If the area of a structure, room, or object is large, the roof must have a very reliable and durable structure. The best option is to use rafters made of pipe metal in this case. They will become a strong, durable, economical structure capable of covering a span of any length. Calculation of a truss made from a profile pipe is the most important condition for its correct installation.

Such systems are ideal for large spaces.

Design features

Pipes of this category are produced by rolling and then processing the metal using special machines.

According to the type of section, profile products are divided into:

- oval;

- rectangular;

- square.

Initially, profile products are round. When it is processed by hot or cold rolling, the pipes acquire the required shape.

Metal profiled products have different sizes. Their cross-section is minimum 15×15 mm, maximum – 45×5 cm. Wall thickness is 1.12 mm, average length is 6.12 m.

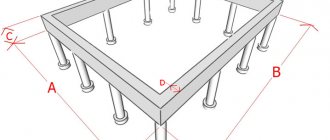

Main elements of a steel truss:

- belts playing the role of a contour;

- racks;

- braces;

- main (support) brace.

- fastening elements: gussets, welding, rivets, bolts, etc.

Types of farms

Diagram of a hanging structure.

The instructions indicate that trusses assembled from profiled pipes are divided into two types.

- The first of them is systems in which all their parts are connected in one plane.

- In structures of the second type, the truss is suspended and includes a lower and upper chord.

The choice of one type of rafter system or another depends on the following:

- loads on the product;

- tilt of the structure;

- location points of load-bearing floors;

- span length.

Tilt angle

Drawing of the base of the roof with an angle of 30 degrees.

Based on the angle of inclination, there are the following typical trusses.

- A structure with a slope angle of 22/30° . The best option when constructing a small ceiling. It is best in this case to use a triangular configuration. To determine its height, you need to divide the span length by 5. The main advantage of such an analogue is its low mass.

Note! When the span length is more than 14 m, it is better to give preference to a truss with braces placed top/down. A panel 1.5/2.5 m long is mounted on the top of the structure. Such a rafter system contains two belts with an even number of panels.

When trusses are manufactured from profile pipes, the length of which exceeds 20 m, they are installed using rafter structures. They are connected by supporting columns.

- If the roof has a slope of 15/22°, the height of the truss is determined by dividing the span by 7 . The length of such systems should not be more than 20 m. If it is necessary to increase the height of the structure, the lower belt is made broken.

- If the roof slope is less than 15°, a trapezoidal product is installed . Its height is determined by dividing the span by 7/9. Its exact value depends on the specific slope value.

Design form

The photo shows a pitched roof base.

According to their configuration, rafter systems made from profiled pipes are divided into the following types:

- single-pitched analogues, the price of which is the lowest;

- gable structures;

- straight trusses;

- arched structures.

Belt outline

Outlines of structure belts.

Farms with parallel belts have the following advantages:

- ease of installation due to the fact that most of the elements are the same;

- the length of the pipes of the belt and sheathing is the same;

- the number of joints is minimal;

- the design is standard (unified);

- can be used for soft roofing.

When making a lean-to truss from pipes with your own hands, you will receive the following advantages:

- rigid and durable components;

- absence of excessively long elements in the center of the structure;

- cost-effectiveness of the structure.

Polygonal structures have their own characteristics:

- they are used for buildings with a large mass;

- when constructing farms, pipes are used economically;

- The disadvantages of this type of truss are the complexity and labor-intensive installation.

Diagram of a triangular structure.

Triangular structures are easy to install. They are used for roofs with a steep slope. The disadvantages include the complexity of manufacturing support units and the high cost of materials.

Truss sheathing is divided into the following types.

- Triangular lattice. Usually used in structures with parallel sides, less often in analogues of a triangular or trapezoidal shape.

- The diagonal type of sheathing is labor-intensive and expensive to produce due to the high cost of materials.

- Grilles of original shapes are arranged taking into account the features and dimensions of the trusses.

Advantages of metal shed trusses

Despite the complexity of the manufacturing process of single-pitched metal trusses, the assembly of such structures is characterized by economical consumption of material. In addition, the structures are characterized by a high level of rigidity and strength.

The main advantages of farms are:

- resistance to rotting;

- long service life;

- high levels of durability;

- ease of use in the construction of high-rise structures of large areas.

In addition, properly designed and installed lean-to structures are highly resistant to wind. And their construction takes less time compared to trusses of other designs.

However, these structures also have certain disadvantages:

- Heavy weight. Even if the structure is assembled from a thin-walled steel profile, it can weigh up to 5 tons with a length of about 15 m.

- Installation of the truss is impossible without the use of specialized equipment and welding equipment.

- When it rains, water flows to one side, therefore, it is necessary to additionally install a drainage system.

The scope of application of single-pitch structures is quite wide.

They are used in the construction of covered car parks. Bus stops, shopping pavilions and shops cannot do without them.

Also, such structures are designed to protect small technical structures from precipitation.

Truss calculation

Professional design drawing of a truss.

- Before you calculate a truss made from a profile pipe, decide on its layout. Indicate in it the dependence of the length of the structure on the roof slope angle.

- When drawing up a diagram, select the contours of the belts. They depend on the purpose of the truss, the type of roofing and the slope angle.

- Next, determine the dimensions of the structure. When choosing its length, take into account the future angle of the roof. The height depends on the type of floors, the possibility of delivering the truss and its weight.

- If the length of the structure is more than 36 m, calculate the construction lift.

- Decide on the dimensions of the panels. Do this based on the loads that will affect the product. When designing a triangular truss, the slope angle should be 45°.

- The final stage is determining the distances between nodes. Next, a drawing of the structure is drawn up.

Some tips

The design results depend on the roof slope angle.

- If it is 6/15°, a trapezoidal truss should be selected. Its height should be in relation to 1:7 or 1:9 to the length of the span. If, according to the project, the height of the ceilings (attic, attic) should be greater, polygonal structures are built.

- For single-pitch structures with a slope angle of 6/10°, it is better to prefer their asymmetrical shape.

- When the roof slope is 15/22°, the height of the truss should be 1:7 to the span length. If there is a need to increase the height of the ceiling, a broken lower chord is mounted.

- If the roof slope is 22/30°, triangular trusses are constructed. Their height should not exceed a fifth of the span length. (See also the article Gazebo from a profile pipe: features.)

Note! To design the structure and before welding a truss from a profile pipe, read SNiP No. II /23/81, the code describes the rules regarding metal structures. SNiP No. 2.01.07/85 should also be studied; the document covers the topic of loads and impacts.

Manufacturing of the structure

The production of knots usually takes place on the ground.

- To assemble or fix parts, use paired angles or tacks.

- When installing the top of the belts, take 2 T-angles with different side lengths. Fix them together with smaller strips.

- To connect the bottom of the belts, use corners with identical sides.

- When producing a long and voluminous truss, use overhead plates as clamps. To ensure that the loads are distributed evenly, use paired channels.

Installation of braces in two ways: with attachment to a belt and to a cylindrical overlay.

- Mount the braces at an angle of 45°, and the racks at 90°. To assemble them, use cross-shaped or T-shaped corners with identical sides. Secure them with plates.

- To install integral welded trusses, brands are used.

- To facilitate the construction with a minimized slope, use additional gratings.

- When arranging a long structure, only an even number of panels should be installed.

- The gap between two trusses should not be more than 1.75 m.

Welding of elements.

- When the assembly of the units using tacks is completed, welding of the trusses from the profile pipe begins. This can be done automatically or manually. At the end of welding, all seams are cleaned. (See also the article Butt welding of pipes: features.)

- At the final stage, the product is coated with an anti-corrosion compound and then paint.

What are farms?

These are structures that consist of rods (elements that are connected to each other). Intended as a frame for a future building. The rods located at the top are called the upper chord, and at the bottom - the lower one. Parts of trusses that are located vertically are racks. Elements that are at a certain angle are called diagonal. It is the bracing elements and racks that form the lattice of the structure. Points on trusses at which braced blocks and struts (vertically placed) assemblies of a reinforced concrete beam are connected.

There are two types of farms:

- monolithic (integral structure; created in factories);

- composite (the structure consists of several parts).

Monolithic ones, as mentioned above, are manufactured in factories. They are transported to the immediate construction site, then supported on stable columns (supporting a reinforced concrete structure). Composite structures are assembled at the repair site from parts that have a rectangular cross-section.

Return to contents