Any person strives to equip his own summer cottage with the necessary additional structures. One of these is the bathhouse. Previously, its construction was made of wood. This material gave the building an aesthetic appearance and also provided good thermal insulation. However, to build a bathhouse, you must have certain skills in working with wood. Therefore, cinder blocks are often used nowadays. What are the pros and cons of a cinder block bathhouse, reviews? More about this and more in the article.

Characteristics of cinder block

According to regulatory documentation, this is a building material that has a rectangular shape and is made from cement mortar. To obtain it, a special solution is poured into a mold, after which it is pressed mechanically (or wait until natural shrinkage occurs). A cinder block can be solid or hollow, that is, when there are holes in the rectangular shape.

They are designed to make the structure lighter, as well as for better adhesion to the cement-sand mortar during laying. The procedure for making cinder blocks can be seen not only at the factory, but also directly at the construction site, using improvised means. What are the pros and cons of a cinder block bathhouse using wood and gas? This article will help you compare this. Let's take a closer look at these structures.

Bathhouse made of cinder block - pros and cons, photo

The advantage is that in terms of speed of construction, any other material is significantly inferior to cinder block. Anyone can build a bathhouse.

All you need is to have basic knowledge and skills. If they are not there, then you will have to spend money on a team of specialists. Among the shortcomings, one can only note the appearance. Wood analogues look much more organic.

Minuses

This material also has many disadvantages:

- Appearance. Without special modification, a cinder block does not have a very attractive appearance. Hence the need for additional cladding and interior finishing.

- Poor resistance to water. Despite the fact that slag is chemically inert, cinder blocks do not have such a monolithic structure that they are not afraid of water. Systematic exposure to steam or liquid can lead to destruction of the material. For a bathhouse, this is a significant drawback, so waterproofing of the wall structure, high-quality drainage and other means of minimizing contact with water are necessary.

- Controversial environmental safety. You understand that industrial waste is used in production. The risk is greatly reduced if the blocks are made independently.

- Not ideal thermal insulation. If you don’t want to heat the bathhouse empty, then in addition to waterproofing, you will also have to install thermal insulation on the walls.

Environmental friendliness

What are the pros and cons (comparison) of a cinder block bathhouse in terms of environmental friendliness? When making cinder blocks, no materials are used that have an impact on human health.

At some factories, molds are filled not with cement-sand mortar, but with environmental waste. Only in this case will there be a negative impact.

Building shrinkage and finishing

House shrinkage

The interior decoration of log houses has many nuances precisely because of the high degree of shrinkage. Bathhouses made from cinder blocks do not have this drawback; you can safely attach any finishing materials to walls and other surfaces without fear of their deformation.

For example, the exterior finishing of a bathhouse with siding is performed in the following order:

- a sheathing made of wooden blocks or aluminum profiles is mounted on the external walls of the house;

- slab/roll insulation 150 mm thick is laid in the space between the sheathing strips;

- A rolled vapor barrier is stretched over the insulation. Adjacent sheets of material should be laid with a ten-centimeter overlap and taped with foil tape;

- a counter-lattice is mounted to which the panels of the selected siding are attached.

Insulation

A ventilated facade will decorate the bathhouse and will not allow moisture to accumulate in the walls.

The inside of the bathhouse walls are also insulated with any available “breathable” materials (for example, mineral wool), covered with a vapor barrier and covered with decorative panels (wooden lining is used in the steam room).

Lathing on the walls

Laying insulation

Vapor barrier

Interior finishing with clapboard

Floors must be waterproofed, and it is also important to install an effective ventilation system to prevent condensation from accumulating in the rooms.

Video - Comparison of building materials

Thermal conductivity

The material owes its heat-insulating properties to the presence of an element such as slag, which has a high density. In terms of this property, it is significantly superior to other materials. Thermal conductivity depends on the technology for producing the block.

In this indicator, it is superior to brick, but inferior to wood. Solid blocks have higher thermal conductivity. To improve the thermal insulation properties, more slag must be used. Such a change will affect the quality of the building material. It will lose its strength.

Reviews recommend using blocks with internal voids. This material is dense, which will ensure durability and heat retention for a long time. A high-quality cinder block should weigh about 15 kilograms. Blocks that are too light or heavy are an indicator of defective material.

Flaws

What are the pros and cons of a cinder block bathhouse? First of all, you need to pay attention to environmental friendliness. As mentioned earlier, in some factories, not cement mortar is used as a filler, but various environmental wastes. The use of such blocks will lead to serious consequences. Quality can only be checked in laboratory conditions. Although it costs money, health is more expensive.

What other pros and cons does a cinder block bathhouse made with your own hands have? Another significant disadvantage is high water absorption.

To reduce it, it is necessary to provide high-quality hydro- and vapor barrier. Particular attention should be paid to the steam room, since the air humidity there reaches 70%. Insulation is made in several layers. Only in this case will the structure last a long time.

It is worth noting that cinder blocks have an unattractive appearance. But this is a controversial issue. On the one hand, the design of the bathhouse does not play an important role, since everything depends on the personal preferences of the owner. Therefore, you can leave everything in its place.

On the other hand, enterprises have appeared that produce cinder blocks of different colors. To do this, special dyes are added to the cement mortar. Therefore, you can choose the appropriate color and start building a bathhouse. The cost of such blocks is not much different from standard ones.

pros

The first advantage will, of course, be cost. Cinder block is made from a solution using the following components:

- Cement (about 1 tenth of the total solution);

- Filler in the form of slag from metallurgical production or other waste (broken brick, sawdust, crushed stone);

- Water;

- Modifying additives.

The main share in the solution for cinder blocks is allocated to various wastes, which can significantly reduce the cost of the material compared to other types of blocks (foam concrete, aerated concrete).

Since the use of various fillers largely determines the specific properties of a cinder block, next we will consider the advantages of those blocks that are based on metallurgical slag:

- Cinder blocks don't burn. In a sauna environment, this is a significant plus, especially if you tend to use homemade stoves of dubious design.

- The blocks are not affected by mold and biological factors (if the filler is sawdust, then this item can be excluded). In conditions of high temperature and high humidity, the property of biological stability is extremely important, because otherwise mold will instantly appear on the walls.

- Chemical inertness. Slag from the metallurgical industry has already been subjected to extreme temperatures and chemical processing. What went into waste was precisely what was insensitive to such factors.

- Ease of construction. Working with blocks is easier than with other wall materials. If you make the blocks yourself, then you can make them of any size you need.

- Maintainability. Repairing a bathhouse using cinder blocks will cost less than any other.

- Sufficient physical and mechanical properties. It is, of course, not recommended to subject the cinder block to high loads. But in a one-story bathhouse such loads are unlikely to arise, so the strength of the blocks will be quite sufficient.

Which one is better to build a bathhouse?

Today, gas and wood bathhouses are being built. Most users use the first option. First of all, because of its convenient use. Just press a few buttons, and the gas burner brings the air temperature in the bath to the required temperature.

When using firewood, there are many nuances:

- procurement and storage;

- to heat the bathhouse you need to bring and add firewood;

- the presence of soot, which can fall directly into the steam room;

- chimney cleaning.

How to build a bathhouse from cinder blocks yourself?

The construction technology of the structure is divided into several stages. Let's look at each of them in detail.

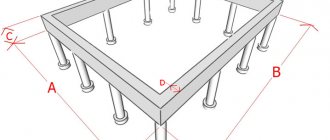

- Construction of the foundation. To begin with, the soil is prepared, a pit is dug and the foundation is poured. Work on laying walls can begin only after two weeks. Cinder blocks have a porous structure, and therefore they are lighter than brick. For the construction of a bathhouse, both strip and column foundations are used. The main requirements are that the foundation must be located above the ground at a height of 0.5 meters, since the cinder block, absorbing moisture, can quickly collapse. After completing the construction of the foundation, waterproofing work is carried out. The process is carried out using bitumen and roofing felt.

- Wall masonry. The process of laying cinder block is no different from brick. However, there is one peculiarity. To strengthen the structure of the bathhouse, reinforcement is laid every three rows of cinder blocks.

- Construction of roof, floor and ceiling. First you need to pour a concrete floor and insulate it with expanded clay tiles. After this, they are engaged in laying ceramic tiles. Depending on personal preferences, you can use wooden elements rather than tiles. It is worth considering that the material absorbs water well and is subject to rotting. The next stage is installation of the ceiling. Next you need to build rafters and cover the roof. Corrugated sheeting or slate can be used as roofing material. During this stage, heat and vapor barrier of the bathhouse premises are carried out. This is done using the following technology: a wooden beam is attached to the cinder blocks every 50 cm. Mineral wool is laid between the beams, and then covered with foil, which serves as a vapor barrier. All wooden structural elements are treated with a special substance against fire.

- Interior decoration. After attaching the foil, another wooden frame should be erected to provide additional ventilation. For interior decoration, you can use lining, which will also give the bath a medicinal smell.

- Exterior finishing. This is one of the important stages of construction. If cold air or precipitation penetrates through the walls, the properties of the bath are reduced to zero. To begin with, two layers of plaster are laid on the cinder block. After it has dried, you can start laying insulating material. To do this, you can cover the external walls with siding or decorative stone. It all depends on the personal preference of the owner, as well as his financial situation.

Bathhouse made of cinder block - analysis of the intricacies of construction, insulation and finishing

Ensuring the insulation of a bathhouse and its waterproofing means killing two birds with one stone. Using waterproofing, we will block the access of moisture to the cinder concrete and prevent harmful fumes from penetrating into the room. Particular care must be taken to insulate the walls in the steam room, where there will be the highest concentration of moisture.

On the walls we arrange a wooden sheathing of slats with a cross-section of 50x50mm and place a heat insulator in the resulting cells. We put foil film or aluminum foil on top for waterproofing. Stitches! We make sure to ensure that the joints are tight, otherwise all the work will go down the drain. The inside of the bathhouse is finished with either clapboard or other finishing material, but preference should still be given to wood.

Using exactly the same method as on the outside, we cover the walls from the inside with foil. We lay the strip on top of the film in increments of 50cm.

It is recommended to make the floor concrete, but do not forget to make a slight slope towards the drainage hole. The floor does not require additional finishing; you just need to make a slatted grid that would be comfortable to walk on barefoot.

In fact, building a bathhouse from blocks is not such an expensive pleasure and everyone can afford it. The average price of one cinder block is 28 rubles, and for the entire structure, taking into account the delivery of materials and finishing, no more than 150,000 rubles should be spent.

In addition to being cheap, slag concrete blocks have the following advantages:

- They have high thermal insulation properties.

- Very light - much lighter than concrete and water.

- Can be absolutely any size.

- Completely resistant to mold and mildew.

- Absolutely fireproof.

- They are extremely easy to use - the bathhouse can be built in a matter of days.

Now about what exactly a cinder block is. Essentially, this is a type of sand-lime brick, but there is no quartz sand - instead, porous slag is used, which is very light and cheap. The structure of the cinder block is porous, and therefore provides excellent thermal insulation for the bathhouse. And this is the most important thing.

The floor of the bathhouse is made of concrete, and a sewer pipe is laid under it to drain water (and, if necessary, water pipes). The floor can be finished with ceramic tiles and then covered with wooden flooring.

The room needs waterproofing. A 50x50 mm beam is attached to the walls, and insulation is laid between the sheathing and covered with foil film. When choosing how to insulate a bathhouse, choose mineral wool. This is an inexpensive and reliable material.

The most common material for interior decoration remains wooden lining. The planks are pre-treated with an antiseptic. To secure them, a new sheathing of 50x30 mm slats is installed.

The sheathing is stuffed in the opposite direction in which the lining will be done. That is, if the lining is fixed horizontally, then the sheathing needs to be filled vertically.

Finishing the bathhouse with siding

It is necessary to line a cinder block bathhouse not only for beauty, but also to protect the material from destruction. The walls are plastered in two layers, and then covered with vinyl siding or faced with decorative brick.

To select a suitable bathhouse project, you can look at numerous photos, and the work process will become clearer after watching a video about the construction technology of the building.