Is it possible to build a bathhouse from aerated concrete?

Many steam room lovers are interested in the possibility of building their own bathhouse, reducing the cost of its construction.

One of the options for relatively inexpensive construction is the use of aerated concrete. When asked whether it is possible to build a bathhouse from aerated concrete, all professionals answer in the affirmative. The main thing is to carefully study the specifics of the material. Knowing the conditions in which construction with aerated blocks is expected, you will build a beautiful and durable bathhouse. Unlike a bathhouse made of expanded clay blocks, the building is resistant to aggressive environments. Due to its low specific gravity and the presence of pores, it will have a low degree of thermal conductivity. This will provide comfortable conditions and save energy resources for heating.

Aerated concrete intended for the construction of steam rooms has:

- porous structure;

- rectangular or U-shaped;

- optimal dimensions 625 x 240 x 250 mm or 600 x 300 x 250 mm;

- frost resistance, which is indicated by the marking, from F35 and above.

The thickness of the walls of a bathhouse made of foam concrete or aerated concrete usually depends on the region of location. In the northern parts of the country, it is recommended to erect walls whose thickness reaches 60 cm. For the middle zone of the country, thinner walls are suitable - with a width of 250 to 400 mm.

In terms of hardness and density, the blocks are not inferior to brick and wood, and they are easier to work with

When purchasing material, it is important to choose products from a trusted manufacturer. One of the well-known brands on the modern market is “Aeroc” - this type of aerated concrete is characterized by high quality, and the percentage of defects is minimal.

Advantages and disadvantages of aerated concrete blocks for baths

The use of aerated block, according to experts, is a rational approach to landscaping the site.

In order for a bathhouse made of aerated concrete to bring pleasure to the owner and his guests for decades, even at the design stage it is necessary to take into account the following features of the material:

- lightweight design, the ability to perform construction operations without the use of special equipment;

- affordable cost - several times cheaper than wood;

- high strength, resistance to vibration and intense mechanical stress;

- excellent thermal insulation qualities (sometimes you can do without the additional use of insulation);

- immunity to the formation and proliferation of fungus and mold;

- Fire safety;

- optimal specific density, low load on the foundation.

Despite the abundance of advantages, there are also a number of disadvantages. If you order gas blocks with a low density, they may be excessively fragile. Some varieties have low thermal conductivity and ability to absorb moisture. These disadvantages can be minimized by choosing high-quality aerated concrete intended for the construction of steam rooms.

When talking about wooden bath structures, environmental friendliness comes first, but gas blocks also consist of natural materials

In addition, some users note such phenomena when using the material, such as:

- blowing through the masonry when using low-quality glue that does not provide the proper level of tightness;

- freezing of the binding row of bricks. It is preferable to replace brick ligation with polymer bonds;

- low temperature of lintels and armored belts - you can replace them with foam concrete floors.

Development of projects for baths made of aerated concrete

Aerated concrete has specific characteristics that must be taken into account when developing a project. It is recommended to contact a construction organization - they will perform this task professionally. The documentation should include recommendations for improving hydro- and vapor barrier inside and outside the bathhouse.

Particular attention should be paid to the tightness of window and door openings, as well as reliable joining of waterproofing material. In some cases, it is necessary to install ventilated facades and membranes that allow steam to pass in one direction.

The project takes into account and identifies the following components:

- location and size of the vestibule, rest room, bathroom and steam room;

- communications supply;

- foundation type;

- swimming pool (if necessary);

- a type of stove for heating a steam room.

If you follow all the technologies, then building a bathhouse from aerated blocks is not difficult with your own hands.

On the Internet on thematic sites you can find simple, budget and non-standard designs for bathhouses made of aerated concrete. Comparing their features, it is necessary to determine the size of the building and construction costs. A standard Russian bathhouse, as a rule, has a small area and consists only of a steam room and a bathhouse. It can be combined with a guest house.

Aerated concrete baths with an attic are especially popular. Guest rooms or a billiard room are often located on the second floor. The area of the first floor in such a building is larger than in a classic Russian bathhouse. Although this affects the cost of construction as a whole, the level of comfort will increase significantly. To make the most of the usable area of the bathhouse, use the services of professional architects. They will take into account all the nuances of the soil, material and your preferences.

After developing the project, preparing construction documentation and clearing the territory, you can begin construction directly.

It consists of several stages:

- laying the foundation;

- waterproofing and insulation;

- drain device;

- raising walls with openings for doors and windows;

- roof construction;

- installation of chimneys and stoves;

- purchase of windows and doors, their installation;

- exterior decoration;

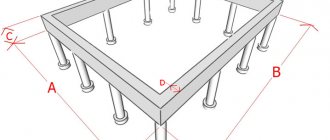

Due to the fact that aerated concrete structures are extremely lightweight, it is possible to use a shallow foundation on almost any type of soil

- floor arrangement;

- ceiling installation;

- interior decoration.

Before pouring the foundation for a bathhouse, take into account the characteristics of the soil - the depth of the foundation depends on it. Light and damp soil needs additional reinforcement, unlike clay. Unstable soil should first be leveled using gravel and sand - it will serve as a kind of cushion for concrete. Before pouring, moisten the bulk raw material - this will compress and compact it more effectively. When setting up a bathhouse on heaving soil, strengthen it with reinforcement.

Climatic conditions also matter. The construction of a bathhouse in winter is fraught with the appearance of cracks in the foundation and supporting structure, since after frost the soil thaws and begins to move.

The standard procedure for constructing a base for a bathhouse is performed in the following sequence:

- performing markings. The width of the future base should exceed the dimensions of the walls by 10 cm;

- installation of cast-off posts and boards - it should be placed at a distance of two meters from the driven pegs;

- foundation construction.

Before you start laying building blocks, the foundation is laid out with roofing felt.

The most common method of laying a strip base involves pouring several layers of crushed stone and sand into a trench and moistening them. Next, the mixture should be cemented and a base should be made, covering it with roofing felt to insulate it from moisture. Sand and gravel are poured halfway into the trench. The surface is leveled and bricks are laid on it. Then you need to build and erect the formwork, fill the cracks with sand and compact it. After a few hours, the foundation must be covered with moisture-permeable material - sawdust or shavings, watered and covered with polyethylene. After 7-10 days, when the solution “sets”, the formwork is removed - the base for the bathhouse is ready.

The roof can be single or gable. If you plan to build a small bathhouse for visiting in the summer, choose a pitched roof. It is easy to install and inexpensive. The angle of its inclination should prevent stagnation of rainwater and the growth of ice thickness. If you want to build a bathhouse with an attic, give preference to a gable structure. It is suitable for year-round use of the steam room.

After assembling the building box from the blocks, proceed to the construction of the support for the rafters and the rafter system (it is attached to the beams or mauerlat).

Further installation of the pitched roof is carried out in the following sequence:

- ensuring optimal height difference between supports;

- installation of rafters in increments of 60 cm;

- if the span is larger than 4.5 meters, install struts.

If you are installing a gable roof, secure the rafter legs to the ridge girder with the upper ends using a nail connection. Start with the racks on the front walls, and to make the frame, use a hanging rafter system, for this you need to make several trusses and place them on the walls. The legs must be connected in pairs with a bolted connection in the ridge.

Gas block during the construction of a bathhouse

After installing the reinforced frame, the formwork can be filled with mortar.

- Site preparation.

- Perimeter marking.

- Digging a trench. The depth of the pit is 50-70 cm.

- Formation of formwork. Wooden boards or chipboard are used for the frame. It is important to ensure that the formwork walls are strictly vertical. A level or plumb line is used for control.

- Installation of reinforced frame. Before pouring, a reinforced frame is assembled inside the formwork. For horizontal guides, reinforcement with a diameter of 10-16 mm is taken, and for vertical guides - 6-8.

- Pouring the foundation. A high-quality concrete solution is pre-prepared or ordered from the factory, which is best poured in one go. The recommended grade of concrete for arranging the foundation is not lower than M300.

- Arrangement of a waterproofing layer. Waterproofing a bathhouse made of aerated concrete is an important step. The main material used is roofing material, which is laid on a dried base in 2-3 layers.

The solution is needed only for laying the first row of material.

It is recommended to build walls from aerated concrete from the top corner of the construction site. The first row of blocks is laid on cement-sand mortar, and the remaining rows are fixed with special construction glue. The evenness of the order is controlled by a cord stretched between the corners. You can strengthen the masonry using a reinforced mesh, which is attached to the surface every 3-4 rows.

When constructing window and door openings, it is important to provide a reinforced concrete lintel or U-shaped tray at the top of the future opening. A T-shaped subcortex is installed under the blocks, which will support the structure until the glue sets. There is no need to rush to remove the supports under the openings.

Roof arrangement

The arrangement of the roof of the building should begin with the installation of the rafter system.

A mauerlat is laid around the perimeter of the finished structure, to which rafter legs and crossbars are attached. The rafter system is covered with wooden sheathing. A layer of insulation, waterproofing, and then the roofing material itself is laid on top. Thermal insulation materials, for example, mineral wool, are placed inside the frame.

Steam room insulation

Aerated concrete blocks already reliably retain heat inside the building. But if desired, you can further insulate the structure. Before installing thermal insulation, it is important to treat the outer wall surface with hydrophobic impregnation. It is advisable to insulate a bath using mineral basalt or stone wool or extruded polystyrene foam.

Decorative interior decoration of aerated concrete bathhouse is an important final stage of construction. It is recommended to use wooden lining made from such tree species as aspen, oak, and alder as a finishing material for walls and floors. In addition, you can line the inside of the structure with ceramic or porcelain tiles.

A bathhouse built from aerated block, with the correct construction technology and high-quality insulation, can be used for many years - up to 85-90. Time has shown that you can save a lot of money on gas blocks, installation work takes little time, and the technological indicators of using a gas block in conditions of elevated temperatures and moisture are quite high.

We invite you to familiarize yourself with taking a steam bath with your family

Advantages

Using a gas block has many advantages.

- The gas block is made from natural material, which when heated does not release toxic substances into the environment. This indicates its environmental friendliness and safety in use.

- The building material has a porous structure and is lightweight. To build a bathhouse, you do not need an overly massive foundation; a shallow, strip foundation will do.

- The gas block holds heat well. Additional heat and waterproofing during finishing improve these indicators.

- Building a gas-block bathhouse is 3-4 times more economical than using traditional timber, and approximately 10 times faster.

- The material lends itself well to processing - sawing, cutting, drilling, gating.

- The gas block is not flammable, which meets fire safety requirements.

- The gas block does not rot and is resistant to chemical and mechanical influence.

An important advantage for a bathhouse is that microorganisms, bugs and rodents do not settle in the gas block.

Flaws

Like any material, aerated block has weaknesses.

- The aerated block easily absorbs moisture and takes a long time to dry, so additional waterproofing of walls (both internal and external) and a forced ventilation system are required.

- With additional waterproofing, the walls will be less breathable, which can affect the microclimate in the bathhouse.

- The walls of the bathhouse will breathe less, which means the climate will not be as comfortable. Excessive condensation may occur.

- In a bathhouse made of aerated concrete, interior finishing is required, which means additional costs and extra time for construction.

- There will never be a special woody spirit in a gas-block bathhouse, as happens in a Russian bathhouse made of timber.

Warning! The aerated block easily absorbs and draws moisture from the soil, so a foundation made of this material must be waterproofed on all sides.

Finishing is the final stage of building a bathhouse made of aerated concrete

For interior cladding, you need to use environmentally friendly, natural materials. They must have excellent thermal insulation characteristics and be resistant to moisture.

The quality of finishing of a bathhouse is directly related to the comfort of its further operation.

The material that meets all the criteria is the following wood species:

- ash;

- coniferous species (spruce, pine) without resin;

- alder.

The bathroom or sink surface is tiled with ceramic tiles. To improve hydro- and thermal insulation, surfaces are insulated from the inside after the building has completely shrinked. Typically, a support beam is used for this, on which a wooden lining is attached. The free space formed between the wooden sheathing is filled with insulation – glass mineral wool. To make the microclimate as favorable as possible, lay a warm concrete floor in the bathhouse.

For exterior decoration it is not necessary to use expensive wood - these days vinyl siding, artificial timber or block house have proven themselves well. Decorative stone and facing brick will look good in combination with a metal tile roof.

Pros and cons of an aerated concrete bath, project and opinions of the owners

The ideal option for building a bathhouse is natural wood, but its high cost limits its availability. Gas block is an inexpensive and convenient type of base.

- Description of gas blocks

- Features of the construction of a bathhouse

- Technology step by step

- Reviews and opinions of developers

- Advantages and disadvantages

- Average prices

Characteristic features of blocks

The building material is of artificial origin. The composition contains quartz sand, lime, cement, aluminum powder and water. The prepared raw material mixture is poured into special large-sized molds. As a result of the chemical interaction between lime and aluminum, hydrogen is released, which forms numerous cavities.

Autoclave production technology involves hardening of aerated concrete blocks under conditions of high temperatures (up to 190°C) and pressure (12 MPa). In such a situation, they acquire structural stability and rock strength.

The porous structure provides the special properties of gas silicate products.

- Pros: light weight of the blocks, low thermal conductivity, good vapor permeability and frost resistance. Aerated concrete is fireproof and noise insulating. This is an environmentally friendly and inexpensive material. Another advantage is the ideal geometry of the shapes and large dimensions. Standard length is 625 mm, height 250/300 mm. The thickness, depending on the purpose, is 100/150/200/300/375/400 mm.

- Minuses. It is not used in the construction of high-rise buildings because it is highly fragile and cannot withstand such heavy loads as brick or concrete. Another serious drawback is high hygroscopicity.

Materials and tools

To build a bathhouse from aerated concrete blocks you will need:

- blocks made of gas-filled composite, the number of which is provided for by the project requirements;

- waterproofing and finishing coatings;

- sand, crushed stone and cement for preparing concrete mortar intended for pouring the foundation;

- a concrete mixer that facilitates the process of mixing concrete;

- binding solution - cement composition or special glue for the production of masonry aerated concrete blocks;

- a power tool that forms grooves for laying reinforcement;

- building level, tape measure and square, designed to control deviations of the masonry of aerated concrete blocks in vertical and horizontal planes;

- a tool with which holes and grooves for communications are formed;

- plumbing equipment, fittings.

We invite you to familiarize yourself with Finishing the stove in a bathhouse with decorative stone

Aerated concrete is a popular material from which you can build a building for any purpose. The blocks are made using a special technology, adding aluminum paste to the concrete solution. The chemical reaction produces a gas that makes the structure of the product porous. Thanks to gas bubbles, the walls of the structure are able to reliably retain heat inside the room, which is especially important if you plan to build a bathhouse. Other positive properties of aerated concrete:

- ease of use without special assistance. technology;

- light weight;

- high coefficient of hardness and density;

- environmental friendliness.

Is it permissible to build from aerated blocks?

Characteristics of the base material in relation to the specifics of the object.

- Simple processing and installation scheme. Having masonry skills, it is possible to build a bathhouse with your own hands. The cost of services of a professional team of masons reaches 40% of the total costs.

- Maximum height – 3 floors. The gas block has a density of 350-750 kg/m3, so it is not suitable for the construction of tall buildings. A dense layer of thermal insulation can be laid on the ceiling.

- High temperature resistance. The thermal resistance of blocks that have undergone autoclave processing is three times higher than that of brick. A bathhouse built from aerated concrete warms up quickly and retains heat for a long time. The amount of energy that is expended is much less than in buildings made of wood, brick or stone.

Baths require minimal wall insulation, which greatly simplifies the work.

Nuances of construction

1. Foundation.

Since aerated concrete blocks are lightweight, the bathhouse does not need to reinforce the base. A shallow strip foundation is quite suitable for it. It can be installed on almost all types of soil.

2. Laying walls.

- The optimal thickness is 250-500 mm. For leveling, use a rubber hammer; it is better to cut with a hacksaw.

- The first level is laid out on cement mortar, which allows the gas blocks to be well leveled horizontally. Subsequent laying is carried out using an adhesive composition with a seam thickness of 5-7 mm.

- Reinforcement is done every 3-4 rows. To do this, the walls are grooved along the entire perimeter at a distance of 5-6 mm from the top edge. This is convenient to do with an end mill. The holes are filled with glue and pieces of reinforcement are placed in them. The use of perforated strips eliminates the need for gating and speeds up the process.

- The last row on which the roof is mounted is reinforced with a monolithic stiffening belt. First, metal pins (studs or large anchor bolts) are screwed into the wall, then twisted wires are placed on them. This prevents the rafters from moving. Concrete mortar is poured from above into the pre-assembled formwork. The ring strap helps to distribute the load evenly.

3. Hydro and vapor protection.

- Penofol, glassine, and foiled propylene foam are used as a waterproof layer on the outside. You can also apply hydrophobic impregnations or primers.

- For internal waterproofing and insulation, it is recommended to cover the bathhouse with foam glass. The material is a foamed (cellular) glass mass, the main advantage of which is zero water absorption. Another option for protecting internal surfaces is treating with liquid glass and covering with aluminum foil. This will create a thermos effect.

- Vapor barrier is performed using film or polymer membranes.

4. Insulation and finishing.

For external protection of a bathhouse made of blocks, a ventilated facade is required. The design reduces the likelihood of moisture penetration. The top of the walls can be lined with decorative slabs, plastic panels or wooden lining. Some owners recommend covering the outside with brick, but it’s easier to just build with it.

- For external insulation using the wet facade method, mineral wool or expanded polystyrene are chosen.

- When decorating the ceiling and finishing walls, you can use linden or aspen lining. The big advantage of these types of wood is their good thermal conductivity and resistance to moisture. To create an air gap between the foil and the finishing layer, a lathing is installed.

- Natural wood or ceramic tiles can be used as flooring.

5. Roof.

The optimal option for arranging a roof is a gable structure. For covering you can use flexible tiles, slate, metal tiles.

Owner reviews

“All reviews that it is better not to build anything from aerated concrete come from ignorance of the features. If everything is done according to technology, then this is an excellent option for a bathhouse. I built it with my own hands, I didn’t skimp on finishing, the walls turned out to be quite thick. It’s a great pleasure to take a steam bath with the whole family and invite friends.”

Evgeniy, Samara.

“4 years have passed since I built a bathhouse with my own hands from an aerated block. First, I studied all the pros and cons, listened to reviews from the owners, and read the installation instructions. Then I carefully thought through the waterproofing of external and internal surfaces (although I am not an expert myself). The steam room was insulated with fiberglass, mineral wool was laid on the floor, and the top was finished with pine clapboard. I was also pleased with the price of construction.”

Mikhail, Perm.

“Last year I decided to build a steam room out of aerated concrete at my summer cottage. Since the porous material needs protection from moisture, a wooden frame was installed inside. I stepped back a little from the wall to create a ventilated space. I attached fiberglass insulation and topped it with alder strips.”

Victor, Moscow.

“I’ll point out the main advantages of building with aerated concrete. Firstly, it is convenient and quick to do the masonry yourself, even without special skills. Secondly, a bathhouse made from blocks is warm. Walls 200 mm thick are comparable to wooden walls 400 mm thick. Thirdly, it is profitable, since the blocks are inexpensive and available.”

Nikolay, St. Petersburg.

Add a review

Pros and cons of aerated block baths

- High thermal conductivity. For middle latitudes, wall thicknesses of 250-350 mm are enough to quickly warm up a room and keep it warm for a long time.

- Environmentally friendly. Porous stone has good vapor permeability (“breathes”), which creates a healthy microclimate.

- Fire resistance. The artificial material does not burn at all, which is a very important advantage for a bathhouse.

Unlike natural logs or timber, gas blocks do not require calibration, cutting, pre-treatment with antiseptics and other complex manipulations. They are easily and quickly laid on an adhesive base.

The big disadvantage is exposure to moisture. This drawback can be mitigated by using hydro- and vapor barrier in the arrangement of walls.

Construction cost

The final price depends on the size of the structure, the complexity of the layout, as well as the level and capabilities of the contractor. On average, the construction of a turnkey budget bathhouse costs 10,000-12,000 rubles per square meter. Taking into account the finishing work, the price increases to 19,000-22,000. If you do everything yourself, the savings can be 40-50%.

You can use a ready-made plan or develop a custom project. This helps to determine the location of windows and doors, choose insulation, insulation, and calculate the amount of material needed. When developing a project, you need to take into account all the features of aerated concrete. To avoid mistakes in construction and cost overruns, consultation with an experienced designer is recommended.

Often, a gazebo becomes a real decoration of a personal plot, or even an entire country estate, a real work of art. However, often most often people are interested in a more mercantile and everyday question: how to build this structure cheaper and easier, what material to choose and at the same time build a nice structure.

The question of choosing the main material arises immediately, even at the design stage of the object. This should be a favorite and cozy place for the whole family. And at the same time, you need to choose a material that allows you to build quickly, efficiently and beautifully, without unnecessary costs, both labor and material.

Proper insulation of a gas silicate brick bath

Wall cladding with siding

Let's first define the terms. Two completely different building materials are used in construction: sand-lime brick, usually white, obtained by pressing from sand and lime, and gas silicate block, obtained from sand, water and lime with the addition of gas-forming additives, usually by autoclave processing.

I have already written many times that a bathhouse should be insulated with mineral wool from the outside (see here, here). You were correctly told that it is impractical to insulate the inside with mineral wool; it will quickly become unusable. If the bathhouse is rarely used, then it will in any case cool down to the outside temperature.

And, indeed, before using it, the walls will need to be warmed up well each time. No matter how you insulate the walls from the inside, the internal insulation will still not be able to retain heat so much that the walls remain cold (even from gas blocks), especially the walls of the steam room. The main purpose of the insulation inside is to prevent moisture from entering the walls.

Now about the external protection of the walls of your bathhouse with siding. Most often, this term refers to plastic siding. I have already written several times about the dangers of using this material for the construction of a bathhouse. In addition, it is necessary to correctly make a multi-layer insulation cake when covering external walls with siding.

- location, area, entry/exit point of water, sewer pipes and power supply;

- the presence of main and additional premises and their footage, the location of windows and doors;

- preliminary location of the boiler, other plumbing, as well as ventilation and smoke ducts.

Based on the finished project, you can calculate the amount of materials required for construction and draw up an estimate.

A sauna from an aerated block can be made in a variety of ways - from a simple, budget option to a more expensive one, with an attic and a terrace. The building material allows you to make a multi-story bathhouse, but with a mandatory armored belt between floors.

A gas-block bathhouse can be of different sizes, have several rooms, and be different in shape, height and finish. All these factors depend on the needs, taste and financial capabilities of the owner.

Such a bathhouse will fit well into a small garden plot. This project assumes the presence of all the necessary service premises - a steam room, a shower room (washing room) and a hallway (or rest room). Due to the small size of the steam room, the sauna quickly heats up to the desired temperature, which significantly saves fuel. The shower room can accommodate a bath or cabin, and the relaxation room can accommodate a small dressing room and a compact sofa.

Such a bathhouse can accommodate up to 5-6 people at the same time, and it will not be crowded. For 1 person, you can make a bathhouse even more compact - 3x4 m.

Important! According to sanitary standards, there must be at least 2 m² per person in the bathhouse.

The design of this bathhouse is designed for a large area, since in addition to the necessary premises it has a fairly spacious terrace. For the summer, such a bathhouse is just a godsend. The sauna terrace can be used as an independent building under a roof, for example, for a summer holiday with a barbecue.

The bathhouse for this project is designed for 8-10 people. The steam room is small, so it won’t take too long to warm up. The washing room (or shower room) can be equipped with a font, a compact Jacuzzi or a shower stall. The comfort zone is arranged according to the taste preferences of the owner.

Important! The optimal area for building a bathhouse designed for 1 person is 3x4 m, for 5-6 people - 6x6 m, for a large company - 8x8 m or more.

It is not difficult to build a more expensive and spacious bathhouse from an aerated block with your own hands. Lovers of Russian baths, who spare no expense on their hobby, create two-story baths with a large area of comfortable areas for relaxation and entertainment. Quite often, such baths are designed with an attic floor and a terrace.

The first floor is the bathhouse itself with a steam room, shower, toilet and changing room. The terrace can be either under its own canopy or with a common one. Terrace enclosing partitions are made of gas blocks, as well as with a metal or wooden frame.

The second floor of the bathhouse is a relaxation area. It can be with a bedroom, a games area (billiards, table tennis) and a small gym.

The optimal layout of sauna plumbing and heating equipment varies.

Advice! Before starting the construction of a bathhouse, it is necessary to check with the registration chamber (FKP Rosreestr) the list of documents for registration of this building and obtain a “Construction Permit”.

Construction stages

When the bathhouse project is ready and calculated, you can proceed to the actual installation of the bathhouse. The entire construction process is divided into several stages, the quality of each of them is very important, since this ultimately affects the durability and performance of the entire structure as a whole.

Foundation

For a bathhouse, you can make a strip or monolithic foundation from an aerated block. But most often a strip foundation is used for a building, since it is more reliable and cheaper. The question of choice depends on the preferences of the owner and his financial capabilities.

We invite you to familiarize yourself with Yantarnoye apple jam

How to make a strip foundation:

- Clear the area of vegetation and level it.

- Use pegs and string to make markings.

- Form a trench (depth from 50 to 80 cm, width 30 cm).

- Place crushed stone and sand (“sand cushion”) at the bottom of the trench; the thickness of the cushion is 20-25 cm.

- Make wooden formwork around the entire perimeter (height for the bathhouse 75-80 cm).

- Mount a reinforced belt made of steel cable and knitting wire inside the formwork walls.

- Drill holes for outlet pipes and communications.

- Fill the formwork with concrete mortar and leave to dry.

Next, waterproofing work is carried out. For this purpose, rolled roofing felt impregnated with fusible bitumen is used.

You can make a monolithic foundation for a bathhouse from an aerated block according to the following instructions.

- Level the area and mark it.

- Dig a pit 80 cm deep.

- Pour a 15 cm layer of sand and compact it.

- Pour crushed stone in a 15 cm layer and compact it.

- Install wooden formwork around the perimeter.

- Place and fix the reinforcing mesh over the entire area of the pit.

- Pour in concrete mortar and leave to dry.

After complete drying, the foundation is insulated from moisture with rolled bitumen roofing felt.

Warning! The finished foundation must stand without load for 30-40 days (minimum), after which the walls of the bathhouse can be erected.

Walls made of aerated concrete are laid starting from the corners, carefully checking the dimensions of the finished box. Then, a cord is pulled between the blocks so that the first row of the wall along it is as even as possible. The first row of blocks is laid on cement mortar, adjusting the size and height using a building level and a rubber hammer.

After laying the first row of gas blocks, the cement mortar is given time to dry completely so that when laying the next row, the blocks of the first do not move under load and have good adhesion.

Next, the gas blocks are laid on a special glue using a glue carriage, spatula or ladle, with dressing applied to half the block. The adhesive seam should not be more than 7-8 mm.

Every fourth row of masonry is reinforced with an armored belt. To do this, a double groove is punched in the upper part of the gas block along the entire perimeter. A steel cable is placed in it and filled with mortar. For the convenience of this operation, a wall chaser is used, which helps to punch grooves in aerated block building materials.

For the installation of window and door openings, special U-shaped gas blocks are used. A temporary support is installed under the openings, the block with the tray is filled with reinforcement ties and filled with concrete mortar.

For openings, steel lintel corners are also used. Corners (50, 75 mm) are laid in place of the opening, extending beyond the edge at least 10 cm on each side. The metal corner must be cut into the block so that the remaining edge is equal to 1/3 of the total width of the block.

The very last, top row of aerated concrete blocks is reinforced with a stiffening belt. It is necessary not only to tighten the structure from above, but also for further installation of the roof truss system.

Roof

At the last stage of wall construction, when installing the reinforced belt, it is necessary to install special mortgages (studs) and wire twists on the anchors to securely fix the Mauerlat. This simple device helps protect the roof from strong winds and minimize the “windage” of the roof.

Gable roof installation diagram.

- Install the rafter system (base, rafter leg and crossbar).

- Mount the front triangles.

- Perform lathing (continuous or interval).

- Make an attic flooring with exit vents.

- Sheathe the pediment (if it was not embedded in the masonry).

- Cover the frame with waterproofing.

At the final stage, cover the roof with any roofing material.

Exterior finishing

High-quality external finishing of the bathhouse and compliance with special rules for working with gas blocks directly affects the performance of the building as a whole.

A building made of aerated blocks needs protection from moisture and temperature fluctuations. In addition, the appearance of an unfinished aerated block building is unattractive. Therefore, external decoration of walls made of aerated concrete is not only desirable, but also necessary.

To begin with, the outer walls of the bathhouse must be treated with a hydrophobic soil mixture. Further, the following types of finishing are used for aerated block walls:

- brickwork (face brick);

- ventilated facade (siding, panels, facade tiles);

- lining (plastic, wooden);

- block house (vinyl, wood, metal);

- plastering with special mixtures;

- façade putty.

Advantages of foam blocks

Foam concrete is a relatively new material on the construction market, but has already gained quite wide popularity. For the construction of a gazebo, foam block is good, first of all, for its low price and ease of use. The price of a cubic meter of foam block with delivery, regardless of its size, will average 3,000 rubles. The cost of a cube of the cheapest brick is 4,000 rubles.

Foam concrete blocks pros and cons

The material is very light, its specific weight is almost three times lighter than the same brick. This allows you to greatly speed up installation time, while doing it yourself. Light weight reduces the pressure on the foundation, and this, in turn, reduces the cost of its construction.

Foam blocks are easily sawed with a special hacksaw, which allows you to create non-standard shapes of the structure. Of course, like any building material, foam concrete has its drawbacks. It does not have the same strength as brick, especially low-density brands of blocks. Capable of absorbing moisture, which forces the use of additional protective measures. Any finishing will have to be applied to it, since the appearance of the foam blocks does not agree with our ideas about the lightness and elegance of a summer gazebo in the garden.

Foam concrete has the bad property of easily chipping, especially on the edges. Lifting work with it must be carried out carefully and carefully.

The standard length of all blocks is 600 mm, the width can be in the range of 250 - 400 mm, and the thickness - from 75 to 200 mm. Blocks are also available in lengths of 300 mm.

The laying of foam blocks is carried out using a special assembly adhesive, which is widely available.

We recommend reading the article: how to build a bathhouse with a gazebo and barbecue under one roof.

We are drawing up a gazebo project

Before starting the zero cycle of work on the site, it is necessary to draw up a basic design of the structure. They are determined by the size and shape of the gazebo, its external design. You need to determine in advance what and where will be located inside. Since we are considering a gazebo made of foam block - a non-flammable material, the design can include built-in barbecues and barbecue stoves.

A gazebo made of foam blocks can be closed and have three blank walls. In this case, the roof is placed on the walls made of blocks. The gazebo may have one or two blank walls made of blocks, walls that do not reach the roofing. In these cases, a frame made of metal or wood must be erected, on which the roof is built, and only then the walls made of foam concrete are erected.

Gazebo with supports made of concrete blocks

You can draw a drawing of the structure yourself, or you can use ready-made projects on the relevant websites on the Internet.

Having recorded the main structural elements in the drawing, it is easier to make a list of purchased materials, consumables, tools, and calculate upcoming expenses. If necessary, at this stage, adjustments are made to the previously drawn up project. It is important that the entire construction concept is deeply thought out in advance and takes shape in a specific drawing.

At this stage, it is also necessary to think over a plan for connecting electrical wires and pipes for supplying and draining water to the future gazebo.

Choosing a foundation

Since our gazebo is made of foam blocks, you will need to build a reliable foundation for it. This material is lightweight, so a lightweight foundation for it is possible, without complex structures and a large amount of earth and concrete work.

As a rule, buildings of this kind are erected on a prefabricated or strip foundation. On unstable soils, it makes sense to pour a solid slab.

Making the foundation for the gazebo

The prefabricated foundation consists of concrete blocks placed in a trench around the perimeter of the measured area. Such a foundation is usually completed in one day. The very next morning you can begin building walls from foam blocks. However, we must take into account the additional costs of using a truck crane. In addition, the location of the site may not always allow you to fit the car.

The second option is practiced more often. A strip foundation is erected under many brick structures. It makes no sense to dig it deep into the ground under the gazebo; it is enough to dig a trench 40 cm deep. Sand with fine crushed stone is poured to a depth of 20 cm at the bottom, and formwork is installed. Along the entire trench, reinforcing bars with a diameter of 8-10 mm are laid on transverse supports along the bottom and concrete is poured.

The pouring height should be 30-35 cm, it will be buried 20 cm into the trench. Thus, the foundation will protrude 10-15 cm above the ground. Its width can be equal to the base of the foundation block or protrude by several centimeters.

The construction of walls on such a foundation is possible only after the concrete strip has hardened after 25-30 days.

Construction of a monolithic foundation

The foundation option made of a solid concrete slab over the entire area of the gazebo is the most expensive. But there are several factors in favor of his choice. Firstly, if there is peat or water-saturated soil under the building, then there can be no other option. Secondly, the flooring of the gazebo will still require a concrete screed. Thirdly, if a built-in barbecue is planned in a gazebo made of foam blocks, then a concrete base is also necessary for it. Well, and finally, given that the thickness of the concrete base will not exceed 30 cm, the cost of such a slab will not seem prohibitive.

Monolithic foundation for a gazebo

Making a monolithic slab is a rather labor-intensive operation and one cannot do without assistants, especially at the stage of preparing and pouring concrete into the formwork over the entire area of the slab. This operation must be carried out in one go.

• The creation of any foundation begins with marking the site. Remove the surface layer of soil in the designated area. The location of the first corner is determined and a peg is driven into it. • From the starting corner, measure the length and width of the structure, install stakes and stretch a cord between them. • Mark the location of the fourth corner and measure the diagonals in the resulting quadrilateral. They must be equal, in which case the angles are right. • The measured area is deepened by 200 - 250 mm. • In the resulting pit, formwork is installed along the entire perimeter of the site. • Sand and crushed stone are poured into the bottom of the excavation in layers of 50-70 mm. Each layer is compacted well. • A reinforcement structure is laid on top of the crushed stone layers. • The entire area of the pit, enclosed by formwork, is poured with concrete to a height of 35 cm, leveling its surface. • For effective drying of concrete, the surface of the slab is covered with plastic film or a damp rag. • After 7-10 days, when the concrete has set, the formwork is removed. • It is recommended to coat the edges of the resulting slab with a waterproofing compound and backfill with crushed stone.

Video: example of masonry

Construction of walls from blocks

• The first row of foam blocks must be laid over a waterproofing layer, which is laid from roofing felt along the entire perimeter of the wall. Ruberoid is glued with bitumen mastic.

Start of laying walls

• Start laying blocks from the corner. The first row is laid on cement mortar 2 cm thick. First, a beacon block is installed. It is carefully leveled in all directions. • Then other corner blocks are laid and aligned with the first beacon element. • A cord is pulled between the corner blocks and laying is carried out along it. • The blocks of the first row are laid on cement mortar, but the adhesive mortar is applied to their sides with a special notched trowel. • Level them using the thickness of the glue by lightly tapping them with a rubber hammer. • The laying of the second and subsequent rows is carried out using adhesive mortar, always with dressing, the seams are located in the middle of the block of the adjacent row.

• After three or four rows, reinforcement of the masonry is carried out. To do this, two parallel grooves are cut out in the upper part of the blocks using a device, reinforcing bars are laid in them and the next row is installed

Finishing the walls of the gazebo from foam blocks

Since foam concrete strongly absorbs moisture, a wall made from it must be covered with some kind of protective layer. This may be paint applied to the primer layer. You can use decorative thin-layer plaster of various colors. The decoration with decorative stone will look great.

The interior design of the room is maintained in a certain style, depending on your preferences, based on the design options and arrangement of the gazebo. You can cover the inside walls with beautiful panels, natural wood, or original cork panels.

Foundation work

The construction of a building begins with the foundation. The stronger the foundation, the more likely it is that the structure will last a long time without being subject to deformation. A bathhouse made of aerated concrete also needs a reliable foundation.

Setting the dimensions of the bathhouse should take into account the arrangement of an internal wooden ventilated frame, which will “eat up” part of the usable space

Due to the fact that the mass of gas-filled elements is significantly less than the mass of brick or stone, you can opt for a shallow strip foundation, suitable for any type of soil. The exception is soils prone to heaving. In this case, it will be necessary to equip a pile foundation that can prevent violations of the integrity of the structure. Create a strip foundation for a bathhouse made of aerated blocks in several stages:

- Prepare the construction site surface for foundation construction. Clear it of debris and vegetation.

- Remove the top layer of soil and level the surface.

- Make markings according to the developed project.

- Dig a trench 0.5–0.6 m deep and level the surface.

- Level the vertical walls and fill the bottom with a gravel-sand mixture 15–20 cm thick.

- Install the formwork. Use any material - sheets of metal, scraps of boards, slate. Check the verticality of the surface.

- Place a reinforcing frame in the trench. You can do without reinforcement, but a bathhouse made of aerated concrete blocks will last longer if the masonry is done on a reinforced foundation.

- Prepare concrete mortar for pouring. Remember that the strength characteristics of the foundation depend on the brand of cement used.

- Fill the foundation, preferably in one go, to avoid uneven hardening.

- Wait until it hardens, moistening the surface. Remove the formwork.

- Carry out waterproofing work on the foundation surface. Use bitumen mastic, roofing felt or plastic film.

We invite you to familiarize yourself with a DIY steel pipe for a bath

Having completed the work on arranging the foundation, let it settle and only then begin laying.

The construction of the foundation structure must be taken seriously. Deviations and flaws in its design can lead to the formation of cracks in wall blocks. Aerated concrete reacts to any deformation, so a bathhouse made from it must be built on a reliable foundation.

For a steam room made of artificial blocks, a shallow foundation strip is sufficient. To fill the foundation structure, a trench is dug along the entire perimeter of the bathhouse. A cushion of sand and crushed stone is installed at the bottom, after which formwork is installed, a reinforcement frame is formed and filled with concrete mortar.