In private homes, a common problem is heat leakage through the ceiling. In multi-apartment housing, things are different, since there is another, warm apartment on top. In this situation, there is a street or a cold attic above the ceiling. Insulating the ceiling from the inside in a private house is not so difficult; you need to understand what tools and materials are needed. Often this decision is made if there is no access from the attic.

How to insulate a concrete ceiling outside and inside?

Reinforced concrete is an excellent composite material that has good strength characteristics, which cannot be said about its thermal insulation qualities.

Insulation of a concrete ceiling from the inside and outside

Heavy concrete has a fairly high thermal conductivity coefficient - 1.7 watt/(m*deg), which makes it an unsuitable material for enclosing rooms where the temperature inside must be positive in winter. At the same time, concrete has a heat capacity of 840 J/(kg*deg), which allows it to accumulate heat well and release it if necessary, if the thermal insulation is done correctly.

Concrete floor base in a private house - features of a concrete slab

The floor is a critical element of the structure. Trying to increase the service life of a building, many people prefer concrete. After all, concrete surpasses most building materials in terms of performance characteristics. But along with a set of advantages, the material also has weaknesses.

Concrete has superior performance characteristics to most building materials.

Let's start with the main advantages of concrete floors, which include the following characteristics:

- increased safety margin. The concrete surface is able to withstand significant compressive loads, maintaining the structure and integrity of the mass;

- long period of use. The service life is commensurate with the service life of the building, thanks to the durability of the base;

- environmental cleanliness. The ingredients included in the concrete mixture are safe for health and do not harm the environment;

- ability to resist the accumulation of static electricity. Airborne dust is not attracted to the surface;

- Fire safety. The concrete base has increased fire resistance and is not destroyed by open fire;

- resistance to capillary penetration of moisture. Despite the reduced hygroscopicity, waterproofing the floor is a prerequisite;

- resistance to aggressive environments and chemicals. The concrete base is not destroyed upon contact with acids and alkaline compounds;

- maintainability. If necessary, it is easy to repair the damaged area.

Thinking about which insulation for a concrete floor is best, let’s look at the disadvantages of a concrete base. Main disadvantages:

- increased thermal conductivity. Without additional thermal insulation, significant heat loss occurs;

- condensation formation. Due to the increased temperature difference between the soil and the floor of the lower floor, moisture condenses on the concrete surface.

The concrete base has increased fire resistance

Condensation causes a number of negative factors;

- increased indoor humidity;

- deterioration of the internal microclimate;

- development of fungal colonies and mold;

- formation of dampness.

In addition, in winter, cold floors cause many inconveniences to residents:

- reduce indoor temperature;

- increase heating costs.

But, thanks to a serious set of advantages, many people build a concrete floor. How to insulate its surface to avoid heat loss is of interest to owners of private houses, summer cottages and novice developers. Let's try to answer this question.

How and how to insulate the concrete ceiling of your home?

In order for thermal insulation measures to work, it is necessary to ensure the technological correctness of the work so that all the physical properties of the materials involved in the work retain their specified characteristics. First of all, the insulation must be protected from moisture and from physical impact (birds, rodents).

Insulation of concrete floors is relevant only for the upper floors of the building. There are, of course, unfavorable situations related to the social situation in depressed settlements, where residents move out of their apartments en masse. And the remaining residents of multi-storey buildings have to fight to maintain heat in their apartments.

Concrete floors can be insulated both from the inside and outside.

The negative aspect of insulation from the inside is that the reinforced concrete slab ceases to be a heat-intensive structural element, and the cold boundary moves closer to the heated room, forming new cold bridges.

Insulation of concrete ceiling with polystyrene foam

When installing internal thermal insulation from materials based on polystyrene foam (foam), first you should clean the ceiling surface from dirt and crumbling particles. Next, the expanded polystyrene slabs are glued to the ceiling using polyurethane foam or regular tile adhesive, and the initial fixation of the slabs should be ensured to prevent them from falling. This is done with the help of “umbrellas”. It is recommended to lay out expanded polystyrene boards with gaps that are subsequently filled with polyurethane foam.

Finishing options for such insulation can be:

- putty applied to a reinforcing mesh fixed over the insulation;

- suspended ceiling made of plasterboard, lining, decorative panel;

- the most practical option is a suspended ceiling.

Also, when using polystyrene foam, good sound insulation is provided.

Insulation with mineral wool

If mineral wool insulation is used indoors, it is necessary to make a frame from timber or special galvanized building profiles, secure the insulation, install a vapor barrier using special membrane fabrics, and complete the installation of the ceiling. If the insulation is of poor quality, moisture will penetrate through the insulation and condense on the surface of the floor slab, which will lead to saturation of the insulation with moisture and, accordingly, loss of its properties (the work will have to be redone).

Insulation with cotton wool from the inside video:

It is preferable to insulate concrete structures outside the building; with this method of insulation, concrete also participates in retaining and preserving heat.

Floors can be insulated with bulk materials such as expanded clay, slag, sawdust. In the case of sawdust, it is necessary to ensure protection against accidental fire. These methods do not require any additional costs.

The method of insulation using mineral wool is quite simple. A layer of vapor barrier (special fabric materials, roofing felt) is laid on a flat concrete floor, then a layer of insulation is placed directly, and a layer that protects from wind and moisture is placed on top of the insulation (special fabric materials, roofing felt).

Exterior insulation with mineral wool video:

Insulation with polyurethane foam

When insulating the floor with polyurethane foam, you will have to use the services of specialized organizations, but the result will justify the money spent. Polyurethane foam is sprayed under pressure into an aerosol, the two components of the polyurethane foam immediately react, and the resulting foam expands to fill voids.

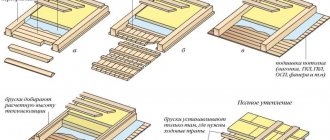

If the attic space is used and a durable floor is needed for movement, wooden logs are installed from a board with a section of 100 by 50 mm in increments of 500 mm (depending on the thickness of the floorboard). The logs are installed at a level at a height that provides the required layer of heat-insulating material. After installing the logs, insulation is placed, it can be any of the above materials, and upon completion of the insulation, a wooden floor is laid. In this case, the tree will also participate in thermal insulation.

The floor can also be made of concrete if a dense material like extruded polystyrene foam is used as insulation. Expanded polystyrene is laid on a flat floor surface, then a reinforcing mesh is laid on top and a concrete or mortar screed is made. If the floor slabs are laid unevenly, it is recommended to make a leveling screed.

Thermal insulation work must be carried out after thermal engineering calculations.

Insulation from inside the room

Insulation of a concrete ceiling from the inside is carried out using expanded polystyrene (foam plastic and its extruded variety), basalt wool and mineral wool. Depending on the density of the material, frame or frameless insulation technology is used. Using the frameless method, basalt wool and expanded polystyrene are installed, and assembly of the sheathing is required if mineral wool is used.

Inexpensive do-it-yourself insulation of the garage ceiling from the inside

Expanded polystyrene

The following types of foamed polystyrene are suitable for thermal insulation measures:

- Pressless foam is the cheapest type of expanded polystyrene. Its structure contains granules and pores of different sizes. This material has high water absorption and different densities. Its thermal insulation characteristics are not as high as those of subsequent varieties.

- Pressed polystyrene foam has closed pores, so it better protects against heat loss. The material is durable and dense.

- The extruded variety of polystyrene also has small closed pores in its structure. This is a product with the lowest thermal conductivity.

Insulating the ceiling in an apartment with penoplex, that is, extruded polystyrene foam, provides the following advantages:

- high thermal insulation efficiency;

- ease and speed of installation;

- resistance to deformation;

- acceptable price;

- waterproof;

- due to the low weight, the floors are not overloaded;

- durability (will last up to 30 years);

- the surface is not affected by mold and rot;

- impact noise absorption.

The disadvantages of expanded polystyrene are considered to be their easy flammability, although extruded products are self-extinguishing. In addition, polystyrenes are not chemically resistant, so when choosing an adhesive for gluing to the ceiling, you should not buy compounds with solvents that are aggressive to the foam. Foamed polystyrenes do not protect against airborne noise and have low air permeability.

Specifications:

- water absorption - from 0.4% to 4% (the highest for conventional foam);

- vapor permeability – from 0.019 to 0.015 (the best indicator for extruded polystyrene foam);

- strength – from 0.4 to 1 kg/cm³.

Mineral wool

There are several varieties of mineral wool. Only two types are suitable for insulating apartments:

- Glass wool is considered a budget option for insulation. Since the material releases small glass fibers into the air, it is not installed indoors. But glass wool is suitable for external insulation of floors.

- Stone wools have a higher density than the first type and are characterized by mechanical stability. Rocks, such as basalt, are used to make them. Due to their high strength and density, basalt wool can be installed using frameless technology.

Important! Since stone wool is fire resistant, it is allowed to be used in areas with a high fire hazard.

The minimum thermal conductivity of mineral wool is 0.041, the density of the material is in the range of 20-220 kg/m³. The vapor permeability of the insulator is 0.48.

Advantages of mineral wool:

Insulation of a concrete floor in a private house

- waterproof (this only applies to basalt wool);

- low thermal conductivity;

- the material does not interfere with air circulation;

- the product is resistant to chemicals;

- high thermal insulation rates;

- fire resistance;

- durability;

- harmlessness and environmental friendliness.

Only non-stone mineral wools have disadvantages. So, the disadvantage of glass wool is its strong dusting. In addition, when these insulation materials get wet, their thermal insulation properties decrease.

How to insulate a concrete ceiling with thermal insulation materials

The need to insulate a concrete ceiling from the inside often arises among owners of the upper floors of buildings with a flat roof. If it is possible to insulate the ceiling from the attic side, then this is the best option to keep the apartment warm.

Multi-storey buildings in cities traditionally have inter-storey floors made of concrete slabs . Some private houses have the same floors, resting on the foundation or its continuation - the ground floor, where utility rooms for various purposes are located.

Floor slab - ceiling and floor at the same time in apartment buildings. The slabs rest on load-bearing walls, the ceiling is covered with several slabs. The sealing of the seams between the slabs and the places where the slabs rest on the walls cracks: either due to shrinkage of the building, or poor work of the builders. Part of the heat leaves apartments precisely through the joints of the slabs: wall or ceiling.

Houses in need of major repairs are usually insulated from the outside using the thermal fur coat method . This method is applicable for insulating the ceiling from the inside. Having some construction skills, you can insulate the ceiling from the inside yourself.

How to insulate a concrete ceiling

Houses that were built 20-30 years ago were designed taking into account maintaining heat in the house with excessive consumption of thermal energy . This is due to the fact that gas and electricity were cheap, and therefore the requirements for thermal conductivity of building panels were low. But the times of cheap energy consumption are over; houses still operate with heat losses, for which the owners pay.

The natural desire to reduce heat loss is to insulate the building . There are enough methods and materials for this.

But if putty is supposed to be applied over the material, this condition is not necessary.

In the course of the work that you will now see, decide what tool and material you need.

1. Preparing the ceiling. Remove the peeling plaster, seal the cracks and cracks with cement mortar. Apply two coats of primer perpendicular to each other.

2. Leveling the ceiling : using a thin layer of putty if the ceiling is flat, or immediately after priming, level the ceiling with a 50 x 50 or 50 x 70 mm beam along the location of the slabs and at a distance so that the joint falls on the central axis of the beam.

The primer is applied with a roller or brush. If the ceiling is smooth and covered with a thin layer of putty, then make notches with a spatula, clean it and prime it with a spray bottle: this additionally blows away dust from the ceiling, and the primer under pressure penetrates deeper into the pores of the concrete slab.

3. Then apply a sheet of insulation , mark the boundaries of the sheet and apply a layer of 1-2 mm KNAUF Sevener plaster-adhesive mixture and smooth it with a comb spatula.

Effective insulation of a private house

For external insulation, you can use different materials - mineral insulation, expanded clay, polystyrene foam, polystyrene foam and even sawdust or straw. Of course, the last two types of materials are now practically not used due to their impracticality, but all the others are excellent heat insulators.

When choosing insulation, you need to take into account not only their cost, but also other characteristics. First of all, pay attention to the weight of the material, because a thick layer of heat insulation will put a lot of pressure on the floors.

In cold regions, it is recommended to choose lighter materials that are laid in two, three, or even four layers. But in areas with a mild climate, the insulation layer on the ceiling may not be very thick, therefore, the material can be chosen heavier.

Regardless of what material you choose, the initial stage of work is always the same. First, the entire ceiling is cleared of debris and foreign objects. Between the beam ceilings it is necessary to lay a layer of vapor-proof film or glassine.

These materials need to be cut into strips of such width that after laying them between the beams there is a margin of several centimeters. The edges of the film are secured with a stapler to the walls and beams.

Insulation of the ceiling in the basement of an apartment building

The choice of insulation method depends on the purpose of the basement:

- Premises for storing agricultural products;

- Placement of heating and plumbing equipment;

- Arrangements for gyms, billiard rooms;

- Premises for other purposes.

Of these, it is necessary to designate: heated and unheated basements. This is important for residents of the first floors of apartment buildings. As a rule, residents insulate concrete floor slabs with basements by installing additional thermal insulation on the floor side . It is not only effective, but also cheaper.

In most cases, it is necessary to open the floors down to the cement screed and eliminate defects (potholes, cracks); You can additionally pour a thin layer of self-leveling cement mortar, and after hardening, make a substrate from the thermal insulating material Parkolag from ICOPAL - a Finnish thermal insulating substrate for laminate, linoleum, parquet.

This substrate is laid on a flat surface of a cement screed without waterproofing or vapor barrier, because the bottom layer of the substrate has micro-gaps with the floor and this achieves ventilation between the laminate and the concrete floor.

In another case, storage facilities for agricultural products . In addition to maintaining a certain temperature, such cellars must be dry so that the food lasts longer. Warm air, rising upward, encounters a barrier in the form of a cold cement slab, where it cools to the “dew point” on its surface and falls in the form of droplets from the ceiling. To prevent this from happening, you must prevent warm air from coming into contact with the stove. Installing ventilation with temperature control will solve this problem, but we need to look at what energy consumption occurs.

A simple “vent” device, natural ventilation , directs the convection flow in the desired direction and prevents air vapor from depositing on the surface of the slab. Another thing is maintaining the temperature. This is where it is necessary to insulate the ceiling, and possibly the entire basement room, in order to increase the temperature inside. The insulation method is not new - it is the same as for walls:

- Additional beams are attached to the ceiling, from wall to wall: an edged board 20 mm thick and 100 mm wide, impregnated with an antiseptic solution, is attached to the ceiling with an edge using corners along the entire length with a distance of 50-60 cm between each other.

- The junctions with the ceiling are foamed with polyurethane foam. Between the beams prepared in this way, roll insulation is laid, then a vapor barrier is fastened with a stapler, and the seams are taped.

- Then a spacer strip 10-15 mm thick is nailed along the beams.

- They cut sheets of gypsum board or gypsum board "Knauf", you can use moisture-resistant plywood and sew them to the slats.

You can use a stainless metal profile, attaching it to the ceiling on hangers and also laying thermal insulation with subsequent filing of gypsum boards.

Polystyrene foam and polystyrene foam

Characteristics

The basis of the foam is a foamed polymer. Polystyrene foam is sold in sheets with a thickness of 20 to 100 mm. The material has a low density of 15-25 kg/sq.cm. Sheet size – 1x0.5 m or 1x1 m.

Foam plastic in section.

Expanded polystyrene is made from styrene. It has a higher density compared to foam plastic (35-45 kg/cm2).

But the price of this material also differs depending on the position. Thickness 20-50 mm. Sheet size 1x0.5m.

The photo shows sheet polystyrene foam

Advantages:

- light weight;

- convenient dimensions;

- ability to maintain geometric dimensions during service life;

- low cost;

- high installation speed;

- does not allow moisture to pass through;

- the estimated service life is about thirty years.

Flaws:

- flammability;

- Without the use of a special mesh, the putty will not “lay” on the foam.

Installation

Installation of these materials does not require special skills or tools. The sheet is cut with a regular knife.

Its installation can be done in two ways:

- Without arranging a frame

- Apply an adhesive solution to the surface of the sheet;

- press the sheet to the surface and hold for several minutes;

- drill a through hole through the sheet into the ceiling;

- fix the sheet using screws with a large head, which are then sealed with aluminum tape;

- blow foam into the seams. Required in order to eliminate possible “cold bridges” at the junction of panels

Photo - Foam insulation

Photo – Insulation of the loggia with polystyrene foam

The methods described above are used in cases where the ceiling will be decorated with putty in the future.

Helpful advice. If you cover polystyrene foam or expanded polystyrene with penofol, you get excellent insulation. Only in this case, penofol needs to be glued to the foam. Then you will need to install a frame or counter slats between the foil and the finishing material.

Photo - Additional insulation on polystyrene foam.

Photo – Containers on penofol

- With frame arrangement

Note! Professionals, answering the question of how to insulate the ceiling in an apartment from the inside, recommend using this method. It is good because it is possible to install any finish on the frame - lining, plastic or suspended ceiling.

This installation method is carried out as follows:

- a frame is prepared from wooden beams or galvanized profiles;

- insulation is placed between them;

- Next comes the finishing material.

Helpful advice. If you want to use penofol in this case. It should be glued to polystyrene foam/expanded polystyrene. And be sure to attach the counter rails.

Insulation of a concrete ceiling in the basement of a private house

Additional rooms for various uses are being built in the basements of private houses. The insulation of agricultural product storage premises is similar to that for the basements of apartment buildings. It’s another matter when basements are insulated for the purpose of additional space for living activities.

Such rooms are usually always heated. Their heat is insulated when the basement is located under a terrace, garage or other unheated premises. The method of insulation is the same as for apartments with attic floors, if it is not possible to insulate from the outside.

Insulation of a concrete ceiling in a private house

If it is possible to insulate the ceiling from above, then the scheme is as follows.

On the side of the heated basement, in order to preserve heat, it is recommended to insulate the walls , and the ceiling is more insulated for sound insulation purposes, so high-density foam plastic is attached to the ceiling with an adhesive solution. Extruded polystyrene foam (XPS) boards can also be attached. This material has a dense structure and high thermal insulation and sound insulation properties.

In addition to the above methods, a more expensive method may be suitable - applying a polyurethane foam (PPU) layer to the insulated surface . Without special equipment, high-quality components for foam formation, mixing and application technology, it is impossible to make thermal insulation yourself.

So, to successfully insulate your basement, determine the cause of heat loss, the location of the leak, and the formation of condensation in the insulation.

The situation urgently needs to be corrected. For questions regarding thermal insulation of basements, please contact specialized construction organizations . A specialist will determine the method of thermal insulation of a particular room. Additional waterproofing or installation of drainage systems may be required. This will be determined by a specialist from a company engaged in complex work on thermal insulation and ventilation of premises. Only a professional approach to this problem will reduce the costs of this work.

How to insulate the ceiling in a panel apartment and in a country house?

There are two ways to solve this problem:

- Insulate the ceiling from the inside using mineral wool insulation.

- Insulate the ceiling above in the attic.

Which method is most effective?

It is clear that insulation of ceilings in a private house can be done using both options. But experts are sure that it is best to stick to the second insulation method. It will cost much less, and the work will be much easier to complete. But owners of apartments located in a multi-storey residential sector can only use the first option.

How to insulate a ceiling from inside a room?

In such a situation, it is impossible to do without erecting a suspended structure. It will help create a space in which you can put all the necessary material. When deciding how to insulate the ceiling from the inside, you will need to figure out how to attach the insulation to the ceiling. It is better to use mineral fiber material as the main material.

Synthetic bases are not suitable for this method because they do not have sufficient vapor permeability. This means that condensation will accumulate inside the multilayer “pie”. Penetrating into the main ceiling, it will gradually begin to destroy it.

Ceiling insulation technology

Only mineral wool can prevent these processes. It will allow the entire layer to “breathe”, so there will be no need to be afraid of the formation of moisture and mold.

If at this stage foam plastic is chosen as ceiling insulation, even forced ventilation will not save the situation. The ceiling will very quickly become covered with characteristic dark spots. This means that a different tactic is needed.

If you live in a panel house and don’t know how to insulate a concrete ceiling, listen to the following tips.

Ceiling insulation technology in a panel apartment

Initially, the concrete base must be treated with special impregnations that will allow the ceiling to “breathe” and protect it from possible condensation. A special membrane film can be used as a vapor barrier layer, which will also cope with the indicated functions.

Then you can begin building the frame. The distance between it and the main ceiling should not exceed 10 centimeters. Rolls of mineral wool can be inserted into the cells of the frame, or you can glue the insulation directly to the ceiling.

Ceiling insulation technology in a panel apartment

When insulating the ceiling, experts recommend using ordinary putty as a binding adhesive. It is simply applied to the ceiling, and mineral wool is immediately applied to the still fresh layer. There is no need to maintain the insulation, since the cotton wool will stick well.

You can find different rolls of mineral wool on sale. What should be the thickness of the insulation for the ceiling? To determine it, just look at the technical passport of the apartment. Remember that the thickness of the insulation must be at least half the thickness of the concrete ceiling slab. Essentially, the thicker the mineral wool, the more reliably it will retain heat.

Once the insulation is installed, you can choose the finishing layer of the “pie”. It can be plasterboard or ceiling amstrong, wooden panels or plastic slats - anything, but not suspended ceilings.

Please note that if the use of tension structures is envisaged, the insulation is laid on the ceiling somewhat differently:

- The concrete base must first be treated with mastic.

- Then, when it dries well, roll mineral wool is glued to it using putty.

- A frame system is assembled on top of it, and before installing the stretch ceiling, the entire structure is protected with a vapor barrier material.

This is done in order to prevent the insulation fibers from shedding. If this happens, the finish will look a little sloppy. In addition, there will be a risk of damage to the expensive canvas.

When deciding how to insulate a ceiling with mineral wool, the most important thing is not to get confused and to correctly distribute the front and back sides of the vapor barrier membrane.

How to insulate a concrete ceiling?

Concrete ceilings can cause a lot of trouble for the owners of an apartment or private house with reinforced concrete floors. The main problem is their ability to perfectly transmit noise from neighbors and poor heat-saving characteristics. Only owners of apartments in high-rise buildings face the problem of noise from neighbors, but the problem of insulating a concrete ceiling affects all owners of both apartments and private houses. Therefore, next, we will talk about the insulation of such floors.

Options for arranging an insulating layer

The most important factor when creating a heat-saving layer will be the type of construction. If this is a private house, then all work can be carried out from the attic, but in a city apartment, this is only possible on the last, upper floors of buildings. But, usually it is the residents of these apartments who feel the need for this procedure.

In an apartment building, you will have to insulate from the inside of the premises, and here the choice of material will be of great importance - it should be as thin as possible, and at the same time retain heat very effectively.

In private houses, insulation work can be carried out by placing a heat insulator in the internal cavities of the ceilings. Here you can use a lot of different materials - from sawdust to the most modern heat-insulating coatings.

Studying heat loss

Where does the heat go?

Before choosing what and how to insulate a house, you need to find out what, first of all, needs insulation. The picture shows where the heat evaporates in our homes.

Sources of heat loss in the house

As a rule, they try to equip walls with thermal insulation material during the construction or major renovation process. And the material is most often attached from the outside. But people begin to think about insulating the ceiling in a private house much later.

Let's figure out what's stopping us from insulating the ceiling and saving 20-30% of the wasted heat?

What affects the temperature in the house

The following factors influence the temperature in the house:

- wind rose (determines the wind direction in your region);

- wind speed;

- the material from which the house is built;

- quality characteristics of double-glazed windows;

- arrangement of the heating system and its autonomy;

- presence of thermal insulation in the house.

And if we are not able to fight some of them, then we are quite capable of reducing heat loss by installing insulation. But, before you start figuring out how to insulate a ceiling from the inside, you need to understand what materials are suitable for this.

Consequently, the question on the agenda is what types of insulation materials are applicable for insulation. As well as brief instructions for their installation.

Material selection

It is possible to insulate a concrete ceiling using almost the same materials that are used for other types of buildings. The only difference will be that the reinforced concrete floors are not hollow, and it will not be possible to take advantage of the existing voids.

The main and most popular insulation, regardless of the type of construction, is mineral wool. It has many advantages over other types of insulating materials, but it also has a significant drawback - it is necessary to lay a sufficiently thick layer of mineral wool to ensure high-quality thermal insulation.

If the height of the room where the ceiling is supposed to be insulated is not too large, using mineral wool is not the best idea. It will “eat up” too much space under the ceiling. The only option when this parameter will not be of fundamental importance is thermal insulation of the ceiling of the upper floor of the building. All work can be done from the outside of the ceiling, and this will not in any way affect the existing height of the rooms.

The second, no less popular insulation material, which is used with great success for the same purposes in city apartments and private houses, is polystyrene foam. It is laid in a much thinner layer, which no longer reduces the height of the premises so much. It can also be used for outdoor installation.

All bulk insulation, such as expanded clay, or mixtures of sawdust with various other materials, can only be used externally. They cannot be used indoors for thermal insulation of the ceiling.

External installation of thermal insulation

External insulation of an apartment is carried out if there is a higher technical floor or attic space. It is important that the communications laid in the technical floor do not interfere with the implementation of this insulation option. Otherwise, you will have to abandon external installation.

Insulation of a concrete ceiling from the outside is most often carried out using expanded clay, but the materials listed above are also suitable. Usually they are laid between rows of joists, the height of which is equal to the thickness of the insulation. Vapor and waterproofing must be used. The heat insulator is covered with a boardwalk on top so that when walking on the technical floor or attic the heat insulation layer is not damaged.

Expanded clay

This is a product of processing shale clay. The granules are exposed to heat, after which their surface is sintered, and the material becomes porous from the inside, which gives the product high thermal insulation characteristics. Typically, expanded clay of different fractions is used to insulate a concrete floor from the outside. The optimal granule size is 10-20 mm.

Advantages of expanded clay insulation:

- The material is not flammable and does not support combustion. The granules do not emit harmful substances during a fire, do not melt or drip. Therefore, we can say that expanded clay has absolute fire safety.

- Expanded clay is very light, so after installation there are no unnecessarily high loads on the floor.

- The product is resistant to mold and other microorganisms. It is not damaged by insects and rodents. In combination with hardness and strength, this ensures long-term operation of the heat insulator.

- The material is easily laid on the ceiling without the use of special devices, which allows you to install it yourself.

- Reasonable price is one of the advantages of insulation.

Among the disadvantages of expanded clay, it is worth mentioning the dust that is observed during transportation and installation. The hygroscopicity of the granules is also considered a disadvantage. Because of this, after getting wet, they lose some of their thermal insulation qualities. Therefore, after laying expanded clay, a waterproofing layer must be laid out, which makes it possible to level out this shortcoming of the material.

Insulation methods

The only difference in the methods will be that some of the heat insulators can be mounted on a specially constructed frame, and some can be laid on the outside of the ceiling, which is the floor in the upper room.

From the inside of the rooms, you can simply glue foam tiles to the ceiling, immediately obtaining both the design of the ceiling with a beautiful finishing material and a small heat-saving layer.

But such insulation, as a rule, is not enough. More significant measures need to be taken. And with this, the same polystyrene foam can help, but with a greater thickness than decorative tiles.

Its advantage is that you can glue foam boards directly onto the ceiling using regular tile adhesive. After gluing, the foam plastic is plastered over the mesh and finished with a finishing layer of decorative coating. The method is inexpensive, but requires fairly good plasterer skills for subsequent finishing.

If you don’t have such skills, you can use any insulation, like mineral wool. They are not just attached to the ceiling, but placed in a special frame. It has to be collected.

Assembling the base is exactly the same as for any suspended ceiling system. First, a vapor barrier is laid into the frame base. The overlap of adjacent strips must be at least 10 centimeters. All joints of the material are taped with reinforced construction tape.

Next, you need to lay a layer of mineral wool or other similar insulating materials. Its thickness in each case is calculated separately, but, as a rule, it is equal to the thickness of the concrete floor.

On top of the insulation, another pass is made with a vapor barrier, gluing all joints and overlaps.

After this, you can install a plasterboard finish on the frame, or use another finish. One option could be plastic or wood-imitating panels.

When creating a heat-saving pillow outside, all work begins with laying a vapor barrier film or glassine. Other vapor barriers can also be used.

Next comes the insulation. Options are possible here, since on the outside there is usually an attic, the height of which can be sacrificed and cheaper types of insulation can be used, which require laying in a thick layer.

If you plan to walk on an insulated surface, it is necessary to lay joists for the future floor. The cells obtained after their installation are placed sequentially - a vapor barrier film or other types of insulators, an insulating layer, and again a vapor barrier.

Next, a sheathing is constructed that creates the necessary ventilation gap between the floor and the layer of insulating material. It is necessary to ensure the release of moist air.

The subfloor is laid on the sheathing slats, which is subsequently covered with a finishing coating.

Ceiling insulation: basic methods

There are two such methods: insulating the ceiling outside and insulating the ceiling inside.

Insulation of the ceiling from the inside of the room (from the inside)

This method of ceiling insulation is most often used in apartments of multi-storey buildings, in particular, if we consider such an option as insulating the ceiling in an apartment on the top floor, which in this case is generally possible. The presence of a technical floor or attic in a multi-storey building often does not allow for the possibility of insulation for the simple reason that various types of communications are located along the floor (as an example, we can indicate the wiring of the heating system, etc.). Unimpeded access to such communications is important for utility workers and repairmen, which is why insulating the ceiling in an apartment from the outside is usually excluded.

- Styrofoam

As already noted, various methods and materials can be used for this purpose; let’s start with foam plastic. Its characteristic feature is low vapor permeability and thermal conductivity; in addition, it is resistant to mechanical loads and various aggressive environments, non-toxic and easy to install.

So, for insulation using polystyrene foam, you will need foil insulation, dowels, polyurethane foam, glue, tools (an electric jigsaw or a regular hacksaw, hammer and drill), and, in fact, foam boards. Work on insulating the ceiling in an apartment can be carried out at temperatures ranging from +5 to +30 degrees.

First, you need to lay a layer of isolon (NPE or PPE brand) on the ceiling; the foil side should be inside when laid. Izolon is an excellent material for eliminating the effects of low temperatures. Next comes the stage of laying the sheets of insulation used - polystyrene foam. You can start from any of the corners in the room, the main goal is to gradually cover the entire surface of the ceiling with foam. The foam is fastened using dowels, or it is attached with glue. Each sheet must be provided with at least 5 attachment points (whether with glue or dowels); as a rule, the corners of the sheet and its middle are chosen as the basis for such points. The joint areas formed as a result of laying polystyrene foam are subsequently filled with polyurethane foam.

Next, after the foam has been laid, they begin finishing the ceiling. Often, decorative panels are used for it; they are attached to metal or wooden slats. PVC skirting boards are used for the edges, which ensures a smooth and neat finish.

Insulating the ceiling with foam plastic from the inside

- Basalt wool or mineral wool

An equally common method of insulating the ceiling followed by installing drywall. This type of insulation is available for use in the form of slabs or rolls. Its advantages are its affordable cost, excellent performance characteristics, resistance to chemical attack, it is also not subject to rotting and burning, and is easy to install.

Ceiling insulation using wool and plasterboard is carried out with the previous installation of a frame or a specific type of fastening, because the position of the insulation is taken into account here, and, as is clear, it will be practically suspended. According to this scheme, you need to make a wooden or metal frame using dowels and a hammer drill. Next, insulation is glued into the interprofile space, for which it is better to use glue for laying tiles - with its help you can almost instantly achieve gluing of mineral wool to the ceiling.

It would be a good idea to read the instructions supplied with the insulation - it often happens that for a particular type of insulation it is necessary to first provide a vapor barrier or other type of specific conditions. Mineral wool can also be fixed using plastic dowels with rounded wide caps. After this, electrical cables and other types of communications are laid, this is done along the surface of the insulation. And finally, the final stage, during which the ceiling is covered with plasterboard. The ideal solution for this would be to use self-tapping screws based on hardened steel; this recommendation is explained by their significant strength and increased resistance to loads.

There is another method for insulating the ceiling; it can rightfully be defined as the most labor-intensive. It uses hard-type mineral wool slabs (for example, PPZh-200, etc.), installed on the ceiling, after which they are fixed, and then a plaster mesh is laid over their surface. The final step here is putty. In this case, the mesh should be sunk with a layer of putty, after which the entire surface is leveled with a spatula. Next, this layer must be allowed to dry, after which the final layer can be applied. After the surface has completely dried, the ceiling is sanded, then coated with a primer, after which you can begin painting.

Let’s add some recommendations to a seemingly simple technology. For example, it is important to take into account that the insulation cannot be pressed. The fact is that mineral insulation contains at its core a lot of air bubbles, due to which the effect of retaining heat is ensured.

Another problematic issue may be the installation of lamps in the ceiling, in particular spotlights. Surely you know that energy-saving lamps are subject to a certain amount of heat. Due to the fact that the insulation acts as an obstacle to the removal of heat from the lamps, the possibility of ventilation of the space between it and the lamp is excluded, and this, in turn, causes their rapid failure (literally within one to two hours at condition of constant lighting). In this regard, it is possible to make a small gap between the insulation and the lamps, which will ensure sufficient air circulation. As an alternative, you can even opt for a regular chandelier or wall sconces to illuminate the room.

How to insulate a concrete ceiling?

Concrete ceilings can cause a lot of trouble for the owners of an apartment or private house with reinforced concrete floors. The main problem is their ability to perfectly transmit noise from neighbors and poor heat-saving characteristics. Only owners of apartments in high-rise buildings face the problem of noise from neighbors, but the problem of insulating a concrete ceiling affects all owners of both apartments and private houses. Therefore, next, we will talk about the insulation of such floors.

Options for arranging an insulating layer

The most important factor when creating a heat-saving layer will be the type of construction. If this is a private house, then all work can be carried out from the attic, but in a city apartment, this is only possible on the last, upper floors of buildings. But, usually it is the residents of these apartments who feel the need for this procedure.

In an apartment building, you will have to insulate from the inside of the premises, and here the choice of material will be of great importance - it should be as thin as possible, and at the same time retain heat very effectively.

In private houses, insulation work can be carried out by placing a heat insulator in the internal cavities of the ceilings. Here you can use a lot of different materials - from sawdust to the most modern heat-insulating coatings.

Cost of insulation

Prices for ceiling insulation work vary and depend on the materials used and installation method. Since laying insulating material involves various preparatory and basic work, the cost consists of the following prices:

- installation of ceiling lathing – from $2.8 per square meter;

- ceiling preparation (priming, antiseptic treatment) – from $1/m²;

- installation of a vapor barrier layer – from $1.5 per square;

- laying mineral wool (internal installation) – from $6.7/m²;

- external installation of mineral wool – from $4.8/m²;

- fastening slab insulation with dowels (frameless technology) – from $7 per square.

Do not forget that after laying the thermal insulation material from the inside of the room, the ceiling surface needs finishing. If you also plan to entrust its installation to professionals, then do not forget to add the cost of finishing work to the final amount.

Material selection

It is possible to insulate a concrete ceiling using almost the same materials that are used for other types of buildings. The only difference will be that the reinforced concrete floors are not hollow, and it will not be possible to take advantage of the existing voids.

The main and most popular insulation, regardless of the type of construction, is mineral wool. It has many advantages over other types of insulating materials, but it also has a significant drawback - it is necessary to lay a sufficiently thick layer of mineral wool to ensure high-quality thermal insulation.

If the height of the room where the ceiling is supposed to be insulated is not too large, using mineral wool is not the best idea. It will “eat up” too much space under the ceiling. The only option when this parameter will not be of fundamental importance is thermal insulation of the ceiling of the upper floor of the building. All work can be done from the outside of the ceiling, and this will not in any way affect the existing height of the rooms.

The second, no less popular insulation material, which is used with great success for the same purposes in city apartments and private houses, is polystyrene foam. It is laid in a much thinner layer, which no longer reduces the height of the premises so much. It can also be used for outdoor installation.

All bulk insulation, such as expanded clay, or mixtures of sawdust with various other materials, can only be used externally. They cannot be used indoors for thermal insulation of the ceiling.

Ceiling insulation: basic principles and materials

Particularly important is the insulation of the ceiling of an apartment on the top floor, although, given the feature noted above, such a need should not be excluded for other types of housing. To insulate the ceiling today, a variety of types of materials are used, not to mention insulation methods. To begin with, let us dwell on the materials, or more precisely, on their most common varieties used for the purpose of interest to us, in particular these:

- Styrofoam;

- penoizol;

- foam ceilings;

- mineral wool;

- polyplex;

- foil polyethylene foam;

- expanded clay;

- ecowool;

- expanded polystyrene, etc.

The choice of a specific ceiling insulation option is influenced by the inherent characteristics of the room, consumer preferences, as well as the budget planned for the implementation of this event under consideration. For insulation, as you can understand, you need a structure that includes a layer of insulation (including a frame underneath it, if it is provided using insulation technology), as well as a finished facing coating - that is, what, simply put, you will see every day after completion all ceiling insulation work.

By insulating the ceiling, you can not only ensure a comfortable temperature regime at one time or another of the year, but also significantly reduce heating costs. Insulation of the ceiling in an apartment, house or cottage in this regard, determines the need to guide a number of the following basic principles:

- maintaining an optimal steam circulation regime during the implementation of measures to minimize heat loss;

- eliminating the possibility of condensation getting into the insulation;

- the use of exclusively environmentally friendly and fire-resistant materials.

If we briefly dwell on the choice of the most suitable method of ceiling insulation, then one of the main determining factors is, for example, the possibility of some lowering of the ceiling due to the materials used (i.e. whether it exists in principle). The use of the same mineral wool justifies such a limitation, because it requires first securing a frame profile to the ceiling, after which, as a final part, it will be possible to attach lining or plasterboard to the ceiling.

Space saving is allowed as an option if insulation is carried out without the subsequent installation of a suspended ceiling. This option involves applying a layer of plaster to the insulation attached to the ceiling, after which a reinforced mesh is installed over its surface (it is literally pressed into the base, that is, into the insulation). Subsequently, the ceiling is leveled, puttyed, primed, and finally painted.

If you need to resolve the issue of ceiling insulation as soon as possible, then the best solution would be to use a foam ceiling.

Insulation methods

The only difference in the methods will be that some of the heat insulators can be mounted on a specially constructed frame, and some can be laid on the outside of the ceiling, which is the floor in the upper room.

From the inside of the rooms, you can simply glue foam tiles to the ceiling, immediately obtaining both the design of the ceiling with a beautiful finishing material and a small heat-saving layer.

But such insulation, as a rule, is not enough. More significant measures need to be taken. And with this, the same polystyrene foam can help, but with a greater thickness than decorative tiles.

Its advantage is that you can glue foam boards directly onto the ceiling using regular tile adhesive. After gluing, the foam plastic is plastered over the mesh and finished with a finishing layer of decorative coating. The method is inexpensive, but requires fairly good plasterer skills for subsequent finishing.

Penofol

Characteristics

Penofol is a combined material, one side of which is foamed polyethylene, and the other is aluminum foil . Its thickness is 2-5 mm and penofol is usually not used as a full-fledged insulation. But, there are exceptions to any rule.

Penofol

Penofol structure

Advantages:

- resistance to moisture absorption;

- resistance to temperature changes;

- reflective effect

Flaws:

- low compressive strength;

- requires the use of additional insulation.

Installation

Penofol is attached to the ceiling using an adhesive solution or using a stapler. In this case, the foil side should be facing inside the room. Fastening is carried out end-to-end. And the joint is taped with aluminum tape.

Sealing joints.

The final look is shown in the photo below.

Wall insulated with penofol

Helpful advice. If you purchased double-sided material, then you need to mount the sheathing before you begin attaching it. This is due to the absolute moisture resistance of penofol.