sill has at least two functional purposes:

- is a kind of barrier that does not let cold air into the living space, and warm air is dispersed inside the window sill structure;

- controls warm air flows, directing them to the surface of the glass, and therefore condensation does not form.

When manufacturing a plastic window sill, a standard standard PVC profile is used. Window profiles are extruded using an extruder - a specialized device that softens the plastic material and gives it the desired shape by pressing it through extrusion holes. Inside, the space of plastic profiles is divided into several chambers, which are called honeycombs, as well as vertical and diagonal stiffeners. This design helps to increase heat capacity and give rigidity to the window sill, preventing it from sagging and breaking. After this, the product is laminated.

Concrete window sill

When thinking about a concrete window sill, the scary gray products of the last century come to mind. But now the production of these products is fundamentally different from the technologies of past decades: it is a complex process for which only high-quality raw materials and specialized equipment are used.

High grade cements, plasticizers and substances that increase the performance properties of concrete are used for production.

The advantages of concrete products are:

- practicality;

- ease of restoration;

- Possibility of painting in different colors;

- fire resistance;

- frost resistance;

- moisture resistance.

The disadvantages include:

- heavy weight;

- concrete has high thermal conductivity, so it is almost always cold.

In living rooms such a window sill may not be needed, but in the kitchen it comes in very handy. You can put hot pots on it without hesitation, it is easy to clean and is not afraid of moisture.

Types of window sills

Window sills are made from different materials.

Type 1. Plastic

For plastic windows, a plastic product is most often chosen.

Models made from this material are varied in shape, texture, and color. The base of the board is a PVC panel, inside it there are stiffening ribs. Their number is an indicator of how much load the panel can withstand. The more, the stronger the window sill will be.

The panel can be smooth, rough or textured like wood.

In stores you can buy both cheap models and premium products. The difference is in the quality of plastic and coating. Cheap window sills quickly turn yellow and sag a few years after installation.

Prices for the material are flexible and depend on the size: the wider the board, the more expensive it is.

Plastic

Type 2. Wooden

The wooden version looks noble. The tree is hardy and can withstand loads and heat. It will not be possible to make a window sill from an ordinary board; you need to select a blank.

The design is quite simple, the base is a solid board, well sanded and cut. It has a special film coating on it.

Prices depend on the type of wood (pine is the cheapest option). Such products are less moisture resistant, and making a wide and massive finish using wood is expensive.

Wood

Type 3. Composite

Composite materials include PVC boards that imitate wood, or chipboards covered with vinyl film.

They are cheaper and come in different colors. However, there is a good reason to abandon them - insufficient moisture resistance. Due to the mixing of materials, the structure of the structure is damaged upon contact with moisture. It is not worth installing a composite window sill on windows that are likely to leak.

Type 4. Stone

Such window sills belong to the premium class.

Stone is a massive, comfortable and durable material. There are models carved from solid natural stone. Window sills made of artificial stone are much cheaper.

This material is durable and can withstand heavy loads. Moisture-resistant - the rocky structure does not tend to “unstick” or react in any other way to water. However, there are also significant disadvantages, including the serious danger of chipping. Damaged stone window sills are difficult to repair; deep cracks usually require a complete board replacement.

Stone

Type 5. Concrete

Concrete is a durable material. It is used to cover floors, and slabs are made from it to cover streets. It is also used for making window sills.

There are so-called “homemade” options, made from slabs, and some cast in special molds. Outwardly, both of them resemble stone ones.

For residential premises, concrete is not the best option. It is durable, moisture-resistant, but at the same time quite massive and cold, often disrupting the atmosphere of comfort and coziness. But for public places or entrances, concrete will be just right.

Accessories for window sill boards

To enhance the design and match it with the interior, there are special accessories. Among them:

Stub. The parts are installed at the ends. They are usually used to cover the inside of a plastic panel. They look familiar and beautiful; they are sometimes glued to wooden and composite products.

Stub

Connector. Used to smooth the transition from one board to another. It can be angular or longitudinal.

Molding. This is a kind of connector attached between the window sill and the bottom of the window frame. This is a rational solution: the molding is additional protection against the flow of cold air and minor joint leaks.

Lattice. Special grilles are installed, thanks to which warm air from a radiator or other heating device rushes upward.

Lattice

Window sill production

When building or renovating a house, the question often arises about the material of the window sill board. When choosing material for a product, you need to take into account your budget, personal preferences, interior features, and room size.

Production of products can be carried out using:

- Plastic.

- Wood.

- Chipboard and MDF.

- Natural and natural stone.

Often consumers choose for window sill boards: mosaic, WPC, porcelain stoneware, casting technology, glazed tiles. The window sill can have a rectangular shape, curves, or be round.

PVC products are considered affordable. Products made from particle board are characterized by increased strength. A window sill board, made of natural or artificial stone, is a decorative element and an example of good style. Choosing expensive and high-quality material for the window sill will allow you to get a durable product.

Window sills made of plastic

Today, plastic window sills hold a leading position on the market, as they are distinguished by their performance qualities and affordable price. The surface can be covered with special protective and decorative films, which give the products an elegant appearance and beautiful texture.

These products are more resistant to temperature conditions, they prevent the material from drying out, and there is no need for additional surface coating. At the customer's request, products are covered with melamine or PVC film. The products are made from environmentally friendly material that does not contain harmful additives and is resistant to various influences, chemicals, and combustion.

Advantages of plastic products:

- Stiffening ribs provide good strength.

- Light weight.

- Wide range of colors.

- Resistant to fading, chemicals, humidity.

- Easy to care for.

- Easy to install.

- Fire resistance.

- Moisture resistance.

- Low cost.

Pros and cons of wood boards

The tree has been popular at all times. Beautiful texture and pleasant to the touch surface suitable for any interior. There are the following types of window sills: pine, oak and beech. They may differ in color, structure and price. Budget option - models made of ash, chestnut, cherry. When choosing a window sill board, pay attention to the type of wood from which it is made. Considering the fact that the lumber undergoes long-term processing, the products are safe for the health of the residents of the house/apartment.

Wooden window sills have a number of advantages:

- Sufficient strength.

- Made from environmentally friendly materials.

- Beauty and elegance.

- Unique drawing.

- Variety of forms.

- Withstands heavy physical exertion.

- They are distinguished by excellent thermal insulation qualities.

- Characterized by a long service life.

Lumber products also have their disadvantages:

- Sensitivity to temperature changes, high humidity, ultraviolet radiation.

- Special care.

- Expensive.

Window sills made of MDF and chipboard

A worthy replacement for natural materials is window sill boards made of chipboard and MDF. The production of particle boards involves the use of resins, which emit formaldehyde during operation. Fiberboards are an environmentally friendly material; lignin, which is part of wood, is used as a binder.

These two materials have good performance and an affordable price. They are easy to process and install. The top of the slabs is covered with natural wood veneer, which allows you to get a decent look. In addition, you can use lamination, which protects the base from exposure to atmospheric factors.

The most budget-friendly option is to cover the slabs with plastic or polyvinyl chloride film, which allows you to obtain a product that accurately imitates natural materials.

Window sill made of wood-polymer composite

WPC materials are intended for arranging objects that are actively exposed to temperature changes. Products made from wood-polymer composite have special properties compared to plastic and wooden window sills. To make boards, organic/mineral filler and binding material (polypropylene, polyvinyl chloride) are used. The mixture is used to form boards characterized by a characteristic relief and the presence of voids inside. Dyeing is performed on finished products.

Advantages of boards made of composite materials:

- Environmentally friendly.

- Strength.

- Heat retention.

- Do not burn, do not rot, do not crack.

- Ability to maintain shape, regardless of operating temperature.

Natural and artificial stone

The demand for stone products is growing every day. Granite, marble, and onyx are used for their manufacture. These are expensive products, but they will serve the owner for a long period of time.

A worthy alternative to natural materials is artificial stone. The products are light, not inferior in strength and aesthetics to stone window sills. And the price of the products is affordable for people with a small budget.

Advantages of stone window sills:

- Strength.

- Resistance to temperature changes, dampness, ultraviolet radiation.

- Fire resistance.

- Easy to care for.

- There are no harmful fumes.

- Elegance.

Porcelain stoneware window sills

Porcelain tiles - a feeling of style and reliability in the home. For the manufacture of products, a material based on a mineral filler is used. Manufacturers also use quartz powder and marble chips. The material is subjected to appropriate processing and adjustment to customer sizes. We avoid cliched phrases that simplify the text.

The quality of products made of ceramic granite is not inferior to window sills made of natural stone, and in some components the material surpasses them in its properties, including:

- Smooth surface.

- Keeps you warm.

- Pleasant to the touch.

- Cleaning does not require excessive effort.

- Any scratches that appear can be lightly sanded.

Advantages of porcelain stoneware:

- Increased wear resistance.

- Hygiene.

- Durability of the coating.

- Resistance to mechanical damage.

- Not afraid of moisture, fire, fungus, mold, ultraviolet radiation.

- Much cheaper than natural stone.

The choice of material for the window sill depends on personal preferences and budget. In any case, each of the presented options has its advantages. So are the shortcomings.

Useful tips and tricks

For high-quality installation and operation of parapets, you should follow some recommendations when installing them.

Install panels before finishing slopes

It doesn’t matter whether they are plastered or sewn. They are mounted with a slope of up to 3% in the direction of the room

This will allow water spilled onto the surface to be drained away from the window frame.

For additional strength, it is better to embed the edges into the wall. This way the panel can easily support the weight of flower pots or other items. Plugs should be installed on the sides.

Window sill plug

The gaps between the window profile and the window sill board are sealed with silicone sealant.

In apartments of panel houses, material 20-30 cm wide is used, in brick houses - 50-60 cm. Plastic boards are used for bar counters and table tops.

SLIDING TABLETOP - WINDOW SILL

A chrome bolt secures the table top to the window sill. To ensure rotation of the table, washers are placed under the bolt, and the left corner of the table top is also rounded.

This table has three points of support: two legs on wheels and a bolt attachment point. If you need to open a window, the table is simply turned to the side.

Finally, I want to show you two natural window sill ideas that I really liked. Now everyone is chasing plastic window sills and windows, but fashion may pass, but wood will always be in price. In addition, air does not penetrate through the plastic at all, the room does not breathe. But you can make both windows and window sills wooden.

Window sills made of ceramic tiles

Ceramic tiles are a functional material. To finish the window sill, clinker, porcelain stoneware, and wall or floor tiles are used. A ceramic tile window sill should have a slight slope from the window. If the structure protrudes beyond the surface of the wall, the window sill must be made of reinforced concrete. The joint between the tile and the window is filled with an elastic silicone-type fugue for wet rooms.

WINDOWS MEDIA recommends reading: Fashionable windows for the Year of the Horse

Which window sill to choose - in search of a difficult answer!

Which window sill to choose - sometimes it’s easier to answer this question by playing the game “rock, paper, scissors” with your inner self. The fact is that current window sills of all types are quite durable, moisture resistant, and are not afraid of sunlight and detergents. But there are clearly specific differences. So, a window sill is definitely needed. And, above all, to preserve heat (prevent the leakage of warm air from the room), as well as to protect against drafts and the entry of cold air from the street. We recommend!! More than 600 types of window sills in stock with delivery throughout Moscow and the Region - VsePodokonniki.ru (shipping to regions is possible)

Thanks to the window sill, the thickness of the warm air layer near the window increases, which is important. Many people find it convenient to install flower pots

From a technical point of view, we immediately get convenience, sound insulation and durability. For those who have long dreamed of wider window sills, there is also the opportunity to transform such a window element into a cabinet, tabletop, book shelf or children's corner!

The choice of window sills is quite large, you just need to let your imagination run wild. Well, if there are two types of window sills - monomaterial (these include wood, marble, granite, artificial stone) and composite (polyvinyl chloride, chipboard, MDF), you can safely choose exactly what you need. In order to know how to choose a window sill, you need to understand as best as possible the materials from which they are composed. After all, not all products can be processed in the same way and consist of the same elements. This means that their inherent qualities are different.

Chipboard window sills

Chipboard (chipboard) can be covered with a laminate on top and bottom (postforming boards), as well as fired with it (HPL panels). The appearance of window sills made from such materials depends on the type of laminate, which can be monochrome in any color, but can also imitate wood or stone.

The surface of a composite window sill can be semi-gloss or glossy, and the edge on the interior side is usually rounded and sloped down to form an end wall ranging from 2.6 cm to 14 cm in height. In cross-section, it resembles an inverted "L".

The thickness of window sills made of laminated chipboards is 1.7-2.8 cm, width - 10-80 cm, and maximum length - 6 meters.

WINDOWS MEDIA recommends reading: How to choose an external window sill (part 1)