15029 0 8

Mullvatt September 7, 2016Specialization: Capital construction work (laying a foundation, erecting walls, constructing a roof, etc.). Internal construction work (laying internal communications, rough and fine finishing). Hobbies: mobile communications, high technology, computer equipment, programming.

Only thanks to insulation, a comfortable microclimate for living is formed in the attic.

Some time ago I completed an order to insulate the attic for winter living. While doing the work, I thought that the technology I used was quite simple and even an untrained person could make thermal insulation from the inside with his own hands.

In today’s material I will tell you what is better and how to properly insulate an attic from the inside with your own hands. This instruction will help you avoid making mistakes that I had to face at the beginning of my construction career.

I assure you, upon completion of the work, the attic floor of a wooden house will turn from a useless storage of rubbish into a cozy and comfortable room in which all your household members will fight to live.

General points

Let's start with the fact that the attic is a bit of a special room. Its overall structure requires a careful, meticulous approach. And the insulation of the attic roof is even more so:

- Mostly vertical or inclined surfaces . Therefore, it is better to immediately exclude all soft “pliable” materials, namely mineral wool rolls.

- It is advisable to focus on materials with low dead weight . Since the rafter system is already experiencing significant loads from wind and snow. In addition, the load on load-bearing walls will not increase much.

- Often insulation is required for gables . They are not always made by analogy with a main wall. May be made of facing material. Or the frame is simply built for insulation.

- It happens that the area of the attic significantly exceeds the size of the house itself , while part of it rests on columns. In this case, you will also have to insulate the ceiling in contact with the street.

If the attic floor protrudes beyond the house, additional insulation of the floor is required. Source metasold.com

It should be understood that the thickness of the insulation must correspond to the weather conditions of a particular climate zone, while having a small margin. To gain the required thickness, the insulation is installed in several layers, and the relatively small dimensions require joining.

Important: splicing any insulation requires a careful approach. The joints of different layers should not be concentrated in one place. To prevent freezing, they should be spaced as far apart as possible. It is important to constantly remember this so as not to spoil the material, especially when insulating a sloping roof.

Features of geometry: insulation of the attic from the inside if the roof is already covered

On the one hand, there seem to be no particular difficulties in solving the question of how to properly insulate an attic from the inside with your own hands. But it was not there. The main difficulty may lie in the geometric shapes of the roof, especially if you tried to make it as attractive as possible. As a rule, the shape of the attic floor follows all the curves of the roof. The insulation is mounted directly on sloping walls. By the way, a heat insulator that is too elastic can sag, so it is important to think about how to securely attach it.

But what if you've added a pointed cone to your roof or other architectural flourishes? In this case, you will have to slightly correct the geometry from the inside using additional walls or even a ceiling.

An example of working with uneven ceilings in the attic in this video:

As you can see, it is quite possible to slightly correct the geometry from the inside, if necessary. In this case, all insulation work must be carried out on installed additional partitions.

Preparation

All wooden surfaces must be treated with antiseptic and fireproof impregnations.

All wooden components must be treated with protective materials Source remontik.org

It is necessary to immediately identify “unreliable places” on structural elements. For example, the connection of the outer rafter to a pediment made of facing bricks. Or an overlapping connection between a rafter and a screed, made without insulation. It is necessary to eliminate the shortcomings - if possible, foam them or line them with a sealant. Otherwise, they will not be able to withstand through blowing and freezing.

It is necessary to minimize the use of metal fasteners. This is especially true for metal linings secured with bolts. Of course, the bolted connections will remain, but the plates should be made from thick, durable plywood and replaced. The remaining metal parts are painted with primer-enamel and covered with a layer of polyurethane foam. Metal directly in the insulation is a source of condensation and dampness.

Insulating the attic roof

Insulation of the entire roof or part of it is carried out according to the standard scheme after installation of the entire supporting structure:

- A superdiffusion membrane is laid on the outer side of the rafters, starting from the eaves towards the ridge.

The canvases are fixed to the rafters with a stapler and a counter-lattice beam, at least 5 cm high, is nailed on top. It sets the ventilation gap between the membrane and the roof. If a vapor-waterproofing film like Izospan DM is used, two ventilation circuits must be created. The first block (2 cm high) is attached to the rafters, and a film is fastened to it with a stapler - this counter-lattice sets the 1st circuit for ventilating moisture vapor from the insulation and preventing the wooden structural elements from getting wet. The second block (5 cm high) serves as the basis for installing ordinary roof sheathing and creates a 2nd circuit for weathering condensate. - Semi-rigid thermal insulation mats are laid between the rafter legs. If it is a combined roof, so that the insulation does not slip, a transverse sheathing is installed between the rafters below the mounting point for the racks.

- From the inside, a vapor barrier with an anti-condensation or reflective surface is attached to the insulation in a continuous layer towards the room.

- Install the sheathing for the interior lining. It also creates a ventilated gap necessary for the evaporation of condensate or the normal “operation” of the reflective surface of the vapor barrier.

Read more in the article: how to insulate an attic roof.

In combined roofs, insulation between the rafters can be laid from the tightening to the line of intersection with the wall. From the inside, additional sheathing is installed for another thermal insulation layer of the roof along the perimeter of the attic.

Insulation of the rafter system

It’s great when the insulation of the attic from the inside was planned in advance, or “just in case” the constructive points for this were observed by the builders:

- A roofing membrane is mounted on the rafters.

- A counter-lattice is provided.

- The pitch of the rafters is maintained corresponding to the common length or width of the insulation.

It is convenient to carry out insulation if it was planned at the construction stage Source bamban.ru

It is worth noting that these are ideal initial data that allow you not to look for a “way out of the situation” and to insulate the maximum volume of the attic efficiently without extra costs. Such conditions make it possible to use vapor-permeable insulation. And these are comfortable living conditions.

See also: Catalog of projects of houses with an attic presented at the exhibition “Low-Rise Country”.

Insulation materials

As mentioned above, mineral wool is the most popular. It is well suited for this purpose, but is not ideal, as it is afraid of moisture. Accordingly, you have to take care of its careful protection from all sides so that it does not lose its own properties.

Expanded polystyrene

Extruded polystyrene foam or polystyrene foam is used for roofing. Polystyrene foam has good performance, but emits toxic compounds when burned. You can also find so-called self-extinguishing modifications with special additives. They are best used for roof insulation.

The key advantage of polystyrene foam is its affordable price. It is quite easy to install. It is enough to install the material between the rafters and then cover the joints with foam. It is convenient to use polystyrene foam to insulate the attic from the inside. You can order slabs of the required size, which are 15 mm larger than the clearance between the rafters. They must be installed tightly. The elasticity will allow them to stick well.

The ventilation gap is left on the roof side. Install waterproofing. But it is most effective in relation to wooden structures, since polystyrene foam is not afraid of moisture. It almost does not absorb it and does not conduct steam. This is where the main drawback lies. The fact that the material does not allow steam to pass through means that it will incur additional costs. It is necessary to equip a good ventilation system.

Extruded polystyrene foam has more advanced characteristics. Under the same conditions, its thickness is 2 times less than that of similar materials with the same density. Compared to polystyrene foam, this figure is one and a half times less. It has a locking system that reduces the possibility of gaps appearing through which heat will escape.

Another advantage is the lack of interest in the material from rodents and insects. Fungus and mold do not multiply on it. The only thing that limits its use is its hefty price. Yes, and an additional ventilation system will be required.

Insulation of an unprepared roof

When the decision to insulate is forced, the roof is usually not prepared. There is nothing terrible about this, it is even possible to choose the following options:

- Insulate with materials that do not require waterproofing.

- Build a special frame for living space.

In case of insulation of a roof that is not prepared for this, special compounds can help Source paspraypros.com

Foamed polyurethane foam can play a special role here. Although equipment is required to apply it, insulation occurs in a continuous layer and does not depend on the design features of the roof.

Foamed polyurethane foam is one of them Source da.decorexpro.com

This also includes ecowool. Although its installation requires a roofing membrane, it is quite possible to make a continuous layer of insulation.

What materials are included in the insulation system?

Thermal insulation of the attic is made using various materials. The insulation system most often used by specialists includes three layers. Let's look at them in more detail:

- vapor barrier;

- thermal insulation;

- waterproofing.

The vapor barrier film performs a very important function, namely: it prevents the penetration of water vapor into the room. Without it, unwanted condensation will form on the inner walls. The waterproofing material is represented by a moisture-proof membrane.

The thermal insulation layer is the main one. There are many materials that can be used for high-quality insulation of an attic space. For self-installation, experts recommend choosing the most environmentally friendly of them. Ecowool and mineral wool are the leaders in this indicator. The second option is more preferable, since the cost of mineral wool is lower.

Note! It is best to insulate the structure from the outside. This will protect the attic space from freezing, as well as condensation on the walls. External work should never be carried out in rainy weather

Before starting installation, you should inspect the roof. It is also strongly recommended that you familiarize yourself with the educational video material, which covers the topic of attic insulation in more detail.

External work should never be carried out in rainy weather. Before starting installation, you should inspect the roof. It is also strongly recommended that you familiarize yourself with the educational video material, which covers the topic of attic insulation in more detail.

Effective insulation

Next, we will consider the most effective materials that do not require serious equipment in order to efficiently insulate the attic.

Stone wool

Due to their elasticity, the mats adhere well between the rafters and allow installation without additional fastening. And the relatively dense structure of stone wool prevents its shrinkage over time. Therefore, it has proven itself well on vertical surfaces.

Stone wool mats come in different thicknesses, and you can choose the one you need based on climatic conditions and other materials used Source pallazzo.su

To further reduce the risks, every 3 meters of height it is necessary to arrange supports for the insulation - add a horizontal frame element.

Indoor insulation

This option makes it possible to postpone interior finishing work for some time. This will be useful to those owners of residential buildings who do not have enough funds. After installing the rafter system, you need to do the following:

- roll out the waterproofing and fix it;

- fill the sheathing or counter-lattice, if necessary;

- install roofing material.

This is the entire list of necessary work at the first stage. As soon as it becomes possible to continue, it is necessary to insulate the attic roof from the inside. It will no longer be so convenient to work. The fact is that you will have to equip the enclosing structure. It prevents the insulation from being pushed out higher than required. The mineral wool will have to be fixed somehow. She may fall on her head.

Algorithm of actions:

- The columns are filled with a step of 40 cm between the logs. They will retain heat and provide a ventilation gap.

- Thermal insulation of a certain thickness is laid, and then secured.

- The sheathing is stuffed to hold the insulation in place.

- Cover the vapor barrier membrane and glue it.

- Install sheathing and finishing materials.

When it comes to laying thermal insulation material, it is important to take into account a number of features. If you use high-density mineral wool mats, everything is more or less simple. They hold up well on their own. If rolled mineral wool is laid, the work becomes more complicated. When insulating a room, the insulation is laid in the direction from bottom to top.

Take a lace and a construction stapler. Roll out the roll and press the material against the columns. A piece of lace is secured with staples, as if drawing the English letter Z. The first layer is secured, then the second and the rest. In general, if you want to provide your attic roof with a comfortable temperature in any weather, it is better to take mineral wool mats with a density of 30 to 50 kg per cubic meter. They are quite rigid and allow the material to hold its shape. Softer rolled products may cake on vertical surfaces. They seem to settle down, reducing the thermal insulation capabilities of the attic roof.

Proper completion of work

The insulation has been installed, but the process must also be completed correctly. It must be protected from damp vapors from the room. For this, a vapor barrier film is installed. Moreover, the overall result greatly depends on the thoroughness of execution. Although each package is supplied with instructions, let us briefly repeat:

- The subsequent canvas overlaps the previous one by at least 15 cm.

- The joints are taped with special tape.

However, attic vapor barrier has a dual purpose. Oddly enough, it also protects the residents themselves. The fact is that vapor-permeable insulation is not strong enough and can be slightly weathered. From the outside this is not so important, plus it is protected by the roofing membrane. And inside it is necessary to exclude even the minimal possibility of the insulation components being released into the air - to reliably cover it.

The final stage is covering the insulation with canvases, on which the finishing is subsequently applied. Source obustroeno.com

Of course, this does not apply to Penoplex. But it is also recommended to protect against it; an effective material is penofol.

As for insulation of any type. In addition to the vapor barrier device, a technique that at first glance is unnecessary, but effective, is often used. Before finishing, intermediate, seemingly unnecessary material is installed. It can be OSB, GVL or GKL - it depends on the design. Moreover, the technology is fully observed - all joints are carefully sealed. This is an additional barrier against the unwanted effects of materials.

Laying vapor barrier

Vapor barrier deserves a special mention. This should also be a membrane material. Which products do not fit the specifications:

- polypropylene;

- polyethylene film.

The fact is that the vapor permeability of a given layer , expressed in grams per square meter, should be minimal. Ideally it is zero. It turns out that the layer of material should not allow vapors to pass from the room into the insulation. The use of mineral wool is very important. After getting wet, it loses more than half of its properties. If it freezes while wet and subsequently melts, its structure will crumble.

For this reason, vapor barrier film is laid with one panel overlapping another. Often these joints are taped with special double-sided vapor-tight tape. This product is somewhat reminiscent of adhesive rubber. Simple stationery or masking tape will not work. It does not guarantee absolute protection against steam. In addition to the joints, any junctions located above and below, as well as on the sides, are also glued.

The vapor barrier is usually secured with a fist using staplers. The internal sheathing strip for installation of the sheathing is also suitable for this purpose. Another ventilation gap is formed here. The lining can be fixed directly on top of the membrane.

Selecting the type of insulation

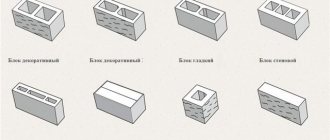

Modern industry offers three types of heat-insulating materials: slabs, rolls, and shapeless (foam). In this case, we do not consider bulk insulation, since insulating inclined and vertical surfaces with bulk materials is extremely inconvenient.

The material for insulating the attic should be selected in accordance with the design and necessary parameters of the heat-insulating layer, namely density, thermal conductivity and vapor permeability.

Density affects the weight of the material - it is undesirable to make the rafter structure too heavy, especially if it was originally designed “end-to-end”, without a margin of safety. Insufficient thermal conductivity will significantly increase heating costs, and poor vapor permeability will lead to increased humidity in the room.

Accordingly, the optimal choice for the attic would be:

- when covering with plasterboard or other similar materials - mineral wool. Plates or roll sections (depending on density) are laid in the spaces between the rafters. The spacer beams remain visible, the inclined elements of the attic are covered with sheet material;

- expanded polystyrene, regular or extruded, as well as polystyrene foam - for plaster or plasterboard finishing, if the finishing is not afraid of high humidity;

- polyurethane foam for complex roof geometry and in the presence of additional elements that complicate insulation with slabs or rolls.

If, in addition to the walls and ceiling of the attic, it is also necessary to insulate the floor (actually the floor between the first and attic floors), it is permissible to use either any of the listed heat-insulating materials or bulk insulation materials. More on this later.

Which insulation to choose for the attic

The question of what is the best way to insulate an attic from the inside is a very pressing one, and reviews on forums vary radically; each material has its undoubted advantages, as well as disadvantages.

Styrofoam

Insulating the attic with polystyrene foam is the most cost-effective option to keep the room warm. To insulate the attic space, you will need a layer of foam plastic with a thickness of at least 100 mm. This is an almost weightless material, easy to install, suitable for insulating children's rooms and attic bedrooms. But it burns, becomes infected with mold, and in addition, rodents use it to organize their passages throughout the house. Despite the fact that this method of insulation has stood the test of time, the question of whether it is worth insulating the attic with polystyrene foam, reviews vary from “in no case” to “only polystyrene foam,” remains open. We invite you to watch the instructions, which tell you in detail how to insulate an attic with polystyrene foam; the video clearly demonstrates all the advantages and disadvantages of working with this material.

Extruded polystyrene foam

Insulation of the attic floor with extruded polystyrene foam is usually carried out from the outside of the building. Although many people think of this material as foam, their chemical composition is very different. Expanded polystyrene tolerates chemical influences well, has a thermal conductivity lower than that of polystyrene foam, and practically does not allow moisture to pass through. Even if water has penetrated the surface of the insulation, the material will retain its thermal insulation characteristics during freezing and thawing. Expanded polystyrene has different densities; the higher this indicator, the heavier the insulation; the lower the density, the better the heat and sound insulation properties. But extruded polystyrene foam is destroyed upon contact with complex carbohydrates, and it is also deformed by ultraviolet rays, therefore, when arranging a residential attic, it is not recommended to use nitro-based paints.

Watch the video on how to insulate an attic with your own hands using extruded polystyrene foam

Penofol

Insulating the attic with penofol is financially expensive compared to polystyrene foam. This is a new roll insulation that is a competitor to mineral wool. It has a low thermal conductivity coefficient, a good thermal insulator, and is resistant to moisture. A huge advantage of penofol is that it protects the room from the effects of radioactive substances, but does not tolerate mechanical loads well, and requires skills when laying the thermal insulation layer; violation of the technology leads to a deterioration in the thermal insulation characteristics of the insulation.

Spraying polyurethane foam

Thermal insulation made by spraying polyurethane foam has no joints and, therefore, cold bridges. Such insulation does not require the cost of preliminary preparation of the attic for thermal insulation; the material is poured to the thickness of the attic rafters or more. The insulation is sprayed directly onto the walls, floor, and ceiling using special equipment. Polyurethane foam is resistant to fungi, and practically does not allow moisture to pass through, but does not tolerate the effects of esters and concentrated acids.

Ecowool

Ecowool consists of 80% cellulose, and 20% antiseptics and fire retardant additives. When using this material to insulate an attic, you need to take into account the volume, since the insulation is greatly loosened. To perform high-quality insulation of the attic with ecowool, you should apply a layer about 200 mm thick. This is an environmentally friendly insulation material, it is applied to surfaces like papier-mâché, manually or mechanically, and does not form joints. It has a low thermal conductivity coefficient, is resistant to fungi and bacteria, and practically does not burn. Installation of the thermal insulation layer requires knowledge of application technology and professional skills.

Insulation with ecowool, this method of thermal protection requires skills and knowledge of the technology of applying material to surfaces

Mineral wool

Using mineral wool for insulation is the most popular way to keep heat in the attic. Depending on the composition and density of the wool, it can be placed in a spacer or in a special frame. Mineral wool does not rot, but absorbs moisture, because of this its thermal insulation characteristics are reduced, and the insulation saturated with moisture becomes noticeably heavier, which puts significant loads on the rafters and roof of the attic. When insulating with mineral wool, there is practically no waste left and it is easy to cut. To insulate the attic floor, a layer 100-200 mm thick is required, depending on the design features of the structure. When working with mineral wool, you should wear a protective suit and goggles.

Insulation of the attic, video instructions on how to properly lay a thermal insulation layer of mineral wool

Sawdust

I would like not to abandon the old, old-fashioned and almost free method of insulation. Construction of a thermal insulation cake using sawdust. This is an environmentally friendly, time-tested method of insulation. Sawdust is mixed with lime and an insulating layer 100 mm thick is laid. Such thermal insulation is several times inferior to modern insulation; in addition, it is a fire hazardous insulation method. But if this is a country house, and according to the design the attic is a cold, unheated room, then this method of insulation is completely justified.

To insulate the attic, you can use both traditional materials and modern insulation materials, the main thing is to correctly calculate the thickness of the thermal insulation layer

Now the market is represented by a huge selection of insulation: rockwool stone wool, slab foam, backfill, plates, mats, etc. Which insulation is better for an attic depends on what room should be insulated: if it is a warm attic, then basalt wool, PPU, and if it’s cold - polystyrene foam and sawdust. The second criterion for choosing insulation is how much you are willing to spend on thermal insulation. It is believed that in principle there cannot be universal insulation materials; each of them has its own advantages and disadvantages. We tried to select for you the most useful tips on how to insulate an attic; video materials will help you understand the intricacies of thermal insulation with each specific material.

Subtleties of insulation and hydro-vapor barrier of the attic

How to install insulation correctly?

When thinking about how to insulate the attic floor, we often lose sight of important things. For example, how correctly the material was laid plays a big role in the effectiveness of insulation.

- The material should be laid in two layers, with the second covering the seams and joints of the first.

- The thickness of the rafter legs and the first layer of insulation should be the same. Otherwise, the slabs of the second layer will get bent, which will lead to a loss of joint density.

- The width of the insulation should be equal to the distance between the rafter legs. This way the slabs will lie flat, with complete abutment, and the insulation of the attic floor from the inside will be complete.

The second layer of insulation does not stay in place, what should I do?

There are usually no problems with insulating the attic with slab materials - they fit between the battens of the counter lathing at a loss. Rolled types are soft, they sag and, as a result, fall out of their place. A logical question arises: how to properly insulate an attic with your own hands so that everything is securely fixed? The problem is solved with nails and synthetic cord:

- We hammer small nails along the edges of the counter batten slats.

- The cord is tied to the topmost nail.

- The material is put into place and secured with a cord, overlapping from one slat to the other.

We work like this until we finish insulating the attic with our own hands.

How to insulate walls under roof slopes?

If the internal walls of a residential attic under a sloping roof are made vertical, in addition to choosing how to insulate the attic walls from the inside, you are faced with another task: placing the insulating material. There is no need to do this directly along the roof slopes. The insulation is placed on panels that will serve as the walls of the future room. And so that the material does not fall out into the space under the roof, the back side of the boards is hemmed with scraps of boards. Insulating walls from the inside, the photo of which you see below, is done in exactly this way.

Is it possible to replace floor vapor protection with moisture protection?

Typically, the insulation of an attic floor in a country house consists of a layer of waterproofing, insulation and vapor barrier. The idea of installing a moisture barrier instead of a vapor barrier seems logical - protecting the floor from spilled water. Not so simple. The insulation works as long as it is dry. Thermal insulation values decrease with increasing humidity levels.

If we flood a floor with a vapor barrier, the water will sooner or later evaporate, and the insulation will restore its properties. When there is moisture protection on top, and water somehow gets inside the ceiling, there will be no escape for the moisture. We get: lack of floor insulation in the attic floor and the presence, over time, of mold underneath.

How to properly install a vapor barrier?

Insulating an attic floor from the inside can never be done without installing vapor barrier membranes. This process has its own nuances:

- Foil membranes are installed with the shiny side into the room.

- The positioning of conventional fiberglass sheets is determined by touch - the smooth side towards the insulation, the rough side towards the room.

- Installation of any vapor barrier sheets is carried out in strips, in a horizontal direction, from bottom to top.

These rules apply to the insulation of the attic floor both along the roof slopes and gables.

How wide should the ventilation gap be between the roof and the insulation layer?

The width of the ventilation gap depends on the type of roofing material, and not on what you are going to use to insulate the attic from the inside:

- Bituminous shingles, rolled materials, asbestos-cement sheets, galvanized steel - there must be at least 50 mm under them.

- Any corrugated sheets such as metal tiles, profiled galvanized steel - from the roofing material to the attic insulation layer from the inside, leave a gap of 25 mm.

How to avoid mistakes when insulating an attic with polystyrene foam?

- Do not use mushroom dowels when insulating the attic with polystyrene foam. Reviews usually do not reflect this, but multiple cold bridges resulting in the process increase heat loss.

- When thinking about how to insulate an attic with polystyrene foam, remember that this material is not suitable for wooden surfaces.

- Avoid using polyurethane foam to fill gaps between foam boards. It is better to choose a material that has a tongue-and-groove connection. If you need to put the cut pieces together, just adjust them with a knife.

Which is better, basalt wool or slag wool?

Many people are at a loss as to which insulation is best for the attic. This is especially true for slag and basalt mineral wool - they are called in one word, they look similar. The latter is better because it has a lower thermal conductivity coefficient - 0.12. For slag wool this indicator is 0.48. Another advantage of basalt insulation is the absence of formaldehyde in the composition. Therefore, when deciding how best to insulate the attic from the inside, it is preferable to choose basalt wool.

What to do if the thickness of the insulation is greater than the height of the sheathing?

If, while insulating the attic gable from the inside, you find that the insulation is too thick and protrudes above the sheathing, under no circumstances should you press it down. The thermal properties of a material directly depend on its density: the lower it is, the greater the effect of the insulation.

By crushing, for example, slag wool, we compact it, worsening its properties. How to insulate the gable of an attic without redoing the sheathing? Simply increase its thickness by stuffing slats of the desired section on top. They do the same with roof slopes, increasing the rafters in width.

Is it possible to do without insulating the insulated attic floor?

When deciding how to insulate an attic for winter living, we often doubt whether we need to take so much care about the hydro- and vapor barrier of the floor. In theory, if the floor is well insulated and insulated along the walls and roof, this need not be done. However, do not forget that warm air tends to rise, and with it moisture rises. That is, the floor of the top floor receives moisture from the entire house. Therefore, in the winter version of the attic, the layers of insulation must be enclosed in water and vapor barrier membranes.

How to insulate an attic for winter living - video and nuances of the process

So, we’ve decided on thermal insulation materials. Now let's look at how to properly insulate an attic roof.

Do-it-yourself insulation of the attic with mineral wool from the inside: video and photo instructions

| Photo | Description of work |

| The mineral wool is laid out on the attic floor. The required width is measured, which corresponds to the distance between the rafters, plus 2-3 cm. This is done so that the insulation fits tightly between the elements of the rafter system, without leaving cold bridges. | |

| Now a piece of insulation cut to the required dimensions must be laid between the rafter legs. If the slope of the roof slope is sufficiently flat, then the heat-insulating material under its own weight may fall out of the cell. | |

| Therefore, transverse slats are packed along the rafters from the inside, which are temporarily attached with self-tapping screws to the rafter legs. | |

| Instead of slats, you can use a strong thread, which is pulled over nails driven in a checkerboard pattern along the inner planes of the rafter legs. | |

| Insulation is laid under the padded slats. | |

| All that remains is to cover the thermal insulation cake with waterproofing film. Its purpose is to keep moist air vapors from penetrating the thermal insulation layer. Because mineral wool is a hygroscopic material, and under the influence of humidity it begins to lose its properties. | |

| The waterproofing membrane is nailed with nails or metal staples to the rafter legs. Laying is carried out in overlapping stripes, starting from bottom to top. |

Watch this video on YouTube

Insulating the attic with foam plastic

As mentioned above, it is not recommended to use polystyrene foam boards to insulate the attic. One of their main advantages is low, almost zero, water absorption. Therefore, there is no need to install protective layers for this insulation. That is, if during the construction of the roof a hydro- or vapor barrier membrane was not used under the roofing material, then PP slabs are the cheapest option for thermal insulation.

| Photo | Description of work |

| As in the case of mineral wool, polystyrene foam boards are cut to fit the distance between the rafters. | |

| The slabs, cut to size, are laid in the rafter system. It is necessary to indicate that there should be a space between the insulation and the roofing material, which will be used in the future as ventilation, removing not only moist air vapors, but also some harmful components of the heat-insulating material itself. Without forming this gap, PP cannot be laid. | |

| Another layer is laid on top of the rafters. Its main task is to cover the entire surface and prevent cold air from passing between the first layer and the rafters, because it is very difficult to lay PP boards tightly to the rafter structure. The second layer is attached to the rafters using self-tapping screws with a wide metal washer. |

Watch this video on YouTube

Insulation of the attic with polyurethane foam

Polyurethane foam is a material with a high adhesion rate. It adheres perfectly to all building materials. Therefore, there is no need to prepare anything for it. They simply assemble the installation under the attic roof, connect the parts with hoses, open the valves, and turn on the compressor. And they begin to apply the material in layers until it is completely filled between the rafters. To make it clearer, watch the video below:

Watch this video on YouTube

Before insulating an attic roof with polyurethane foam, be sure to familiarize yourself with the foam application technology. Here are just a few nuances.

When applying a thermal insulation layer, you need to take care of the ventilation of the attic. The worker must wear protective equipment: goggles, gloves, safety shoes and overalls. It is very important to mix the insulation components correctly; their ratio should be 1:1.

How to work correctly when applying polyurethane foam, where overalls are the main component of safety