Advantages of houses with attics

Directly at the design stage, it is necessary to take into account whether the attic space will be equipped for housing.

View gallery

Together with the use of foam blocks, the homeowner will receive the following benefits from this solution:

- The space will expand significantly and the area suitable for living will increase. Moreover, the amount of space directly depends on which roof structure is chosen.

- Building an attic is much easier and cheaper than building a second floor - this is a clear advantage.

- You will be able to make the most of the land allocated for building a house.

- A significant reduction in heat loss at home due to the installation of hydro- and thermal insulation materials.

- If the need arises, you can complete construction work in the attic after the first floor of the house has been occupied.

If you take into account that the construction period is being reduced, you can understand why such projects of houses made of foam blocks with an attic are very popular.

Material advantages

So, foam block is a type of building material that is made from cellular (foam) concrete. In principle, such a brick consists of cement, sand, water, and a foaming agent, which makes it porous. The main advantages of foam blocks include excellent sound insulation and thermal insulation. The material has fairly low shrinkage and water absorption coefficients, and is also not particularly susceptible to temperature changes, which is especially important in the harsh Russian winter!

A foam block house looks like this

What benefits will come from using foam blocks in construction?

Foam concrete is often used as a base. On its basis, modern materials are produced that have very high heat saving rates. Technological characteristics of foam concrete have the following advantages:

- The surface is perfectly flat, resulting in high-quality masonry and minimal joint thickness. Consequently, heat loss through them will also be negligible.

- Large sizes of foam concrete blocks contribute to faster assembly of the house frame.

- High energy saving rates. The material has very low thermal conductivity, so it is possible to cladding walls without additional insulation work.

- Even small houses made of foam blocks with an attic can keep cool in the summer and not lose heat in the winter. Consequently, you will be able to reduce the cost of heating and cooling your home.

- The material is environmentally friendly, as there are no harmful substances in its composition. It meets all safety requirements and has quality certificates.

- Foam blocks are resistant to prolonged exposure to high temperatures and are non-flammable. It can also be noted that fungus or mold does not grow on the material; insects and rodents are also indifferent to it.

- Large temperature changes do not affect the material; even high humidity will not damage the foam block.

- Since the blocks are large in size, the consumption of mortar for laying walls will be significantly reduced.

View gallery

These advantages are enough to choose foam concrete blocks as the main material. They will last for decades, and even a novice builder can work with the material.

Construction of houses

25 votes

+

Vote for!

—

Vote against!

When choosing building materials for constructing a garage, foam blocks have an optimal balance of reliability and affordable cost. The main advantages of this material are its resistance to ultraviolet radiation, frost, moisture, and most importantly, the preservation of heat in the room. Therefore, by building a garage from foam blocks, the risk of the car freezing in it is minimized. Let's look at how to build a garage with an attic from foam blocks below.

Table of contents:

- Advantages of building a garage with an attic made of foam blocks

- Garage made of foam blocks with an attic photo and construction features

- Two-story garages with an attic: building a foundation

- Garage with attic: construction technology and calculation of materials

- How to equip a viewing hole or basement in a garage

Advantages of building a garage with an attic made of foam blocks

Construction of a garage is a very important process that should be approached with the utmost seriousness. The initial stage of constructing a garage is drawing up a project for a garage with an attic made of foam blocks. There are several options for designing a garage:

- independent drawing up of drawings of a garage with an attic, however, to perform this action you need to have extensive experience in the construction industry, in addition, you should carry out a series of calculations to determine the level of mail freezing, and on their basis determine the optimal depth of the foundation and its type, the slightest errors in this matter, will lead to irreparable actions and damage to the entire building;

- searching for a ready-made plan for a garage with an attic - this option will save time on calculations, however, you should take into account the fact that the individual characteristics of the area and the specific area where construction work will be carried out will not be taken into account;

- The third and best option would be to contact a specialized organization, whose experienced specialists will advise and select a project for a garage with an attic that will serve you for as long as possible.

Having chosen foam blocks as a material for building a garage, we suggest that you familiarize yourself with some of their advantages and disadvantages. Among the positive characteristics of foam blocks, we note:

- the high level of strength allows you to construct not only a garage from foam blocks, but also a second floor in the form of an attic;

- excellent performance characteristics make foam blocks a popular material in low-rise construction;

- low level of density ensures ease of installation, low weight, which does not load the foundation;

- low level of thermal conductivity helps maintain optimal room temperature in the winter;

- good sound insulation characteristics - due to the fact that inside the foam blocks there are pores filled with air, they have good sound insulation, thanks to this, sounds coming from the street are not heard in a house or garage made of foam blocks;

- resistance to moisture ensures the frost resistance of the material and the duration of its operation;

- fire safety protects the building from sudden fire or from the spread of fire;

- The homogeneous structure of the foam blocks allows them to be sawed and drilled, if necessary.

Despite this, foam blocks have certain disadvantages. This is, first of all, its fragility, so during the transportation of foam blocks, they quite often break. Due to the presence of a large number of pores, when moisture gets into foam concrete, it loses its strength and changes its technical characteristics. In addition, the construction market is overflowing with cheap fakes of foam concrete. which is manufactured by non-specialized organizations and, in addition to low cost, has the same quality.

The structure and technical features of foam concrete make it possible to build a garage, the top floor of which will be an attic. Therefore, if necessary, the attic can be used both as a living space and as a place to store unnecessary things.

Garage made of foam blocks with an attic photo and construction features

Before we move on to considering the stages of constructing a garage with an attic. We invite you to familiarize yourself with the advantages of using foam blocks for this process:

- first of all, foam blocks are quite light and do not load the foundation at all, therefore, with their help it will be possible to save significantly in the process of erecting and determining the type of foundation for construction;

- in addition, the certain strength of foam concrete makes it possible to construct a garage space with an attic out of it;

- high thermal insulation characteristics will save heat in the garage, even in the most severe winters;

- the speed of work and ease of construction will allow you to build a garage in a few weeks;

- the affordable cost of the material ensures a low budget structure.

At the beginning of planning, it is necessary to determine the level of groundwater on the surface of the site for the construction of a garage. In addition, you can ask this question from geological organizations or people with recent construction experience in your region.

If you decide to contact a specialized organization involved in design, then all you need to do is present them with all your requirements for construction, and after a while you will have a ready-made project for a garage with an attic. At the same time, you should clarify the size of the building, the number of cars that will be located in the garage, the type of roof - single or double slope, the presence of an attic, its purpose: residential or non-residential. In addition, a garage can be solely a place to store a car, or it can become a full-fledged building with a ventilation, air conditioning, heating, water supply, etc. system connected to it. All of these things are taken into account during the design process.

If you plan a garage with an attic yourself, then you should provide in advance elements in the form of an inspection hole, a cellar, a place to locate tools and other accessories.

Arranging a garage with a residential attic requires a special approach to its layout. Since it will be necessary to provide the most comfortable conditions for staying in a residential area. Exhaust and ventilation systems should be considered to help get rid of exhaust gases.

If the construction budget is limited, then the best option would be to arrange a garage for one car, which has a pitched roof and no inspection hole. The minimum length of a garage is about 600 cm. The optimal height for a garage space is from 250 to 300 cm.

The construction of a garage with an attic consists of the following stages:

- preparatory work on the site, its leveling, clearing of debris;

- foundation construction;

- laying walls;

- installation of windows and doors;

- arrangement of the roofing system;

- finishing work both outside and inside the premises.

Two-story garages with an attic: building a foundation

Work on the foundation should begin after drawing up the final design of the building. It determines the type and depth of the foundation. These factors depend primarily on the soil characteristics of a given region, as well as on the size of the building and its load on the foundation.

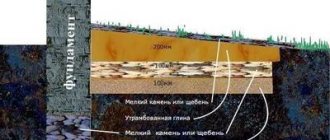

If you have chosen a strip foundation, then in this case you should mark the area for digging a pit. For these purposes, it is necessary to use pegs installed in the corners and perimeter of the future building. After fixing the corners, you should check the evenness of the future foundation. You also need to make sure that it will be convenient for the car to enter the garage and that there will be no obstacles in its path.

Next comes the process of digging a pit; there are two options for its implementation:

- manual;

- automated.

The first option is appropriate when the depth of the foundation does not reach one meter. Otherwise, it is better to use a special technique that will save both time and physical effort.

A shallow strip foundation is relevant for clay-sand soils with a dense structure. If the soil is heaving and mobile, we recommend choosing a monolithic foundation. In this case, one continuous slab of reinforced concrete is installed under the building or the surface is completely filled with a concrete grid with preliminary reinforcement. However, in this case, it will not be possible to equip a viewing hole or basement.

We return to the construction of a strip foundation for the construction of a garage with an attic made of foam blocks. After the pit is dug, the process of arranging a cushion of sand and crushed stone in it follows. The thickness of each layer is about 10-15 cm, and they are carefully compacted. Next, the formwork is installed and the surface is reinforced.

It is recommended to fill the strip foundation at one time, thus ensuring a higher level of its strength. Don't forget to use a concrete vibrator, which will remove excess air from the concrete and make it stronger.

Garage with attic: construction technology and calculation of materials

Before starting the construction of garage walls, you should calculate the number of foam blocks that will be required for the work. This information is included in the estimate. You should also calculate the mortar used for laying.

To the total amount that will be obtained after the calculation, you should add from 10 to 15% to compensate for damage to the material during work or during transportation.

In order to erect the external walls of a building, it is recommended to use material whose size is 20x30x60 cm, and to build internal partitions, foam blocks measuring 10x30x60 cm are sufficient.

Next you need to decide on the method of laying foam blocks:

- in relation to height;

- in relation to width.

The amount of material in the first and second cases will be different for garages made in the same size. Foam blocks are sold on pallets and are calculated in cubic meters, so in order to find out how much material is required, you should find out the volume of each of the walls and partitions of the garage. One cubic meter contains on average about 26 foam blocks.

To lay the walls of a garage with an attic, you should use a special cement-based mortar. It is recommended to add plasticizers during its preparation to improve the adhesion of the solution to the material. In addition, it is possible to use construction adhesive for laying foam blocks. Its cost is much higher than cement mortar, but the preparation process is simpler, so installation is faster.

Please note that the horizontal seams, after laying each of the two rows, need additional reinforcement using reinforced mesh. After laying the walls, the beams are installed, from which the floor of the future attic will be formed. If the room is residential, it is recommended to additionally insulate the ceiling using mineral wool or polystyrene foam.

It is necessary to begin the construction of walls from the corner areas, gradually moving towards the center of the wall. After the first row has been laid, it should be left for several hours for the concrete to fully set. In addition, while the solution hardens, you should check the wall for evenness using a building level.

When the last row is laid, a gap of 200 mm is left in the longitudinal wall, at intervals of 200 cm. This process will facilitate the procedure for laying cross beams for the floor in the attic.

How to equip a viewing hole or basement in a garage

For every lover of cars and any other transport, it is quite important to have an inspection hole in the garage. To set it up, use these instructions:

1. First, decide on the optimal dimensions of the pit for the basement or inspection pit.

2. Next, you should dig a hole in relation to the previously determined depth. Please note that the minimum interval between the pit and the garage floor is 300 mm.

3. Next, the sand cushion is installed, compacted and the inspection hole is filled.

4. When arranging a basement, a reinforced floor should be installed. The formwork is placed on it and then poured.

5. During the work process, only high-quality concrete should be used.

6. After the concrete has hardened, it is possible to finish the walls using ceramic tiles, paint or porcelain stoneware.

Technological features of cottage construction

Projects of houses made of foam blocks with an attic have some technological features of roofing. If you follow everything, then later you will be able to operate both the attic and the entire house as comfortably as possible. The project serves as the basis for calculating the required materials. You need to pay attention to these points when choosing a project for construction:

- The frame must be made from dry wood of the highest quality possible. This will further prevent deformation of the entire structure, and will also ensure stability over a long period of operation.

- The correct choice of insulating materials is the key to successful work. Many experts choose mineral wool and basalt insulation. It is these materials that recommend themselves on the positive side.

- The inside of the roof must be covered with plywood. In this case, you will get a very easy and simple installation, and most importantly, the characteristics of the attic will be very high.

- For roof covering. You can use metal tiles, it will provide an aesthetic appearance, and most importantly, it has very good performance qualities.

To successfully implement the project into reality, it is necessary to select high-quality building materials. But the installation of all structural elements must be carried out with the highest possible quality, otherwise the service life of the house will decrease many times.

How to choose a project

The latest technologies make it possible to choose absolutely any project; its level of complexity does not matter much.

View gallery

But you will need to take into account in advance what a one-story house with an attic made of foam blocks will end up like:

- Consider the size of the area that you are willing to allocate for construction. This is what determines what area needs to be prepared for the foundation of the house.

- Calculate what the living area will be. In the attic, the free space depends on the shape of the roof.

- You need to carefully draw up a layout taking into account the number of people living in the house.

- The use of foam blocks allows you to build a house of any shape and size.

Try to look through as many projects as possible to choose the one that suits you best. It is worth noting that a standard project turns out to be much cheaper than an individual one.

Attic made of foam blocks

Let's talk about this material in detail. But first you need to understand what it is made of.

The raw material for creating foam blocks is foam concrete - a special type of concrete characterized by high porosity. During its manufacture, several components are mixed:. The mixture is quickly poured into the molds, after which an active reaction begins - a large amount of foam is formed, saturating the concrete with numerous pores that remain after setting and hardening.

Most often, the formwork is a parallelepiped, but in general it can have a more complex shape, as well as voids for better thermal insulation and weight reduction, as well as tenons and grooves for a reliable connection. Some manufacturers prefer to pour foam concrete into an elongated form, which is later sawn into standard bars. Both options have certain advantages and disadvantages. Injection molding is a simpler process.

This does not require expensive equipment and experienced specialists, due to which the cost of the material is significantly reduced. But often there are not very even corners, as well as serious damage when removing finished products from the mold. The cutting technology is noticeably different. In order to quickly cut large timber into blocks, you need specialized equipment.

What benefits will come from using foam blocks in construction?

Only an experienced engineer can operate it. Of course, this increases the cost of the material. But there are no chips on it, the ribs are perfectly even. Foam blocks vary in purpose and, accordingly, dimensions.

Today, the most common options are:. The use of this material allows you to realize the best designs of houses with an attic. Why should you give preference to this particular construction option?

Let's talk about it. More and more people are choosing the design of a one-story house with an attic made of foam blocks. What advantages do they see in this option?

Why is it preferred to standard solutions - one-story or two-story houses? In fact, there are really a lot of advantages here.

Construction Features

The peculiarity of building a house from 8x9 foam blocks with an attic according to a standard design is that there is no complex cladding. To give the facade of a building the most aesthetic appearance, you can simply apply several layers of paint to the foam concrete. If you are building according to an individual project, you can choose one of the finishing options:

- decorative stone or brick;

- siding;

- tiles;

- vinyl materials.

It all depends on what your capabilities and wishes are.

View gallery

When using a standard layout, it is not always possible to cover all the needs of the people living in the house. Only drawing up an individual project can help take into account the wishes of all the people who will live in the house. But there is a drawback to this solution - an increase in the cost of building a house.

Order design and construction from Brickhouse!

- We carry out all stages - from laying the foundation to finishing work of the finished cottage;

- You can control every stage of construction - we install online cameras at the site, and then send reports on how the work is progressing;

- We do not deviate from the budget - we will offer an estimate, agree on it with you and meet it;

- We do quality work - this is guaranteed by our registration with the SRO.

We offer a wide range of ready-made solutions for houses made of foam blocks to choose from: you can look at the projects and prices on the website. Write or call us if you are planning construction.

Main stages of construction

In general, the construction of a house with an attic made of foam blocks can be divided into several main stages:

- Marking and leveling the site for construction.

- Digging pits or wells to construct a foundation. It all depends on what type of base will be used.

- Foundation installation.

- Making a plinth or grillage.

- Laying the walls of the house.

- Arrangement of the attic and installation of roofing material.

- Carrying out interior finishing works.

- Exterior decoration of the building.

Creating an individual project

The creation of an individual project must be entrusted to real professionals. Such projects are created by a team. Designers, planners, and construction engineers take part in the creation of an individual building. This approach allows you to reduce the occurrence of any inaccuracies or errors to a minimum. Each parameter is checked many times. In addition, a team of professionals will always provide photos of finished projects. There are many advantages of a team approach to creating an individual project:

— more accurate transfer in reality of all the customer’s desires. High-level specialists will carefully consider the customer’s wishes;

House made of foam blocks with an open summer terrace

— the ability to create a reliable project. All parameters and technical requirements of future construction will be taken into account;

— qualified assistance in choosing the design and shape of the house. The craftsmen will not only create the necessary project, but will also assist in choosing a more advantageous construction option. Such a house will fit perfectly into the landscape of the land;

- creating a house that will satisfy the requirements of all residents. When creating a project, it is worth remembering that the house should be comfortable for everyone. Professionals will create a project in which the built house will be cozy for everyone.

Stone finishing of foam concrete walls

Spacious mansion with attic and garage

Building a house with an attic made of foam block according to an individual project is a budget option, because when creating it, it is possible to accurately calculate how much material is needed for construction, and, accordingly, carry out the necessary cost calculations. A team of professionals will do everything in the best possible way. In addition, the created house designs strictly comply with the requirements of building codes and correspond to the climatic indicators of the region.

What kind of foundation can I use?

View gallery

The first stage of construction is the construction of a reliable foundation. Country houses with an attic made of foam blocks can be placed on the following types of foundations:

- Tape.

- Pile (including screw ones).

- Slab.

- Columnar.

However, any base can be used, since the mass of the structure is not very large. Regardless of what type of base you choose, you need to prepare the area. To do this, you need to completely remove the entire fertile layer of soil and get rid of plant roots.

How to make a foundation for a house?

Next, you need to dig a pit (if you plan to make a strip foundation) or drill holes (for a pile foundation).

View gallery

The procedure for making a foundation, regardless of its type, is the same:

- Compact sand at the bottom of the trench or hole.

- You install the formwork and place a grid of reinforcement inside the trench or well.

- Pour the concrete solution.

- Using a special vibrator or shovel, compact the solution. It is necessary that there are no air bubbles left in it - this will affect the quality of the concrete.

If you choose a pile foundation, you must carefully calculate the number of supports. First of all, you need to install them in the corners of the building. Then you need to evenly distribute the piles along the outer walls and partitions. It should also be noted that a foundation must be made for a heating boiler, stove or fireplace, which should not be in contact with the main one.

Wall masonry

You definitely need to carefully consider the layout features of a house with an attic made of foam blocks. Contact specialists if you are not confident in your abilities - they will be able to help you with advice. There are not so many features in the construction of walls; the main thing is to maintain evenness. To ensure that the walls are perfectly positioned in a vertical plane, use plumb lines. For horizontal alignment, use a level. All angles must be right angles (or those specified in the individual project).

View gallery

Please note that you cannot lay many rows of foam blocks at once. Start working from the corners - lay no more than three rows of material. It is the corners that you need to focus on during construction. Mark the location of all door and window openings so that you don’t “accidentally” block the entrance to your future home.

To build a one-story house with an attic, it is allowed to use foam blocks when making the walls of the attic floor. But you can make the entire attic from timber - it all depends on the specific project.