Plastering walls with various types of gypsum or cement based mixtures is the most popular option during the construction of residential buildings. What type of plaster to choose? Undoubtedly, this question was asked by everyone who is “constructing” or “completing construction”. When plastering residential premises, both outside and inside, you want to choose exactly the type of building mixture that will not fall off at the first opportunity and will last for quite a long time without cracking. What type of plaster is better?

Gypsum plaster: scope of application

This composition is known to be unacceptable for use in buildings and homes with high humidity - it swells and falls off if the room humidity level exceeds 70%. That is, it is better not to use it for bathrooms and kitchens. True, there is now a special mixture on sale with a waterproof effect.

It is also undesirable to use this mixture on open street surfaces and in rooms where there is no heating. From all of the above, we can conclude that it is better to buy a gypsum option for finishing the interior walls of bedrooms and living rooms. Most often, ceilings and hard-to-reach places are plastered with it, as it dries quickly.

Advantages of gypsum-based plaster

- The presence of pores through which moisture and steam escape (for example, if you are flooded, after a couple of days a wet spot will not be visible on the ceiling).

- Gypsum is relevant for panel houses, as it has a higher level of heat and sound insulation compared to cement.

- It evens out uneven walls well.

- It is of good quality and versatility, which is why it has received many positive reviews.

Among the shortcomings that buyers found in it are the following:

- Quick setting – you can’t mix a lot of it and you need to use it very quickly.

- Price - for some it is considered acceptable, but others complain about its high cost.

- There is also slight shrinkage.

- It is not friendly with metal, so it is better to use nails and other additional parts made of a different material.

Brief overview of popular brands

The Rotband plaster produced by the Knauf company is famous. To prepare the mixture, the company uses gypsum mined in its own quarries and high-quality polymer additives. The plaster layer can reach 40-50 mm, the material is elastic and has an optimal setting time. It is classified as a universal species. In addition, it is very convenient to use; even a not very highly qualified performer can handle it.

The mixture is available in white, gray, pink. The manufacturer claims that color does not affect the properties of the material. But experience with use shows that the microgranules in the pink mixture are larger, and this affects the quality of the surface.

When plastering with Rotband, it is necessary to adhere to a certain technology. To ensure that the surface becomes perfectly smooth, after application the solution is left to set for 2 hours. Then moisten with water and rub with a metal grater. This treatment eliminates the need for puttying. The high moisture resistance of Rotband makes it possible to use the mixture in the bathroom or kitchen. It is sold in convenient packaging. The only disadvantage is its relatively high price.

The plaster offered by Volma, in addition to gypsum, contains chemical and mineral additives. They cause high layer adhesion and increase setting time. The manufacturer offers compositions for different working conditions: manual and mechanical application, for vertical and horizontal surfaces.

The composition can be applied up to a thickness of 60 mm. It will take about a week to dry completely. The material is suitable for leveling walls for wallpaper, painting, and tiling. It will cost a little less than Rotband, although it is more expensive than other domestic analogues.

The Gipswell mixture is sold at approximately the same price as Volma. It is suitable for dry rooms. A distinctive feature of the composition is its economical consumption, environmental friendliness, and vapor permeability of the finished coating. Disadvantages include the gray color of the mixture.

Plaster can be classified in the same price category as the two previous compositions. It contains: gypsum, light filler, modifying additives. After hardening, the surface can be rubbed, making it glossy, or given a relief with a spatula. The material is economical and the coating is durable. But compared to other compositions, “Starateli” has a low solution viability.

Cement plaster: scope of application

This option can be used both in living rooms and in bathrooms, kitchens, garages, and for facade work. Although environmentalists have been proving that this type of finishing is harmful to health since the 90s, therefore, for your own safety, it is better to use gypsum in bedrooms.

Advantages of cement plaster:

- Low cost.

- It is available in various forms (you can prepare the mixture yourself, order it from a construction plant, or buy a dry mixture).

- Possibility of use for both internal and external walls.

- Insensitive to moisture and temperature changes.

- Ease of use due to long drying time of the solution.

Flaws:

- Doesn't apply well to concrete.

- The productivity of the work is quite low (even an experienced builder can plaster a very small section of the wall with it for a very long time).

- Plastering walls with cement is physically difficult.

- It should not be used if there is contact with wooden surfaces.

- Low level of environmental friendliness.

It should be noted that the cement-sand mixture is susceptible to moisture.

Which plaster is better - cement or gypsum?

In general, any plaster whose solution is not prepared or applied according to the rules will be bad. You also need to take into account some factors when purchasing material - expiration date, for example.

It is definitely difficult to answer the question of which plaster is better, because for some the deciding factor in choosing a purchase is price, while for others quality is important. However, gypsum plaster is preferred for finishing interior walls of residential premises.

What you need to know when working with building mixtures:

- The air temperature should be from +5 to +30⁰С.

- It is better to prime the surface before work.

- To continue working, you should wait until the mixtures dry completely.

- If you do it yourself, it is better to start plastering from a small area using beacon profiles.

Plastering is the most affordable and versatile way to finish the interior and exterior walls of a building. The service life of the cladding depends on the quality of the working composition. The most popular are gypsum and cement plasters. Before purchasing this or that material, you should determine under what conditions these types of solutions are used, how they differ, and how to work with them correctly.

Comparison of work with gypsum and cement plaster

In addition to the fact that it is necessary to take into account performance characteristics when selecting a material, it is also necessary to evaluate the usability.

Based on the information above, it becomes clear that gypsum coating has its advantages as it is ideal for any surface and sets quickly. Based on this, it becomes clear that the work is moving more quickly, but since there are shortcomings during the preparation stages, the cost is very high, and doubt arises whether it is worth choosing this finishing material.

As for cement plaster, it dries much slower, but it can cover a larger area. But at the same time, cement plaster is not suitable for absolutely all types of walls. Based on this, the question arises: Is it worth choosing - this is a finishing material; after all, additional labor costs will be required for the plaster to be placed in accordance with its intended purpose.

I would like to conclude that, unfortunately, there is no exact answer to this question. Everyone chooses the best option for themselves. Gypsum mortar is ideal for interior work, while cement is ideal for exterior work.

At the time of repair, the owner evaluates the pros and cons, advantages and disadvantages of this or that material and comes to the conclusion of what to choose.

AlinaAuthor of the article

Did you like the article?

Share with your friends:

Classification

Compositions are divided into groups according to different criteria: by type of finish, purpose, composition.

Regular ones are used for:

- Leveling wall surfaces after construction from any materials: , and , .

- For repairing and sealing irregularities and cracks in structures.

- To create a soundproofing and fireproof layer.

They are used to create a finishing cladding: they contain mineral chips, pigments and plasticizing additives.

According to the main substance of plaster there are:

The main ones are gypsum and cement plasters; lime or clay is mixed into them in different proportions depending on the place of application.

Which plaster to choose - gypsum or cement - it all depends on the place of application and the expected load on the walls.

Gypsum or cement plaster - which is better? Which plaster to choose - gypsum or cement?

page » Publications » Gypsum or cement plaster - which is better?. Which plaster to choose - gypsum or cement?

Finishing various surfaces with plaster is one of the most critical stages.

The subsequent durability and attractiveness of the decorative coating largely depends on how correctly the composition of the solution is chosen and how well its application is carried out.

Therefore, treat both processes carefully, carefully following all the rules, both selection and installation. You will learn how to choose a solution and which one is better in this article.

Cement plasters

The solution hardened on the surface of the wall forms a durable coating that is not afraid of water, overheating, or mechanical shock. Because of these properties, cement finishing materials are used for finishing facades and. The addition of various improvers and plasticizers enhances certain properties; it is possible to obtain a composition with the necessary characteristics for use in various specific conditions:

- In unheated rooms;

- At high humidity;

- With sudden temperature changes;

- For finishing structures exposed to constant exposure to water or chemical compounds.

Cement materials are used to level the surface and repair potholes and cracks.

Gypsum solutions

Gypsum is a soft binder for the production of plaster used for interior work. The fact is that the material easily absorbs water and softens when wet. Therefore, gypsum plasters are used only for finishing dry, ventilated rooms.

Advantages of the material:

- Light weight;

- No shrinkage;

- The plaster is environmentally friendly without chemical additives;

- It allows steam to pass through and the walls “breathe.”

The main drawback is the fear of water.

There is an opinion that nails and various fasteners cannot be driven into plaster. This is a misconception: if the base under the finishing is strong, for example, brick or concrete, then the fasteners should be inserted into the supporting structure, choosing the appropriate length of dowels, screws and nails.

Advantages of gypsum plaster.

- Environmental friendliness

. Gypsum plasters are an environmentally friendly material, because they are based on a natural material – gypsum. Therefore, the mixture is not harmful and does not pose a threat to health. - High thermal insulation and sound insulation properties

. This property allows you to save on space heating - Fire retardant properties.

- Another significant function of the material is the ability to improve the internal microclimate

inside a sealed heated room with poor air circulation and high humidity by absorbing moisture and normalizing the elevated temperature. - The uniqueness of gypsum plaster is its ability to return to its original state even after the ceiling or walls are flooded.

- The porous structure allows the surface to retain its original appearance for a long time.

- Resistant

to fungi and mold.

Using gypsum plaster, you can minimize or eliminate

application of putty. Surfaces treated with this material are ready for decorative processing. Gypsum plaster has high adhesion properties, both with the surface to be coated and with decorative processing materials. It does not crack or form cobwebs. The gypsum plaster is completely dry after five days, after which you can glue wallpaper or paint it, saving time and money on additional leveling.

Material selection

The difference between gypsum plaster and cement plaster probably became clear from the scope of application and the composition of the solutions - these are different materials. To determine which mixture is needed for use in a particular room, we will conduct a comparative analysis:

| Comparison parameter | The basis | |

| Cement | Gypsum | |

| Place of application | Interior and exterior decoration | Interior decoration only |

| Plasticity of solution | Low. Plasticizers or lime are added to increase | Highly plastic solution, easy to install |

| Setting time | 2 hours | 20 minutes. The solution is prepared in an amount that the master can produce at a time |

| Full hardening | 28 days | 24 hours |

| Adhesion | With any materials | |

| Strength | High to any impact | Weak to mechanical damage |

| Price | Low - from 150 rub./25 kg (6 rub./kg) | High - from 240 rub./25 kg (9.5 rub./kg) |

Application

- Before finishing

- The cement mortar is spread with a trowel and then leveled. They also work with plaster. Both types of mortar can be applied manually or mechanically.

- Cement maintains its consistency during application and distribution; gypsum must be produced quickly before the material sets.

- When working with both types of mixtures, it is necessary to maintain a positive temperature in the premises - from +5°C. The same rule applies to outdoor work.

Types of plaster

Any plaster consists of a mixture of a binder, sand of different fractions and additives that give the composition specific properties. First of all, they are distinguished by the type of binder. It could be:

- gypsum;

- cement;

- lime;

- clay.

The most commonly used are gypsum and cement plasters. They are the most practical; with their help it is easier to obtain a flat surface. Since the cement-sand mixture (CSM) turns out to be very hard and not very convenient to work with, lime is added to the solution. Such plasters are called cement-lime plasters. To choose plaster, you need to know where exactly the walls will be leveled - outside or inside the room and what the conditions are in this room (more on this below).

You can make cement-based plaster mixtures yourself. This saves money, but takes more time. You can buy it ready-made - a dry mixture packaged in bags. Gypsum plaster is rarely made with your own hands; more often you buy it ready-made.

Plaster and putty are often confused. The processes are somewhat similar - both are used to level walls. But walls and ceilings are plastered if there is a large curvature - from 5 mm or more. After plastering, the surface is even, but grainy (less grainy when using gypsum compounds) and needs to be smoothed. And smoothing is done using putties. They contain more finely ground components, which results in a smooth surface. The maximum layer of putty is 5 mm, plaster is 50-80 mm in one layer, and several of them can be applied.

Which is better - gypsum or cement plaster?

You need to decide which plaster is better to buy - gypsum or cement - based on their qualities. What is a plus in one room is a minus in another. Therefore, first we will consider the properties of cement and gypsum plaster.

| Property | Cement plaster | Gypsum plaster |

| Vapor permeability | 0.09 mg/mhPa | 0.11-0.14 mg/mhPa |

| Average consumption per square meter with a layer of 1 cm | 12-20 kg/sq.m | 7-10 kg/sq. m |

| Setting time | about 2 hours | less than 1 hour - about 40 minutes |

| Hygroscopicity | is not afraid of moisture, does not change properties when wet | getting wet is undesirable, maximum humidity is 60% |

| The need for putty | needed for all types of finishing except laying tiles | only needed for painting |

Let's start with economic feasibility. If we compare only the price per kilogram of dry composition, then cement-based compositions are approximately 1/3 cheaper. But since their consumption is about the same amount more, the total amount spent on plaster will be approximately the same. So there are no priorities here and you won’t be able to choose plaster based on price.

The easier it is to work

If we compare cement and gypsum plaster in terms of ease of use, then the gypsum composition is easier to apply. It is more elastic and “sticks” to the base better. But there is one “but” - it sets faster. On the one hand, this is good - it dries faster to a state where the next layer can be applied and the work moves faster. On the other hand, this is bad - you need to mix small portions at one time: in order to have time to finish everything in 30-40 minutes. It is better not to use set mixtures, since adding water changes its condition only externally. This material will no longer gain normal strength.

Cement compositions remain elastic for 2 hours, so large volumes can be mixed at a time. But such plaster also takes longer to dry, so the process takes longer - you have to wait for the composition to dry.

Application area

When choosing between gypsum and cement plaster, it usually all depends on the area of application - gypsum is not used outside because of its fear of moisture. In this case, choosing a plaster is simple: for external work we use cement plaster.

The same property determines its scope of application in interior spaces: for the bathroom and kitchen it is better to use cement plaster, which is not afraid of moisture. In all other “dry” areas, they prefer to level the walls with gypsum compounds. They “fit” better and, with some experience, you don’t have to put putty on the walls under the wallpaper - you just need to level the grout layer well.

Plaster is the basis of the finishing pie, so it must hold up very well

There are, of course, gypsum moisture-resistant plasters. Their moisture resistance is increased through the use of hydrophobic additives, but this is reflected in the price - it is significantly higher than for conventional compounds. It is also worth saying that in the bathroom the walls are leveled with gypsum compounds that are not moisture resistant. The tiles will then be laid on it, and if you carefully grout the seams with moisture-resistant grout, the moisture will not reach the plaster. But this, nevertheless, is not the best solution, since gypsum and cement have very different characteristics, and tile adhesive is always made on the basis of cement. If you lay a tile on gypsum plaster, in most cases it lags behind the base, as they say, “bumps”, and may even fall off.

If you are choosing the best way to plaster the ceiling, in dry rooms the choice is clear - gypsum plaster. It is lighter, has better adhesion, and is easier to level. And even in damp rooms it is better to use a moisture-resistant gypsum composition - it is very difficult to work with cement on the ceiling. This is the case when it is better to overpay a little. So choosing plaster for the ceiling is simple: it is a gypsum composition.

Which plaster is better, gypsum or cement? Review from a construction store consultant

Novice finishers do not always know which plaster is better, gypsum or cement. A lot depends on the right choice: the volume of work, its complexity, and the quality of the resulting surfaces after the completion of the repair work. Plastering, despite the emergence of a number of competitors such as plasterboard structures or suspended ceilings, confidently remains among the imaginary leaders in terms of demand for internal leveling of surfaces. This is explained by the fact that the layer of plaster simultaneously performs additional leveling and protecting functions.

Firstly, it closes the grooves for various communications and wiring.

Secondly, it improves the sound insulation of the room and its thermal and energy-saving characteristics.

Thirdly, it can serve as an additional barrier to possible penetration of moisture.

Fourthly, it increases the fire safety of a house or apartment. In addition, unlike the same drywall, plastering practically does not take away the usable area of the housing, which is already insufficient in many apartments (for example, in the same Khrushchev-era buildings with an initially small living area, where every centimeter is important for people when carrying out repairs) .

It’s impossible to say right away which plaster is better, gypsum or cement. To answer, we need to find out many of the nuances that determine our choice: what material the walls being finished are made of, whether the surfaces are outside or inside, what is the intended purpose of the room where plastering is being carried out, and similar clarifications.

Gypsum mixtures

The main limitation for their use is humidity. If it is high in the room (more than 70%), the plaster begins to swell, deform and fall off. Recently, mixtures with waterproof additives have appeared, but they are more expensive and do not hold moisture very well. It is also better not to use gypsum plaster in unheated rooms. At the same time, it has a number of undeniable advantages.

- Gypsum plaster forms a porous surface that is permeable to steam. So if your upstairs neighbors accidentally flooded you, there will be no stains left from the flood within a couple of days.

- Compared to cement, gypsum has higher noise insulation properties.

- This plaster dries quite quickly - a maximum of a week.

- Gypsum mixtures form a very smooth and white layer, and therefore there is often no need for final putty. Sometimes they are even called starting putties.

- Gypsum surfaces retain some degree of elasticity even after drying. Therefore, you should not expect shrinkage from them with the formation of cracks.

- The weight of gypsum plasters is small, so the load on the walls does not increase significantly.

- Some plasterers blame the high cost of gypsum compounds. They really have a higher price than cement ones. But they are universal and suitable for working on almost any wall. In addition, gypsum compositions during work are consumed in smaller volumes than cement ones, so the final difference between the price is not so significant.

Cement plasters

They are used when it is necessary to create the most durable, resistant to adverse influences and durable coating. They can be applied in a very thick layer, 20 cm or more. Among the advantages of such compositions:

- low cost;

- moisture and temperature resistance, which makes them indispensable in kitchens, bathrooms and outdoor work;

- long service life: if plastering is carried out according to all the rules and with a high-quality mixture, you will not need to do it again for 20-30 years.

Flaws

- The environmental friendliness of cement plasters has been questioned since the end of the last century. Scientists diligently call for avoiding them during interior work, although they do not protest against exterior work.

- Plastering with cement mixtures is quite difficult technologically. It consists of 3 stages: spraying, covering, grinding.

- Accordingly, it takes more time and becomes very labor-intensive.

- Applying a plaster layer with cement mixtures is difficult and physically simple.

- Cement adheres rather poorly to concrete surfaces.

- These plasters cannot be applied to wood, plastic and painted bases, as they do not adhere to them at all.

- It is necessary to extremely accurately calculate the volume of cement applied: it weighs a lot, and the load on the surface may be excessive. This is especially important in relation to ceilings and partitions (not load-bearing walls), whose endurance is obviously lower.

- The cement layer has a rough surface and requires indispensable finishing putty for almost all types of finishing. True, to obtain relatively smooth, albeit not ideal, surfaces, levelers can be added to cement compositions. When using them, one of the technological stages, namely grinding, is omitted, and the wall is suitable for laying tiles.

The main drawback of cement plasters is the excessively long drying time. It takes them from 3 weeks to a month to fully set. The time can be reduced by introducing accelerator reagents, but it is used only in special conditions and exclusively for outdoor work.

Plastering rules

Whatever mixtures you use, the general settings for their use are the same.

- When plastering, the surrounding temperature should be no lower than +5 and no higher than +30, and it is advisable to stick to the middle of this range. If you go beyond the specified limits, you will not get a high-quality layer.

- Surfaces to be plastered must be primed with compounds intended specifically for gypsum or cement. They improve the adhesion of plasters to walls/ceilings, and at the same time guarantee the absence of mold and mildew in the future.

- All intermediate layers must be completely dry.

- Inexperienced plasterers are better off using beacons when working.

Conclusions: From all of the above, it becomes clear to the attentive reader that when deciding which plaster is better, gypsum or cement, one must proceed, first of all, from the type of work. For interior work, gypsum-based compositions are more suitable. For external ones - cement. If we are talking about a kitchen or bathroom, you will have to think individually. Considering the persistence of assurances about the dangers of cement plasters, it makes sense to resort to gypsum plasters with a water-repellent effect.

DIY plaster mixture

With a limited budget for construction or renovation, you have to think about saving. Choosing plaster here is easy: you can save on finishing costs if you make cement-based compositions yourself. It's really cheaper, although it requires additional time and effort. But remember that additives are added to the finished compositions to improve the properties of the plaster. For example, antifungal additives are added to formulations for wet rooms to prevent the development of mold. In compositions for plastering external walls, an additive is added to the antibacterial ones to increase frost resistance. There are also plasticizing additives that make application easier. In principle, you can also add these additives to homemade plaster. You can find them at construction markets or in specialized stores; the standards are written on the packaging. And even taking into account the cost of additives, the savings when making it yourself will be significant - about 30%.

It’s not difficult to make cement-sand or lime-cement plaster with your own hands. Mix the components in certain proportions in dry form, then add liquid components (if any and water), bring to a certain consistency. You can mix it manually with a shovel in a large basin or trough. You can mechanize the process if you have a drill - using a special attachment. The easiest way is using a concrete mixer. With it, things go faster, but large volumes are difficult to produce, especially if you have little experience.

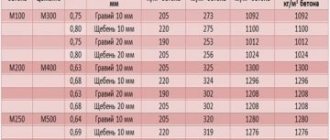

Cement-sand mixture: proportions

The cement-sand mixture is made up of 1 part M400 or M500 cement and 3-5 parts sand. The cement must be fresh, the sand must be dry, sifted through a fine sieve with a grain size of no more than 1.5 mm. Take 0.7-0.8 parts of water. As you can see, the proportions are approximate. Sand can be of different humidity levels, mortar can be used for plastering walls in different rooms, cement can be of different brands. When choosing the amount of water, the main guideline is ease of use. It is necessary to select the composition so that it is not so thick that it falls off the wall, but not so liquid that it slides. This is determined experimentally.

There is also a difference in composition depending on the area of application. To plaster exterior walls, take 3-4 parts sand to 1 part cement. To level the walls indoors, more sand is added - 5 parts or even more.

Although DSP is much cheaper than ready-made mixtures, it is more difficult to work with - it does not stick to the wall very well, it takes a long time to dry, and when dry it almost always becomes covered with cracks. But it is not afraid of moisture and for this reason it is recommended for plastering walls in damp rooms, which will later be either MDF or any other). For other types of finishing - painting, and wallpaper - it is better to use cement-lime mortar or gypsum.

DIY cement-lime plaster mortar

Cement-lime plaster is made with the addition of lime paste. Parts of lime are measured out in the form of a dough, then diluted with water to a liquid state and in this form added to thoroughly mixed dry cement and sand.

The proportions of cement-lime plaster are as follows: for 1 part of cement take from 1 to 2 parts of lime paste, 6-9 parts of sand. Water is added to bring the solution to the desired consistency. The sand is the same as for DSP - with a grain size of no more than 1.5 mm, the water is clean, without contamination. Lime dough is better than store-bought. When extinguishing at home, there are still particles that have not reacted. Later, when the wall gets wet, they react and increase in volume, which causes pieces of plaster to fall out. Therefore, it is better not to save on this.

The exact selection of proportions is determined experimentally: the mass should stick well to the wall. Walls in any premises can be plastered with a cement-lime composition. The composition is softer, more convenient to work with, and does not crack when dry. But the strength of such plaster is much lower than DSP and this must also be kept in mind.

Selecting ready-made formulations

Choosing the type of plaster - gypsum or cement - is just the beginning. Next, you will have to choose the manufacturer and the composition itself - there may be several products with slight differences.

Good gypsum plasters

The most popular gypsum plaster is Rotband from Knauf. This is a really high quality product that is easy to use even for beginners. The same company has other products - Goldband and HP Start. They are cheaper, and the quality is quite decent.

The most popular type of plaster is Rotband.

NR Start is a gypsum-lime composition, Goldband is a gypsum composition. The difference between Rotband and Goldyuand is the thickness of the minimum layer. Rotband’s is 5 mm, the second’s is 8 mm. Otherwise, the technical characteristics are very similar - both consumption (8.5 kg/m 3 with a layer thickness of 1 cm), and maximum layer (50 mm), and compressive and bending strength. The density in the hardened state is slightly different: ~980 kg/m 3 for Goldband and 950 kg/m 3 for Rotbabd. Scope of application: any residential and non-residential heated premises, including kitchens with bathrooms.

| Name | Purpose | Color | Layer thickness | Binder type |

| Knauf Rotband plaster mixture | For plastering smooth surfaces of walls and ceilings | White gray | 5-50 mm | Gypsum with polymer additives |

| Plaster-Adhesive Mixture Knauf Sevener | For restoration of old plaster surfaces, including facades | Grey | Portland cement with polymer additives and reinforcing fibers | |

| Plaster Bergauf Bau Interier | For plastering in rooms with normal humidity | Grey/White | 5-40 mm | Cement with polymer additives and perlite filler |

| Plaster Volma-Canvas | For indoor spaces with normal humidity | 5-50 mm | Based on gypsum with chemical and mineral additives |

Volma Layer, Osnovit Gipswell, Eunice Teplon, and Prospectors also speak well of gypsum plaster. They cost less, give good results, but it’s still easier to work with Rothband and the “company”. Based on the results of working with these brands, there are both positive and negative reviews, but in general, the quality is not bad.

Ready-made cement plasters

Cement plasters are available for manual and machine application. We will talk about compositions for manual application. For interior work, Forward, Weber Vetonit, Osnovit Startwell, Weber Stuk Cement are good. They fit well on a clean, pre-moistened surface. For better adhesion, it is better to prime the walls first, and after drying, start on your own

If you choose cement-based plaster for exterior work (including for plastering an open loggia or balcony), you need façade compounds. They differ from ordinary ones in the increased number of freezing/unfreezing cycles. Facade cement plasters - Yunis Silin facade, Osnovit Profi Startwell, Knauf Unterputz, Bergauf Bau Putz Zement. Ceresit CT 24 Light plaster is suitable for both facade and interior work.

Aerated concrete walls require special plaster. It has increased vapor permeability to prevent moisture from being trapped inside the wall. This is Ceresit CT 24, Knauf Grundband (contains the smallest particles of polystyrene foam, which increases its thermal insulation properties and reduces consumption).

Have you decided to renovate a house with your own hands, or to carry out the initial finishing of a new building, and don’t know which plaster to choose: cement or gypsum?

Before making a decision, you should familiarize yourself with the characteristics of modern building mixtures. We will offer you a comparative overview of different types of solutions, and tell you where and how they can be used. The video in this article will help you understand this issue.

Gypsum mixtures for internal plastering: composition, features, popular types of plasters

06.10.2019

A dry mixture based on gypsum with the addition of plasticizers is an ideal option for finishing work in a residential area. Especially if you plan to carry out the repairs yourself.

The fine powder is combined with water in certain proportions and mixed with a mixer until a light paste-like solution is formed. To level the surface, one layer of plaster is usually sufficient.

Advantages of dry gypsum plaster

The well-founded advantages of gypsum material have made it the most popular for interior decoration. The product outperforms its cement-based prototype due to:

- Environmentally friendly. The mixtures do not contain components that are harmful to health. Due to the low density of the finishing layer, the natural circulation of air masses is not disrupted.

- Plasticity. Optimal viscosity allows the solution to adhere to the surface without reinforcement. The finish does not flow or deform. If necessary, you can safely use even multi-layer plastering.

- No shrinkage. The surfaces do not develop cracks during the drying process, and the finishing results are predictable.

- Vapor permeability. The porosity of the plaster layer not only optimizes the microclimate, but also prevents the development of fungus and mold.

- Increased heat and sound insulation characteristics. Plaster finishing is an additional way to increase the energy efficiency of a home. Plastered walls are not cold to the touch, retain heat in the room, and also absorb noise.

- Low specific gravity. This characteristic allows you to minimize the consumption of the working solution and not overload the supporting structures.

- High hardening speed. A wall repaired with gypsum-containing mortar dries in three days. And only when applying several layers, the hardening process can take a week.

Top best gypsum products based on user reviews

Four types of gypsum-containing mixtures from different manufacturers have proven themselves to be the best for plastering heated rooms:

Knauf Rotband

(universal) – the most adhesive. For several years in a row it has been leading the ranking of the best building mixtures for repairing ceilings and walls. The properties of plaster, improved by polymer components and plasticizers, make it possible to finish any rooms, including those with high humidity (kitchens, bathrooms, toilets). A plastic material with high adhesive properties works on any base (including brick, concrete), creating a layer 5-50 mm thick. The only disadvantage of Rotband is its high cost.

Vetonit Profi Gypsum –

the most flexible. Microfibers and plasticizers in the gypsum base make it possible to apply smooth and uniform plaster up to 50 mm thick at a time. Moreover, these components prevent surfaces from cracking during hardening. Due to the increased adhesion of Vetonit, the range of use of working bases is expanding, from gypsum to concrete surfaces. The solution is easy to apply and level. However, there may be mixtures that harden almost instantly.

Volma Layer –

the most environmentally friendly. The inexpensive domestic mixture consists of a high-quality base, improved with mineral and chemical additives. The environmental friendliness of the composition is confirmed by certificates. The plaster breathes, maintaining a healthy microclimate. The material is ideal for finishing premises in medical and children's institutions. The solution is suitable for plastering plasterboard, brick, concrete and aerated concrete bases. After leveling with Volma, the surface becomes glossy, which makes it possible to do without puttying. The key drawback is the loss of elasticity after half an hour from the moment the solution is prepared.

Unis Teplon – with

the most economical in consumption. The fine mixture consists of gypsum, mineral additives and modifiers. The Teplon plaster coating has high thermal insulation and is able to normalize the humidity conditions in the room. The thickness of a single-layer finish can reach 50 mm. The key advantage of Unix is the whiteness of the surface after drying. Simply sand the base and you can begin painting or gluing. I am also pleased with the reasonable price of dry plaster. Among the disadvantages, builders cite weak adhesion.

Due to gypsum plastering, the air in the rooms will not be too dry or humid. And at a normal level of humidity, interior items last longer and people get sick less.

Consult a professional before purchasing a gypsum product.

Mortars: classification

If we talk about building mixtures in general, then they are, first of all, classified according to their intended purpose.

These are four main groups:

- Masonry mortars for installation work

- Facing (adhesive) solutions

- Plaster mixtures

- Decorative and special plasters (see Decorative plaster in the interior: beautiful, stylish, non-standard)

In terms of their component composition, they can be simple, based on one type of binder, or complex, with at least two binders. When thinking about which plaster is better: gypsum or cement, many do not even realize that there are also cement-clay and cement-lime mortars, as well as mixtures based on lime and gypsum (see Types of plasters for interior decoration: choosing the right one).

- In large-scale construction, these types of plasters are most often used. They are made at on-site putty stations, or delivered ready-made from the nearest mortar-concrete unit. During the preparation of the solution, additives are introduced into it to provide certain characteristics, and the recipes can be quite complex.

- It is almost impossible to make such a solution yourself, so dry mixtures that are already balanced in components are produced for private construction. In production, their compositions are modulated using polymer additives, which makes it possible to obtain a material with desired properties. The more complex the composition, the higher the price of the material, and this is quite understandable.

- Factory mixtures have an undeniable advantage: just add water, as the instructions say, and you can work. It is convenient to mix a small amount of solution so that one person can quickly work it out. Moreover, the use of ready-made mixtures allows you to avoid errors in the recipe of each batch, and for those who plaster walls and ceilings on their own, this is the best option.

- Finishing plasters are divided into two categories: leveling mixtures and solutions with a decorative effect. Each of these categories may vary in composition, depending on the purpose: for facade (see Facade plaster using foam plastic or penoplex) or for interior work.

There are options that, due to the presence of silicone, acrylate resins, or polyurethane, are considered universal and can be used both outside and inside buildings. They are called polymer-cement or gypsum-polymer, or simply modified, and you see one of these options in the photo above.

Requirements for finishing mixtures

As you can see, there are many recipes for plaster mortars, and to answer the question: “Which is better: cement or gypsum plaster?” – not as easy as it seems. Naturally, the characteristics of the solution are determined by its purpose, but there are requirements that all finishing compositions must meet.

So:

- First of all, this is appropriate mobility and high adhesion. In addition, it is necessary that the solution retains its volume when dried. That is, to avoid cracking of the screed, the plaster must be non-shrinking.

- The degree of mobility of the solution may vary depending on the filler fraction. For example, mixtures for machine application may be less mobile than solutions for manual plastering.

- Gypsum plasters should be the most flexible; for this purpose, organic plasticizing additives are added to them. Gypsum-based solutions set very quickly, so their hardening time also needs to be regulated. As in the case of mobility, this is achieved by introducing special additives into the composition.

- Decorative plasters are distinguished by the highest plasticity, because such a composition must not only be applied and leveled, but also have time to mechanically process the covering layer before hardening.

- In their production, white and colored Portland cements are used if these are compositions for exterior finishing, and gypsum if the plaster is intended for interior work. Lime can be added to both mixtures - for example, if they are intended for plastering walls made of silicate concrete.

Finishing plasters made from organic fillers use only sand. As for decorative solutions, depending on the effect, they may contain crushed glass or mica, marble or granite chips, crushed limestone, dolomite, as well as artificial and natural pigments.

Gypsum plaster or cement plaster – what to choose for the bathroom?

Leveling the walls is a mandatory procedure, and difficult for a beginner. But the fact is that the quality of work depends not only on the professionalism of the person, but also on the choice of mixture. Gypsum plaster or cement plaster? Difficult choice. Each mixture has its own characteristics. In this article we will look into this. We will point out the pros and cons of each material.

Gypsum plaster - features

This is a popular and frequently used material. Wide application. Gypsum plaster is a powdery dry mixture. The consumables contain fine gypsum and various types of modified plasticizers - artificial and natural fillers, polymer additives.

Application

The scope of use of the material is large. Gypsum plaster in the bathroom is used for:

- leveling walls;

- preparing surfaces for wallpapering or laying ceramic tiles;

- decorative wall cladding.

Gypsum plaster is an excellent option for finishing brick and concrete. When using this mixture, you do not need to use additional putty.

Advantages of gypsum plaster

A gypsum-based mixture is a good solution for the bathroom. Let's not be unfounded. Below we list the advantages of the material:

- gypsum plaster is an environmentally friendly mixture. When used, it does not emit substances harmful to humans into the air;

- By using this material, you will forget about shrinkage. After hardening, the plaster does not crack, and the surface remains as smooth as before hardening;

- the weight of the mixture is low relative to other materials. This allows you to reduce the load on the walls during repairs;

- gypsum plaster is plastic. This allows you to apply a thick layer of solution without using a reinforcing mesh;

- The material has good vapor permeability. The porous structure ensures the circulation of moisture, so the likelihood of mold and mildew formation is excluded;

- Gypsum plaster is applied easily and simply. Hardens quickly. Even if a thick layer is applied, it will harden within 2-3 days;

- provides warmth and sound insulation of the room. The bathroom will always be warm and quiet.

These are the key advantages. The material is universal and excellent for interior decoration. The stores offer a large selection of mixtures from different manufacturers. The cost varies, but starts from 148 rubles. per package of 5 kg .

Disadvantages of the material

Despite its benefits, gypsum plaster is not an ideal mixture for a bathroom. There are some nuances that need to be discussed:

- The material does not tolerate excessive moisture. Therefore, it must be used extremely carefully in the bathroom. Suitable for leveling walls near which there are no installed plumbing fixtures or water sources.

- The cost of gypsum plaster, compared to other solutions and mixtures, is the highest. Sometimes the price tag is 1.5 or 2 times higher than that of a cement mixture.

Despite these disadvantages, gypsum plaster is popular and preferred by most people. As for the bathroom, we recommend using it where there is least interaction with water.

Cement plaster in the bathroom

This is another popular type of material for leveling walls. Cement plaster, unlike gypsum plaster, is durable and extremely reliable. To form a solution, only cement, sand and water are required. By mixing them, you get a solution that has been used for a very long time in the construction industry.

For what?

Before we list the advantages and disadvantages of such a material, let’s figure out where and when cement plaster is relevant. It is appropriate to use it to:

- level the walls;

- use as a finishing material indoors and outdoors;

- Use in rooms with high humidity to prepare walls for painting, wallpapering or tiling.

This is a universal material. Cement plaster has excellent technical qualities. We'll talk about them in the next section.

Advantages of cement plaster

There are many advantages to such a mixture. Let's focus on the key ones:

- cement plaster is very durable. Other materials, including gypsum mixture, are inferior to this solution;

- due to the quick and reliable adhesion of the wall to the material, this type of plaster is durable;

- The cement mixture has excellent moisture-resistant properties. The solution is allowed to be used in the bathroom. This is an ideal solution for finishing walls in a shower stall or above a bathtub, near the sink;

- low cost. Cement plaster is available to absolutely everyone.

In the store you can buy dry mixture from different manufacturers. Cost varies depending on brand and package size. The price starts from 96 rubles. per package of 5 kg .

Disadvantages of the material

Although this material has advantages, it is not without its disadvantages. Let's list them:

- plaster has a high specific gravity, so you need to accurately calculate the load on the wall;

- hardens for a long time. On average you need to wait 2 weeks;

- the application procedure is complex and takes place in several stages;

- to level the wall you will have to use reinforced mesh;

- cement plaster is not used for finishing walls, as it has an unsightly gray color, but only for leveling them;

- After the solution hardens, additional work is required - puttying the surface.

Application of plasters

Cement-based solutions are the most durable, and when dry they form a stone that is practically impervious to moisture. That is why they are used for plastering facade walls, as well as rooms with high levels of humidity. Pure cement mortars are not very plastic, which is why lime or polymer additives are added to them.

- Lime-cement and lime-gypsum mortars are good for plastering wooden surfaces. Polymer-cement compositions are ideal for systematically moistened structures. So, if you need to carry out protective plastering of basement walls, this is the best option.

- Inside the house, such compounds are used only for leveling walls in bathrooms. In other rooms, they are recommended to be used only for making leveling screeds for facing with ceramic tiles or natural stone. This is important, because the strength of the base should always be higher than the strength of the coating.

In other cases, gypsum-based solutions are used for interior decoration of residential buildings and apartments, and readers’ interest in them is the highest. For this reason, we will pay more attention to the question in what situation and which gypsum plaster to choose in order to perform leveling at the lowest cost.

Types of gypsum compositions

So, you went to a hardware store to buy the necessary material. Before you is a considerable assortment: gypsum plaster - which is better? Let's look into this issue together.

The main criterion for selecting a plaster mixture option is the quality of the base. Therefore, before you go to buy building mixtures, the condition of the surface that needs to be plastered must be assessed.

- To do this, you first need to clean it if this is a repair, or immediately hang it if this is a primary finish. This will make it possible to calculate how thick the screed should be, and accordingly, decide which gypsum plaster is better.

This does not mean products under a certain brand, but the physical and mechanical properties of the mixture, which are declared by this manufacturer. So, the best gypsum plaster is the one that meets a specific task, in which there are two main conditions: the type of surface and the size of its deviations from the plane.

Plasters for different types of surfaces

When it comes to apartments, most often the walls in them are either built from large panels, which are made from heavy concrete, or they are masonry made of silicate - less often, red brick.

So:

- In private houses and cottage construction, blocks of lightweight and cellular concrete are often used. They are also used in the construction of multi-story frame buildings. In them, the main load is carried by the frame, and light blocks of a small format are very convenient for the construction of enclosing structures.

- Of course, the design features of buildings do not play any role in choosing plaster. But it matters what kind of filler is used in the production of concrete blocks from which the walls are built.

- For polystyrene concrete, gas silicate blocks and foam blocks, special plasters are provided (see How to plaster foam blocks according to technology) that provide increased adhesion and vapor permeability of the screed. In principle, adhesive compositions used for masonry work can be used to plaster such surfaces.

- That’s what they are called: adhesive plasters, and they are always made on a cement basis. Gypsum-based compositions are used only for plastering, since they are not suitable for masonry and installation work. Due to the large number of pores, which can be either closed or open, cellular concrete intensively allows moisture and air to pass through.

- The compositions for plastering them often contain perlite - an organic filler, which, due to its low thermal conductivity, belongs to the category of thermal insulation materials. Perlite granules partially close the pores on the surface of the concrete, while simultaneously allowing the walls to “breathe.”

In general, lime-cement and lime-gypsum plasters are simply ideal for plastering such surfaces. The technology for producing plastering work on a concrete base with a cellular structure also has its own characteristics, but this is a completely different topic.

For interior decoration of walls made of brick and heavy concrete, any gypsum plaster compositions, and not only gypsum, are suitable.

Application of gypsum plaster.

Such plasters are mainly used in interior finishing

surfaces of rooms that do not have increased dampness. For example, in residential premises, in offices, in premises intended for shops.

The main purpose of gypsum-based plaster is to level the surface and prepare it for decorative finishing.

The ability to apply a thick layer of material allows you to remove all irregularities on the surface, ranging from minor defects to damage and holes.

You can use gypsum plaster to level the surface, paying attention to the areas that are piled back.

Interior work: why gypsum mixture is better

Preference is given to gypsum-based compositions due to their white color. For interior work, water-dispersion paints are mainly used, but they do not have such high hiding power as, for example, oil paints or alkyd enamels.

This means that in order to paint over a dark cement screed, you will have to apply more layers, which leads to waste of material.

- Even when wallpapering, cement plaster can be visible through a thin light-colored canvas and spoil the entire aesthetics of the finish. For this reason, when leveling walls indoors, cement-based compositions are used only for tiling.

- And one more important nuance. Many readers are interested in: “How long does it take for gypsum plaster to dry?” Of course, this depends on the thickness of the layer and the room temperature. But in any case, the gypsum screed will dry twice as quickly as the cement screed. In the first case, a layer of 1 mm hardens in 4-5 hours, in the second case, it will take 8-10 hours.

Answer to the question: “Gypsum plaster: how long does it take to dry?” - quite simple. In practice, each layer usually takes at least 12 hours to dry. That is, during the day they apply a layer of plaster, say, 2 mm thick - it dries overnight, and you can safely continue work in the morning.

If the unevenness of the base base is such that it is necessary to plaster with a thick layer of 15-20 mm, then it may take at least 3-4 days to dry.

Finishing plaster: cement or gypsum

Now the finishing materials market is overflowing with leveling mixtures. There are both modern materials and “time-tested” ones. Among all the variety, the most popular leveling mixtures are plasters based on gypsum and cement. We will tell you what their difference is, and what plaster to use for what purposes in this article.

Cement plaster – time-tested strength. Cement plaster is very durable and hard. Thanks to these qualities, it is quite durable, and what is its greatest advantage is that it is not afraid of moisture and temperature changes. Cement plaster can be used in bathrooms and toilets, as well as in unheated rooms and even on the facade.

Of course, cement plaster is not without its drawbacks. Take, for example, the dust that is formed both during the process of mixing the mixture and when processing the finished surface. In addition, cement plaster is difficult to apply and dry. Which naturally increases the finishing time with its use.

In addition, it is important to know that cement plaster is not a “warm” material. Therefore, if you are going to decorate the walls with it, it is important to choose the right heating equipment. To find out more about this, click on the website.

The difficulty in application, I would even say a large expenditure of effort and energy, is due to the technology of covering the wall surface with raw cement plaster. To implement your plan, you need to put a grater with a solution in one hand and take a spatula in the other. Taking a little mortar with a spatula, you need to vigorously move it into the wall. The wall must be pre-moistened with water. Only this technology will allow cement plaster to adhere well to the wall.

So, having covered the wall, you need to start rubbing the plaster. The wall with the applied leveling layer is rubbed using a trowel. Those places where, after rubbing, there is a shortage of plaster, need the addition of this material.

If the area is large enough, then it must be rubbed using a special rule. Due to its shape and dimensions, this tool is ideal for solving such problems.

The first layer is made no more than 5 cm. Otherwise, it will not be very convenient to work, and the plaster may peel off from the wall during the drying process. The second layer is applied after 6 hours. If the room temperature is not high, the drying time will increase.

Cement plaster hardens completely within 3-4 weeks. The wall with the applied cement-based leveling mixture should be rubbed down no earlier than 12 hours have passed.

Gypsum plaster – ease and comfort in work. Gypsum plaster is quite easy to apply. In addition, it dries quickly and produces little dust during operation.

Naturally, compared to cement plaster, a gypsum-based mixture also has its disadvantages. Firstly, this is a fear of moisture, and secondly, this is the lower strength of such plaster. Gypsum plaster is intended only for heated rooms with low humidity.

Before you start working with gypsum plaster, you need to read the packaging. Namely, the place where the setting time of this leveling mixture is indicated. The thing is that such plasters take about half an hour to set. So before work you need to mix as much of the mixture as you can produce during this time.

As a rule, to apply gypsum plaster, they hire a qualified craftsman who feels all the stages of setting the mixture, which are very important in the work process.

Gypsum plaster dries completely in 2-3 days. The next layer can be applied after 2 hours.

General rules when working with plasters. You can work with leveling mixtures at a temperature of no less than 5 degrees and no more than 30. Before working with plasters, you need to prime the surface for better adhesion. This will also avoid problems with fungus and mold. When working with plasters, you need to postpone the remaining finishing work until the applied mixtures have completely dried.

To save on material, as well as your time, it is advisable to hire a specialist to level the walls with plaster. If you want to do it yourself, then start first with a small wall and using beacon profiles.

Selection of plaster according to the quality of the base

Gypsum plaster: which is better? Which option should you prefer if the walls are relatively flat, and which option if the brickwork is curved? In this part of the article we will discuss the principle of selecting a mixture based on the quality of the base.

- If the walls or ceiling do not have significant deviations from a single plane, it is often enough to putty small cracks and surface cavities, and then apply a thin layer of plaster.

- According to this principle, walls in panel houses are plastered, cosmetic repairs are made to old, but still strong plaster, and surfaces that are leveled “dry” are prepared for painting using drywall.

- For such walls, gypsum-polymer compounds are usually used that do not require puttying. Due to their high ductility, they have excellent adhesion and are suitable for plastering almost all surfaces, even foam concrete walls. In any case, you need to read the manufacturer’s instructions, where the purpose of a particular composition, as well as the thickness of the applied layers, are clearly regulated.

- Everything related to masonry: be it brick or block, does not look so optimistic. Walls built from blocks are even more or less even. But brickwork can rarely boast of high quality, because, as a rule, everything goes into work: bricks with potholes, chipped corners, cracks.

- Therefore, even if there are no bumps or large recesses in the masonry, there are still many other shortcomings that have to be eliminated during the plastering process. To level such walls, it is necessary to use compounds with different filler fractions.

- Starter plasters, or, as they are also called, base plasters (putties), have a coarser dispersion and are applied as the first layer to a primed wall. This layer is the thickest and is designed to hide the largest defects in the base.

- If the depth of the recesses exceeds 2 cm, and this happens quite often, leveling can be done in two layers, between which a reinforcing fiberglass mesh is mounted.

- Since the components of the base putties have a fairly large dispersion, the surface of the screed turns out to be grainy, and a finishing compound is used to smooth it out. Its ingredients are finely ground, so the dry mixture is more like powder.

- The finishing plaster solution is unusually elastic, and when applied to the starting screed, it fills the smallest pores and cracks in it. Thus, the surface is brought to perfect smoothness.

Finally, let us remind you that it is better to purchase “start” and “finish” mixtures from one manufacturer. In this case, you can be sure that their compositions are maximally adapted to each other and will not create any problems in the work.

Features of cement plaster

Essentially plaster or facing material, which is designed to level the walls. Based on this, it is impossible to give a definite answer which type of plaster is better; everyone chooses certain factors for themselves. Positive aspects of cement finishing mortar:

- It's universal.

- Plastic, ready to maintain a soft structure for several hours.

- The cement becomes strong.

- Acceptable price.

Negative sides:

- This mixture does not fit well on a concrete base.

- In order for the thick layer to finally exhale, it takes 14 days.

- The humidity level in the room becomes higher due to the mixture.

- The color of the cement base makes the room appear grey.

- Ultimately, it is also necessary to apply finishing putty in order for the walls to become white.