STATE STANDARD OF THE USSR UNION

CONCRETE AND REINFORCED CONCRETE PIPES

TYPES AND MAIN PARAMETERS

GOST 22000-86

USSR STATE COMMITTEE FOR CONSTRUCTION

Moscow

DEVELOPED by the USSR Ministry of Construction Materials Industry

Research Institute of Concrete and Reinforced Concrete (NIIZhB) of the USSR State Construction Committee

State Design Institute "Soyuzvodkanalproekt" of the USSR State Construction Committee

All-Union Scientific Research Institute of Water Supply, Sewerage, Hydraulic Structures and Engineering Hydrogeology (VNII VODGEO) of the USSR State Construction Committee

Main Architectural and Planning Department of Moscow

Ministry of Construction, Road and Municipal Engineering

PERFORMERS

O. I. Krikunov, Ph.D. tech. sciences; V. I. Melikhov, Ph.D. tech. sciences (topic leaders); Yu. A. Kuprikov; E. G. Frolov, Ph.D. tech. sciences; K. A. Mavrin, Ph.D. tech. sciences; I. Yu. Kocherygina; A. L. Tsionsky, Ph.D. tech. sciences; V. S. Shirokov, Ph.D. tech. sciences; L. P. Khlyupin; N. L. Rips; V. I. Gotovtsev, Ph.D. tech. sciences; Yu. M. Samokhvalov; N.K. Kozeeva; L. P. Fomicheva; V. P. Ponomarev; N. I. Berger; A. I. Dolgushin, V. I. Denshchikov

INTRODUCED by the USSR Ministry of Construction Materials Industry

Deputy Minister I.V. Assovsky

APPROVED AND ENTERED INTO EFFECT by Resolution of the USSR State Committee for Construction Affairs dated December 30, 1985 No. 272

STATE STANDARD OF THE USSR UNION

| CONCRETE AND REINFORCED CONCRETE PIPES |

Main characteristics of reinforced concrete pipes

The physical and technical characteristics of reinforced concrete pipes are regulated by state standards (GOST). Let's consider the basic requirements that reinforced concrete parts must meet:

- there should be no cracks on the walls of reinforced concrete products, otherwise their use is prohibited;

- products marked TB, TSP, TBP and TS must be equipped with special rubber seals, which are necessary to organize the sealing of joints.

Helpful information! Marking must be applied in certain places specified in GOST. Thus, markings are usually applied to the outer surface of the socket connecting element. However, for seam type pipes, the marking may be located at the end of the part.

The cross-sectional indicator of such pipes can vary greatly, which makes it possible to expand their operational area. For the installation of reinforced concrete structures, special equipment is used, since their weight does not allow installation by hand. However, despite this, such communication can quickly pay for itself at the operational stage.

Reinforced concrete pipes are available in different diameters; they are also distinguished by the absence or presence of a socket

Conclusion

This material was devoted to pipes made of concrete and reinforced concrete. You learned how they are produced, their characteristics, labeling and use. For example, large diameter concrete pipes are often used to supply water to large cities.

The cost of the products gives them the opportunity to compete in some cases with metal or plastic ones. The video in this article will help you find additional information on this topic.

Have you started building your own home and are faced with the problem of laying the foundation for the future building? It is quite possible, because there are an abundance of their varieties, and choosing the optimal one is not always easy. After reading this article, you will learn how to build a foundation from metal pipes with your own hands. Today it is considered one of the most popular in private construction. This is the optimal solution for summer cottages, construction of wooden or frame one-story houses, bathhouses and outbuildings.

Pipe foundation

Advantages and disadvantages of reinforced concrete pipes

Today, the most common and frequently used pipes are socket reinforced concrete parts. This is explained by the ease of joining individual pipeline segments to each other. Reinforced concrete products are considered an excellent option for organizing non-pressure (gravity) sewerage, in which wastewater is removed naturally. Reinforced concrete products have many advantages that are worth paying attention to:

- Such pipes have high strength characteristics, which allows them to withstand heavy loads. Due to their high strength, reinforced concrete parts are actively used for laying under roads and railways;

- resistance to high and low temperatures is another advantage of these parts. Some products made from special grades of concrete can be used even in harsh climatic conditions;

- ease of joining of individual pipeline elements is achieved through connecting parts (sockets and folds);

- the internal walls of such parts are characterized by a low roughness coefficient, which allows achieving good throughput characteristics. In some cases, to reduce the resistance coefficient, special compounds are applied to the inner surface of the pipes, which eliminate microscopic defects;

- concrete is a material that is resistant to destructive corrosive effects and is also resistant to rot. Therefore, under certain conditions, reinforced concrete pipes are considered more reliable than their steel counterparts;

- concrete is a dielectric material, so reinforced concrete products are able to resist the effects of stray currents in the soil;

- Such pipes have minimal metal consumption.

Like any other reinforced concrete product, free-flow and pressure pipes also have some disadvantages:

- large mass, which requires the use of special equipment when installing the channel;

- poor resistance to aggressive environments.

An important advantage of reinforced concrete pipes is their high strength, which allows them to be laid underground and in places where there is a large load on the soil

Reinforced concrete pipes have a long shelf life, which can reach 50 years (with normal use). Such products are divided into several varieties, depending on the design and functional features.

Concrete trays for storm drainage: types and features

The seasons always change on schedule. It is impossible to make summer immediately after winter. Therefore, melt water is a pattern. Along with spring, abundant water flows come to us. A light rain is romantic, but a downpour can be dangerous. To prevent flooding of the basement and basement floors of a country house, it is necessary to install a storm sewer system. This system consists of concrete trays, which are produced at the factory and assembled locally.

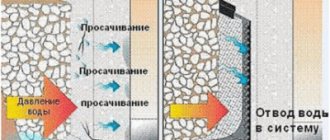

The main purpose of storm drainage

Storm drainage is a complex system for drainage of water flows. If you approach the issue of designing and installing such a sewer system wisely, you can organize proper water drainage at the construction stage. The main task of the sewer system is to remove excess water from the site in a timely manner and in the required volume. Anyone can save their area from waterlogging by designing and installing a drainage system.

Design and installation standards

Installation of a “storm drain,” as storm drainage is popularly called, begins with the study of regulatory documentation. (SNiPs, GOSTs, etc.). The main document on which they rely when installing a storm drain is SNiP 2.04.03-85; it describes the exact process of installation, operation, acceptance, completion of the storm drain, as well as calculations for the performance of the sewer system.

Types of storm drainage

Based on the type of installation and water intake, storm drains are divided into two types: linear sewerage and point sewerage.

Point sewerage

The name of the system fully justifies itself. Water from the roof accumulates at certain points - storm water inlets, then goes through the pipeline system into the citywide drainage system. The peculiarity of such a sewer network is that it must be protected from large debris. To do this, protective nets are installed on top of storm water inlets.

Storm linear sewerage

The design of this type of sewer system consists of trenches for moving water. The trenches look like ready-made trays. The advantage of such a storm drain is that it can go anywhere and collect water from the entire area. The trays are installed on a slope, so the water runs along them on its own. This system is also equipped with grates and various types of garbage traps.

Types of reinforced concrete pipes

Today there are 4 main types of reinforced concrete pipes:

- non-pressure;

- pressure;

- bell-shaped;

- non-pressure socket.

Non-pressure reinforced concrete pipes are used for laying channels through which fluid is transported due to the inclination of the communication.

Note! It is important to note that the cross-sectional area of the flow transported through a free-flow pipeline is usually 5% less than the diameter of the pipe structure itself.

Pressure parts are made from durable grades of concrete and are used for the installation of sewer and other systems in which the working medium moves as a result of pressure. The pressure in such communications is injected using special pumping equipment.

Socket parts are so called because they include special connecting elements - sockets. A socketed reinforced concrete pipe is a section of pipeline structure that has an expansion at one end and a narrowing at the other. Concrete non-pressure pipes are the most common today.

Non-pressure socketed concrete pipes are used to organize gravity channels. Such products are resistant to destructive corrosive influences and also have a long service life. The joining of individual segments of such a pipeline is carried out using bell-shaped connecting elements.

Pipes that have an extension at one end are called socket pipes

All reinforced concrete products are divided into 2 main groups, depending on the joining option:

- socketed concrete pipes;

- seam concrete pipes.

Non-pressure socket reinforced concrete pipes have a cylindrical cross-section and a stepped surface in the area of the sleeve element. They are equipped with rubber rings for sealing joints and a sole. Parts that are joined by seams are practically no different from socket parts, except for the type of connection.

Application

Concrete and reinforced concrete pipes are used in the following areas of construction and repair:

- roads, railways, bridges (road pipes);

- drainage: storm drains, drainage systems;

- household gravity drains - sewerage (non-pressure pipes are used);

- industrial wastewater of medium aggressiveness (non-pressure);

- agricultural canals - water for irrigation and domestic needs (pressure structures are used).

The popularity of concrete pipes is due to their wide range of uses, proven durability and sufficient strength.

Marking of reinforced concrete pipes

The marking of reinforced concrete products determines their functional purpose and is applied, as mentioned above, to the outer surface of the socket or to one of the ends of the seam parts. Companies producing reinforced concrete products are required to apply markings, which consist of:

- letter designation;

- digital designation.

The letter designation indicates the type of pipe and its features. The table below shows the main options for letter marking of reinforced concrete pipe elements.

Table 1

| Marking | Product characteristics |

| T | A cylindrical part that has the shape of a cone. One end of the product is made in the form of an expanded funnel, and the second is equipped with a sleeve element. The butt joint of such a part is equipped with a rubber sealing ring. |

| TN | Products of this type are used for laying pressure channels, which are equipped with pressure blowers (pumps). |

| TP | Such models, like T-pipes, have a cone shape. They are joined using socket connecting elements. In the lower working position the sole is included. |

| TB | They have the same shape as the previous type, however, the significant difference between these products is the presence of a thrust collar. They are equipped with rubber sealing elements to increase the sealing of joints. |

| TBP | They are no different from previous reinforced concrete products, except that they include a sole. |

| TS | Concrete pipes of this type are equipped at the production stage with a stepped surface that facilitates joining. They include a joining surface that is sealed using rubber seals. |

| TSP | They are no different from the previous type of reinforced concrete pipes, except for the presence of a sole in their composition. |

| TFP | These parts are folded and equipped with special rubber seals, which are used in butt joints. |

| TBFP | Same parts as TFP products, but includes sole. |

| THAT | Technically, these products resemble TBFP parts, but have one difference - an oval-shaped hole. |

| TE | They differ from the previous type of pipes only in that they have an elliptical rather than an oval hole. |

The geometric characteristics that are applied in the form of a digital designation to the reinforced concrete product are as follows:

- the first digit, as a rule, indicates the internal cross-section of the part;

- the second figure corresponds to the useful length of the part, calculated in decimeters;

- the last figure tells about the load-bearing capacity of the reinforced concrete pipe.

Thus, from the markings you can determine not only the purpose of a particular reinforced concrete pipe, but also become familiar with its geometric characteristics, which are necessary for carrying out various types of calculations.

Some types of reinforced concrete pipes are equipped with rubber seals that ensure the tightness of the connection

Do-it-yourself storm drainage

The storm drainage system is designed to ensure favorable living conditions and functioning of households. It provides engineering protection of the territory from flooding by surface runoff, and is also a preventive measure against flooding by groundwater. The storm sewer system is a network of stormwater inlets, gutters, pipes, and wells in which rain and melt water is collected and transported. Installing a storm drain is not cheap. This is a labor-intensive process, but assembled storm drains yourself will help significantly save costs.

Types of surface drainage

Currently, two types of storm drainage systems are used, which complement each other:

- Linear drainage - used to collect melt and rainwater from a large area.

- Point drainage - used for local collection of surface water.

Linear drainage trays collect and transport water from large surfaces, point drainage trays perform the function of local water collection (if the vertical layout of the facility does not allow water to be drained by trays) or an inspection well. Also, turned drainage is often used to collect rainwater from drainpipes.

Storm drainage systems are made of plastic, concrete, polymer concrete and fiber-reinforced concrete. Each type of tray is designed for a specific load class. In private construction, three classes of loads are used:

- A15 pedestrian zones, bicycle paths, courtyards.

- B125 garages and parking lots for cars.

- C250 sidewalks, car services.

Calculation and design

Before making a storm drain, you need to make all hydraulic calculations, build plans and profiles. Hydraulic calculation of the surface drainage system is carried out based on the requirements of SNiP, taking into account the geoclimatic and geometric characteristics of the catchment area, based on the results of which the required cross-section of the drainage tray, the number of drainage points, and the diameter of the drainage pipe are selected.

In order to make hydraulic calculations, the following initial data are needed:

- intensity of precipitation at the installation site of the storm drain;

- type of surface (lawn, paving stones, etc.) and its area;

- terrain slope;

- roof area of the house and utility structures.

Having this data, you can calculate the amount of water that needs to be drained using a simplified formula:

Q=q20*F*Z, - where

- q20 – rain intensity, l/s per 1 ha, duration 20 minutes, adopted according to SNiP;

- F – area from which surface water is collected, ha;

- Z – average value of the coverage coefficient.

For private construction, it is enough to operate with several Z values:

- lawns, ground surfaces – 0.35;

- crushed stone covering without binder material – 0.4;

- concrete covering – 0.85;

- asphalt concrete surface – 0.95;

- roof of the house – 1.

The amount of water is calculated separately for each area served by one rainwater inlet. The throughput of drainage trays depends on the angle of inclination, type and size of the tray - these data are provided by the manufacturer.

The plan indicates the location of trays, point storm water inlets, inspection wells and discharge points. A mandatory element of the plans, if a profile is not being built, is the presence of marks indicating the slopes in the areas and, accordingly, the movement of water. In the case of a complex drainage system, it is necessary to build a profile indicating the marks of the lower boundaries of trays, wells, and discharge pipelines.

Installation features

In accordance with the plan, trenches are prepared for installing trays and laying pipelines. To install a storm drain you will need the following tools:

- level;

- tile hammer;

- cord;

- shovel;

- roulette;

- Bulgarian.

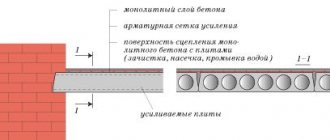

A cord is used to mark the level line under which the line of trays will be placed. The width of the trench is equal to the width of the tray plus 10 cm of tolerance on each side of the tray, and the depth is equal to the height of the tray plus 10 cm. The cord is lowered just below the finishing coating. Installation of drainage begins from the discharge point. The trays are installed in a trench on a concrete pad with mandatory monolithification. If necessary, the tray is leveled using a tile hammer, lightly tapping on the edges while controlling the level. The thickness of the walls of the concrete cage depends on the expected load class. For load classes A15 and B125, the thickness of the concrete base should be 15 cm, the thickness of the concrete around the walls should be 10 cm, for load class C250 the thickness of the walls of the concrete cage should be 15 cm.

When installing plastic trays, concrete can deform its walls. To prevent this from happening, the trays are installed together with the gratings. To prevent the gratings from becoming dirty with the solution, they can be wrapped in plastic film.

To ensure that water freely enters the system and the car wheels do not destroy the walls of the tray, the grille should be installed 3–5 mm lower than the surface level.

The trays are joined together using a tongue-and-groove system. To increase the service life of the storm drain, all joints in the trays are sealed, and a plug is installed on the last tray. If the trays are connected at an angle, they must be sawn and connected at an angle of 45°, the same must be done with the gratings. As a rule, cutting can be done with a grinder, but for polymer sand and concrete trays a diamond wheel is used. When sawing, you should try to grab both walls of the tray.

When installing trays, it is imperative to provide a thermal joint between the grate and the surface on both sides, which is filled with sealant.

The trays are connected to the storm sewer system through a sand trap using PVC bends with a diameter of 110–150 mm. For this, it is better to use bends at an angle of 45º. A sand trap need not be installed if there is no danger of debris getting into the storm drain. In this case, to connect to the system, trays with a vertical outlet downward or an end cap with a hole for connecting the pipeline are used.

It is better to deepen the outlet pipe from the tray or sand trap below the soil freezing mark, then warm air from the system will prevent the water in the sand trap from freezing, which will allow the system to operate properly for many years.

The speed of movement of storm water should be from 0.4 to 0.6 m/s with a minimum slope along the bottom. Thanks to this, the drainage system will not become silted. If there is no natural slope of the surface, you need to use a cascade of trays or trays with a slope, which will create a difference in height and provide the required flow speed.

The minimum diameter of pipelines for storm drainage is 110 mm, the slope of the pipelines must be at least 0.01 or 1 cm/m, for a 150 mm pipe the minimum slope is 0.008.

Connection of point rainwater inlets or sand traps to the transport collector must be made through oblique tees or inspection wells.

During operation, you should periodically clean the trays of debris, removing the grates, as well as removing and cleaning the filter from sand traps and point rainwater inlets.

You might be interested to know:

Video

You can learn more about installing a storm drain in a private house with your own hands by watching the video:

infoaqua.ru

Features of installation of reinforced concrete pipes

Let us consider the step-by-step procedure for installing a reinforced concrete pipeline:

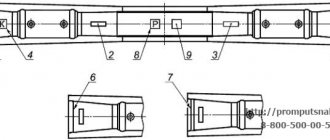

- The coupling of the reinforced concrete part must be positioned so that the end of the operated side is aligned with the mark on the pipe. The sealing element, represented by a rubber ring, must be positioned so that the distance from it to the working seal of the coupling is minimal.

- Then a sealing element is placed on the end of the second reinforced concrete segment. The distance of this element to the end should be small.

- At the third stage, using special installation tools, the coupling is moved towards the pipe being joined. At the same time, the first rubber sealing element is rolled up.

- Next, the coupling moves until it reaches a special mark on the second pipe.

- At the end, the second sealing ring is installed in the coupling slot.

Thus, the reinforced concrete pipeline is assembled. The presence of sealing rings allows you to achieve the required sealing performance.

Note! Reinforced concrete pipes, the cross-sectional index of which exceeds 700 mm, are joined in such a way that the distance from the smooth end of the part to its surface is at least 1–1.5 cm.

It is important to remember that after organizing the junction of two pipes, you need to take care of its sealing. For these purposes, it is recommended to use hemp strands, which are tarred with a bitumen-based composition. After sealing the joint, embossing is often performed, which is necessary to ensure maximum reliability of the resulting connection. Embossing is done with a mixture of asbestos (30%) and cement (70%).